|

市場調查報告書

商品編碼

1528162

全球防禦3D列印市場(2024-2034)Global Defense 3D Printing Market 2024-2034 |

||||||

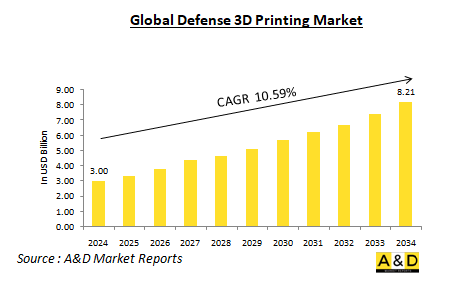

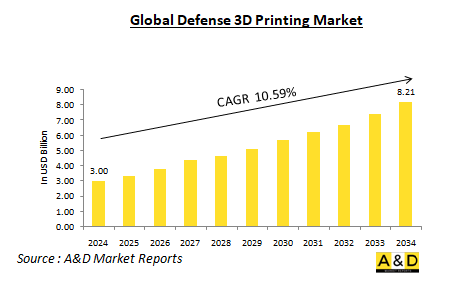

估計到2024年,全球防禦 3D 列印市場將達到 30億美元,在預測期內(2024-2034年)年複合成長率(CAGR)為 10.59%,到2034年也將持續成長。 82.1億美元。

全球防禦 3D 列印市場概況

3D 列印,也稱為積層製造(AM),徹底改變防禦工業。該技術透過順序分層材料來創建3D物體。與傳統的減材製造(去除材料以形成所需形狀)相反,3D 列印逐層建構物體。對防守的影響是巨大的。從快速原型設計到最終用途組件製造,3D 列印改變防禦系統的設計、製造和部署方式。

科技對全球防禦 3D 列印市場的影響

3D 列印對防禦部門的影響是多方面的。主要優勢之一是快速原型製作,其中 3D 列印加快了設計到製造的周期,實現了原型的快速迭代和完善。這種能力導致新武器系統、車輛和設備的快速發展,能夠快速回應不斷變化的防禦需求。另一個好處是供應鏈優化。透過實現零件的本地生產,3D 列印減少了對複雜而脆弱的供應鏈的依賴。此功能在傳統供應線可能中斷的偏遠或惡劣環境中特別有用。 3D 列印還可以創建優化重量和強度的複雜形狀,有助於減輕重量。這對於航空航太和地面車輛非常重要,減輕重量可以提高性能和效率。該技術更具可自訂性,能夠根據特定需求和條件生產高度客製化的零件和組件。這種靈活性可以在防禦應用中提供更精確的解決方案。最後,3D 列印可按需生產備件,減少物流挑戰和停機時間,有利於物流和維護。這種能力能夠快速維護和修復防禦系統,並在各種情況下保持作戰準備。

全球防禦3D列印市場的關鍵驅動因素

有幾個因素推動 3D 列印在防禦工業中的普及。關鍵因素之一是運作效率:快速製造零件和原型的能力可顯著提高效率、降低成本並簡化防禦技術的開發和部署。技術進步也發揮關鍵作用,隨著 3D 列印材料和製程的不斷改進擴大了應用範圍,使該技術變得越來越通用和有效。供應鏈彈性也是關鍵驅動因素。透過減少對全球供應鏈的依賴,3D 列印可以使防禦行動更具彈性,即使在充滿挑戰的條件下也能在本地生產關鍵零件。地理優勢進一步促進了3D列印的採用。特別是在軍事基地分散的國家,零件的本地生產可以減少物流挑戰。最後,3D 列印培育了防禦工業的創新和實驗文化。該技術促進了新的和改進的防禦技術的開發,在快速發展的領域促進進步並保持競爭優勢。

全球防禦3D列印市場的區域趨勢

防禦 3D 列印的區域趨勢將根據技術成熟度、經濟狀況和地緣政治優先事項而有所不同。美國是 3D 列印領域的先驅,大力投資該技術的防禦應用。這裡的重點是開發先進材料和過程來製造高性能零件,反映了美國在推進防禦技術方面的領導作用。在歐洲,各國積極探索 3D 列印在防禦領域的潛力,重點是協作和標準化。歐洲國家共同努力製定共同標準並分享知識。這將有助於將3D列印整合到各種防禦系統中並增強其整體能力。在亞洲,中國和韓國等國家正快速增強其3D列印能力。在國內產業政策和不斷擴大的防禦預算的推動下,這些國家大力投資3D列印技術,以加強其防禦部門並支持各種軍事應用。以其技術創新而聞名的以色列有效地將 3D 列印用於軍事目的。該國利用這項技術來製造無人機(UAV)和其他先進系統,展示其在將尖端技術融入防禦行動方面的領導者地位。

