|

市場調查報告書

商品編碼

1666901

真空鍍膜設備市場機會、成長動力、產業趨勢分析及 2024 - 2032 年預測Vacuum Coating Equipment Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2024 - 2032 |

||||||

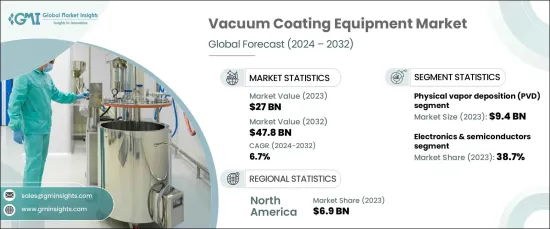

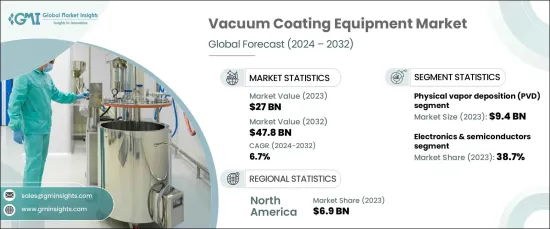

2023 年全球真空鍍膜設備市場價值為 270 億美元,預計 2024 年至 2032 年期間的複合年成長率為 6.7%。物理氣相沉積 (PVD) 和化學氣相沉積 (CVD) 方法的創新一直是關鍵促進因素,可提高塗層的耐久性、均勻性和品質。此外,等離子輔助製程的引入透過提供更高的效率和精度來應用專用塗層,從而改變了整個產業。

對小型電子設備的需求不斷成長,極大地促進了市場擴張。真空塗層對於製造高性能電子元件(包括半導體和先進顯示器)至關重要。隨著設備變得越來越緊湊和複雜,對能夠滿足嚴格性能標準的塗層的需求也激增。

| 市場範圍 | |

|---|---|

| 起始年份 | 2023 |

| 預測年份 | 2024-2032 |

| 起始值 | 270億美元 |

| 預測值 | 478億美元 |

| 複合年成長率 | 6.7% |

儘管真空鍍膜系統具有諸多優勢,但由於前期成本較高,市場也面臨挑戰。 PVD和CVD系統等先進設備的購買、安裝和維護需要大量投資。這些財務障礙通常會限制中小企業和對成本限制敏感的地區的採用。透過具有成本效益的解決方案和靈活的融資選擇來解決這些問題對於擴大市場覆蓋範圍和推動這項技術的更廣泛應用至關重要。

在設備方面,PVD 部門在 2023 年的收入為 94 億美元,預計在預測期內的複合年成長率為 7.2%。它能夠生產出高品質、精確且耐用的塗層,成為多個行業的首選。該技術的環保特性進一步支持了它的採用,因為它符合更嚴格的環境法規和全球永續發展目標。

電子和半導體行業在 2023 年佔據了 38.7% 的市場佔有率,預計到 2032 年將以 7.1% 的複合年成長率成長。日益成長的技術進步推動了對創新塗層方法的投資,以滿足日益成長的需求。

2023 年北美的市場收入為 69 億美元,預計到 2032 年的複合年成長率將達到 7.3%。

目錄

第 1 章:方法論與範圍

- 市場範圍和定義

- 基礎估算與計算

- 預測參數

- 資料來源

- 基本的

- 次要

- 付費來源

- 公共資源

第 2 章:執行摘要

第 3 章:產業洞察

- 產業生態系統分析

- 影響價值鏈的因素

- 利潤率分析

- 中斷

- 未來展望

- 製造商

- 經銷商

- 零售商

- 衝擊力

- 成長動力

- 塗層方法的技術進步

- 電子產業需求不斷成長

- 對永續和節能塗料的需求

- 汽車產業成長

- 產業陷阱與挑戰

- 初期投資成本高

- 嚴格的監管和環境標準

- 成長動力

- 技術與創新格局

- 消費者購買行為分析

- 人口趨勢

- 影響購買決策的因素

- 消費者產品採用

- 首選配銷通路

- 成長潛力分析

- 監管格局

- 定價分析

- 波特的分析

- PESTEL 分析

第4章:競爭格局

- 介紹

- 公司市佔率分析

- 競爭定位矩陣

- 戰略展望矩陣

第 5 章:市場估計與預測:按設備類型,2021 – 2032 年

- 主要趨勢

- 物理氣相沉積 (PVD)

