|

市場調查報告書

商品編碼

1684785

製造業人工智慧市場機會、成長動力、產業趨勢分析及 2025 - 2034 年預測AI in Manufacturing Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

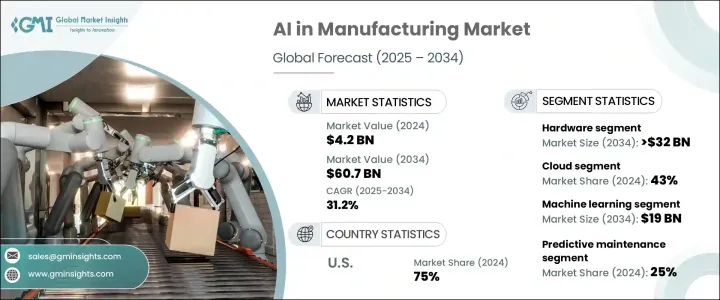

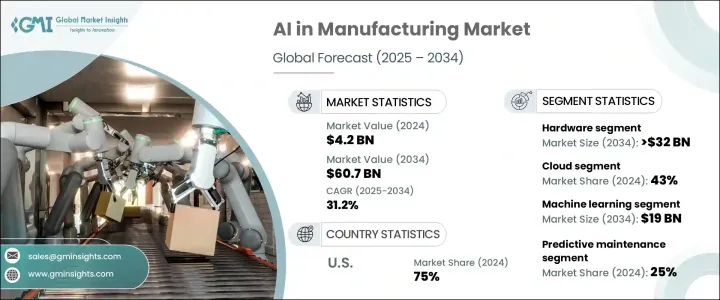

2024 年全球製造業人工智慧市場價值為 42 億美元,預計 2025 年至 2034 年期間的複合年成長率為 31.2%。製造業對精簡外包解決方案的需求日益增加,推動了人工智慧的採用。企業正在整合人工智慧,透過自動化生產控制、檢查和庫存管理等流程來提高生產效率、降低成本並擴大營運規模。人工智慧解決方案的日益普及,使從大型製造商到中小型企業等各種規模的企業受益。世界各國政府都優先考慮人工智慧的研究和開發,並提供資助計畫、稅收減免和監管支援等財政激勵措施來促進人工智慧的實施。這些措施旨在推動各行業的創新、提高生產力並降低成本。

市場根據組件分為硬體、軟體和服務。 2024 年,硬體領域的市佔率超過 55%,預計到 2034 年將超過 320 億美元。對先進計算硬體的不斷成長的需求推動了這一成長,因為製造業中的人工智慧應用(例如機器人、預測性維護和品質控制)需要高效能組件進行即時資料處理。機器學習和深度學習演算法也在推動對強大硬體的需求,以提高人工智慧的效能。資料處理能力的快速進步實現了更高程度的自動化、更強的生產力和更好的決策。

| 市場範圍 | |

|---|---|

| 起始年份 | 2024 |

| 預測年份 | 2025-2034 |

| 起始值 | 42億美元 |

| 預測值 | 607億美元 |

| 複合年成長率 | 31.2% |

根據部署模式,市場分為內部部署和雲端解決方案。 2024年,雲端運算部分約佔市場的43%。隨著各行各業的公司紛紛擁抱數位轉型,對基於雲端的人工智慧解決方案的需求不斷上升,從而增強了製造業的競爭力。雲端運算提供靈活性和可擴展性,降低營運成本並簡化流程。此外,遠端實施可以增強資料儲存和處理,這對於依賴大量資料集的人工智慧應用至關重要。基於雲端的解決方案還支援製造商、供應商和客戶之間的即時協作,從而改善決策並加快產品上市時間。

市場也按技術細分,包括機器學習、電腦視覺、自然語言處理和情境感知計算。機器學習引領市場,預計到 2034 年將創造約 190 億美元的市場價值。這一成長歸因於機器學習在智慧自動化和數據驅動決策中的應用日益增加。人工智慧驅動的品質控制解決方案提高了產品檢測準確性,最大限度地減少了生產損失。物聯網技術的興起也推動了製造業機器學習的應用,物聯網技術可以收集、分析和處理資料以最佳化營運。

