|

市場調查報告書

商品編碼

1528160

全球防禦複合材料市場(2024-2034)Global Defense Composites Market 2024-2034 |

||||||

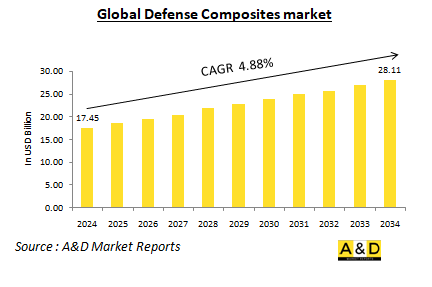

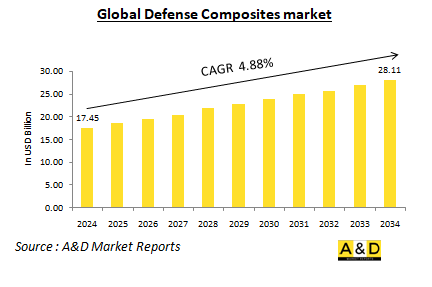

預估2024年全球防禦複合材料市場規模為 174.5億美元,預計將成長至 281.1億美元,2024年至2034年年複合成長率為 4.88%。

防禦複合材料市場概況:

防禦複合材料是結合兩種或多種組成材料以實現卓越性能的先進材料,對於軍事應用非常重要。這些複合材料通常由纖維增強聚合物(FRP)、陶瓷和金屬基複合材料組成,具有輕量、強度和耐環境因素的獨特組合。複合材料的發展是由於需要能夠承受惡劣條件的材料,同時提高軍用車輛、飛機和個人防護設備等防禦系統的性能。從歷史上看,複合材料在防禦中的使用始於第二次世界大戰期間,主要用於軍用飛機。從那時起,技術取得了顯著進步,複合材料被納入各種防禦應用,包括裝甲系統、無人機(UAV)和海軍艦艇。這些材料的多功能性和適應性使其對於現代防禦戰略非常重要,在現代防禦戰略中,輕量和耐用性非常重要。

科技對防禦複合材料市場的影響:

技術對防禦複合材料的影響是巨大的,特別是在材料性能和製造過程方面。複合材料的創新促進了高強度纖維、先進樹脂和混合材料的發展,並增強了防禦系統的機械性能。例如,碳基複合材料由於其輕量和高性能的特性,日益用於化學感測器和雷達技術等應用。此外,積層製造和自動纖維鋪放等製造技術的進步簡化複雜複合材料結構的生產。這些技術提高了設計靈活性和效率,並能夠快速原型設計和製造適合特定防禦需求的零件。將智慧技術整合到複合材料中,例如用於結構健康監測的嵌入式感測器,進一步增強了複合材料的功能和操作能力。

防禦複合材料市場的關鍵驅動因素:

防禦複合材料的成長和採用受到幾個關鍵驅動因素的影響,這些驅動因素反映了不斷變化的軍事需求以及這些材料提供的好處。主要驅動力之一是減輕重量。在防禦應用中,對輕量材料的需求非常重要,因為它直接影響燃料效率、有效載荷和整體性能。複合材料是軍用飛機和車輛的理想選擇,因為與金屬等傳統材料相比,它們具有卓越的強度重量比,並且重量減輕可以提高機動性和操作效率。抗衝擊性也是一個重要因素。複合材料具有高抗衝擊性,這對於防護服和車輛零件等防護應用非常重要。它們在撞擊時破碎的能力有助於降低二次傷害的風險,並比傳統材料在接觸時無法有效消散能量提供了顯著的優勢。耐腐蝕性也是複合材料的重要特性。惡劣環境下的耐用性減少了維護需求並延長了防禦設備的使用壽命。這種特性在海軍應用中特別有價值,因為暴露於海水和其他腐蝕性元素會嚴重威脅船舶和潛艇所用材料的完整性。設計彈性是複合材料提供的另一個優勢。將複合材料模製成複雜形狀的能力可以實現創新設計,提高性能,同時簡化組裝過程。這種靈活性對於下一代防禦系統的開發非常重要,該系統需要獨特的幾何形狀來實現最佳功能,使設計人員能夠創建更有效率、更有效的解決方案。最後,永續性在防禦部門中變得越來越重要。隨著人們對環境問題的認識不斷增強,環保複合材料的使用也越來越普遍。製造商探索生物基樹脂和可回收纖維,以盡量減少複合材料生產對環境的影響,使防禦工業實踐與更廣泛的永續發展目標保持一致,並減少軍事行動的生態足跡。

