|

市場調查報告書

商品編碼

1408217

塑膠托盤:市場佔有率分析、行業趨勢和統計、2024-2029 年成長預測Plastic Pallets - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts 2024 - 2029 |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

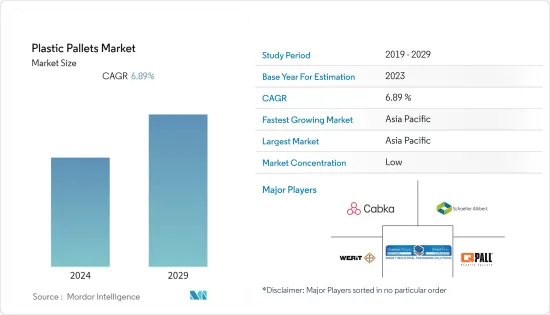

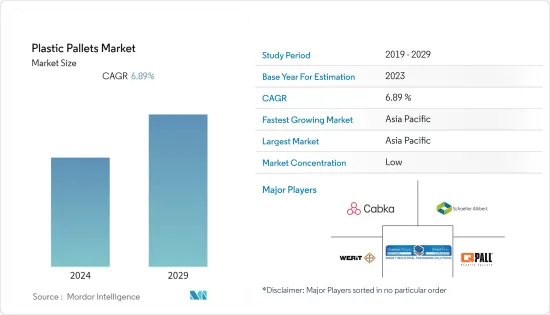

塑膠托盤市場預計將從 50.2 億美元成長至 70.1 億美元,預測期內複合年成長率為 6.89%。

塑膠托盤是剛性形式,可在搬運過程中為散裝貨物提供機械穩定性,以保持品質。搬運是指與起重、堆放、儲存產品以及透過陸地或海上運輸產品相關的所有活動。塑膠托盤是為了透過堆高機、托盤搬運車和前端裝載機等設備移動而開發的,使貨物的移動變得更加容易。

主要亮點

- 塑膠托盤的材質有HDPE、聚丙烯等。 HDPE(高密度聚苯乙烯)是塑膠托盤中最常見的樹脂。這種材料具有大多數標準應用所需的所有特性,包括耐用性、剛性和防潮性。 HDPE 非常適合在倉庫中重複使用的重型材料。

- 電子商務的日益普及導致物流活動的擴大,進而導致全球對托盤的需求激增。此外,隨著組織零售的滲透率不斷提高,托盤被廣泛用於零售空間,用於裝卸重型貨物,預計這將推動需求。

- 據 Tosca Services LLC 稱,幾年前,住宅建築商、製造商和供應鏈營運商面臨挑戰,成本升至每 1,000 英尺 1,500 美元,幾乎加倍。這種變化直接影響了木棧板的使用。木棧板多年來一直是供應鏈最佳化的核心,現在已成為主要支出。但為了穩定價格並避免意外成本,企業在 2020 年找到了可重複使用塑膠托盤的長期智慧包裝解決方案。可重複使用的塑膠托盤的好處不僅限於價格,還將影響全球運輸的未來,從環境法規到供應鏈可追溯性。

- 然而,有幾個因素限制了普及,包括塑膠托盤的高成本和永續性問題。塑膠托盤是一體成型的,一旦損壞就無法修復。此外,塑膠托盤的表面光滑,沒有木棧板的粗糙紋理,因此有證據表明產品可能會在其上滑動,從而導致產品損壞。

- COVID-19 和俄羅斯-烏克蘭衝突的影響對所研究的市場產生了重大的長期影響。其影響包括消費行為的變化、供應鏈中斷以及大流行造成的政府干涉。俄羅斯和烏克蘭衝突的影響波及各地區。受影響的主要領域是供應鏈瓶頸和能源價格,這為原料供應商帶來了問題。俄羅斯和烏克蘭是多種原料的重要供應國和生產國。衝突也造成商業投資的不確定性和金融市場的不穩定。

塑膠托盤市場趨勢

高密度聚苯乙烯(HDPE)佔據主要市場佔有率

- 聚乙烯 (PE) 是目前最耐用的塑膠類型之一。它耐化學品且成本低。 PE衍生石油聚合物,可以承受任何環境危害。高密度聚苯乙烯(HDPE) 是最常用於硬質包裝的塑膠之一,尤其是在製造業中。 HDPE 以其強度和耐用性而聞名。這種類型的塑膠有時可以進行顏色匹配,其中白色最受歡迎。 HDPE 經常用於塑膠托盤的生產。