防禦3D列印關鍵計畫

澳洲陸軍繼續鼓勵金屬 3D 列印在防禦部門的潛在機會。澳洲陸軍和 SPEE3D 將在2021年繼續合作,對 SPEE3D 的技術再進行 12 個月的測試。澳洲陸軍第一戰鬥支援營再次與當地公司 SPEE3D 合作。此次合作將重點開發新技術,這些新技術有可能大幅增加現有的獨特金屬維修零件的庫存。

加拿大為海事和防禦工業建造了第一個 3D 列印金屬研究設施。新不倫瑞克大學與 CFM(客製化製造商和機械師)以及新不倫瑞克省和新斯科細亞省的社區機構合作,建立了海洋積層製造卓越中心。該中心是該國第一個使用金屬 3D 列印為海洋工業生產經過認證的客製化零件的中心,集研究、商業化以及勞動力發展和培訓於一體。中心主任兼新布倫大學機械工程系副教授 Mohsen Mohammadi 博士將負責該中心的研發活動。

西班牙造船公司 Navantia 已與防禦部簽署協議,使用增材製造技術為西班牙海軍建造 5 艘 F-110 護衛艦。該公司表示,這些船舶將是船隊中第一艘採用工業4.0技術的船舶,包括3D列印零件和網路安全系統,以保護船舶免受威脅。這五艘護衛艦將使用最先進的整合控制和類比系統(數位孿生)建造,作為西班牙海軍 ASTILLERO 4.0 框架的一部分。該框架是 Navantia 努力利用數位化創建更有效的運輸網路並改變船舶建造方式的一部分。

目錄

防禦 3D 列印市場:報告定義

防禦 3D 列印市場區隔

- 依用途

- 依地區

- 依材質

防禦3D列印市場分析(未來10年)

防禦3D列印市場的市場技術

全球防禦3D列印市場預測

防禦 3D 列印市場:區域趨勢與預測

- 北美

- 促進/抑制因素和挑戰

- PEST分析

- 市場預測與情境分析

- 主要公司

- 供應商層級狀況

- 企業基準比較

- 歐洲

- 中東

- 亞太地區

- 南美洲

防禦 3D 列印市場:國家分析

- 美國

- 防禦規劃

- 最新趨勢

- 專利

- 該市場目前的技術成熟度等級

- 市場預測與情境分析

- 加拿大

- 義大利

- 法國

- 德國

- 荷蘭

- 比利時

- 西班牙

- 瑞典

- 希臘

- 澳洲

- 南非

- 印度

- 中國

- 俄羅斯

- 韓國

- 日本

- 馬來西亞

- 新加坡

- 巴西

防禦 3D 列印市場:市場機會矩陣

防禦 3D 列印市場:專家對研究的看法

結論

關於航空和防禦市場報告

The Global Defense 3D Printing Market is estimated at USD 3.00 billion in 2024, projected to grow to USD 8.21 billion by 2034 at a Compound Annual Growth Rate (CAGR) of 10.59% over the forecast period 2024-2034.

Introduction to Defense 3D Printing Market:

3D printing, also known as additive manufacturing, is revolutionizing the defense industry. This technology involves creating three-dimensional objects by successively layering materials. In contrast to traditional subtractive manufacturing, which removes material to form a desired shape, 3D printing builds up objects layer by layer. The implications for defense are profound. From rapid prototyping to the production of end-use parts, 3D printing is transforming how defense systems are designed, manufactured, and deployed.

Technology Impact in Defense 3D Printing Market:

The impact of 3D printing on the defense sector is multifaceted. One significant advantage is rapid prototyping, where 3D printing accelerates the design-to-production cycle, enabling rapid iteration and refinement of prototypes. This capability leads to faster development of new weapons systems, vehicles, and equipment, allowing for quicker adaptation to changing defense needs. Another benefit is supply chain optimization. By enabling local production of parts, 3D printing reduces reliance on complex and vulnerable supply chains. This capability is particularly beneficial in remote or hostile environments, where traditional supply lines may be disrupted. 3D printing also facilitates light weighting by allowing for the creation of complex geometries that optimize weight and strength. This is crucial for aerospace and ground vehicles, where weight reduction can lead to improved performance and efficiency. The technology further enhances customization, enabling the production of highly customized parts and components tailored to specific needs and conditions. This flexibility allows for more precise solutions in defense applications. Finally, 3D printing offers advantages in logistics and maintenance by producing spare parts on demand, reducing logistical challenges and downtime. This capability ensures that defense systems can be maintained and repaired quickly, maintaining operational readiness in various situations.

