|

市場調查報告書

商品編碼

1708143

汽車皮帶張緊輪市場機會、成長動力、產業趨勢分析及 2025 - 2034 年預測Automotive Belt Tensioner Pulleys Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

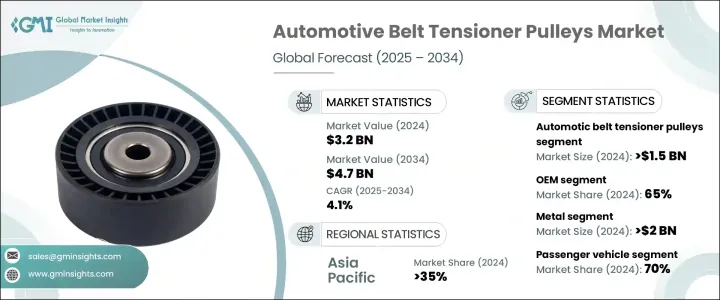

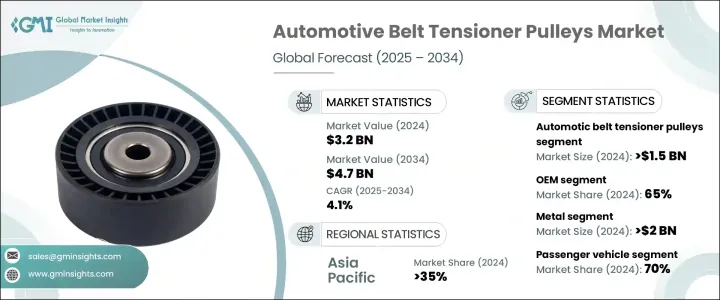

2024 年全球汽車皮帶張緊輪市場價值為 32 億美元,預計 2025 年至 2034 年期間的複合年成長率為 4.1%。受全球乘用車和商用車產量不斷成長的推動,該市場正在穩步成長。汽車皮帶張緊輪在維持適當的皮帶張力、減少磨損和最佳化引擎效率方面發揮關鍵作用。隨著汽車製造商專注於高性能、省油和耐用的引擎,對這些部件的需求持續上升。

汽車產業的快速擴張,尤其是在新興經濟體,進一步推動了市場的成長。旨在減少排放和提高燃油效率的嚴格監管標準促使汽車製造商整合先進的張緊解決方案。皮帶傳動系統的創新,包括輕質和高耐用性材料,正在提高皮帶張緊輪的性能。此外,電動和混合動力車的日益普及正在重塑市場動態,為針對先進動力系統量身定做的專用張緊解決方案創造了機會。隨著向永續移動性和模組化引擎設計的轉變,製造商正專注於開發皮帶張緊輪,以確保在不同操作條件下保持一致的性能。

| 市場範圍 | |

|---|---|

| 起始年份 | 2024 |

| 預測年份 | 2025-2034 |

| 起始值 | 32億美元 |

| 預測值 | 47億美元 |

| 複合年成長率 | 4.1% |

市場分為兩大主要產品類別:自動和手動皮帶張緊輪。自動皮帶張緊輪部分在 2024 年的估值為 15 億美元,佔據了相當大的市場。這些自調整皮帶輪在各種車型中都受到青睞,因為它們無需人工干預即可保持最佳皮帶張力,從而提高引擎的壽命和效率。現代車輛對低維護、高精度零件的需求不斷成長,推動了這一領域的擴張。

汽車皮帶張緊輪市場也按最終用途應用分類,包括原始設備製造商(OEM)和售後市場銷售。 2024年, OEM領域佔據65%的市場佔有率,預計將穩定成長。汽車製造商正在整合客製化設計的皮帶張緊輪,以提高引擎性能、滿足燃油效率法規並增強耐用性。電動和混合動力車對下一代引擎設計和模組化皮帶傳動系統的推動正在加速OEM領域對先進張緊輪的採用。

2024 年,中國汽車皮帶張緊輪市場規模達到 3.325 億美元,鞏固了其作為主要區域參與者的地位。中國是全球最大的汽車製造國之一,其汽車產量不斷成長以及消費者對節油汽車的需求不斷增加,推動了對先進皮帶張緊輪系統的需求。在物流成長和車隊管理計畫的推動下,商用車隊的擴張進一步推動了對這些零件的需求。隨著汽車產業的不斷發展,皮帶張緊輪對於確保各種車輛類別的無縫引擎性能仍然不可或缺。

