|

市場調查報告書

商品編碼

1548919

表面黏著技術:市場佔有率分析、產業趨勢/統計、成長預測(2024-2029)Surface Mount Technology - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2024 - 2029) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

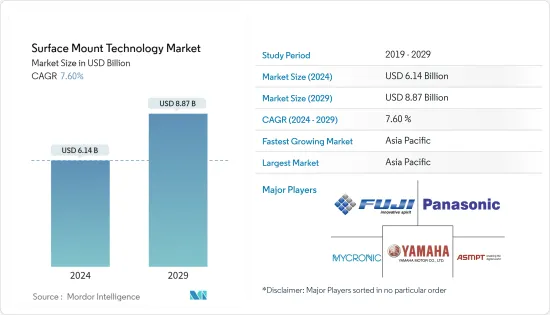

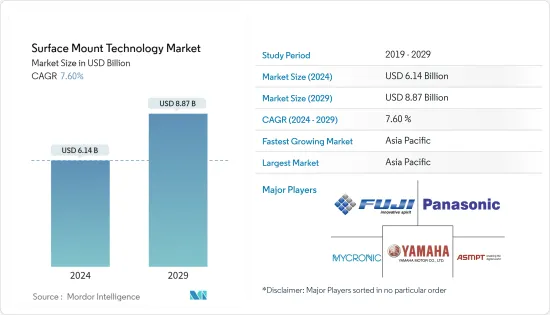

表面黏著技術(SMT)市場規模預計2024年為61.4億美元,預計2029年將達到88.7億美元,在預測期內(2024-2029年)複合年成長率為7.60%,預計將成長。

表面黏著技術(SMT) 是一種建構電子電路的方法,涉及將組件直接安裝到印刷電路基板(PCB) 的表面上。這與傳統的通孔技術形成鮮明對比,在傳統的通孔技術中,元件被插入 PCB 上鑽的孔中。 SMT 中使用的元件稱為 SMD,具有小型金屬片或端蓋,可直接焊接到 PCB 表面。這樣可以在單一 PCB 上安裝更小、更輕和更多的元件。

受疫情影響,筆記型電腦和伺服器市場需求激增。印度電子與半導體協會 (IESA) 表示,隨著在家工作並採用協作工具,將更多資料儲存在雲端。伺服器、資料中心和運算領域的需求激增。美國美光科技公司也報告稱,由於遠距工作經濟、遊戲和電子商務的增加,其資料中心的需求更加強勁。此外,根據 Cloudscene 的數據,截至 2024 年 3 月,美國有 5,381 個資料中心,比世界上任何其他國家都多。另外 521 個地點位於德國,514 個地點位於英國。

電子元件的小型化使得可以隨身攜帶的小型攜帶式可攜式電腦設備的生產成為可能。因此,現在市場上出現了體積更小、重量更輕、處理能力更高的設備。組件變得更加耐磨,因為它們可以輕鬆嵌入(例如放入衣服袋中)並長期攜帶。元件變得越來越小,對安裝元件的印刷電路基板的設計提出了新的要求。 NCAB 集團堅定致力於 IPC 努力定義超高密度 Ultra HDI 印刷電路基板標準,並預計能夠在 2023 年為客戶提供這些標準。

表面黏著技術(SMT) 已成為現代電子製造的關鍵要素,以其眾多優勢超越了傳統的通孔方法。 SMT 的一個顯著優勢是它顯著減少了所需的 PCB 鑽孔。製造商可以透過消除鑽孔步驟來節省時間和成本,這對於複雜的高密度基板來說尤其有利。這一轉變簡化了生產,降低了人事費用和材料成本,並提高了製造過程的整體成本效益。

表面黏著技術透過生產更小、更有效率且更具成本效益的電子設備,徹底改變了電子製造業。然而,儘管 SMT 具有眾多優點,但它並不適合所有應用。 SMT不適合高功率/高電壓元件,例如變壓器和電源電路。這些組件會產生熱量並承載高電力負載,而 SMT 無法有效處理這些負載。

據美國預算辦公室稱,美國國防支出預計每年都會增加,直到 2033 年。 2023年美國國防支出將達7,460億美元。同樣的預測也預測,到 2033 年,國防支出將增加至 1.1 兆美元。

