|

市場調查報告書

商品編碼

1665189

金屬加工和採礦靜電集塵器市場機會、成長動力、產業趨勢分析與預測 2025 - 2034Metal Processing and Mining Electrostatic Precipitator Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

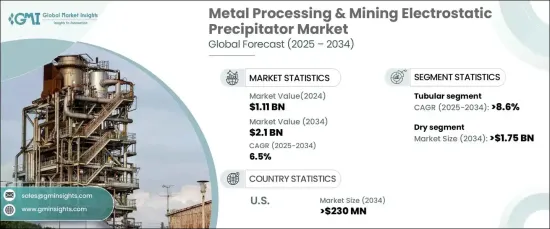

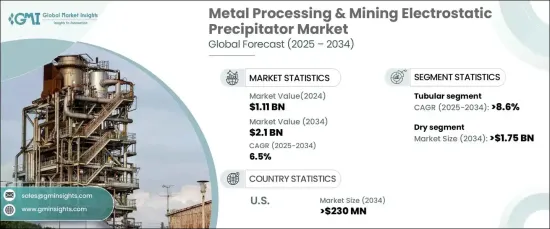

全球金屬加工和採礦靜電除塵器市場呈現動態成長軌跡,其價值將在 2024 年達到 11.1 億美元,並預計在 2025 年至 2034 年期間以 6.5% 的複合年成長率成長。這些設備對於冶煉、精煉和礦石提取等過程至關重要,對於那些面臨更嚴格的環境要求和日益嚴重的健康問題的行業來說至關重要。

隨著全球工業化進程加速,控制排放、保障公眾健康的重點日益加強。更嚴格的監管框架要求有效的污染控制解決方案,而企業則面臨採用永續做法的壓力。人們越來越意識到顆粒物排放對工人和社區的有害影響,這增加了對先進技術的投資。靜電除塵器因其能夠有效處理高顆粒負荷和大量氣體且不影響運行性能而成為首選解決方案。此外,推動降低成本並支持永續發展目標的節能系統正在重塑市場格局。

| 市場範圍 | |

|---|---|

| 起始年份 | 2024 |

| 預測年份 | 2025-2034 |

| 起始值 | 11.1億美元 |

| 預測值 | 21億美元 |

| 複合年成長率 | 6.5% |

在金屬加工和採礦業,空氣中的顆粒物會帶來嚴重的健康風險並導致環境惡化。公司正在優先考慮更清潔的技術以遵守監管標準並提高工作場所的安全性。這些作業過程中產生的灰塵和煙霧不僅影響空氣質量,而且還會對生態系統產生長期影響。先進的靜電集塵器因其能夠降低這些風險同時滿足對更清潔、更環保的工業流程日益成長的需求而越來越受到關注。採用具成本效益的系統也有助於企業平衡效率與法規遵從性,進而推動市場大幅成長。

市場依系統類型分為乾式系統和濕式系統。乾式靜電集塵器預計將佔據主導地位,到 2034 年其市場價值預計將達到 17.5 億美元。乾式系統具有用水量低、廢棄物處理簡化、維護成本降低等特點,是一種經濟實用的解決方案。技術的進步,包括緊湊的設計和增強的各種粒度性能,進一步推動了它們在整個行業中的應用。

在設計方面,管狀和板狀系統代表兩大主要類別。預計到 2034 年,管狀部分將以驚人的 8.6% 的複合年成長率成長,這得益於其卓越的細顆粒物捕獲能力。其緊湊的設計對於空間受限的設施特別有吸引力,使其成為舊工廠和密集營運的首選。該設計能夠滿足嚴格的顆粒控制要求且不影響效率,這是推動其需求的重要因素。

美國是全球市場的重要參與者,其金屬加工和採礦靜電除塵器產業預計到 2034 年將創造 2.3 億美元。企業正在加大對清潔技術的投資,以解決人們對工人健康和公共安全日益成長的擔憂。隨著各行各業努力削減營運成本並支持永續發展計劃,節能系統的採用也正在獲得發展動力,鞏固了美國作為靜電除塵器領先市場的地位。

目錄

第 1 章:方法論與範圍

- 研究設計

- 基礎估算與計算

- 預測模型

- 初步研究與驗證

- 主要來源

- 資料探勘來源

- 市場定義

第 2 章:執行摘要

第 3 章:產業洞察

- 產業生態系統

- 監管格局

- 產業衝擊力

- 成長動力

- 產業陷阱與挑戰

- 成長潛力分析

- 波特的分析

- 供應商的議價能力

- 買家的議價能力

- 新進入者的威脅

- 替代品的威脅

- PESTEL 分析

第4章:競爭格局

- 介紹

- 戰略儀表板

- 創新與技術格局

第 5 章:市場規模及預測:依設計,2021 – 2034 年

- 主要趨勢

- 盤子

- 管狀

第6章:市場規模及預測:依系統,2021 – 2034 年

- 主要趨勢

- 乾燥

- 濕的

第 7 章:市場規模及預測:按地區,2021 – 2034 年

- 主要趨勢

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 德國

- 英國

- 法國

- 西班牙

- 義大利

- 荷蘭

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 印尼

- 澳洲

- 中東和非洲

- 沙烏地阿拉伯

- 阿拉伯聯合大公國

- 南非

- 奈及利亞

- 安哥拉

- 拉丁美洲

- 巴西

- 阿根廷

- 智利

- 秘魯

第8章:公司簡介

- ANDRITZ GROUP

- Babcock & Wilcox

- Elex

- Environ Engineers

- GEA Group

- Kraft Powercon

- McGill AirClean

- Sumitomo Heavy Industries

- Thermax

- VT Corp

- Valmet

The Global Metal Processing And Mining Electrostatic Precipitator Market is on a dynamic growth trajectory, with its value reaching USD 1.11 billion in 2024 and poised to expand at a CAGR of 6.5% from 2025 to 2034. Electrostatic precipitators, engineered to remove fine particulate matter such as dust and smoke from industrial exhaust gases, are becoming indispensable for ensuring cleaner air. These devices are integral to processes like smelting, refining, and ore extraction, making them vital for industries grappling with stricter environmental mandates and rising health concerns.

