|

市場調查報告書

商品編碼

1687371

粉末冶金:市場佔有率分析、產業趨勢與統計、成長預測(2025-2030 年)Powder Metallurgy - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

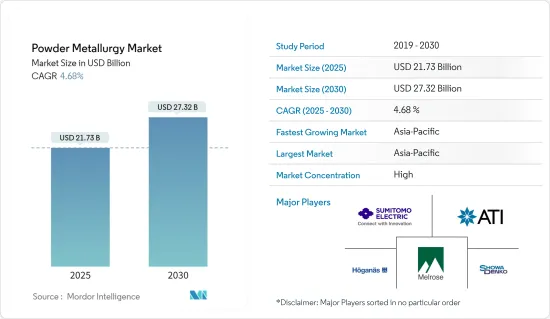

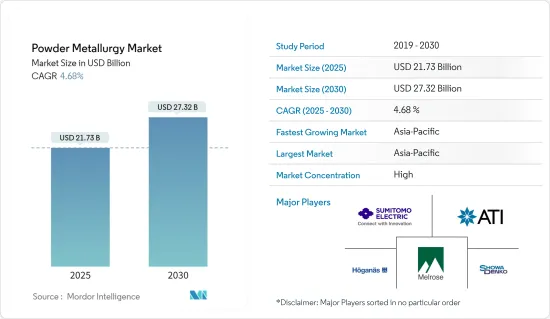

預計 2025 年粉末冶金市場規模為 217.3 億美元,到 2030 年將達到 273.2 億美元,預測期內(2025-2030 年)的複合年成長率為 4.68%。

2020年,新冠疫情對市場產生了負面影響。不過,目前估計市場已達到疫情前的水平,並預計將繼續穩定成長。

主要亮點

- 粉末冶金擴大被汽車OEM所採用,這是推動市場的主要因素之一。此外,電氣和電磁應用的日益普及也有望推動市場成長。

- 另一方面,原料和工具成本的上升可能會減緩市場成長。

- 粉末冶金在醫療領域的應用日益廣泛以及航太和國防部門的快速成長預計將為市場創造機會。

- 粉末冶金市場由亞太地區主導,預計未來幾年將出現最高的成長率。

粉末冶金市場趨勢

汽車應用主導市場

- 粉末冶金零件可以具有自由控制的孔隙率,並可具有自身的潤滑性,從而可以過濾氣體和液體。這使得粉末冶金成為製造具有複雜彎曲、凹坑和突起的零件的絕佳方法。

- 這種靈活性可以開發具有多種成分的機械零件,包括金屬和非金屬以及金屬和金屬組合,從而可以生產具有高尺寸精度的汽車零件,確保一致的性能和尺寸,並且很少產生廢料或材料浪費。

- 軸承和齒輪是採用粉末冶金工藝製造的最常見的汽車零件。該製程也用於許多汽車零件,包括底盤、轉向、排氣、變速箱、避震器組件、引擎、電池、座椅、空氣濾清器和煞車盤。

- 汽車零件由多種金屬製成,包括黑色金屬(鐵、鋼、鋼合金、不銹鋼)和有色金屬(銅、青銅、鋁合金、鈦合金)。粉末冶金的重點是改善淨形、利用熱處理、應用特殊表面處理和提高精度。

- 根據歐洲汽車工業協會(ACEA)的報告,2022年前三個季度全球乘用車產量約5,000萬輛,較2021年同期成長近9%。

- 此外,根據中國汽車工業協會的數據,從2021年12月到2022年12月,全國生產的新能源汽車數量增加了96.9%。因此,預計預測期內電動車市場的擴張將增加市場需求。

- 由於這些因素,汽車領域對粉末冶金的需求正在增加。

亞太地區佔市場主導地位

- 隨著經濟成長和人們的消費能力增強,亞太地區已成為最重要的粉末冶金市場之一,也是製造商的主要投資目的地。

- 近年來,中國、印度和日本等國家良好的經濟趨勢推動了對粉末冶金產品和應用的需求。

- 根據中國工業協會統計,中國是全球最大的汽車生產基地。預計2022年中國汽車產量將達2,700萬輛,比2017年的2,600萬輛成長3.4%。

- 此外,2022年前七個月,全國汽車產量為1,457萬輛,與前一年同期比較去年同期成長31.5%。

- 此外,根據印度汽車工業協會(SIAM)的數據,預計2021-22 年(2021 年 4 月至 2022 年 3 月)印度汽車業將生產 22,933,230 輛汽車,而 2020-21 年(2020 年 4 月至 2020 年 365 月)生產 25,65 月)生產 25,65 月)生產 25,65 月)生產 25,65 月)。