市場根據應用進一步分類,包括品質管理、預測性維護、庫存管理、能源管理、工業機器人等。預測性維護在 2024 年佔據最大佔有率,約 25%。人工智慧預測性維護解決方案使用機器學習演算法即時監控和評估設備效能,幫助企業預防故障、降低維護成本並最大限度地減少生產中斷。對更高生產力和減少停機時間的不斷成長的需求推動了對這些系統的需求。

2024年美國引領北美製造業人工智慧市場,佔有約75%的區域佔有率。中國政府對人工智慧驅動的智慧製造的大力支持是市場成長的關鍵因素。政策制定者優先考慮自動化和先進技術,以增強國家製造業的競爭力。此外,對加強供應鏈彈性和最佳化生產效率的關注進一步推動了產業對人工智慧的應用。

目錄

第 1 章:方法論與範圍

- 研究設計

- 研究方法

- 資料收集方法

- 基礎估算與計算

- 基準年計算

- 市場估計的主要趨勢

- 預測模型

- 初步研究和驗證

- 主要來源

- 資料探勘來源

- 市場範圍和定義

第 2 章:執行摘要

第 3 章:產業洞察

- 產業生態系統分析

- 硬體提供者

- 軟體供應商

- 服務提供者

- 技術提供者

- 最終客戶

- 供應商概況

- 利潤率分析

- 技術與創新格局

- 專利分析

- 重要新聞及舉措

- 監管格局

- 製造業人工智慧的演變

- 使用案例

- 衝擊力

- 成長動力

- 自動化需求日益成長

- 機器學習技術的快速發展

- 採用人工智慧預測性維護解決方案

- 增加工業自動化的投資

- 產業陷阱與挑戰

- 資料隱私問題

- 缺乏熟練的專業人員

- 成長動力

- 成長潛力分析

- 波特的分析

- PESTEL 分析

第4章:競爭格局

- 介紹

- 公司市佔率分析

- 競爭定位矩陣

- 戰略展望矩陣

第5章:市場估計與預測:按組件,2021 - 2034 年

- 主要趨勢

- 硬體

- 處理器

- 中央處理器 (CPU)

- 圖形處理單元 (GPU)

- 現場可程式閘陣列 (FPGA)

- 專用積體電路 (ASIC)

- 張量處理單元 (TPU)