目錄

第1章:方法論與範圍

- 研究設計

- 研究方法

- 資料收集方法

- 基礎估算與計算

- 基準年計算

- 市場估計的主要趨勢

- 預測模型

- 初步研究與驗證

- 主要來源

- 資料探勘來源

- 市場定義

第2章:執行摘要

第3章:行業洞察

- 產業生態系統分析

- 供應商格局

- 製造商

- 零件供應商

- 服務提供者

- 經銷商

- 最終用途

- 利潤率分析

- 技術與創新格局

- 重要新聞和舉措

- 成本分析

- 價格趨勢

- 材料性能比較分析

- 專利分析

- 監管格局

- 衝擊力

- 成長動力

- 汽車產量和售後市場需求不斷增加

- 皮帶傳動系統的進步

- 電動和混合動力汽車的需求不斷成長

- 嚴格的排放和燃油效率法規

- 產業陷阱與挑戰

- 耐用性和性能限制

- 原物料價格波動

- 成長動力

- 成長潛力分析

- 波特的分析

- PESTEL分析

第4章:競爭格局

- 介紹

- 公司市佔率分析

- 競爭定位矩陣

- 戰略展望矩陣

第5章:市場估計與預測:按產品,2021 - 2034 年

- 主要趨勢

- 自動皮帶張緊輪

- 手動皮帶張緊輪

第6章:市場估計與預測:依車型,2021 - 2034 年

- 主要趨勢

- 搭乘用車

- 掀背車

- 轎車

- 越野車

- 商用車

- 輕型商用車(LCV)

- 中型商用車(MCV)

- 重型商用車(HCV)

第7章:市場估計與預測:依資料,2021 - 2034 年

- 主要趨勢

- 金屬

- 塑膠

第8章:市場估計與預測:按應用,2021 - 2034 年

- 主要趨勢

- 引擎正時系統

- 交流發電機系統

- 動力轉向系統

- 空調系統

- 水泵系統

- 其他

第9章:市場估計與預測:依最終用途,2021 - 2034 年

- 主要趨勢

- OEM

- 售後市場

第10章:市場估計與預測:按地區,2021 - 2034 年

- 主要趨勢

- 北美洲

- 美國

- 加拿大

- 歐洲

- 英國

- 德國

- 法國

- 西班牙

- 義大利

- 俄羅斯

- 北歐人

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 澳洲

- 東南亞

- 拉丁美洲

- 巴西

- 墨西哥

- 阿根廷

- MEA

- 阿拉伯聯合大公國

- 南非

- 沙烏地阿拉伯

第 11 章:公司簡介

- ACDelco

- Bando Chemical Industries

- BorgWarner

- Cloyes Gear & Products

- Continental

- Dayco Products

- Fenner

- Gates

- Goodyear Belts

- Hutchinson

- INA Tensioner

- JTEKT

- Litens Automotive

- Mitsuboshi Belting

- NSK Automation

- NTN

- Pricol Limited

- Schaeffler

- SKF Group

- Tsubakimoto Chain

The Global Automotive Belt Tensioner Pulleys Market was valued at USD 3.2 billion in 2024 and is projected to grow at a CAGR of 4.1% between 2025 and 2034. This market is witnessing steady growth, driven by the increasing production of passenger and commercial vehicles worldwide. Automotive belt tensioner pulleys play a critical role in maintaining proper belt tension, reducing wear and tear, and optimizing engine efficiency. As vehicle manufacturers focus on high-performing, fuel-efficient, and durable engines, the demand for these components continues to rise.

The rapid expansion of the automotive industry, particularly in emerging economies, is further propelling market growth. Stringent regulatory standards aimed at reducing emissions and improving fuel efficiency have prompted automakers to integrate advanced tensioning solutions. Innovations in belt drive systems, including lightweight and high-durability materials, are enhancing the performance of belt tensioner pulleys. Additionally, the rising adoption of electric and hybrid vehicles is reshaping market dynamics, creating opportunities for specialized tensioning solutions tailored for advanced powertrain systems. With a shift towards sustainable mobility and modular engine designs, manufacturers are focusing on developing belt tensioner pulleys that ensure consistent performance under varying operating conditions.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $3.2 Billion |

| Forecast Value | $4.7 Billion |

| CAGR | 4.1% |

The market is segmented into two primary product categories: automatic and manual belt tensioner pulleys. The automatic belt tensioner pulleys segment garnered a valuation of USD 1.5 billion in 2024, holding a significant market share. These self-adjusting pulleys are preferred across vehicle models as they maintain optimal belt tension without manual intervention, enhancing engine longevity and efficiency. The increasing demand for low-maintenance, high-precision components in modern vehicles is fueling the expansion of this segment.

The automotive belt tensioner pulleys market is also categorized by end-use applications, including original equipment manufacturers (OEM) and aftermarket sales. In 2024, the OEM segment accounted for 65% of the market share and is expected to grow steadily. Automakers are integrating custom-engineered belt tensioner pulleys to improve engine performance, meet fuel efficiency regulations, and enhance durability. The push for next-generation engine designs and modular belt drive systems in electric and hybrid vehicles is accelerating the adoption of advanced tensioner pulleys in the OEM sector.