As industrialization accelerates globally, the focus on controlling emissions and safeguarding public health is intensifying. Stricter regulatory frameworks demand efficient pollution control solutions, while businesses are under pressure to adopt sustainable practices. The increasing awareness of the detrimental effects of particulate emissions on workers and communities has amplified investments in advanced technologies. Electrostatic precipitators are emerging as a preferred solution due to their ability to handle high particulate loads and large gas volumes efficiently without compromising operational performance. Furthermore, the push for energy-efficient systems that reduce costs while supporting sustainability goals is reshaping the market landscape.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $1.11 Billion |

| Forecast Value | $2.1 Billion |

| CAGR | 6.5% |

In the metal processing and mining sectors, airborne particulates pose significant health risks and contribute to environmental degradation. Companies are prioritizing cleaner technologies to comply with regulatory standards and enhance workplace safety. Dust and fumes generated during these operations not only affect air quality but also have long-term repercussions on ecosystems. Advanced electrostatic precipitators are gaining traction for their ability to mitigate these risks while meeting the growing demand for cleaner, greener industrial processes. The adoption of cost-effective systems is also helping businesses balance efficiency with regulatory compliance, driving substantial market growth.

The market is segmented by system type into dry and wet systems. Dry electrostatic precipitators are projected to dominate, with their market value expected to reach USD 1.75 billion by 2034. These systems are favored for their exceptional efficiency in capturing non-hygroscopic particles commonly found in metal processing and mining operations. With lower water usage, simplified waste disposal, and reduced maintenance costs, dry systems offer an economical and practical solution. Advancements in technology, including compact designs and enhanced performance across various particle sizes, are further boosting their adoption across the industry.

In terms of design, tubular and plate systems represent the two key categories. The tubular segment is forecast to grow at an impressive CAGR of 8.6% through 2034, driven by its superior capacity to capture fine particulates. Its compact design is particularly appealing to facilities with space constraints, making it a top choice for older plants and densely packed operations. This design's ability to meet stringent particulate control requirements without compromising efficiency is a significant factor propelling its demand.

The United States is a key player in the global market, with its metal processing and mining electrostatic precipitator sector expected to generate USD 230 million by 2034. The country's strict environmental regulations and heightened focus on reducing emissions are driving demand for advanced pollution control technologies. Companies are increasingly investing in clean technologies to address growing concerns about worker health and public safety. The adoption of energy-efficient systems is also gaining momentum as industries strive to cut operational costs while supporting sustainability initiatives, solidifying the U.S. as a leading market for electrostatic precipitators.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Research design

- 1.2 Base estimates & calculations

- 1.3 Forecast model

- 1.4 Primary research & validation

- 1.4.1 Primary sources

- 1.4.2 Data mining sources

- 1.5 Market definitions

Chapter 2 Executive Summary

- 2.1 Industry synopsis, 2021 – 2034

Chapter 3 Industry Insights

- 3.1 Industry ecosystem

- 3.2 Regulatory landscape

- 3.3 Industry impact forces

- 3.3.1 Growth drivers

- 3.3.2 Industry pitfalls & challenges

- 3.4 Growth potential analysis

- 3.5 Porter's analysis

- 3.5.1 Bargaining power of suppliers

- 3.5.2 Bargaining power of buyers

- 3.5.3 Threat of new entrants

- 3.5.4 Threat of substitutes

- 3.6 PESTEL analysis

Chapter 4 Competitive landscape, 2024

- 4.1 Introduction

- 4.2 Strategic dashboard

- 4.3 Innovation & technology landscape

Chapter 5 Market Size and Forecast, By Design, 2021 – 2034 (USD Million)

- 5.1 Key trends

- 5.2 Plate

- 5.3 Tubular

Chapter 6 Market Size and Forecast, By System, 2021 – 2034 (USD Million)

- 6.1 Key trends

- 6.2 Dry

- 6.3 Wet

Chapter 7 Market Size and Forecast, By Region, 2021 – 2034 (USD Million)

- 7.1 Key trends

- 7.2 North America

- 7.2.1 U.S.

- 7.2.2 Canada

- 7.2.3 Mexico

- 7.3 Europe

- 7.3.1 Germany

- 7.3.2 UK

- 7.3.3 France

- 7.3.4 Spain

- 7.3.5 Italy

- 7.3.6 Netherlands

- 7.4 Asia Pacific

- 7.4.1 China

- 7.4.2 India

- 7.4.3 Japan

- 7.4.4 South Korea

- 7.4.5 Indonesia

- 7.4.6 Australia

- 7.5 Middle East & Africa

- 7.5.1 Saudi Arabia

- 7.5.2 UAE

- 7.5.3 South Africa

- 7.5.4 Nigeria

- 7.5.5 Angola

- 7.6 Latin America

- 7.6.1 Brazil

- 7.6.2 Argentina

- 7.6.3 Chile

- 7.6.4 Peru

Chapter 8 Company Profiles

- 8.1 ANDRITZ GROUP

- 8.2 Babcock & Wilcox

- 8.3 Elex

- 8.4 Environ Engineers

- 8.5 GEA Group

- 8.6 Kraft Powercon

- 8.7 McGill AirClean

- 8.8 Sumitomo Heavy Industries

- 8.9 Thermax

- 8.10 VT Corp

- 8.11 Valmet