防禦複合材料市場的區域趨勢:

防禦複合材料的前景因地區而異,並受到地區防禦需求、技術能力和經濟因素的影響。在北美,美國在防禦複合材料的開發和應用方面處於領先地位。這種領先地位來自於軍事研發的大量投資。美國軍方對先進飛機和無人機(UAV)的關注推動輕量複合材料的創新,Boeing和Lockheed Martin等大公司處於這些進步的最前線。他們的工作有助於保持該國在軍事應用方面的技術優勢。在歐洲,複合材料在防禦應用的採用日益增加,特別是在航空和海軍領域。歐盟(EU)聯合防禦計畫促進了先進材料的研究,這將促進下一代戰車和飛機的開發。這種合作方式不僅提高了各國的能力,而且還透過共享創新和資源共享加強了該地區的整體防禦態勢。亞太地區的特點是防禦能力快速擴張,中國和印度等國家致力於複合材料的國內生產。中國致力於軍隊現代化,並在飛機和船舶複合材料技術方面投入大量資金。同時,印度利用其在複合材料方面的專業知識來增強防禦應用,強調其促進防禦部門自力更生和技術進步的戰略目標。在中東,防禦部門轉向使用先進材料實現武器現代化。該地區國家對複合材料越來越感興趣,以提高防禦系統的性能,特別是考慮到地區安全挑戰。這種向先進複合材料的轉變反映了中東地區為加強其防禦能力和有效應對不斷變化的安全動態所做的努力。

防禦複合材料重大計畫

位於英國北約克郡 Kirkbymoorside 的 Marshall Slingsby Advanced Composites 將交付這份價值約 1800 萬英鎊的合約。該公司計劃進一步擴張,目的是重新配置和更新其設施,同時投資最新的生產技術和設備。馬歇爾已獲得一份合約,支持一家領先的防禦工業合作夥伴提供下一代防空系統,以防止英國防禦部和北約盟國在海上和陸地上抵禦飛彈和無人機威脅。

Infinite Composites Inc. 已獲得美國陸軍價值 160 萬美元的小型企業創新研究(SBIR)直接合約(第二階段),為未來的氫動力汽車開發適應性罐。氫氣日益被軍用和商用車輛採用,作為化石燃料的有吸引力的替代燃料來源。防禦部已啟動多項舉措,增加用於軍用車輛(包括飛機、地面支援和海上應用)的新型和改進氫技術開發的資金。 Infinite Composites Inc. 的提案被選中是為了增強氫燃料儲存技術,特別關注儲存容器的設計。

Albany International Corp. (NYSE:AIN) 宣布,其子公司Albany Engineered Composites (AEC) 已獲得美國陸軍價值 400 萬美元的合約,以支持高超音速飛行器的開發。 AEC 使用獨特的、完全工業化的、近淨成形 3D 紡織技術來進一步推進高超音速應用的熱防護系統。與競爭技術相比,該技術具有獨特的性能優勢,並提供卓越的經濟性和可擴展性,以滿足高超音速飛行器的嚴苛需求。

目錄

防禦複合材料市場:報告定義

防禦複合材料市場區隔

- 依類型

- 依地區

- 依用途

防禦複合材料市場分析(未來10年)