表面黏著技術(SMT)市場趨勢

消費電子最終用戶產業預計將佔據主要市場佔有率

- 在汽車產業,SMT用於電控系統(ECU)、儀表板顯示器、雷達和相機模組、電池管理系統(BMS)、安全輔助系統等。 SMT 已成為汽車應用中的關鍵製造流程。 SMT 以其效率、精度和可靠性而聞名,對於為 ADAS(高級駕駛輔助系統)、資訊娛樂系統和車輛控制系統等各種車載電子產品供電至關重要。

- 在現代汽車中,車載控制系統充當汽車的“大腦”,監督和協調其電子元件的功能。車載控制系統對於從導航到音訊再到空調等一切設備的無縫運作至關重要。 SMT 技術對於這些控制系統的可靠性至關重要。此技術能夠將微小電子元件精確安裝在電路基板,確保系統高效可靠的運作。

- 引擎控制單元 (ECU) 是汽車電子系統的核心,監督引擎性能、變速箱和煞車等關鍵操作。表面黏著技術(SMT) 對於將微晶片、電阻器、電容器和其他表面黏著技術元件組裝到 ECU 中至關重要。

- 此外,人工智慧技術預計將在汽車行業中得到更多採用。電子元件組裝中表面黏著技術(SMT)的精度和效率將提高人工智慧晶片和處理器的生產。因此,汽車電子將增強自主決策能力,從而實現更智慧的駕駛和車輛自動化。

- 正如國際能源總署所強調的那樣,全球汽車產業正在經歷重大變革時期,這對能源產業可能產生重大影響。據預測,到 2030 年,電氣化的進步預計將消除每天 500 萬桶石油的需求。

- IEA報告也顯示,電動車銷量將大幅成長,2023年銷量將比2022年增加350萬輛,成長35%。值得注意的是,全年每週新增註冊量超過 25 萬人。到 2023 年,電動車將佔總銷量的約 18%,高於五年前的 2%,到 2022 年將佔 14%。這些趨勢表明,隨著電動車市場的成熟,預計強勁成長將持續下去。此外,預計到 2023 年,電動車保有量的 70% 將由純電動車組成。

亞太地區預計將經歷最快的成長

- 亞太地區,特別是日本、中國、韓國、台灣和東南亞等國家,已成為全球電子製造中心。該地區強大的製造基礎設施、熟練的勞動力和支持性的政府政策正在吸引跨國公司並促進當地電子產業的成長。對平板電腦、智慧型手機和其他電子設備的需求持續成長,需要使用表面黏著技術的高效、大量生產能力。該公司預計,透過在當地實施SMT(表面黏著技術),付加將從目前的15%增加到25%。

- 例如,2023年8月,印度政府宣布全球電子產業將提高在印度組裝的產品的本地付加,目標是在未來5-10年內顯著成長60-80%。為了實現這一目標,政府鼓勵印度工業採用表面黏著技術(SMT)線等先進的生產方法。

- 碳化矽(SiC)因其耐高溫、良好的導電性和優異的能源效率而日益受到關注。隨著工業 4.0 中對電動車 (EV)、太陽能板和先進電源管理的需求不斷增加,碳化矽製造的重要性日益增加。由於需要最大限度地減少這些區域的功耗,寬能能隙導體是自然的選擇。

- 2024 年 2 月,大陸設備印度有限公司 (CDIL) 邁出了重要一步,運作了一條專用SiC表面黏著技術(SMT) 組件的新組裝。這使得 CDIL 成為印度碳化矽零件製造領域的先驅。透過此增強,CDIL 現在能夠生產各種汽車級裝置,例如 SiC 肖特基二極體、SiC MOSFET、齊納二極體、整流器、TVS 二極體等,以滿足全球和國內市場的需求。

- 2024 年 4 月,TDK 公司發布了 B40910 系列,這是一系列混合聚合物電容器,支援高達 4.6 A(100 kHz,+125 度C時)。這些表面黏著技術元件在室溫下具有令人驚訝的低 ESR 值,分別為 17mΩ 和 22mΩ。

- 與使用液體電解質的標準電解電容器不同,TDK 電容器的 ESR 隨溫度變化很小。它是一個小型 10 x 10.2 mm 或 10 x 12.5 mm (D x H) 元件,額定電壓為 63 V,電容為 82 μF 至 120 μF。因此,SMT 製造商正在透過技術整合和創新來推動對該技術的需求。這些努力促進了表面黏著技術(SMT) 在各行業的廣泛採用和發展。

