|

市場調查報告書

商品編碼

1630175

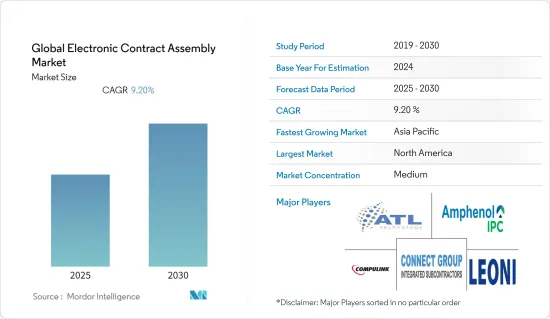

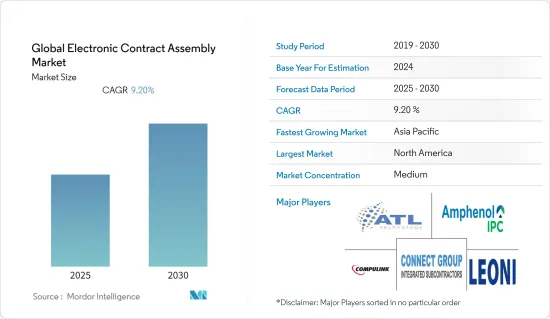

全球專業電子代工組裝市場:市場佔有率分析、產業趨勢/統計、成長預測(2025-2030)Global Electronic Contract Assembly - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

價格

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

簡介目錄

全球專業電子代工組裝市場預計在預測期內複合年成長率為 9.2%

主要亮點

- 不穩定的經濟狀況正迫使製造商重新思考傳統的經營模式並專注於收益。大多數經營團隊將合約組裝主要視為降低成本、提高靈活性和簡化生產流程的機會。

- 透過業務給電子製造服務供應商,目的地設備製造商 ( OEM ) 可以大幅降低固定成本,同時騰出資金投資於新產品開發和行銷等策略措施。減少直接就業也可以降低人事費用。

- 由於建立內部生產是大多數公司面臨的重大挑戰,因此外包被認為是降低成本的理想選擇。因此,對該服務的需求預計很快就會以健康的速度成長。 PCB 組裝服務被大多數OEM廣泛考慮,因為它們缺乏技術知識,並被視為任何電子設備的重要組成部分。

- 一方面,汽車產業正在迅速增加電子產品的使用,以提高舒適性、安全性、性能和整體駕駛體驗。由於延長了車輛保固期,汽車製造商要求層級供應商提供更高的可靠性、提高製造效率並顯著減少保固缺陷。

- 醫療電子也是合約組裝能夠提高效率、降低成本的關鍵領域之一。由於醫療生物醫學市場的持續成長,Saline Lectronics 等公司長期以來一直投資於製造電路基板組件所需的認證。

- COVID-19 疫情對全球供應鏈的持續影響加劇了電子產業現有的挑戰。由於距離病毒控制還有幾個月的時間,製造商現在正在重新考慮他們的策略,並專注於尋找中國以外的供應鏈來源。

專業電子代工組裝市場趨勢

消費性電子產品推動市場成長

- 通訊設備和電腦產品預計將成為推動電子產業成長最大的主要領域。外包流程已成為電子產業持續擴張、成本逐年下降的關鍵因素,並成為拉動消費需求的強大因素。

- 物聯網 (IoT) 的出現為家用電子電器製造商創造了許多新的機會。智慧型手錶等穿戴式裝置採用晶片和軟性感測器。這些裝置設計和製造技術的突破會對PCB市場產生重大影響。過去十年來,多個地區的網路連線系統數量也有所增加。

- 蘋果等主要OEM也從富士康聘請電子產品契約製造,富士康擁有約 35 萬名員工,生產全球約一半的 iPhone。在繁忙的夏季,工廠每天生產約 50 萬部 iPhone,然後秋季新 iPhone 上市。

- 此外,對具有互動式和快速響應介面的高性能、超薄、輕型顯示器的需求正在將材料需求推向極限。這些先決條件正在推動各種應用的顯示材料技術以取得新的進步,從觸控螢幕中的 ITO 取代到軟性設備中的顯示創新。