防禦複合材料市場的市場技術

全球防禦複合材料市場預測

防禦複合材料市場:區域趨勢與預測

- 北美

- 促進/抑制因素和挑戰

- PEST分析

- 市場預測與情境分析

- 主要公司

- 供應商層級狀況

- 企業基準比較

- 歐洲

- 中東

- 亞太地區

- 南美洲

防禦複合材料市場:國家分析

- 美國

- 防禦規劃

- 最新趨勢

- 專利

- 該市場目前的技術成熟度等級

- 市場預測與情境分析

- 加拿大

- 義大利

- 法國

- 德國

- 荷蘭

- 比利時

- 西班牙

- 瑞典

- 希臘

- 澳洲

- 南非

- 印度

- 中國

- 俄羅斯

- 韓國

- 日本

- 馬來西亞

- 新加坡

- 巴西

防禦複合材料市場:市場機會矩陣

防禦複合材料市場:專家對研究的看法

結論

關於航空和防禦市場報告

The Global Defense Composites Market is estimated at USD 17.45 billion in 2024, projected to grow to USD 28.11 billion by 2034 at a Compound Annual Growth Rate (CAGR) of 4.88% over the forecast period 2024-2034.

Introduction to Defense Composites Market:

Defense composites are advanced materials that combine two or more constituent materials to achieve superior properties, making them essential in military applications. These composites typically consist of fiber-reinforced polymers (FRPs), ceramics, and metal matrix composites, which provide a unique combination of lightweight, strength, and resistance to environmental factors. Their development has been driven by the need for materials that can withstand extreme conditions while offering enhanced performance in defense systems, including military vehicles, aircraft, and personal protective equipment. Historically, the use of composite materials in defense began during World War II, primarily for military aircraft. Since then, the technology has evolved significantly, leading to the incorporation of composites in various defense applications such as armor systems, unmanned aerial vehicles (UAVs), and naval vessels. The versatility and adaptability of these materials have made them crucial for modern defense strategies, where weight reduction and durability are paramount.

Technology Impact in Defense Composites Market:

The impact of technology on defense composites is profound, particularly in terms of material performance and manufacturing processes. Innovations in composite materials have led to the development of high-strength fibers, advanced resins, and hybrid materials that enhance the mechanical properties of defense systems. For instance, carbon-based composites are increasingly used in applications such as chemical sensors and radar technologies due to their lightweight and high-performance characteristics. Additionally, advancements in manufacturing techniques, such as additive manufacturing and automated fiber placement, have streamlined the production of complex composite structures. These technologies allow for greater design flexibility and efficiency, enabling the rapid prototyping and fabrication of components tailored to specific defense needs. The integration of smart technologies into composites, such as embedded sensors for structural health monitoring, further enhances their functionality and operational capabilities.

Key Drivers in Defense Composites Market:

Several key drivers are influencing the growth and adoption of defense composites, reflecting the evolving needs of the military and the advantages these materials offer. One of the primary drivers is weight reduction. In defense applications, the demand for lightweight materials is critical because it directly affects fuel efficiency, payload capacity, and overall performance. Composites provide a superior strength-to-weight ratio compared to traditional materials like metals, making them ideal for military aircraft and vehicles, where reduced weight can lead to enhanced maneuverability and operational efficiency. Impact resistance is another crucial factor. Composites exhibit high impact resistance, which is essential for protective applications such as body armor and vehicle components. Their ability to shatter upon impact helps reduce the risk of secondary injuries, providing a significant advantage over conventional materials that may not dissipate energy as effectively upon contact. Corrosion resistance is also a vital property of composites. Their durability in harsh environments reduces maintenance needs and prolongs the lifespan of defense equipment. This attribute is particularly valuable for naval applications, where exposure to saltwater and other corrosive elements poses a significant threat to the integrity of materials used in ships and submarines. Design flexibility is another advantage offered by composites. The ability to mold composites into complex shapes allows for innovative designs that enhance performance while simplifying assembly processes. This flexibility is crucial in developing next-generation defense systems that require unique geometries for optimal functionality, enabling designers to create more efficient and effective solutions. Finally, sustainability is becoming an increasingly important consideration in the defense sector. As awareness of environmental issues grows, the use of eco-friendly composite materials is gaining traction. Manufacturers are exploring bio-based resins and recyclable fibers to minimize the environmental impact of composite production, aligning defense industry practices with broader sustainability goals and reducing the ecological footprint of military operations.