表面黏著技術(SMT) 產業概覽

由於跨國公司和中小企業的存在,表面黏著技術市場高度分散。該市場的主要企業包括富士公司、雅馬哈汽車有限公司、Mycronic AB、ASMPT 和松下公司。該市場上的公司正在透過聯盟和收購來加強其產品供應並獲得競爭優勢。

2024 年 3 月 - 諾信公司在墨西哥克雷塔羅設立了一個新的拉丁美洲技術中心,為該地區的製造商提供及時獲取最適合其生產要求的裝配液、組件、基板和流體塗布設備的機會。該實驗室配備了 3D 列印機、秤和其他測量設備,可協助確定適合每位客戶獨特應用要求的正確流體塗布。

2024 年 1 月 -Yamaha Motor Co, Ltd.汽車宣布推出表面黏著技術YRM10,該機擁有同類產品中最快貼裝性能的稱號。憑藉52,000CPH的驚人速度,在1光束1頭類別中壓倒競爭對手。該裝置結構緊湊、節省空間,提供廣泛的組件相容性和多功能性,使其成為高速模組組裝的下一代解決方案。

其他好處

- Excel 格式的市場預測 (ME) 表

- 3 個月分析師支持

目錄

第1章簡介

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章市場洞察

- 市場概況

- 產業價值鏈分析

- 產業吸引力-波特五力分析

- 供應商的議價能力

- 買方議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭公司之間的敵對關係

- COVID-19 對表面黏著技術市場的影響

第5章市場動態

- 對技術小型化的需求不斷成長

- 與其他技術相比,需要在印刷基板鑽孔較少

- 市場挑戰

- SMT不適合大型、高功率、高電壓元件或經常承受機械應力的元件。

- 高初始成本和返工問題

第6章 市場細分

- 按零件

- 被動元件

- 電阻器

- 冷凝器

- 主動元件

- 電晶體

- 積體電路

- 被動元件

- 按最終用戶產業

- 家用電子產品

- 車

- 工業電子

- 航太/國防

- 衛生保健

- 其他最終用戶產業

- 按地區

- 北美洲

- 歐洲

- 亞洲

- 澳洲/紐西蘭

- 拉丁美洲

- 中東/非洲

第7章 競爭格局

- 公司簡介

- Fuji Corporation

- Yamaha Motor Co. Ltd

- Mycronic AB

- ASMPT

- Panasonic Corporation

- Nordson Corporation

- Juki Corporation

- Hanwa Precision Machinery Co. Ltd

- Zhejiang Neoden Technology Co. Ltd

- Europlacer Limited

- Viscom SE

第8章投資分析

第9章 市場機會及未來趨勢

The Surface Mount Technology Market size is estimated at USD 6.14 billion in 2024, and is expected to reach USD 8.87 billion by 2029, growing at a CAGR of 7.60% during the forecast period (2024-2029).

Surface mount technology (SMT) is a method for constructing electronic circuits in which the components are mounted directly onto the surface of printed circuit boards (PCBs). This contrasts with older through-hole technology, where components are inserted into holes drilled into the PCB. Components used in SMT, known as SMDs, have small metal tabs or end caps that can be soldered directly onto the PCB surface. This allows for using smaller, lighter, and more components on a single PCB.

After the effect of the pandemic, the market for laptops and servers is witnessing a surge in demand. According to the India Electronics and Semiconductor Association (IESA), more data is stored on the cloud as work-from-home increases and more collaboration tools are deployed. A surge in demand is witnessed in the server, data centers, and computing segments. US-based Micron Technology also reported a more robust demand from data centers due to the remote-work economy, increased gaming, and e-commerce activity. Additionally, as per Cloudscene, as of March 2024, there are 5,381 data centers in the United States, the most of any country worldwide. A further 521 are in Germany, while 514 are in the United Kingdom.

Miniaturization of electronic components has made it possible to build small portable and handheld computer devices that can be carried anywhere. As a result, smaller, lighter devices with high processing capacity are available on the market. They are becoming more wearable since components can be easily embedded (for example, in clothing bags) and carried for long periods. Components are shrinking, putting new demands on the design of the PCBs they are mounted on. NCAB Group is firmly committed to IPC's efforts in defining standards for ultra-dense Ultra HDI PCBs and anticipates being able to provide them to clients in 2023.

Surface mount technology (SMT) has emerged as a pivotal element in modern electronics manufacturing, eclipsing traditional through-hole methods with its myriad benefits. A standout advantage of SMT lies in its drastic reduction of necessary PCB drilling. Manufacturers slash both time and costs by sidestepping the drilling process, a notable boon for intricate, high-density boards. This shift streamlines production and trims labor and material expenses, bolstering the overall cost-effectiveness of the manufacturing process.