Key Drivers in Defense 3D Printing Market:

Several factors are driving the adoption of 3D printing in the defense industry. One major factor is operational efficiency; the ability to rapidly produce parts and prototypes significantly improves efficiency and reduces costs, streamlining the development and deployment of defense technologies. Technological advancements also play a crucial role, as continuous improvements in 3D printing materials and processes expand the range of applications, making the technology increasingly versatile and effective. Supply chain resilience is another key driver. By reducing reliance on global supply chains, 3D printing enhances the resilience of defense operations, ensuring that critical components can be produced locally even in challenging conditions. Geographic advantages further contribute to the adoption of 3D printing, particularly for countries with dispersed military bases, where local production of parts can mitigate logistical challenges. Finally, 3D printing fosters a culture of innovation and experimentation within the defense industry. This technology encourages the development of new and improved defense technologies, driving progress and maintaining a competitive edge in a rapidly evolving field.

Regional Trends in Defense 3D Printing Market:

Regional trends in defense 3D printing vary based on technological maturity, economic conditions, and geopolitical priorities. In the United States, which is a pioneer in 3D printing, significant investments have been made in the technology for defense applications. The focus here is on developing advanced materials and processes to produce high-performance components, reflecting the country's leading role in advancing defense technologies. In Europe, countries are actively exploring the potential of 3D printing for defense, with a strong emphasis on collaboration and standardization. European nations are working together to develop common standards and share knowledge, which helps in integrating 3D printing into various defense systems and enhancing overall capabilities. In Asia, countries like China and South Korea are rapidly advancing their 3D printing capabilities. Driven by domestic industrial policies and expanding defense budgets, these nations are investing heavily in 3D printing technology to bolster their defense sectors and support a range of military applications. Israel, known for its innovation, has effectively leveraged 3D printing for military purposes. The country utilizes the technology for the production of unmanned aerial vehicles (UAVs) and other advanced systems, showcasing its role as a leader in integrating cutting-edge technologies into its defense operations.

Key Defense 3D Printing Program:

The Australian Army continues to encourage potential opportunities for metal 3D printing within the Defense sector. The Australian Army and SPEE3D will continue their collaboration in 2021, with plans to test SPEE3D technology for an additional 12 months. Once more, the 1st Combat Service Support Battalion of the Australian Army has given local firm SPEE3D the chance to work with them. This time, the alliance will concentrate on creating new techniques that might vastly enhance the stock of readily accessible unique metal repair parts.

For the maritime and defence industries, Canada constructed its first 3D printing metal research facility. The University of New Brunswick, in collaboration with Custom Fabricators and Machinists (CFM) and community institutions in New Brunswick and Nova Scotia, established the Marine Additive Manufacturing Centre of Excellence. The centre, which is the first in the nation to use metal 3D printing to make certified custom parts for the marine industry, will combine research, commercialization, and workforce development and training. The center's director and associate professor of mechanical engineering at UNB, Dr. Mohsen Mohammadi, will be in charge of the center's research and development activities.

The Spanish shipbuilder Navantia has an agreement with the Ministry of Defense to build five F-110 frigates (warships) for the Spanish Navy using additive manufacturing. These ships will be the first in the fleet, according to the business, to incorporate Industry 4.0 technologies with 3D printed components and cybersecurity systems that protect ships from threats. The five frigates will be built using cutting-edge integrated control and simulation systems, or a digital twin, as part of the Spanish navy's ASTILLERO 4.0 framework. This framework is a component of Navantia's effort to change the way ships are built so that it takes advantage of digitalization to create more effective transportation networks.

Table of Contents

Defense 3D Printing Market Report Definition

Defense 3D Printing Market Segmentation

By Application

By Region

By Material

Defense 3D Printing Market Analysis for next 10 Years

The 10-year Defense 3D Printing Market analysis would give a detailed overview of Defense 3D Printing Market growth, changing dynamics, technology adoption overviews and the overall market attractiveness is covered in this chapter.

Market Technologies of Defense 3D Printing Market

This segment covers the top 10 technologies that is expected to impact this market and the possible implications these technologies would have on the overall market.

Global Defense 3D Printing Market Forecast

The 10-year Defense 3D Printing Market forecast of this market is covered in detailed across the segments which are mentioned above.