- 化學氣相沉積 (CVD)

- 磁控濺射

- 電子束蒸發

- 熱蒸發

第 6 章:市場估計與預測:按最終用途產業,2021 年至 2032 年

- 主要趨勢

- 電子和半導體

- 汽車

- 航太和國防

- 能源(包括太陽能)

- 醫療的

- 其他

第7章:市場估計與預測:按地區,2021 – 2032 年

- 主要趨勢

- 北美洲

- 美國

- 加拿大

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 西班牙

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 澳洲

- 馬來西亞

- 印尼

- 拉丁美洲

- 巴西

- 墨西哥

- 中東及非洲

- 沙烏地阿拉伯

- 阿拉伯聯合大公國

- 南非

第8章:公司簡介

- Adler Pelzer

- Autoneum

- BASF

- Borgers

- Charlotte Baur Formschaumtechnik

- Continental

- DBW Advanced Fiber Technologies

- ElringKlinger

- Greiner Foam

- Röchling

- SA Automotive

- TROCELLEN Automotive

- UFP Technologies

- Unitex India

- Woco Industrietechnik

The Global Vacuum Coating Equipment Market, valued at USD 27 billion in 2023, is projected to grow at a CAGR of 6.7% from 2024 to 2032. This growth is fueled by advancements in coating technologies and the evolving needs of modern industries. Innovations in Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD) methods have been key drivers, offering enhanced coating durability, uniformity, and quality. Additionally, the introduction of plasma-assisted processes has transformed the industry by providing greater efficiency and precision in applying specialized coatings.

The rising demand for miniaturized electronic devices has significantly contributed to the market expansion. Vacuum coatings have become essential in manufacturing high-performance electronic components, including semiconductors and advanced displays. As devices become more compact and intricate, the need for coatings capable of meeting demanding performance criteria has surged.

| Market Scope | |

|---|---|

| Start Year | 2023 |

| Forecast Year | 2024-2032 |

| Start Value | $27 Billion |

| Forecast Value | $47.8 Billion |

| CAGR | 6.7% |

Despite its advantages, the market faces challenges due to the high upfront costs associated with vacuum coating systems. The purchase, installation, and maintenance of advanced equipment such as PVD and CVD systems require substantial investment. These financial barriers often restrict adoption among small and medium-sized enterprises and in regions sensitive to cost constraints. Efforts to address these issues through cost-efficient solutions and flexible financing options are critical to broadening the market's reach and enabling wider adoption of this technology.

In terms of equipment, the PVD segment accounted for USD 9.4 billion in 2023 and is anticipated to grow at a CAGR of 7.2% during the forecast period. Its ability to produce high-quality, precise, and durable coatings has made it a preferred choice across multiple industries. The eco-friendly nature of this technology further supports its adoption as it aligns with stricter environmental regulations and global sustainability goals.

The electronics and semiconductor sector held a 38.7% market share in 2023 and is set to grow at a CAGR of 7.1% through 2032. Vacuum coatings play a pivotal role in improving the performance and reliability of electronic devices by ensuring precise and durable layering. Growing technological advancements drive investments in innovative coating methods to meet the increasing demand.