- HDPE 托盤因其多功能性、成本效益和強度而成為最常用的塑膠托盤。具有高衝擊強度,吸收衝擊,即使在運輸或儲存過程中意外跌落或受到較大外力也能保持穩定。 HDPE 托盤耐腐蝕、耐熱,並且與大多數化學物質相容。然而,必須避免與氧化劑和碳氫化合物的廣泛接觸。這種類型的塑膠也很受歡迎,與 PP 類似,但 HDPE 更硬、更堅固。此外,它比 PP 能承受更高的溫度。當需要承載較大重量或存在衛生法規時,請使用這些托盤。

- 領先的 HDPE 托盤供應商致力於使用 100% 可回收塑膠聚合物製造生態塑膠托盤。從製造方法來看,大多數供應商採用射出成型製造HDPE塑膠托盤。 HDPE 常用於工業產品和汽車產業。因此,HDPE 是全球領先的塑膠托盤,並且預計將繼續保持領先地位。嵌套式塑膠 HDPE 托盤旨在節省空間並降低運輸成本。獨特的設計使它們在空時可以相互嵌套,與傳統的木棧板相比,顯著增加了回程卡車的負載容量。最終用戶群對 HDPE 托盤的需求正在不斷增加。

- 食品和飲料行業中塑膠托盤的使用消除了與木棧板相關的許多風險以及由此產生的食品污染。塑膠托盤比木棧板更容易清洗和消毒。塑膠材質不吸水,因此表面污染物在清洗過程中很容易被破壞。 HDPE一次性塑膠托盤因其在常溫下對有機和無機化學品具有高抵抗力而廣泛應用於食品和飲料行業。

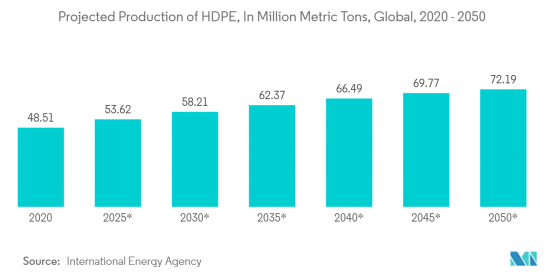

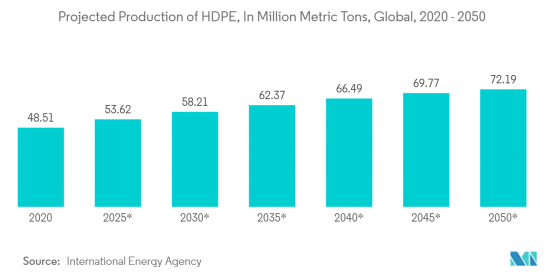

- 根據尼爾森公司2023年3月發表的報導,HDPE是使用最廣泛的塑膠托盤樹脂。 HDPE 具有大多數標準應用所需的所有特性,包括耐用性、剛性和防潮性。 HDPE 適用於重型、重複性應用,例如倉庫中的應用。總部位於巴黎的自治政府間組織國際能源署 (IEA) 表示,全球 HDPE 產能預計將從 2020 年的 4,851 萬噸激增至 2050 年的 7,219 萬噸。隨著預測期內HDPE產能的上升,HDPE托盤市場也有望佔據一定比例。

亞太地區預計將經歷顯著成長

- 塑膠托盤具有防蟲和防真菌功能。它重量輕、成本效益高、品質高,適合長期使用。它還具有高度可靠性和環境安全性。使用四向伸縮堆高機即可輕鬆裝卸。適當的尺寸和緊湊的設計讓您可以將其放置在任何地方,即使在狹窄的區域也能節省空間。塑膠托盤之所以有吸引力,是因為它們可以回收利用,但在中國和印度,它們並不是優先考慮的對象。

- 自2009年危機以來,中國的出口表現在過去十年中持續成長,但2016年除外,當時全球需求再次下降。

- 根據世界貿易組織(WTO)的數據,中國不僅是世界上人口最多的國家之一,而且已成為世界上最大的生產國和出口國。

- 在印度,對水產品和電子產品的需求正在成長,不吸濕的塑膠托盤預計也會成長。塑膠托盤可以有控制地解決木棧板常見的蟲害、腐爛、吸臭、燻蒸、除靜電等問題,並且可以在使用過程中快速、徹底地清潔,還具有能夠要清洗又洗。

- 在日本,零售業普遍使用塑膠托盤展示架。這些顯示器用於降低運輸過程中損壞的風險並方便貨物的運輸。只有托盤需要搬運,而不是裡面的物品。因此,貨架選擇對於處理精緻物品的零售店來說是理想的選擇。