Regional Trends in Defense Composites Market:

The landscape of defense composites varies significantly across different regions, influenced by local defense needs, technological capabilities, and economic factors. In North America, the United States stands out as a leader in the development and application of defense composites. This leadership is driven by substantial investments in military research and development. The U.S. military's focus on advanced aircraft and unmanned aerial vehicles (UAVs) has spurred innovations in lightweight composite materials, with major companies like Boeing and Lockheed Martin at the forefront of these advancements. Their work is instrumental in maintaining the country's technological edge in military applications. In Europe, there is an increasing adoption of composites for defense applications, particularly in the aerospace and naval sectors. The European Union's collaborative defense initiatives have fostered research into advanced materials, leading to the development of next-generation combat vehicles and aircraft. This cooperative approach not only enhances the capabilities of individual nations but also strengthens the overall defense posture of the region through shared innovation and resource pooling. The Asia-Pacific region is characterized by rapid expansion in defense capabilities, with countries like China and India placing a growing emphasis on indigenous manufacturing of composite materials. China's focus on modernizing its military has led to significant investments in composite technology for aircraft and naval vessels, highlighting its commitment to advancing its defense infrastructure. Meanwhile, India is leveraging its expertise in composite materials to enhance its defense applications, underscoring its strategic objective to boost self-reliance and technological advancement in the defense sector. In the Middle East, the defense sector is undergoing a shift towards modernizing military equipment with advanced materials. Countries in this region are increasingly looking to composites to enhance the performance of their defense systems, especially given the context of regional security challenges. This move towards advanced composites reflects the Middle East's efforts to bolster its defense capabilities and respond effectively to evolving security dynamics.

Key Defense Composites Program:

The approximately £18 million contract will be executed by Marshall Slingsby Advanced Composites, located in Kirkbymoorside, North Yorkshire. As the company plans for further expansion, it aims to reconfigure and upgrade its facilities while investing in the latest production technologies and equipment. Marshall has secured a contract to support a major defense industry partner in providing next-generation air defense systems for the UK Ministry of Defence and NATO allies, offering protection against missile and drone threats both at sea and on land.

Infinite Composites Inc. has been awarded a $1.6 million Small Business Innovative Research (SBIR) direct-to-phase II contract by the U.S. Army to develop conformable tanks for future hydrogen-powered vehicles. Hydrogen is increasingly seen as an attractive alternative fuel source for military and commercial vehicles, offering a viable replacement for fossil fuels. The Department of Defense has launched several initiatives to boost funding for the development of new and improved hydrogen technologies for military vehicles, including aircraft, ground support, and marine applications. Infinite Composites' proposal was chosen to focus on enhancing hydrogen fuel storage technologies, particularly the design of the storage container.

Albany International Corp. (NYSE: AIN) announced that its subsidiary, Albany Engineered Composites (AEC), has been awarded a $4 million contract by the U.S. Army to support hypersonic development. AEC will use its proprietary, fully industrialized near-net shape 3D weaving technology to further advance thermal protection systems for hypersonic applications. This technology offers unique performance advantages over competing technologies, providing superior affordability and scalability to meet the rigorous demands of hypersonic vehicles.

Table of Contents

Defense Composites Market Report Definition

Defense Composites Market Segmentation

By Type

By Region

By Application

Defense Composites Market Analysis for next 10 Years

The 10-year Defense Composites Market analysis would give a detailed overview of Defense Composites Market growth, changing dynamics, technology adoption overviews and the overall market attractiveness is covered in this chapter.

Market Technologies of Defense Composites Market

This segment covers the top 10 technologies that is expected to impact this market and the possible implications these technologies would have on the overall market.

Global Defense Composites Market Forecast

The 10-year Defense Composites Market forecast of this market is covered in detailed across the segments which are mentioned above.

Regional Defense Composites Market Trends & Forecast

The regional Defense Composites Market trends, drivers, restraints and Challenges of this market, the Political, Economic, Social and Technology aspects are covered in this segment. The market forecast and scenario analysis across regions are also covered in detailed in this segment. The last part of the regional analysis includes profiling of the key companies, supplier landscape and company benchmarking. The current market size is estimated based on the normal scenario.