- 記憶體和儲存

- 網路硬體

- 處理器

- 軟體

- 服務

- 專業服務

- 託管服務

第6章:市場估計與預測:依部署模型,2021 - 2034 年

- 主要趨勢

- 本地

- 雲

第 7 章:市場估計與預測:按技術,2021 - 2034 年

- 主要趨勢

- 機器學習

- 電腦視覺

- 自然語言處理

- 情境感知計算

第 8 章:市場估計與預測:按應用,2021 - 2034 年

- 主要趨勢

- 品質管理

- 預測性維護

- 庫存管理

- 能源管理

- 工業機器人

- 其他

第 9 章:市場估計與預測:按最終用途,2021 - 2034 年

- 主要趨勢

- 汽車

- 電子產品

- 藥品

- 重型機械

- 食品和飲料

- 航太和國防

- 其他

第 10 章:市場估計與預測:按地區,2021 - 2034 年

- 北美洲

- 美國

- 加拿大

- 歐洲

- 英國

- 德國

- 法國

- 義大利

- 西班牙

- 俄羅斯

- 北歐

- 亞太地區

- 中國

- 印度

- 日本

- 澳洲

- 韓國

- 東南亞

- 拉丁美洲

- 巴西

- 墨西哥

- 阿根廷

- 中東及非洲

- 阿拉伯聯合大公國

- 南非

- 沙烏地阿拉伯

第 11 章:公司簡介

- ABB

- AWS

- Cognex

- Dassault

- Fanuc

- GE

- Honeywell

- IBM

- Intel

- Microsoft

- NVIDIA

- Oracle

- PTC

- Qualcomm

- Rockwell

- SAP

- Schneider

- Siemens

- Xilinx

The Global AI In Manufacturing Market was valued at USD 4.2 billion in 2024 and is projected to grow at a CAGR of 31.2% between 2025 and 2034. The increasing need for streamlined outsourcing solutions within the manufacturing sector is driving AI adoption. Companies are integrating AI to enhance production efficiency, cut costs, and scale operations by automating processes such as production control, inspection, and inventory management. The rising availability of AI-powered solutions is benefiting businesses of all sizes, from large manufacturers to small and medium enterprises. Governments worldwide are prioritizing AI research and development, offering financial incentives such as funding programs, tax breaks, and regulatory support to boost AI implementation. These initiatives are designed to drive innovation, improve productivity, and reduce costs across various industries.

The market is segmented based on components into hardware, software, and services. In 2024, the hardware segment held a market share exceeding 55% and is expected to surpass USD 32 billion by 2034. The rising demand for advanced computing hardware is fueling this growth, as AI applications in manufacturing, such as robotics, predictive maintenance, and quality control, require high-performance components for real-time data processing. Machine learning and deep learning algorithms are also driving the need for powerful hardware to improve AI performance. Rapid advancements in data processing capabilities are enabling greater automation, enhanced productivity, and better decision-making.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $4.2 Billion |

| Forecast Value | $60.7 Billion |

| CAGR | 31.2% |

By deployment model, the market is categorized into on-premises and cloud solutions. In 2024, the cloud segment accounted for about 43% of the market. As companies across industries embrace digital transformation, the demand for cloud-based AI solutions is rising, enhancing competitiveness in manufacturing. Cloud computing offers flexibility and scalability, reducing operational costs and streamlining processes. Additionally, remote implementation allows for enhanced data storage and processing, which is critical for AI applications that rely on extensive datasets. Cloud-based solutions also enable real-time collaboration between manufacturers, suppliers, and customers, improving decision-making and accelerating time to market.

The market is also segmented by technology, including machine learning, computer vision, natural language processing, and context-aware computing. Machine learning led the market and is projected to generate around USD 19 billion by 2034. This growth is attributed to the increasing use of machine learning for intelligent automation and data-driven decision-making. AI-driven quality control solutions improve product inspection accuracy, minimizing production losses. Machine learning adoption in manufacturing is also being propelled by the rise of IoT technologies, which collect, analyze, and process data for optimized operations.

The market is further divided by application, including quality management, predictive maintenance, inventory management, energy management, industrial robotics, and others. Predictive maintenance held the largest share in 2024 at approximately 25%. AI-powered predictive maintenance solutions use machine learning algorithms to monitor and assess equipment performance in real-time, helping businesses prevent failures, reduce maintenance costs, and minimize production disruptions. The increasing need for higher productivity and reduced downtime is driving demand for these systems.

The United States led the North America AI in manufacturing market in 2024, holding about 75% of the regional share. The country's strong government support for AI-driven smart manufacturing is a key factor in market growth. Policymakers are prioritizing automation and advanced technologies to enhance the competitiveness of the nation's manufacturing sector. In addition, a focus on strengthening supply chain resilience and optimizing production efficiency is further driving AI adoption in the industry.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Research design