- 零售業是任何經濟體的最大貢獻者之一,也是在整個供應鏈中運輸各種消費品的物流解決方案的最大消費者之一。近年來,物流變得更加專業化,現已成為參與企業的關鍵區別之一。零售業是對物流業務效率要求最高的行業之一,其中托盤、板條箱和貨櫃等塑膠物流解決方案發揮重要作用。這些因素強化了零售物流業務的兩個預期效益:提高永續性和逆向物流。

塑膠托盤產業概況

塑膠托盤市場分散。市場上主要企業包括 Cabka Group GmbH、Q-Pall BV、ORBIS GmbH 和 Schoeller Allibert Group BV。這些公司專注於透過合作和投資擴大業務。

例如,2023 年 7 月,Geoplatics.com 和 Q-Pall 在英國推出了重型托盤。這種重型開放式塑膠托盤由荷蘭 Q-Pall 製造,主要用於為製造商和其他行業處理散裝物料和原料,包括運輸和儲存化學品桶和散裝袋。此托盤尺寸為 1200 毫米 x 1200 毫米 x 165 毫米,是原始 Q-pal 1212 HR 6R 的改良版本。此托盤的靜態負載為 7,500 公斤,動態負載為 2,000 公斤,是重型應用的可靠選擇。

2023 年 4 月,可重複使用包裝領域的參與企業奧比斯公司宣布,40 x 48 英吋可重複使用托盤 P3 在快速生命週期分析中完成了 280 個週期。這是典型 40 x 48 英吋純木縱梁托盤生命週期的 25 倍以上。 P3 是一種高密度、輕質、可堆疊且衛生的可重複使用包裝解決方案,可與手動和自動物料搬運設備無縫整合。

其他福利:

- Excel 格式的市場預測 (ME) 表

- 3 個月的分析師支持

目錄

第1章簡介

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章市場洞察

- 市場概況

- 產業吸引力-波特五力分析

- 供應商的議價能力

- 買方議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭公司之間的敵對關係

- 產業價值鏈分析

- 評估 COVID-19 和最近的烏克蘭-俄羅斯衝突對塑膠托盤市場生態系統的影響

第5章市場動態

- 市場促進因素

- 提高塑膠托盤和泳池服務的再生性

- 電子商務及相關物流需求的擴大

- 市場挑戰

- 木棧板的存在以及製造商對木棧板的依賴

第6章市場區隔

- 依材料類型

- 高密度聚苯乙烯(HDPE)

- 聚丙烯(PP)

- 其他材料(聚氯乙烯(PVC)、PET、聚烯烴(PO))

- 按用途

- 食品和飲料

- 化學

- 建造

- 零售

- 車

- 其他用途

- 按地區

- 北美洲

- 美國

- 加拿大

- 歐洲

- 英國

- 德國

- 法國

- 義大利

- 西班牙

- 歐洲其他地區

- 亞太地區

- 中國

- 印度

- 日本

- 其他亞太地區

- 拉丁美洲

- 中東/非洲

- 北美洲

第7章 競爭形勢

- 公司簡介

- WERIT Kunststoffwerke W. Schneider GmbH & Co. KG

- Gamma-Wopla NV and Smart-Flow NV

- Q-Pall BV

- CABKA Group Gmbh

- Schoeller Allibert Group BV

- Omnipack sro

- Orbis Corporation

- NAECO SL

- Plasgad Plastic Products ACS Ltd

- CHEP(Commonwealth Handling Equipment Pool)

第8章市場的未來

The plastic pallets market is expected to grow from USD 5.02 billion to USD 7.01 billion, registering a CAGR of 6.89% over the forecast period.

Plastic pallets are rigid forms that provide mechanical stability to bulk goods during handling to preserve quality. Handling comprises all activities related to lifting, stacking, product storage, and transportation by land or sea. Plastic pallets are developed to be moveable by equipment such as forklifts, pallet jacks, and front loaders to facilitate the mobility of goods.

Key Highlights

- Plastic pallets are made of HDPE, polypropylene, etc. HDPE, or high-density polyethylene, is the most common resin in plastic pallets. This material has all the properties most standard applications demand: durability, stiffness, and moisture resistance. HDPE is ideal for the demanding and repeated use found in warehouses.

- The increasing popularity of e-commerce resulted in the expansion of logistics activities and, in turn, surged the demand for pallets worldwide. Furthermore, increasing penetration of organized retail is anticipated to drive the demand for pallets as these are widely used in retail spaces for the loading and unloading of heavy merchandise.