North America

Drivers, Restraints and Challenges

PEST

Market Forecast & Scenario Analysis

Key Companies

Supplier Tier Landscape

Company Benchmarking

Europe

Middle East

APAC

South America

Country Analysis of Defense Composites Market

This chapter deals with the key defense programs in this market, it also covers the latest news and patents which have been filed in this market. Country level 10 year market forecast and scenario analysis are also covered in this chapter.

US

Defense Programs

Latest News

Patents

Current levels of technology maturation in this market

Market Forecast & Scenario Analysis

Canada

Italy

France

Germany

Netherlands

Belgium

Spain

Sweden

Greece

Australia

South Africa

India

China

Russia

South Korea

Japan

Malaysia

Singapore

Brazil

Opportunity Matrix for Defense Composites Market

The opportunity matrix helps the readers understand the high opportunity segments in this market.

Expert Opinions on Defense Composites Market Report

Hear from our experts their opinion of the possible analysis for this market.

Conclusions

About Aviation and Defense Market Reports

List of Tables

- Table 1: 10 Year Market Outlook, 2024-2034

- Table 2: Drivers, Impact Analysis, North America

- Table 3: Restraints, Impact Analysis, North America

- Table 4: Challenges, Impact Analysis, North America

- Table 5: Drivers, Impact Analysis, Europe

- Table 6: Restraints, Impact Analysis, Europe

- Table 7: Challenges, Impact Analysis, Europe

- Table 8: Drivers, Impact Analysis, Middle East

- Table 9: Restraints, Impact Analysis, Middle East

- Table 10: Challenges, Impact Analysis, Middle East

- Table 11: Drivers, Impact Analysis, APAC

- Table 12: Restraints, Impact Analysis, APAC

- Table 13: Challenges, Impact Analysis, APAC

- Table 14: Drivers, Impact Analysis, South America

- Table 15: Restraints, Impact Analysis, South America

- Table 16: Challenges, Impact Analysis, South America

- Table 17: Scenario Analysis, Scenario 1, By Region, 2024-2034

- Table 18: Scenario Analysis, Scenario 1, By Type, 2024-2034

- Table 19: Scenario Analysis, Scenario 1, By Application, 2024-2034

- Table 20: Scenario Analysis, Scenario 2, By Region, 2024-2034

- Table 21: Scenario Analysis, Scenario 2, By Type, 2024-2034

- Table 22: Scenario Analysis, Scenario 2, By Application, 2024-2034

List of Figures

- Figure 1: Global Defense Composites Market Forecast, 2024-2034

- Figure 2: Global Defense Composites Market Forecast, By Region, 2024-2034

- Figure 3: Global Defense Composites Market Forecast, By Type, 2024-2034

- Figure 4: Global Defense Composites Market Forecast, By Application, 2024-2034

- Figure 5: North America, Defense Composites Market, Market Forecast, 2024-2034

- Figure 6: Europe, Defense Composites Market, Market Forecast, 2024-2034

- Figure 7: Middle East, Defense Composites Market, Market Forecast, 2024-2034

- Figure 8: APAC, Defense Composites Market, Market Forecast, 2024-2034

- Figure 9: South America, Defense Composites Market, Market Forecast, 2024-2034

- Figure 10: United States, Defense Composites Market, Technology Maturation, 2024-2034

- Figure 11: United States, Defense Composites Market, Market Forecast, 2024-2034

- Figure 12: Canada, Defense Composites Market, Technology Maturation, 2024-2034

- Figure 13: Canada, Defense Composites Market, Market Forecast, 2024-2034

- Figure 14: Italy, Defense Composites Market, Technology Maturation, 2024-2034

- Figure 15: Italy, Defense Composites Market, Market Forecast, 2024-2034

- Figure 16: France, Defense Composites Market, Technology Maturation, 2024-2034

- Figure 17: France, Defense Composites Market, Market Forecast, 2024-2034

- Figure 18: Germany, Defense Composites Market, Technology Maturation, 2024-2034

- Figure 19: Germany, Defense Composites Market, Market Forecast, 2024-2034

- Figure 20: Netherlands, Defense Composites Market, Technology Maturation, 2024-2034