Surface mount technology has revolutionized the electronics manufacturing industry by enabling the production of smaller, more efficient, and cost-effective electronic devices. However, despite its numerous advantages, SMT is unsuitable for all applications. SMT is unsuitable for high-power and high-voltage components, such as transformers and power circuitry. These components generate heat and carry high electric loads, which SMT is not designed to handle effectively.

According to the US Congressional Budget Office, defense spending in the United States is predicted to increase yearly until 2033. Defense outlays in the United States amounted to USD 746 billion in 2023. The forecast predicts an increase in defense outlays up to USD 1.1 trillion in 2033.

Surface Mount Technology (SMT) Market Trends

Consumer Electronics End-user Industry Segment is Expected to Hold Significant Market Share

- In the automotive industry, SMT is used in Electronic Control Units (ECU), dashboard displays, radar and camera modules, Battery Management Systems (BMS), safety assistance systems, and more. SMT has emerged as a pivotal manufacturing process in the automotive application. Renowned for its efficiency, precision, and reliability, SMT is crucial in bolstering various automotive electronic products, including advanced driver-assistance systems (ADAS), infotainment systems, and vehicle control systems.

- In modern cars, the on-board control system acts as the vehicle's 'brain,' overseeing and harmonizing the functions of its electronic components. The on-board control system is crucial in their seamless operation, from navigation to audio and air conditioning. Central to the reliability of these control systems is SMT technology. This technology enables the precise mounting of minuscule electronic components on circuit boards, ensuring the systems operate efficiently and reliably.

- The Engine Control Unit (ECU) is the automotive electronic system's nucleus, overseeing critical operations like engine performance, transmission, and braking. Surface-mount technology (SMT) is essential in assembling microchips, resistors, capacitors, and other surface-mounted components onto the ECU.

- Furthermore, Artificial Intelligence technology is poised to see increased adoption in the automotive sector. The precision and efficiency of Surface Mount Technology (SMT) in electronic assembly are set to bolster the production of AI chips and processors. Consequently, automotive electronic products will have enhanced autonomous decision-making abilities, advancing intelligent driving and vehicle automation.

- As highlighted by the IEA, the global automotive industry is undergoing a significant transformation, with potentially far-reaching implications for the energy sector. According to projections, the rise of electrification is anticipated to result in a daily elimination of the need for 5 million barrels of oil by 2030.

- The IEA's report also revealed a substantial increase in electric vehicle sales, with 3.5 million units sold in 2023 compared to 2022, marking a 35% growth. Notably, over 250,000 new registrations were recorded weekly, and over 250,000 new registrations were recorded weekly throughout the year. In 2023, electric vehicles accounted for approximately 18% of all vehicles sold, a significant increase from 2% five years ago and 14% in 2022. These trends indicate that solid growth is expected to persist as the electric vehicle market matures. Additionally, it was projected that 70% of the electric vehicle stock in 2023 would consist of battery electric vehicles.

Asia Pacific is Expected to Witness Fastest Growth

- Asia-Pacific, particularly countries like Japan, China, South Korea, Taiwan, and Southeast Asia, has become a global hub for electronics manufacturing. The region's robust manufacturing infrastructure, skilled labor force, and supportive government policies attract multinational corporations and promote the growth of local electronics industries. Demand for tablets, smartphones, and other electronic devices continues to grow, necessitating efficient and high-volume production capabilities by surface mount technology. The company projects that by implementing SMT (Surface Mount Technology) locally, the value addition will increase to 25% from the current 15%.

- For instance, in August 2023, the Indian government is actively engaging with global electronics firms to ramp up local value addition in products assembled in India, targeting a significant increase of 60-80% over the next five to ten years. To achieve this, the government is urging industries in India to adopt advanced production methods, like surface-mount technology (SMT) lines.

- Silicon Carbide (SiC) is increasingly in the spotlight for its high-temperature resilience, superior electrical conductivity, and remarkable energy efficiency. As the demand for electric vehicles (EVs), solar panels, and advanced power management rises with Industry 4.0, SiC manufacturing's significance has heightened. Wide Band Gap conductors are a natural fit given the imperative for minimal power consumption in these sectors.

