|

市場調查報告書

商品編碼

1519946

聚醚醯亞胺:市場佔有率分析、產業趨勢、成長預測(2024-2029)Polyetherimide - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2024 - 2029) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

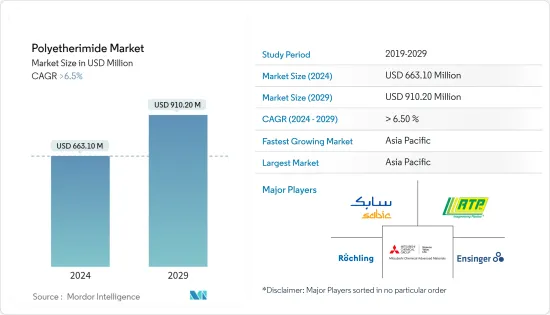

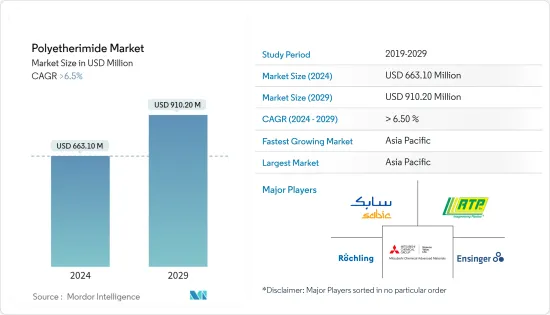

聚醚醯亞胺市場規模預計到2024年將達到6.631億美元,2029年將達到9.102億美元,預計在預測期內(2024-2029年)將以超過6.5%的複合年成長率成長。

COVID-19大流行影響了2020年和2021年的聚醚醯亞胺市場,導致經濟和商業活動減少。由於建築業和工業生產下降,需求仍然較低,但由於貿易復甦和政府指南,預計在預測期內將會復甦。

主要亮點

- 由於電氣和電子行業的消費增加,預計在預測期內,全球聚醚醯亞胺市場將由電氣和電子行業主導。

- 另一方面,聚醚醯亞胺原料價格高、生產品質和產量參差不齊,阻礙因素了市場成長。

- 航太領域對耐熱塑膠的需求不斷成長,預計將為全球市場帶來利潤豐厚的機會。

- 亞太地區是最大的市場,由於中國、印度和日本等國家的消費量不斷增加,預計亞太地區將成為預測期內成長最快的市場。

聚醚醯亞胺(PEI)市場趨勢

電氣和電子產業需求增加

- 聚醚醯亞胺因其卓越的電氣性能而聞名,包括暴露在高溫下時增加的剛度和強度。在電氣和電子領域,聚醚醯亞胺的主要用途包括生產反射器、連接器、外殼等。聚醚醯亞胺廣泛應用於電力開關和控制設備、馬達零件、印刷電路基板、連接器等。

- 在泰國,新電力發展計畫(PDP)中已經宣布了某些目標,目前正在審議中。其中計畫部署16個浮體式浮太陽能混合計劃,總合容量達270萬千瓦。此外,政府也推出了上網電價補貼計劃,計劃於 2025 年至 2026 年啟動。該系統管理小型(小於 90 兆瓦)和超小型(小於 10 兆瓦)發電商生產的可再生能源的銷售。

- 亞太地區的電子產業正在呈現高速成長,隨著中國、印度和其他東南亞國家成為電子產品製造和供應的黃金地段,這種情況預計將在不久的將來持續下去。

- 2022年,台積電開始量產3nm FinFET(N3)技術,在晶圓代工廠中處於主導。台積電的 3nm 製程是業界最先進的半導體技術,可提供最佳的功耗、性能和麵積 (PPA)。這是一個巨大的進步,代表著 5nm 世代的全節點進步。

- 這些產品包括 N3X(一種專門為滿足高效能運算 (HPC) 應用需求而設計的製程)和 N3AE(可協助汽車應用儘早採用先進的矽技術)。 N3A 技術預計將在 2026 年完全合格並投入使用。