- 此外,該地區的航太航太業也正在顯著發展。例如,波音公司《2022-2041年商用飛機展望》預計,到2041年,波音將向中國交付8,485架新飛機,市場服務價值將達到5,450億美元。

- 因此,由於上述因素,亞太地區很可能在預測期內佔據市場主導地位。

其他福利:

- Excel 格式的市場預測 (ME) 表

- 3 個月的分析師支持

目錄

第 1 章 簡介

- 調查前提條件

- 研究範圍

第2章調查方法

第3章執行摘要

第4章 市場動態

- 驅動程式

- 汽車OEM對粉末冶金的偏好日益增加

- 擴大在電氣和電磁應用的使用

- 限制因素

- 原料和工具成本上漲

- 其他阻礙因素

- 產業價值鏈分析

- 波特五力分析

- 供應商的議價能力

- 消費者議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭程度

第5章 市場區隔

- 產品類型

- 鐵

- 有色金屬

- 應用

- 車

- 工業機械

- 電氣和電子

- 航太

- 其他用途

- 地區

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 其他亞太地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 德國

- 英國

- 義大利

- 法國

- 其他歐洲國家

- 南美洲

- 巴西

- 阿根廷

- 南美洲其他地區

- 中東和非洲

- 沙烏地阿拉伯

- 南非

- 其他中東和非洲地區

- 亞太地區

第6章 競爭格局

- 併購、合資、合作、協議

- 市場佔有率(%)**/排名分析

- 主要企業策略

- 公司簡介

- ATI

- Catalus Corporation

- fine-sinter Co., Ltd.

- HC Starck Tungsten GmbH

- Showa Denko Materials Co., Ltd.

- Hoganas AB

- Horizon Technology

- Melrose Industries PLC

- Miba AG

- Perry Tool & Research, Inc.

- Phoenix Sintered Metals, LLC

- Precision Sintered Parts

- Sandvik AB

- Sumitomo Electric Industries, Ltd.

第7章 市場機會與未來趨勢

- 粉末冶金在醫療領域的應用日益廣泛

- 航太和國防領域的快速成長

The Powder Metallurgy Market size is estimated at USD 21.73 billion in 2025, and is expected to reach USD 27.32 billion by 2030, at a CAGR of 4.68% during the forecast period (2025-2030).

In 2020, COVID-19 negatively impacted the market. However, the market has now been estimated to have reached pre-pandemic levels and is expected to grow steadily in the future.

Key Highlights

- Powder metallurgy is being used more and more by automotive OEMs, which is one of the main things driving the market. Moreover, the growing implementation of electrical and electromagnetic applications is also expected to provide market growth.

- On the other hand, rising costs of raw materials and tools are likely to slow the market's growth.

- The increasing adoption of powder metallurgy in the medical field along with the rapid growth in the aerospace and defense sector is expected to provide opportunities to the market.

- The Asia-Pacific region led the market for powder metallurgy, and it is expected to have the highest growth rate over the next few years.

Powder Metallurgy Market Trends

Automotive Applications to Dominate the Market

- Powder metal parts have great control over how porous they are and can lubricate themselves, which lets them filter gases and liquids.Because of this, powder metallurgy is a very good way to make parts that have complicated bends, depressions, and projections.

- This flexibility to develop mechanical parts with diverse compositions, such as metal-nonmetal and metal-metal combinations, enables the production of automotive parts with high dimensional accuracy and ensures consistent properties and dimensions with very little scrap and material waste.

- Bearings and gears are the most common vehicle parts made through the powder metallurgy process. The process is also used for a large number of parts in a vehicle, including the chassis, steering, exhaust, transmission, shock absorber parts, engine, battery, seats, air cleaners, brake discs, etc.

- Auto parts are made from a wide range of metals, such as ferrous (iron, steel, alloy steel, and stainless steel) and non-ferrous (copper, bronze, aluminum alloys, and titanium alloys).The focus of powder metallurgy is to improve the net shape, utilize heat treatment, provide special surface treatment, and improve precision.

- In the first three quarters of 2022, around 50 million passenger cars were manufactured worldwide, up nearly 9% compared to the same quarter in 2021, as per the report of the European Automobile Manufacturers' Association (ACEA).

- Also, the China Association of Automobile Manufacturing says that the number of New Energy Vehicles made in the country rose by 96.9% from December 2021 to December 2022.Thus, the expanding electric vehicle market is expected to increase market demand during the forecast period.

- Due to such factors, the demand for powder metallurgy in the automotive sector is increasing.