China automotive belt tensioner pulleys market generated USD 332.5 million in 2024, cementing its position as a key regional player. With the country being one of the largest automotive manufacturers globally, rising vehicle production and increasing consumer demand for fuel-efficient automobiles are boosting the need for advanced belt tensioner pulley systems. The expansion of commercial vehicle fleets, driven by logistics growth and fleet management programs, is further driving demand for these components. As the automotive industry continues evolving, belt tensioner pulleys remain indispensable in ensuring seamless engine performance across various vehicle categories.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Research design

- 1.1.1 Research approach

- 1.1.2 Data collection methods

- 1.2 Base estimates and calculations

- 1.2.1 Base year calculation

- 1.2.2 Key trends for market estimates

- 1.3 Forecast model

- 1.4 Primary research & validation

- 1.4.1 Primary sources

- 1.4.2 Data mining sources

- 1.5 Market definitions

Chapter 2 Executive Summary

- 2.1 Industry 3600 synopsis, 2021 - 2034

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.2 Supplier landscape

- 3.2.1 Manufacturers

- 3.2.2 Component suppliers

- 3.2.3 Service providers

- 3.2.4 Distributors

- 3.2.5 End use

- 3.3 Profit margin analysis

- 3.4 Technology & innovation landscape

- 3.5 Key news & initiatives

- 3.6 Cost analysis

- 3.7 Price trend

- 3.8 Comparative analysis of material performance

- 3.9 Patent analysis

- 3.10 Regulatory landscape

- 3.11 Impact forces

- 3.11.1 Growth drivers

- 3.11.1.1 Increasing vehicle production and aftermarket demand

- 3.11.1.2 Advancements in belt drive systems

- 3.11.1.3 Growing demand for electric and hybrid vehicles

- 3.11.1.4 Stringent emission and fuel efficiency regulations

- 3.11.2 Industry pitfalls & challenges

- 3.11.2.1 Durability and performance limitations

- 3.11.2.2 Fluctuations in raw material prices

- 3.11.1 Growth drivers

- 3.12 Growth potential analysis

- 3.13 Porter's analysis

- 3.14 PESTEL analysis

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.3 Competitive positioning matrix

- 4.4 Strategic outlook matrix

Chapter 5 Market Estimates & Forecast, By Product, 2021 - 2034 ($Bn, Units)

- 5.1 Key trends

- 5.2 Automatic belt tensioner pulleys

- 5.3 Manual belt tensioner pulleys

Chapter 6 Market Estimates & Forecast, By Vehicle, 2021 - 2034 ($Bn, Units)

- 6.1 Key trends

- 6.2 Passenger vehicle

- 6.2.1 Hatchback

- 6.2.2 Sedan

- 6.2.3 SUV

- 6.3 Commercial vehicle

- 6.3.1 Light commercial vehicles (LCV)

- 6.3.2 Medium commercial vehicles (MCV)

- 6.3.3 Heavy commercial vehicles (HCV)

Chapter 7 Market Estimates & Forecast, By Material, 2021 - 2034 ($Bn, Units)

- 7.1 Key trends

- 7.2 Metal

- 7.3 Plastic

Chapter 8 Market Estimates & Forecast, By Application, 2021 - 2034 ($Bn, Units)

- 8.1 Key trends

- 8.2 Engine timing system

- 8.3 Alternator system

- 8.4 Power steering system

- 8.5 Air conditioning system

- 8.6 Water pump system

- 8.7 Others

Chapter 9 Market Estimates & Forecast, By End Use, 2021 - 2034 ($Bn, Units)

- 9.1 Key trends

- 9.2 OEM

- 9.3 Aftermarket

Chapter 10 Market Estimates & Forecast, By Region, 2021 - 2034 ($Bn, Units)

- 10.1 Key trends

- 10.2 North America

- 10.2.1 U.S.

- 10.2.2 Canada

- 10.3 Europe

- 10.3.1 UK

- 10.3.2 Germany

- 10.3.3 France

- 10.3.4 Spain

- 10.3.5 Italy

- 10.3.6 Russia

- 10.3.7 Nordics

- 10.4 Asia Pacific

- 10.4.1 China

- 10.4.2 India

- 10.4.3 Japan

- 10.4.4 South Korea

- 10.4.5 Australia

- 10.4.6 Southeast Asia

- 10.5 Latin America

- 10.5.1 Brazil

- 10.5.2 Mexico

- 10.5.3 Argentina

- 10.6 MEA

- 10.6.1 UAE

- 10.6.2 South Africa

- 10.6.3 Saudi Arabia

Chapter 11 Company Profiles

- 11.1 ACDelco

- 11.2 Bando Chemical Industries

- 11.3 BorgWarner

- 11.4 Cloyes Gear & Products

- 11.5 Continental

- 11.6 Dayco Products

- 11.7 Fenner

- 11.8 Gates

- 11.9 Goodyear Belts

- 11.10 Hutchinson

- 11.11 INA Tensioner

- 11.12 JTEKT

- 11.13 Litens Automotive

- 11.14 Mitsuboshi Belting

- 11.15 NSK Automation

- 11.16 NTN

- 11.17 Pricol Limited

- 11.18 Schaeffler

- 11.19 SKF Group

- 11.20 Tsubakimoto Chain