- 美國電子市場規模全球最大,由於先進技術的可用性、研發中心數量的增加以及消費者需求的不斷成長,預計在預測期內仍將保持主導市場的地位。

- 根據 CTA 的數據,消費者在遊戲、視訊、音訊和應用程式等技術服務上的支出將連續第五年成長,達到 1,510 億美元。影片串流媒體市場競爭尤其激烈,知名品牌競相吸引消費者。

- 因此,電子電氣行業對聚醚醯亞胺的需求預計在預測期內將成長。

亞太地區主導市場

- 預計亞太地區將在預測期內主導全球聚醚醯亞胺市場。

- 印度的電子工業是世界上規模最大、發展最快的工業之一。印度品牌資產基金會的資料顯示,預計2025年,家電及電器產品產業的市場規模將是目前的一倍,市場規模將達到211.8億美元。

- 國內飛機零件及組裝製造業快速發展,小型飛機零件生產商超過200家。主要生產廠商集中在南昌、上海、成都、西安、哈爾濱、石家莊、瀋陽等地。

- 印度工商聯合會(FICCI)的數據顯示,2020-21會計年度印度電視製作業達42.4億美元。預計未來幾年將繼續大幅成長,在 2025-26 會計年度達到 102.2 億美元,年複合成長率(CAGR)為 20%。

- 中國的航太政策是進入航太研發生產頂級水準的最全面的嘗試之一。預計未來20年中國將成為全球最大的民航機銷售單一國家市場。

- 根據OICA預測,2022年全球汽車產業較2021年將呈現6%的大幅成長。 2022年,包括中國、韓國和印度在內的全球各個已開發國家和開發中國家的汽車產量都會增加。 2022年,汽車產量超過8,500萬輛。

- 國內對PCB的需求預計將大幅增加,主要是由於消費性電子產業需求的增加。印度約有200家PCB製造商。

- 預計這些因素將在預測期內進一步提振聚醚醯亞胺市場的需求。

聚醚醯亞胺 (PEI) 產業概況

聚醚醯亞胺市場部分整合。主要企業(排名不分先後)包括RTP公司、SABIC、三菱化學集團、Ensinger和Rochling。

其他福利:

- Excel 格式的市場預測 (ME) 表

- 3 個月的分析師支持

目錄

第1章 簡介

- 研究成果

- 研究場所

- 調查範圍

第2章調查方法

第3章執行摘要

第4章市場動態

- 促進因素

- 交通運輸業需求增加

- 汽車領域快速成長

- 醫療保健領域的使用增加

- 抑制因素

- 與傳統聚合物相比價格高

- 替代材料的可用性

- 產業價值鏈分析

- 波特五力分析

- 供應商的議價能力

- 買方議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭程度

第5章市場區隔:市場規模(以金額為準)

- 年級

- 加強

- 非強化型

- 最終用戶產業

- 運輸

- 電力/電子

- 消費品

- 衛生保健

- 家用及工業電器產品

- 其他

- 地區

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 馬來西亞

- 泰國

- 印尼

- 越南

- 其他亞太地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 德國

- 英國

- 義大利

- 法國

- 西班牙

- 北歐的

- 土耳其

- 俄羅斯

- 其他歐洲國家

- 南美洲

- 巴西

- 阿根廷

- 哥倫比亞

- 南美洲其他地區

- 中東/非洲

- 沙烏地阿拉伯

- 南非

- 奈及利亞

- 卡達

- 埃及

- 阿拉伯聯合大公國

- 其他中東和非洲

- 亞太地區

第6章 競爭狀況

- 併購、合資、聯盟、協議

- 市場佔有率(%)**/排名分析

- 主要企業策略

- 公司簡介

- Avient Corporation

- Aikolon Oy

- Eagle Performance Plastics, Inc.

- Emco Industrial Plastics

- Ensinger

- GEHR

- Kuraray Europe GmbH

- the Mitsubishi Chemical Group of companies

- Rochling SE & Co. KG

- RTP Company

- SABIC

- Solvay

第7章 市場機會及未來趨勢

- 食品業的多種應用

- 航太和電子產業對耐熱塑膠的需求增加

The Polyetherimide Market size is estimated at USD 663.10 million in 2024, and is expected to reach USD 910.20 million by 2029, growing at a CAGR of greater than 6.5% during the forecast period (2024-2029).