Regional Defense 3D Printing Market Trends & Forecast

The regional Defense 3D Printing Market trends, drivers, restraints and Challenges of this market, the Political, Economic, Social and Technology aspects are covered in this segment. The market forecast and scenario analysis across regions are also covered in detailed in this segment. The last part of the regional analysis includes profiling of the key companies, supplier landscape and company benchmarking. The current market size is estimated based on the normal scenario.

North America

Drivers, Restraints and Challenges

PEST

Market Forecast & Scenario Analysis

Key Companies

Supplier Tier Landscape

Company Benchmarking

Europe

Middle East

APAC

South America

Country Analysis of Defense 3D Printing Market

This chapter deals with the key defense programs in this market, it also covers the latest news and patents which have been filed in this market. Country level 10 year market forecast and scenario analysis are also covered in this chapter.

US

Defense Programs

Latest News

Patents

Current levels of technology maturation in this market

Market Forecast & Scenario Analysis

Canada

Italy

France

Germany

Netherlands

Belgium

Spain

Sweden

Greece

Australia

South Africa

India

China

Russia

South Korea

Japan

Malaysia

Singapore

Brazil

Opportunity Matrix for Defense 3D Printing Market

The opportunity matrix helps the readers understand the high opportunity segments in this market.

Expert Opinions on Defense 3D printing Market Report Report

Hear from our experts their opinion of the possible analysis for this market.

Conclusions

About Aviation and Defense Market Reports

List of Tables

- Table 1: 10 Year Market Outlook, 2024-2034

- Table 2: Drivers, Impact Analysis, North America

- Table 3: Restraints, Impact Analysis, North America

- Table 4: Challenges, Impact Analysis, North America

- Table 5: Drivers, Impact Analysis, Europe

- Table 6: Restraints, Impact Analysis, Europe

- Table 7: Challenges, Impact Analysis, Europe

- Table 8: Drivers, Impact Analysis, Middle East

- Table 9: Restraints, Impact Analysis, Middle East

- Table 10: Challenges, Impact Analysis, Middle East

- Table 11: Drivers, Impact Analysis, APAC

- Table 12: Restraints, Impact Analysis, APAC

- Table 13: Challenges, Impact Analysis, APAC

- Table 14: Drivers, Impact Analysis, South America

- Table 15: Restraints, Impact Analysis, South America

- Table 16: Challenges, Impact Analysis, South America

- Table 17: Scenario Analysis, Scenario 1, By Region, 2024-2034

- Table 18: Scenario Analysis, Scenario 1, By Material, 2024-2034

- Table 19: Scenario Analysis, Scenario 1, By Application, 2024-2034

- Table 20: Scenario Analysis, Scenario 2, By Region, 2024-2034

- Table 21: Scenario Analysis, Scenario 2, By Material, 2024-2034

- Table 22: Scenario Analysis, Scenario 2, By Application, 2024-2034

List of Figures

- Figure 1: Global Defense 3D Printing Market Forecast, 2024-2034

- Figure 2: Global Defense 3D Printing Market Forecast, By Region, 2024-2034

- Figure 3: Global Defense 3D Printing Market Forecast, By Material, 2024-2034

- Figure 4: Global Defense 3D Printing Market Forecast, By Application, 2024-2034

- Figure 5: North America, Defense 3D Printing Market, Market Forecast, 2024-2034

- Figure 6: Europe, Defense 3D Printing Market, Market Forecast, 2024-2034

- Figure 7: Middle East, Defense 3D Printing Market, Market Forecast, 2024-2034

- Figure 8: APAC, Defense 3D Printing Market, Market Forecast, 2024-2034

- Figure 9: South America, Defense 3D Printing Market, Market Forecast, 2024-2034

- Figure 10: United States, Defense 3D Printing Market, Technology Maturation, 2024-2034

- Figure 11: United States, Defense 3D Printing Market, Market Forecast, 2024-2034

- Figure 12: Canada, Defense 3D Printing Market, Technology Maturation, 2024-2034

- Figure 13: Canada, Defense 3D Printing Market, Market Forecast, 2024-2034

- Figure 14: Italy, Defense 3D Printing Market, Technology Maturation, 2024-2034

- Figure 15: Italy, Defense 3D Printing Market, Market Forecast, 2024-2034

- Figure 16: France, Defense 3D Printing Market, Technology Maturation, 2024-2034

- Figure 17: France, Defense 3D Printing Market, Market Forecast, 2024-2034

- Figure 18: Germany, Defense 3D Printing Market, Technology Maturation, 2024-2034