North America accounted for USD 6.9 billion in market revenue in 2023 and is projected to grow at a CAGR of 7.3% by 2032. Regional growth is supported by advancements in high-tech manufacturing, government initiatives for clean energy, and robust R&D activities.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Market scope & definition

- 1.2 Base estimates & calculations

- 1.3 Forecast parameters

- 1.4 Data sources

- 1.4.1 Primary

- 1.4.2 Secondary

- 1.4.2.1 Paid sources

- 1.4.2.2 Public sources

Chapter 2 Executive Summary

- 2.1 Industry 3600 synopsis, 2021 - 2032

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Factors affecting the value chain

- 3.1.2 Profit margin analysis

- 3.1.3 Disruptions

- 3.1.4 Future outlook

- 3.1.5 Manufacturers

- 3.1.6 Distributors

- 3.1.7 Retailers

- 3.2 Impact forces

- 3.2.1 Growth drivers

- 3.2.1.1 Technological advancements in coating methods

- 3.2.1.2 Rising demand from electronics industry

- 3.2.1.3 Demand for sustainable and energy-efficient coatings

- 3.2.1.4 Automotive industry growth

- 3.2.2 Industry pitfalls & challenges

- 3.2.2.1 High initial investment costs

- 3.2.2.2 Stringent regulatory and environmental standards

- 3.2.1 Growth drivers

- 3.3 Technology & innovation landscape

- 3.4 Consumer buying behavior analysis

- 3.4.1 Demographic trends

- 3.4.2 Factors affecting buying decision

- 3.4.3 Consumer product adoption

- 3.4.4 Preferred distribution channel

- 3.5 Growth potential analysis

- 3.6 Regulatory landscape

- 3.7 Pricing analysis

- 3.8 Porter’s analysis

- 3.9 PESTEL analysis

Chapter 4 Competitive Landscape, 2023

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.3 Competitive positioning matrix

- 4.4 Strategic outlook matrix

Chapter 5 Market Estimates & Forecast, By Equipment Type, 2021 – 2032, (USD Billion)

- 5.1 Key trends

- 5.2 Physical vapor deposition (PVD)

- 5.3 Chemical vapor deposition (CVD)

- 5.4 Magnetron sputtering

- 5.5 Electron beam evaporation

- 5.6 Thermal evaporation

Chapter 6 Market Estimates & Forecast, By End Use Industry, 2021 – 2032, (USD Billion)

- 6.1 Key trends

- 6.2 Electronics & semiconductors

- 6.3 Automotive

- 6.4 Aerospace & defense

- 6.5 Energy (including solar)

- 6.6 Medical

- 6.7 Others

Chapter 7 Market Estimates & Forecast, By Region, 2021 – 2032, (USD Billion)

- 7.1 Key trends

- 7.2 North America

- 7.2.1 U.S.

- 7.2.2 Canada

- 7.3 Europe

- 7.3.1 Germany

- 7.3.2 UK

- 7.3.3 France

- 7.3.4 Italy

- 7.3.5 Spain

- 7.4 Asia Pacific

- 7.4.1 China

- 7.4.2 India

- 7.4.3 Japan

- 7.4.4 South Korea

- 7.4.5 Australia

- 7.4.6 Malaysia

- 7.4.7 Indonesia

- 7.5 Latin America

- 7.5.1 Brazil

- 7.5.2 Mexico

- 7.6 MEA

- 7.6.1 Saudi Arabia

- 7.6.2 UAE

- 7.6.3 South Africa

Chapter 8 Company Profiles (Business Overview, Financial Data, Product Landscape, Strategic Outlook, SWOT Analysis)

- 8.1 Adler Pelzer

- 8.2 Autoneum

- 8.3 BASF

- 8.4 Borgers

- 8.5 Charlotte Baur Formschaumtechnik

- 8.6 Continental

- 8.7 DBW Advanced Fiber Technologies

- 8.8 ElringKlinger

- 8.9 Greiner Foam

- 8.10 Röchling

- 8.11 SA Automotive

- 8.12 TROCELLEN Automotive

- 8.13 UFP Technologies

- 8.14 Unitex India

- 8.15 Woco Industrietechnik