- 在醫療領域,穿戴式裝置(戴在手腕或身上的東西)的概念需要靈活的印刷電子產品,而遠端監控(居家醫療)則需要具有更高連接性的設備。這些趨勢也影響設計管理並為合約組裝製造商創造機會。

亞太地區將經歷最高的成長

- 在預測期內,擁有大量OEM的亞太地區預計將成為合約組裝的重要市場。鑑於政府技術的發展,特別是日本智慧型設備和智慧醫療的發展,中國、印度和日本等地區可能會推動需求。

- 國內消費性電子產品尤其是家庭自動化領域的需求快速成長。據知名家用電子電器製造商TCL稱,由於重要的智慧產品的推動,中國家用電子電器市場的市場規模預計將成長至目前規模的三倍。

- 中國在半導體、家用電子電器以及其他IT和通訊設備製造業的強勢地位使其成為全球最重要的市場之一。

- 該國目前約佔全球電子產品生產和組裝能力的60-70%。根據半導體產業協會的數據,該國半導體銷售收入從 824 億美元(2015 年)增加到 1,437 億美元(2019 年)。該國在5G技術方面也處於世界領先地位,預計到2020年下半年將在50個城市實現網路全覆蓋。

- 該地區的公司在開發軟性印刷電路板和剛柔結合印刷電路板等技術方面也取得了長足進步。在PCB製造技術不斷升級的過程中,中國產品結構穩定最佳化。此外,人工智慧、巨量資料、雲端運算等一系列新設立的策略性產業將屬於先進製造業,導致對組裝參與企業的依賴。

- 然而,大流行的爆發迫使該地區的參與企業遵守全國範圍內的封鎖。截至 2020 年 3 月下旬,富士康和緯創資通暫時停止在印度工廠的生產,以遏制 COVID-19 的傳播。這些公司也是大型電子公司的製造合作夥伴。

專業電子代工組裝產業概況

專業電子代工組裝市場是細分且競爭激烈的。新興經濟體中參與企業正在向生產和設計部門提供低成本的外包服務,以增加競爭。此外,主要企業正在尋求透過併購來獲得競爭優勢。宣布市場的一些關鍵發展。

- 2020 年 3 月 - Advanced Circuits 在錢德勒開設最新工廠。該公司投資 700 萬美元新建了佔地 50,000 平方英尺的辦公地點,並於 2019 年 9 月開業。除了該公司位於科羅拉多州科羅拉多和明尼蘇達州楓樹林的製造工廠之外,還擁有這家最先進的工廠。它的規模是亞利桑那州坦佩之前工廠的兩倍。

- 2020 年 3 月 - Sanmina Corporation 宣布擴建泰國工廠。該工廠預計將擁有先進的自訂封裝和組裝能力,用於製造先進的光學、高速、高頻微電子組件和產品。此次擴張將進一步支援網路、5G、資料中心、汽車/雷射雷達以及航太和國防市場新技術產品的快速成長。

其他好處

- Excel 格式的市場預測 (ME) 表

- 3 個月分析師支持

目錄

第1章簡介

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章市場洞察

- 市場概況

- 產業價值鏈分析

- 產業吸引力-波特五力分析

- 供應商的議價能力

- 買方議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭公司之間敵對關係的強度

第5章市場動態

- 市場促進因素

- 市場限制因素

第6章 市場細分

- 活動類型

- PCB組裝服務

- 電纜/線束組裝服務

- 薄膜/小鍵盤開關組裝服務

- 目的

- 醫療保健

- 車

- 工業的

- 資訊科技和電訊

- 其他

- 地區

- 北美洲

- 美國

- 加拿大

- 歐洲

- 英國

- 德國

- 法國

- 歐洲其他地區

- 亞太地區

- 中國

- 日本

- 印度

- 其他亞太地區

- 拉丁美洲

- 中東/非洲

- 北美洲

第7章 競爭格局

- 公司簡介

- Amphenol Interconnect Products Corp.(AIPC)

- ATL Technology

- Compulink Cable Assemblies Inc.