- Figure 21: Netherlands, Defense Composites Market, Market Forecast, 2024-2034

- Figure 22: Belgium, Defense Composites Market, Technology Maturation, 2024-2034

- Figure 23: Belgium, Defense Composites Market, Market Forecast, 2024-2034

- Figure 24: Spain, Defense Composites Market, Technology Maturation, 2024-2034

- Figure 25: Spain, Defense Composites Market, Market Forecast, 2024-2034

- Figure 26: Sweden, Defense Composites Market, Technology Maturation, 2024-2034

- Figure 27: Sweden, Defense Composites Market, Market Forecast, 2024-2034

- Figure 28: Brazil, Defense Composites Market, Technology Maturation, 2024-2034

- Figure 29: Brazil, Defense Composites Market, Market Forecast, 2024-2034

- Figure 30: Australia, Defense Composites Market, Technology Maturation, 2024-2034

- Figure 31: Australia, Defense Composites Market, Market Forecast, 2024-2034

- Figure 32: India, Defense Composites Market, Technology Maturation, 2024-2034

- Figure 33: India, Defense Composites Market, Market Forecast, 2024-2034

- Figure 34: China, Defense Composites Market, Technology Maturation, 2024-2034

- Figure 35: China, Defense Composites Market, Market Forecast, 2024-2034

- Figure 36: Saudi Arabia, Defense Composites Market, Technology Maturation, 2024-2034

- Figure 37: Saudi Arabia, Defense Composites Market, Market Forecast, 2024-2034

- Figure 38: South Korea, Defense Composites Market, Technology Maturation, 2024-2034

- Figure 39: South Korea, Defense Composites Market, Market Forecast, 2024-2034

- Figure 40: Japan, Defense Composites Market, Technology Maturation, 2024-2034

- Figure 41: Japan, Defense Composites Market, Market Forecast, 2024-2034

- Figure 42: Malaysia, Defense Composites Market, Technology Maturation, 2024-2034

- Figure 43: Malaysia, Defense Composites Market, Market Forecast, 2024-2034

- Figure 44: Singapore, Defense Composites Market, Technology Maturation, 2024-2034

- Figure 45: Singapore, Defense Composites Market, Market Forecast, 2024-2034

- Figure 46: United Kingdom, Defense Composites Market, Technology Maturation, 2024-2034

- Figure 47: United Kingdom, Defense Composites Market, Market Forecast, 2024-2034

- Figure 48: Opportunity Analysis, Defense Composites Market, By Region (Cumulative Market), 2024-2034

- Figure 49: Opportunity Analysis, Defense Composites Market, By Region (CAGR), 2024-2034

- Figure 50: Opportunity Analysis, Defense Composites Market, By Type (Cumulative Market), 2024-2034

- Figure 51: Opportunity Analysis, Defense Composites Market, By Type (CAGR), 2024-2034

- Figure 52: Opportunity Analysis, Defense Composites Market, By Application (Cumulative Market), 2024-2034

- Figure 53: Opportunity Analysis, Defense Composites Market, By Application (CAGR), 2024-2034

- Figure 54: Scenario Analysis, Defense Composites Market, Cumulative Market, 2024-2034

- Figure 55: Scenario Analysis, Defense Composites Market, Global Market, 2024-2034

- Figure 56: Scenario 1, Defense Composites Market, Total Market, 2024-2034

- Figure 57: Scenario 1, Defense Composites Market, By Region, 2024-2034

- Figure 58: Scenario 1, Defense Composites Market, By Type, 2024-2034

- Figure 59: Scenario 1, Defense Composites Market, By Application, 2024-2034

- Figure 60: Scenario 2, Defense Composites Market, Total Market, 2024-2034

- Figure 61: Scenario 2, Defense Composites Market, By Region, 2024-2034

- Figure 62: Scenario 2, Defense Composites Market, By Type, 2024-2034

- Figure 63: Scenario 2, Defense Composites Market, By Application, 2024-2034

- Figure 64: Company Benchmark, Defense Composites Market, 2024-2034