- 1.1.1 Research approach

- 1.1.2 Data collection methods

- 1.2 Base estimates & calculations

- 1.2.1 Base year calculation

- 1.2.2 Key trends for market estimation

- 1.3 Forecast model

- 1.4 Primary research and validation

- 1.4.1 Primary sources

- 1.4.2 Data mining sources

- 1.5 Market scope & definition

Chapter 2 Executive Summary

- 2.1 Industry 3600 synopsis, 2021 - 2034

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Hardware providers

- 3.1.2 Software providers

- 3.1.3 Service providers

- 3.1.4 Technology providers

- 3.1.5 End customers

- 3.2 Supplier landscape

- 3.3 Profit margin analysis

- 3.4 Technology & innovation landscape

- 3.5 Patent analysis

- 3.6 Key news & initiatives

- 3.7 Regulatory landscape

- 3.8 Evolution of AI in manufacturing

- 3.9 Use cases

- 3.10 Impact forces

- 3.10.1 Growth drivers

- 3.10.1.1 The growing need for automation

- 3.10.1.2 Rapid developments in machine learning technologies

- 3.10.1.3 Adoption of AI-powered predictive maintenance solutions

- 3.10.1.4 Increasing investment in industrial automation

- 3.10.2 Industry pitfalls & challenges

- 3.10.2.1 Data privacy concerns

- 3.10.2.2 Lack of skilled professionals

- 3.10.1 Growth drivers

- 3.11 Growth potential analysis

- 3.12 Porter’s analysis

- 3.13 PESTEL analysis

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.3 Competitive positioning matrix

- 4.4 Strategic outlook matrix

Chapter 5 Market Estimates & Forecast, By Component, 2021 - 2034 ($Bn)

- 5.1 Key trends

- 5.2 Hardware

- 5.2.1 Processors

- 5.2.1.1 Central Processing Units (CPU)

- 5.2.1.2 Graphics Processing Units (GPU)

- 5.2.1.3 Field Programmable Gate Arrays (FPGA)

- 5.2.1.4 Application Specific Integrated Circuits (ASIC)

- 5.2.1.5 Tensor Processing Units (TPU)

- 5.2.2 Memory & storage

- 5.2.3 Networking hardware

- 5.2.1 Processors

- 5.3 Software

- 5.4 Services

- 5.4.1 Professional service

- 5.4.2 Managed service

Chapter 6 Market Estimates & Forecast, By Deployment Model, 2021 - 2034 ($Bn)

- 6.1 Key trends

- 6.2 On-premise

- 6.3 Cloud

Chapter 7 Market Estimates & Forecast, By Technology, 2021 - 2034 ($Bn)

- 7.1 Key trends

- 7.2 Machine learning

- 7.3 Computer vision

- 7.4 Natural language processing

- 7.5 Context-aware computing

Chapter 8 Market Estimates & Forecast, By Application, 2021 - 2034 ($Bn)

- 8.1 Key trends

- 8.2 Quality management

- 8.3 Predictive maintenance

- 8.4 Inventory management

- 8.5 Energy management

- 8.6 Industrial robotics

- 8.7 Others

Chapter 9 Market Estimates & Forecast, By End Use, 2021 - 2034 ($Bn)

- 9.1 Key trends

- 9.2 Automotive

- 9.3 Electronics

- 9.4 Pharmaceuticals

- 9.5 Heavy machinery

- 9.6 Food & beverage

- 9.7 Aerospace & defense

- 9.8 Others

Chapter 10 Market Estimates & Forecast, By Region, 2021 - 2034 ($Bn)

- 10.1 North America

- 10.1.1 U.S.

- 10.1.2 Canada

- 10.2 Europe

- 10.2.1 UK

- 10.2.2 Germany

- 10.2.3 France

- 10.2.4 Italy

- 10.2.5 Spain

- 10.2.6 Russia

- 10.2.7 Nordics

- 10.3 Asia Pacific

- 10.3.1 China

- 10.3.2 India

- 10.3.3 Japan

- 10.3.4 Australia

- 10.3.5 South Korea

- 10.3.6 Southeast Asia

- 10.4 Latin America

- 10.4.1 Brazil

- 10.4.2 Mexico

- 10.4.3 Argentina

- 10.5 MEA

- 10.5.1 UAE

- 10.5.2 South Africa

- 10.5.3 Saudi Arabia

Chapter 11 Company Profiles

- 11.1 ABB

- 11.2 AWS

- 11.3 Cognex

- 11.4 Dassault

- 11.5 Fanuc

- 11.6 GE

- 11.7 Google

- 11.8 Honeywell

- 11.9 IBM

- 11.10 Intel

- 11.11 Microsoft

- 11.12 NVIDIA

- 11.13 Oracle

- 11.14 PTC

- 11.15 Qualcomm

- 11.16 Rockwell

- 11.17 SAP

- 11.18 Schneider

- 11.19 Siemens

- 11.20 Xilinx