The COVID-19 pandemic has impacted the polyetherimide market in 2020 and 2021, driven by reduced economic and commercial activities. Declines in construction and industrial output kept the demand low, but recovery is anticipated with revived trade and government guidelines during the forecast period.

Key Highlights

- The electrical and electronics industry is expected to dominate the global polyetherimide market over the forecast period due to the increasing consumption from the sector.

- On the flip side, polyetherimide has high raw material prices that are a hindrance to the growth of the market studied, leading to inconsistency in the production quality and production volume.

- The increasing need for heat-resistant plastics in the aerospace sector is expected to create lucrative opportunities for the global market.

- The Asia-Pacific region represents the largest market and is also expected to be the fastest-growing market over the forecast period, owing to the increasing consumption from countries such as China, India, and Japan.

Polyetherimide (PEI) Market Trends

Increasing demand from Electrical & Electronics Industry

- Polyetherimide is recognized for its outstanding electrical characteristics, including enhanced rigidity and strength when exposed to elevated temperatures. In the electric and electronics sector, some of the primary applications of polyetherimide are in the production of reflectors, connectors, enclosures, and more. It is widely used in electrical switches and controls, electrical motor parts, printed circuit boards, and connectors.

- In Thailand, the new Power Development Plan (PDP) currently in discussion has already unveiled certain objectives. These include plans to deploy 16 hydro-floating solar hybrid projects with a combined capacity of 2.7 GW. Additionally, the government has introduced a feed-in tariff mechanism scheduled to begin in 2025-2026. This mechanism governs the sale of renewable electricity generated by small (under 90 MW) and very small (under 10 MW) power producers.

- The electronics industry in the Asia-Pacific region has been witnessing a growth rate, and the scenario is expected to continue in the near future with China, India, and other Southeast Asian countries, standing out as prime locations for electronics manufacture and supply.

- During 2022, TSMC took the lead among foundries by commencing high-volume production of 3nm FinFET (N3) technology. TSMC's 3nm process stands as the most advanced semiconductor technology in the industry, delivering optimal power, performance, and area (PPA). This represents a significant step forward, constituting a full-node advancement from its 5nm generation.

- Among these offerings are N3X, a specialized process designed to meet the demands of high-performance computing (HPC) applications, and N3AE, which enables the early adoption of advanced silicon technology for automotive applications. The N3A technology is expected to be fully qualified and available by 2026.

- The US electronics market is the largest market in the world in terms of size, and it is expected to remain the leading market over the forecast period, owing to the usage of advanced technology, increase in the number of R&D centers, and the rising demand among consumers.

- According to the CTA, consumer expenditure on technology services, which encompass gaming, video, audio, and apps, is set to increase for the fifth consecutive year, resulting in $151 billion in consumer spending. The video streaming market, in particular, is marked by intense competition as leading brands compete for consumer engagement.

- Therefore, the demand for polyetherimide from the electronics and electrical industry is expected to grow during the forecast period.

Asia-Pacific Region to Dominate the Market

- The Asia-Pacific region is expected to dominate the global polyetherimide market during the forecast period.

- The Indian electronics industry is among the largest and most rapidly expanding in the world. According to data from the India Brand Equity Foundation, the consumer electronics and appliance sector is expected to double its current market size, reaching an estimated market value of US$ 21.18 billion by 2025.

- The aircraft parts and assembly manufacturing sector in the country is growing at a rapid pace, with the presence of over 200 small aircraft parts manufacturers. Major manufacturers are concentrated in Nanchang, Shanghai, Chengdu, Xi'an, Harbin, Shijiazhuang, and Shenyang.

- As per the Federation of Indian Chambers of Commerce & Industry (FICCI), the television production industry in India amounted to US$ 4.24 billion in the fiscal year 2020-21. It is expected to experience substantial growth and is projected to reach US$ 10.22 billion by the fiscal year 2025-26, exhibiting a Compound Annual Growth Rate (CAGR) of 20%.

- The Chinese aerospace policy represents one of the most comprehensive attempts to enter the top levels of aerospace development and production. China is expected to be the world's largest single-country market for civil aircraft sales, over the next 20 years.