- In February 2024, Continental Device India Limited (CDIL) took a significant step by inaugurating a new assembly line specifically for SiC Surface Mount Technology (SMT) components. This move positions CDIL as India's pioneer in SiC component manufacturing. With this enhancement, CDIL can now produce a range of auto-grade devices, such as SiC Schottky Diodes, SiC MOSFETs, Zeners, Rectifiers, and TVS Diodes, catering to both global and domestic markets.

- In April 2024, TDK Corporation introduced the B40910 series, a line of hybrid polymer capacitors designed to handle up to 4.6 A (at 100 kHz and +125 °C). These surface mount components boast impressively low ESR values of 17 mΩ and 22 mΩ at room temperature.

- Notably, unlike standard electrolytic capacitors with liquid electrolytes, the ESR of TDK's capacitors shows minimal variation with temperature. These compact components, measuring 10 x 10.2 mm or 10 x 12.5 mm (D x H), feature a rated voltage of 63 V and offer capacitances ranging from 82 µF to 120 µF. Thus, SMT manufacturers drive the need for the technology by integrating and innovating technologies. These efforts contribute to the widespread adoption and growth of surface mount technology (SMT) in various industries.

Surface Mount Technology (SMT) Industry Overview

Surface Mount Technology market is highly fragmented due to the presence of both global players and small and medium-sized enterprises. Some of the major players in the market are Fuji Corporation, Yamaha Motor Co. Ltd, Mycronic AB, ASMPT, and Panasonic Corporation. Players in the market are adopting partnerships and acquisitions to enhance their product offerings and gain competitive advantage.

March 2024 - Nordson Corporation introduced a new Latin America Tech Center based in Queretaro, Mexico, to allow manufacturers in the region to get timely feedback on the best fluid dispensing equipment for their assembly fluid, parts, substrates, and production requirements. The lab has a 3D printer, scales, and other measurement equipment to determine the correct fluid dispensing equipment for each customer's unique application requirements.

January 2024 - Yamaha Motor Co. Ltd announced the launch of YRM10, a surface mounter with the title of being the fastest in its class regarding mounting performance. With an impressive speed of 52,000 CPH, it outshines its competitors in the 1-Beam/1-Head category. This device is compact and space-saving and offers a range of component compatibility and versatility, making it a next-generation solution for high-speed modular assembly.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Value Chain Analysis

- 4.3 Industry Attractiveness - Porter's Five Forces Analysis

- 4.3.1 Bargaining Power of Suppliers

- 4.3.2 Bargaining Power of Buyers

- 4.3.3 Threat of New Entrants

- 4.3.4 Threat of Substitutes

- 4.3.5 Intensity of Competitive Rivalry

- 4.4 Impact of COVID-19 on the Surface Mount Technology Market

5 MARKET DYNAMICS

- 5.1 Rising Demand For Miniaturization of Technology

- 5.1.1 Fewer Holes Required to Drill on PCBs Compared to Other Technologies

- 5.2 Market Challenges

- 5.2.1 SMT is Unsuitable for Any Large, High-Power and High-Voltage Parts and Parts Undergoing Frequent Mechanical Stress

- 5.2.2 High Initial Cost and Rework Issues

6 MARKET SEGMENTATION

- 6.1 By Component

- 6.1.1 Passive Components

- 6.1.1.1 Resistors

- 6.1.1.2 Capacitors

- 6.1.2 Active Components

- 6.1.2.1 Transistors

- 6.1.2.2 Integrated Circuits

- 6.1.1 Passive Components

- 6.2 By End-user Industry

- 6.2.1 Consumer Electronics

- 6.2.2 Automotive

- 6.2.3 Industrial Electronics

- 6.2.4 Aerospace and Defense

- 6.2.5 Healthcare

- 6.2.6 Other End-user Industries

- 6.3 By Geography

- 6.3.1 North America

- 6.3.2 Europe

- 6.3.3 Asia

- 6.3.4 Australia and New Zealand

- 6.3.5 Latin America

- 6.3.6 Middle East and Africa

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Fuji Corporation

- 7.1.2 Yamaha Motor Co. Ltd

- 7.1.3 Mycronic AB

- 7.1.4 ASMPT

- 7.1.5 Panasonic Corporation

- 7.1.6 Nordson Corporation

- 7.1.7 Juki Corporation

- 7.1.8 Hanwa Precision Machinery Co. Ltd

- 7.1.9 Zhejiang Neoden Technology Co. Ltd

- 7.1.10 Europlacer Limited

- 7.1.11 Viscom SE