Asia-Pacific to Dominate the Market

- Asia-Pacific has become one of the most important powder metallurgy markets and a top destination for manufacturers because its economy is growing and people have more money to spend.

- The positive economic growth trends in countries such as China, India, and Japan have boosted the demand for powder metallurgy products and applications in recent years.

- China has the largest automotive production base in the world, according to the China Association of Automobile Manufacturers (CAAM). In 2022, 27 million vehicles were expected to be made in China, which is 3.4% more than the 26 million vehicles made in 2017.

- Further, in the first 7 months of 2022, the country produced 14.57 million units of cars, registering a growth rate of 31.5% year over year.

- Also, the Society of Indian Automobile Manufacturers (SIAM) said that India's automotive industry will make 22,933,230 vehicles in FY 2021-22 (April 2021-March 2022), compared to 22,655,609 units in FY 2020-21 (April 2020-March 2020).

- Furthermore, the aerospace industry is also growing significantly in the region. For instance, the Boeing Commercial Outlook 2022-2041 predicts that by 2041, 8,485 new deliveries with a market service value of USD 545 billion will take place in China.thus boosting market growth.

- Hence, due to the aforementioned factors, Asia-Pacific is likely to dominate the market during the forecast period.

Powder Metallurgy Industry Overview

The powder metallurgy market is consolidated in nature. Some of the major players in the market (not in any particular order) include Melrose Industries PLC, Sumitomo Electric Industries, Ltd., Hoganas AB, ATI, and Showa Denko Materials Co., Ltd., among others.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Drivers

- 4.1.1 Increasing Preference for Powder Metallurgy by Automotive OEMs

- 4.1.2 Growing Implementation in Electrical and Electromagnetic Applications

- 4.2 Restraints

- 4.2.1 Increasing Raw Material and Tooling Costs

- 4.2.2 Other Restraints

- 4.3 Industry Value Chain Analysis

- 4.4 Porter's Five Forces Analysis

- 4.4.1 Bargaining Power of Suppliers

- 4.4.2 Bargaining Power of Consumers

- 4.4.3 Threat of New Entrants

- 4.4.4 Threat of Substitute Products and Services

- 4.4.5 Degree of Competition

5 MARKET SEGMENTATION (Market Size in Value)

- 5.1 Product Type

- 5.1.1 Ferrous

- 5.1.2 Non-ferrous

- 5.2 Application

- 5.2.1 Automotive

- 5.2.2 Industrial Machinery

- 5.2.3 Electrical and Electronics

- 5.2.4 Aerospace

- 5.2.5 Other Applications

- 5.3 Geography

- 5.3.1 Asia-Pacific

- 5.3.1.1 China

- 5.3.1.2 India

- 5.3.1.3 Japan

- 5.3.1.4 South Korea

- 5.3.1.5 Rest of Asia-Pacific

- 5.3.2 North America

- 5.3.2.1 United States

- 5.3.2.2 Canada

- 5.3.2.3 Mexico

- 5.3.3 Europe

- 5.3.3.1 Germany

- 5.3.3.2 United Kingdom

- 5.3.3.3 Italy

- 5.3.3.4 France

- 5.3.3.5 Rest of Europe

- 5.3.4 South America

- 5.3.4.1 Brazil

- 5.3.4.2 Argentina

- 5.3.4.3 Rest of South America

- 5.3.5 Middle-East and Africa

- 5.3.5.1 Saudi Arabia

- 5.3.5.2 South Africa

- 5.3.5.3 Rest of Middle-East and Africa

- 5.3.1 Asia-Pacific

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers and Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Market Share(%)**/Ranking Analysis

- 6.3 Strategies Adopted by Leading Players

- 6.4 Company Profiles

- 6.4.1 ATI

- 6.4.2 Catalus Corporation

- 6.4.3 fine-sinter Co., Ltd.

- 6.4.4 H.C. Starck Tungsten GmbH

- 6.4.5 Showa Denko Materials Co., Ltd.

- 6.4.6 Hoganas AB

- 6.4.7 Horizon Technology

- 6.4.8 Melrose Industries PLC

- 6.4.9 Miba AG

- 6.4.10 Perry Tool & Research, Inc.

- 6.4.11 Phoenix Sintered Metals, LLC

- 6.4.12 Precision Sintered Parts

- 6.4.13 Sandvik AB

- 6.4.14 Sumitomo Electric Industries, Ltd.

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 Increasing Adoption of Powder Metallurgy Techniques in Medical Sector

- 7.2 Rapid Growth in Aerospace and Defense Sector