- Figure 19: Germany, Defense 3D Printing Market, Market Forecast, 2024-2034

- Figure 20: Netherlands, Defense 3D Printing Market, Technology Maturation, 2024-2034

- Figure 21: Netherlands, Defense 3D Printing Market, Market Forecast, 2024-2034

- Figure 22: Belgium, Defense 3D Printing Market, Technology Maturation, 2024-2034

- Figure 23: Belgium, Defense 3D Printing Market, Market Forecast, 2024-2034

- Figure 24: Spain, Defense 3D Printing Market, Technology Maturation, 2024-2034

- Figure 25: Spain, Defense 3D Printing Market, Market Forecast, 2024-2034

- Figure 26: Sweden, Defense 3D Printing Market, Technology Maturation, 2024-2034

- Figure 27: Sweden, Defense 3D Printing Market, Market Forecast, 2024-2034

- Figure 28: Brazil, Defense 3D Printing Market, Technology Maturation, 2024-2034

- Figure 29: Brazil, Defense 3D Printing Market, Market Forecast, 2024-2034

- Figure 30: Australia, Defense 3D Printing Market, Technology Maturation, 2024-2034

- Figure 31: Australia, Defense 3D Printing Market, Market Forecast, 2024-2034

- Figure 32: India, Defense 3D Printing Market, Technology Maturation, 2024-2034

- Figure 33: India, Defense 3D Printing Market, Market Forecast, 2024-2034

- Figure 34: China, Defense 3D Printing Market, Technology Maturation, 2024-2034

- Figure 35: China, Defense 3D Printing Market, Market Forecast, 2024-2034

- Figure 36: Saudi Arabia, Defense 3D Printing Market, Technology Maturation, 2024-2034

- Figure 37: Saudi Arabia, Defense 3D Printing Market, Market Forecast, 2024-2034

- Figure 38: South Korea, Defense 3D Printing Market, Technology Maturation, 2024-2034

- Figure 39: South Korea, Defense 3D Printing Market, Market Forecast, 2024-2034

- Figure 40: Japan, Defense 3D Printing Market, Technology Maturation, 2024-2034

- Figure 41: Japan, Defense 3D Printing Market, Market Forecast, 2024-2034

- Figure 42: Malaysia, Defense 3D Printing Market, Technology Maturation, 2024-2034

- Figure 43: Malaysia, Defense 3D Printing Market, Market Forecast, 2024-2034

- Figure 44: Singapore, Defense 3D Printing Market, Technology Maturation, 2024-2034

- Figure 45: Singapore, Defense 3D Printing Market, Market Forecast, 2024-2034

- Figure 46: United Kingdom, Defense 3D Printing Market, Technology Maturation, 2024-2034

- Figure 47: United Kingdom, Defense 3D Printing Market, Market Forecast, 2024-2034

- Figure 48: Opportunity Analysis, Defense 3D Printing Market, By Region (Cumulative Market), 2024-2034

- Figure 49: Opportunity Analysis, Defense 3D Printing Market, By Region (CAGR), 2024-2034

- Figure 50: Opportunity Analysis, Defense 3D Printing Market, By Material (Cumulative Market), 2024-2034

- Figure 51: Opportunity Analysis, Defense 3D Printing Market, By Material (CAGR), 2024-2034

- Figure 52: Opportunity Analysis, Defense 3D Printing Market, By Application (Cumulative Market), 2024-2034

- Figure 53: Opportunity Analysis, Defense 3D Printing Market, By Application (CAGR), 2024-2034

- Figure 54: Scenario Analysis, Defense 3D Printing Market, Cumulative Market, 2024-2034

- Figure 55: Scenario Analysis, Defense 3D Printing Market, Global Market, 2024-2034

- Figure 56: Scenario 1, Defense 3D Printing Market, Total Market, 2024-2034

- Figure 57: Scenario 1, Defense 3D Printing Market, By Region, 2024-2034

- Figure 58: Scenario 1, Defense 3D Printing Market, By Material, 2024-2034

- Figure 59: Scenario 1, Defense 3D Printing Market, By Application, 2024-2034

- Figure 60: Scenario 2, Defense 3D Printing Market, Total Market, 2024-2034

- Figure 61: Scenario 2, Defense 3D Printing Market, By Region, 2024-2034

- Figure 62: Scenario 2, Defense 3D Printing Market, By Material, 2024-2034

- Figure 63: Scenario 2, Defense 3D Printing Market, By Application, 2024-2034

- Figure 64: Company Benchmark, Defense 3D Printing Market, 2024-2034