- Connect Group NV

- Leoni Special Cables Ltd

- Season Group International Co. Ltd

- Volex Group PLC

- Mack Technologies Inc.

- TTM Technologies Inc.

第8章投資分析

第9章市場的未來

簡介目錄

Product Code: 59163

The Global Electronic Contract Assembly Market is expected to register a CAGR of 9.2% during the forecast period.

Key Highlights

- Volatile economic conditions have forced the manufacturers to reassess their traditional business models and concentrate on the bottom line. A majority of the executives view contract assembling as an opportunity, primarily to reduce costs, improve flexibility, and streamline their production processes.

- Outsourcing tasks to an electronics manufacturing services provider primarily allows the original equipment manufacturers (OEMs) to significantly cut their fixed costs while freeing cash to invest in strategic initiatives, such as new product development or marketing. It also lets a company reduce labor costs by shrinking its direct workforce.

- The establishment of in-house production is a crucial challenge faced by the majority of the players, owing to which outsourcing is considered a preferable option for them to save costs. As such, the demand for this service is expected to rise at a healthy rate shortly. PCB assembly services are widely considered by most OEMs, as they lack the technical knowledge and are considered crucial components in any electronic device.

- For one, the automotive industry is rapidly increasing its use of electronics to enhance comfort, safety, performance, and overall driving experience. As a result of more extended vehicle warranty periods, automobile manufacturers are demanding higher reliability, improved manufacturing efficiency, and vastly reduced warranty failures from their Tier 1 suppliers.

- Healthcare electronics is another primary sector where contract assembly is seen to reduce costs while improving efficiency. Due to the continued growth in the medical and biomedical markets, companies like Saline Lectronics have previously invested in certifications necessary for circuit board assembly manufacturing.

- Adding to the electronics industry's existing challenges is the ongoing impact of the COVID-19 outbreak on the global supply chain. With still months away from the containment of the virus, manufacturers are currently focusing on rethinking their strategies and looking beyond China to find alternative supply chain sources.

Electronic Contract Assembly Market Trends

Consumer Electronics to Drive the Market Growth

- Communications and computer products are expected to be the leading segments driving the most significant growth in the electronics industry. Outsourcing processes has become a critical element in keeping the electronics industry expanding and handling costs to the margin each year, a leading factor in stimulating consumer demand.

- With the emergence of the internet of things (IoT), there have been many new opportunities for consumer electronics manufacturers. Wearable devices, such as smartwatches, incorporate chips and flexible sensors. Breakthrough in designing these devices and manufacturing technology may have a significant impact on the PCB market. The amount of systems connected over the internet is also expanding in multiple regions over the past decade.

- The leading OEMs, such as Apple, also employ electronic contract manufacturing from Foxconn, which employs approximately 350,000 people and produces about half of the world's iPhones. Before the fall release of a new iPhone in the busy summer months, the factory produces around 500,000 phones a day.

- Furthermore, demand for high-performance, ultra-thin, and light displays with interactive, quick reacting interfaces pushes material requirements to the edge. These prerequisites drive new advances in display materials technology for various applications, from ITO replacements for touch screens to display innovations for flexible devices.

- In the healthcare prospect, the concept of wearables (wrist and body-worn) calls for flexible printed electronics, while remote monitoring (home healthcare) calls for more connected devices. These trends again impact the design controls and provide an opportunity for the contract assembly companies.

Asia Pacific to Witness Highest Growth

- Housing a significant number of OEMs, the region is estimated to be a substantial market for contract assembly during the forecast period. The regions, including China, India, and Japan, are likely to drive the demand, considering the government's technology development, especially in the smart devices and smart healthcare in Japan.

- The domestic demand for consumer electronics, especially in the home automation space, increased quickly. In China, the consumer electronics market's market is estimated to witness growth by three times its current size, with the critical smart products, according to a well-known home appliance maker, TCL.