- According to Tosca Services LLC, home construction, manufacturers, and supply chain operators faced challenges as costs rose to USD 1500 per 1000 feet a couple of years back, nearly doubling in prices. This volatility has directly impacted the use of wooden pallets. These wood pallets, central to supply chain optimization for years, have become a significant expense. However, to stabilize pricing and avoid unanticipated costs, companies have found a long-term smart packaging solution in reusable plastic pallets in 2020. The benefits of reusable plastic pallets go beyond price and will influence the future of global shipping in everything from environmental regulation to supply chain traceability.

- However, several factors, such as the high cost of plastic pallet and their sustainability issues, limit their widespread penetration. A plastic pallet is made in the one-piece molding process, so it cannot be repaired once damaged. Since the plastic pallet is not as rough as the wooden pallet and its surface is smooth, it causes the goods to face signs of sliding on it, damaging the products.

- The impact of COVID-19 and the Russia-Ukraine conflict had significant long-term effects on the market studied. The impact brought changes in consumer behavior, supply chain disruptions, and government interventions caused by the pandemic. The impact of the Russia-Ukraine conflict has been witnessed across various regions. Major sectors affected were the supply chain bottlenecks and energy prices that caused problems for raw material suppliers. Russia and Ukraine are significant suppliers and producers of several raw materials. The conflict also added uncertainty to business investment and volatility to financial markets.

Plastic Pallets Market Trends

High-Density Polyethylene (HDPE) to Hold Major Market Share

- Polyethylene (PE) is one of the most durable types of plastic currently available. It is resistant to chemicals and has a low cost. PE has been derived from petroleum polymers and can withstand any environmental hazard. High-density polyethylene (HDPE) is one of the most common types of plastic used for rigid packaging, especially in manufacturing. HDPE is known for its strength and durability. This type of plastic might also be color-matched and is popular in white. HDPE is frequently used in the production of plastic pallets.

- HDPE pallets are the most used plastic pallets due to their versatility, cost-effectiveness, and strength. They have high impact strength, absorb shock, and maintain stability even if accidentally dropped or subjected to a significant force during transportation or storage. HDPE pallets are corrosion and heat-resistant and compatible with most chemicals. However, its preferred applications are expected to avoid extensive contact with oxidizing agents and hydrocarbons. This type of plastic is also popular and similar to PP, but HDPE is stiffer and stiffer. In addition, it can withstand higher temperatures than PP. These pallets are used when larger weights need to be held or when sanitary regulations exist.

- Major HDPE pallet vendors concentrate on producing green plastic pallets using 100% recyclable plastic polymers. Regarding manufacturing methods, most vendors use injection molding to produce HDPE plastic pallets. The industrial goods and automotive industries are common in which HDPE is used. As a result, HDPE is the leading plastic pallet in the world and is expected to remain the leader in the coming years. Nested plastic HDPE pallets are designed to save space and reduce transportation costs. The unique design allows them to be nested inside each other when empty, allowing load significantly more in the truck on the way home than traditional wooden pallets. There is a rising demand for HDPE pallets across the end-user segments.

- The use of plastic pallets in the food and beverage industry eliminates many of the risks associated with wood pallets and associated food contamination. The plastic pallets are easier to clean and sanitize than the wood pallets. The plastic material does not absorb water, so any surface contamination is readily destroyed during cleaning. HDPE disposable plastic pallets are extensively used in the food and beverage industry as they are highly resistant to organic and inorganic chemicals at normal temperatures.

- As per the article published by the Nelson Company in March 2023, HDPE is the most widely used plastic pallet resin. HDPE has all the characteristics that most standard applications require, including durability, rigidity, and resistance to moisture. It is suitable for the heavy and repetitive applications found in warehouses. According to the International Energy Agency, a Paris-based autonomous intergovernmental organization, the global production capacity of HDPE is expected to shoot up from 48.51 million metric tons in 2020 to 72.19 million metric tons in 2050. With the rising capacity of HDPE during the forecast period, the market for HDPE pallets is also expected to gain a percentage contribution.

Asia-Pacific Expected to Witness Significant Growth

- Plastic pallets are highly resistant to insects and fungi. It is lightweight, cost-effective, and offers high quality, so it can be used for a long time. It also offers high and dependable performance and is safe for the environment. It is easy to pull on and off in the four-way stretch forklift. The correct size and compact design allow it to be placed everywhere to free up space in tight places. Plastic pallets are attractive for their recyclable qualities, but this is not a high priority in China and India.

- China's export performance has consistently increased over the past ten years, except in 2016, when global demand decreased again after the crisis in 2009

- In addition to being one of the world's most populated nations, China has established itself as the world's largest producer and exporter, according to the World Trade Organization (WTO).