- As per OICA, the Global Automotive Industry is currently growing at a substantial rate of 6% in 2022 over 2021. In 2022, various developed and developing countries across the world, including China, South Korea, India, and others experienced an increase in automotive production.In 2022, over 85 Million Units of Motor vehicles were manufactured.

- The domestic demand for PCB is expected to increase significantly, primarily due to an increase in the demand from the consumer electronics industry. In India, there are around 200 manufacturers of PCB.

- Such factors are expected to further drive the demand for polyetherimide market over the forecast period.

Polyetherimide (PEI) Industry Overview

The Polyetherimide Market is partially consolidated in nature. The major players (not in any particular order) include RTP Company, SABIC, the Mitsubishi Chemical Group of companies, Ensinger, and Rochling, among others.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Deliverables

- 1.2 Study Assumptions

- 1.3 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Drivers

- 4.1.1 Increasing Demand from the Transportation Industry

- 4.1.2 Rapid Growth in the Automotive Sector

- 4.1.3 Increasing Usage in Healthcare Sector

- 4.2 Restraints

- 4.2.1 High Price When Compared to the Conventional Polymers

- 4.2.2 Availability of Substitute Materials

- 4.3 Industry Value Chain Analysis

- 4.4 Porter's Five Forces Analysis

- 4.4.1 Bargaining Power of Suppliers

- 4.4.2 Bargaining Power of Buyers

- 4.4.3 Threat of New Entrants

- 4.4.4 Threat of Substitute Products and Services

- 4.4.5 Degree of Competition

5 MARKET SEGMENTATION (Market Size In Value)

- 5.1 Grade

- 5.1.1 Reinforced

- 5.1.2 Unreinforced

- 5.2 End-User Industry

- 5.2.1 Transportation

- 5.2.2 Electrical and Electronics

- 5.2.3 Consumer Goods

- 5.2.4 Healthcare

- 5.2.5 Household and Industrial Appliances

- 5.2.6 Others

- 5.3 Geography

- 5.3.1 Asia-Pacific

- 5.3.1.1 China

- 5.3.1.2 India

- 5.3.1.3 Japan

- 5.3.1.4 South Korea

- 5.3.1.5 Malaysia

- 5.3.1.6 Thailand

- 5.3.1.7 Indonesia

- 5.3.1.8 Vietnam

- 5.3.1.9 Rest of Asia-Pacific

- 5.3.2 North America

- 5.3.2.1 United States

- 5.3.2.2 Canada

- 5.3.2.3 Mexico

- 5.3.3 Europe

- 5.3.3.1 Germany

- 5.3.3.2 United Kingdom

- 5.3.3.3 Italy

- 5.3.3.4 France

- 5.3.3.5 Spain

- 5.3.3.6 NORDIC

- 5.3.3.7 Turkey

- 5.3.3.8 Russia

- 5.3.3.9 Rest of Europe

- 5.3.4 South America

- 5.3.4.1 Brazil

- 5.3.4.2 Argentina

- 5.3.4.3 Colombia

- 5.3.4.4 Rest of South America

- 5.3.5 Middle-East and Africa

- 5.3.5.1 Saudi Arabia

- 5.3.5.2 South Africa

- 5.3.5.3 Nigeria

- 5.3.5.4 Qatar

- 5.3.5.5 Egypt

- 5.3.5.6 UAE

- 5.3.5.7 Rest of Middle-East and Africa

- 5.3.1 Asia-Pacific

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers and Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Market Share (%)**/Ranking Analysis

- 6.3 Strategies Adopted by Leading Players

- 6.4 Company Profiles

- 6.4.1 Avient Corporation

- 6.4.2 Aikolon Oy

- 6.4.3 Eagle Performance Plastics, Inc.

- 6.4.4 Emco Industrial Plastics

- 6.4.5 Ensinger

- 6.4.6 GEHR

- 6.4.7 Kuraray Europe GmbH

- 6.4.8 the Mitsubishi Chemical Group of companies

- 6.4.9 Rochling SE & Co. KG

- 6.4.10 RTP Company

- 6.4.11 SABIC

- 6.4.12 Solvay

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 Diverse Applications in the Food Industry

- 7.2 Rise in Demand for Heat-Resistant Plastics in Aerospace and Electronics Industry