- China is one of the significant markets globally, owing to its strong position in the semiconductor, consumer electronics, and other telecommunications devices and equipment manufacturing industries.

- The country currently has about 60-70% of the world's electronics production and assembly capacity. According to the Semiconductor Industry Association, the country's semiconductor sales revenue grew from USD 82.4 billion (2015) to USD 143.7 billion (2019). The country is also leading the world in 5G technology, with full network coverage planned in 50 cities in late-2020.

- The companies in the region are also making significant achievements in developing technologies, such as Flex PCB and Flex rigid PCB. In the continuous upgrades of PCB manufacturing technology, China experiences a stable and optimized product structure. Furthermore, a series of newly established strategic industries in AI, Big Data, and cloud computing belong to advanced manufacturing, leading to the dependence on assembly players.

- However, the pandemic outbreak has made players in the region comply with the nationwide lockdown. As of late March 2020, Foxconn and Wistron suspended production at their plants in India to reduce the spread of COVID-19. These companies are also manufacturing partners to major electronics companies.

Electronic Contract Assembly Industry Overview

The electronics contract assembly market is fragmented and is quite competitive. Market players in developing economies offer low-cost, outsourced services to the production and designing sectors to increase their competitiveness. Furthermore, key players are striving to gain a competitive advantage by engaging in mergers and acquisitions. Some of the key developments in the market are:

- March 2020 - Advanced Circuits inaugurated its newest facility at Chandler. The company has invested USD 7 million in this new 50,000-square-foot location, which opened in September 2019. This State-of-the-art facility is a welcome addition to the company's manufacturing facilities in Aurora, Colorado, and Maple Grove, Minnesota. It is twice the size of the old facility in Tempe, Arizona.

- March 2020 - Sanmina Corporation announced the expansion of its facility in Thailand. The facility is expected to have advanced custom packaging and assembly capabilities to manufacture advanced optical, high speed, and radiofrequency microelectronic assemblies and products. This expansion further supports rapid growth for new technology products across the networking, 5G, data center, automotive/LIDAR, and aerospace and defense markets.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Value Chain Analysis

- 4.3 Industry Attractiveness - Porter's Five Force Analysis

- 4.3.1 Bargaining Power of Suppliers

- 4.3.2 Bargaining Power of Buyers

- 4.3.3 Threat of New Entrants

- 4.3.4 Threat of Substitute Products

- 4.3.5 Intensity of Competitive Rivalry

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.2 Market Restraints

6 MARKET SEGMENTATION

- 6.1 Type of Activity

- 6.1.1 PCB Assembly Services

- 6.1.2 Cable/Harness Assembly Services

- 6.1.3 Membrane/Keypad Switch Assembly Services

- 6.2 Application

- 6.2.1 Healthcare

- 6.2.2 Automotive

- 6.2.3 Industrial

- 6.2.4 IT and Telecom

- 6.2.5 Other Applications

- 6.3 Geography

- 6.3.1 North America

- 6.3.1.1 United States

- 6.3.1.2 Canada

- 6.3.2 Europe

- 6.3.2.1 United Kingdom

- 6.3.2.2 Germany

- 6.3.2.3 France

- 6.3.2.4 Rest of Europe

- 6.3.3 Asia Pacific

- 6.3.3.1 China

- 6.3.3.2 Japan

- 6.3.3.3 India

- 6.3.3.4 Rest of Asia Pacific

- 6.3.4 Latin America

- 6.3.5 Middle East and Africa

- 6.3.1 North America

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Amphenol Interconnect Products Corp. (AIPC)

- 7.1.2 ATL Technology

- 7.1.3 Compulink Cable Assemblies Inc.

- 7.1.4 Connect Group NV

- 7.1.5 Leoni Special Cables Ltd

- 7.1.6 Season Group International Co. Ltd

- 7.1.7 Volex Group PLC

- 7.1.8 Mack Technologies Inc.

- 7.1.9 TTM Technologies Inc.

8 INVESTMENT ANALYSIS

9 FUTURE OF THE MARKET

02-2729-4219

+886-2-2729-4219