- In India, the growing demand for seafood and electronics is expected to support the growth of plastic pallets as they do not absorb moisture. They are prone to common issues with wood pallets, such as infestation, rot, odor absorption and fumigation, and elimination of static electricity in a controlled manner, along with the convenience of quick and thorough cleaning or washing between uses.

- In Japan, the use of plastic pallet displays is a common practice in retail. These displays are utilized to facilitate the transportation of goods with reduced risk of damage during transport. The only items that need to be handled are the pallets, not the contents. Therefore, the shelving option is ideal for retail stores that offer delicate products.

- The retail industry is one of the most significant contributors to any economy and one of the biggest consumers of logistics solutions, transporting various consumer goods throughout the supply chain. Logistics has become more professionalized in recent years and is now one of the key distinguishing factors among the multiple players in the sector. Retail is one of the most demanding sectors in terms of logistics operation efficiency, where plastic logistic solutions such as pallets, crates, and containers play a crucial role. These factors reinforce two expected benefits in the logistics operations of the retail industry: sustainability and improving reverse logistics.

Plastic Pallets Industry Overview

The plastic pallets market is fragmented. Major players in the market include Cabka Group GmbH, Q-Pall BV, ORBIS GmbH, Schoeller Allibert Group BV, and more. These companies focus on expanding their business through collaborations, investments, etc.

For instance, in July 2023, Geoplatics.com and Q-Pall launched heavy-duty pallets in the United Kingdom. This heavy-duty, open-deck plastic pallet manufactured by Netherlands-based Q-Pall has been mainly designed to handle large amounts of materials and ingredients for manufacturers and other industries, including those transporting and storing chemical drums and bulk bags. The pallet, which measures 1200 mm x 1200 mm x 165 mm, is an enhanced version of the original Q-pall 1212 HR 6R. With a static load of 7,500 kg and a dynamic load of 2,000 kg, it is a highly reliable option for heavy-duty applications.

In April 2023, ORBIS Corporation, a global player in reusable packaging, announced that its 40 by 48-inch reusable pallet, the P3, completed 280 cycles in the FastTrack lifecycle analysis. This equates to more than 25 times the lifecycle of a typical 40-by-48-inch white wood stringer pallet. The P3 is a high-density, lightweight, stackable, hygienic reusable packaging solution that seamlessly integrates with both manual and automated material handling equipment.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Buyers

- 4.2.3 Threat of New Entrants

- 4.2.4 Threat of Substitutes

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Industry Value Chain Analysis

- 4.4 Assessment of the Impact of COVID-19 and the Recent Ukraine-Russia Standoff on the Plastic Pallets Market Ecosystem

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Increased Reusability and Pooling Services of Plastic Pallets

- 5.1.2 Growing E-commerce and Subsequent Demand From Logistics

- 5.2 Market Challenges

- 5.2.1 Existence of and Manufacturers Reliance on Wooden Pallets

6 MARKET SEGMENTATION

- 6.1 By Material Type

- 6.1.1 High-Density Polyethylene (HDPE)

- 6.1.2 Polypropylene (PP)

- 6.1.3 Other Materials (Polyvinyl Chloride (PVC), PET and Polyolefin (PO))

- 6.2 By Application

- 6.2.1 Food and Beverage

- 6.2.2 Chemical

- 6.2.3 Construction

- 6.2.4 Retail

- 6.2.5 Automotive

- 6.2.6 Other Applications

- 6.3 By Geography

- 6.3.1 North America

- 6.3.1.1 United States

- 6.3.1.2 Canada

- 6.3.2 Europe

- 6.3.2.1 United Kingdom

- 6.3.2.2 Germany

- 6.3.2.3 France

- 6.3.2.4 Italy

- 6.3.2.5 Spain

- 6.3.2.6 Rest of Europe

- 6.3.3 Asia-Pacific

- 6.3.3.1 China

- 6.3.3.2 India

- 6.3.3.3 Japan

- 6.3.3.4 Rest of Asia-Pacific

- 6.3.4 Latin America

- 6.3.5 Middle East and Africa

- 6.3.1 North America

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles*

- 7.1.1 WERIT Kunststoffwerke W. Schneider GmbH & Co. KG

- 7.1.2 Gamma-Wopla NV and Smart-Flow NV

- 7.1.3 Q-Pall BV

- 7.1.4 CABKA Group Gmbh

- 7.1.5 Schoeller Allibert Group BV

- 7.1.6 Omnipack s.r.o.

- 7.1.7 Orbis Corporation

- 7.1.8 NAECO SL

- 7.1.9 Plasgad Plastic Products ACS Ltd

- 7.1.10 CHEP (Commonwealth Handling Equipment Pool)