|

市場調查報告書

商品編碼

1630341

工業測量儀器 -市場佔有率分析、產業趨勢/統計、成長預測(2025-2030)Industrial Metrology - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

價格

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

簡介目錄

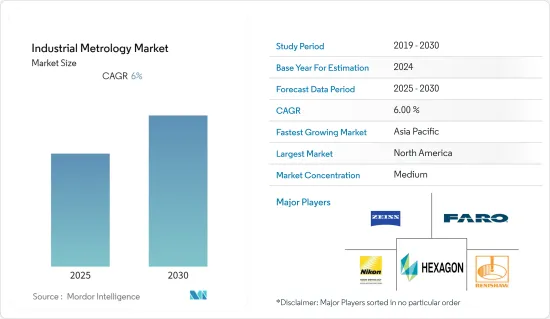

工業測量設備市場預計在預測期內複合年成長率為 6%

主要亮點

- 此外,BMW還開發了一種創新的全自動線上測量單元,用於品管。這種新型在線多測量單元透過將測量過程整合到生產流程中來簡化此步驟,並且如果需要,可以 24/7運作。這個線上測量單元配備了四個機器人和包括雷射雷達在內的創新測量方法。

- 3D測量解決方案、可攜式CMM、機器人安裝的光學CMM掃描儀、雲端基礎的軟體應用平台和尺寸測量服務等新興市場的發展導致了市場的快速成長。例如,2021年10月,蔡司確認收購美國著名的GOM 3D非接觸式測量解決方案供應商Capture 3D。 Capture 3D 提供 3D 計量解決方案,協助客戶大幅改善其產品設計、製造、品管和生產流程。

- 整個製造價值鏈中擴大採用支援物聯網的感測器也推動了測量過程的進步。 2021 年,烏爾姆大學醫療儀器雷射技術實驗室 (ILM) 開發了一種特殊感測器,可縮短測量時間並減少環境影響。它使用多波長數位全像術和相關實現,允許在一張影像中收集漫反射和鏡面表面的全區域地形資料。

- 此外,COVID-19大流行以及世界各地政府和企業採取的措施正在加速產業的數位轉型。這些措施包括增加數位轉型計劃的預算。然而,計量作為其核心要素之一的基礎設施的發展速度並不平衡。

- 由於新冠肺炎 (COVID-19) 疫情的爆發,工作環境經過重新設計,需要物理分散,從而減少了員工在一起的時間。這強烈要求行業變得更加敏捷。因此,未來幾年全球對工業測量設備的需求預計將增加。這種病毒的全球影響正在推動虛擬和線上工具的發展,並可能進一步推動工業測量市場的成長。

工業測量設備市場趨勢

汽車產業預計將佔據最大佔有率

- 隨著汽車製造迅速轉向自動化設備,汽車產業預計將在預測期內發生重大演變。對可靠、高品質工藝的需求以及對電動車不斷成長的需求預計將推動顯著成長。

- 印度投資網格顯示,價值 740 億美元的汽車產業預計到 2026 年將達到 3,000 億美元。印度還有四個大型汽車製造中心:北部的德里-古爾岡-法裡達巴德,西部的孟買-浦那-納西克-奧蘭加巴德,南部的清奈-班加羅爾-霍蘇爾,東部的詹謝普爾-加爾各答也有規劃。

- 此外,汽車產業對各種零件的檢驗、測量和品質檢查的需求不斷成長,正在推動成長。汽車產業擴大使用光學測量系統和座標測量機 (CMM) 來取代傳統的應變計、加速計、感測器和引伸計,以提高車輛的安全性和舒適性。此外,根據豐業銀行的數據,2021年全球汽車銷量為6,670萬輛,預計到2022年將增至6,690萬輛,這將推動未來研究市場的成長。

- 汽車技術的進步提高了零件的精度。汽車中的每個座椅、車門、面板和零件都必須精確對齊,以提高乘客的安全性、舒適度和滿意度。為了檢查和評估機械設備的對準而進行公差測量的需求也推動了對計量服務的需求。此外,據 Ola Electric 稱,印度將於 2024 年開始生產續航里程為 500 公里的電動車。該計劃是印度有史以來最大的汽車項目。

- 從離線品質檢測到近線和線上測量技術的轉變使得汽車領域的採樣率更高,檢測時間更短,從而推動了汽車行業工業測量設備市場的成長。

亞太地區成長最快

- 預計在預測期內,亞太地區將佔據工業測量設備市場的最大佔有率。亞太地區的成長是由該地區不斷成長的汽車和製造業推動的。當地公司不斷的技術進步也推動了市場的成長。

- 此外,亞太國家政府對研發的大量資金和廣泛的工業基礎是該地區工業測量設備市場的關鍵推動因素。中國、韓國和日本是對該地區市場成長做出貢獻的主要國家。

- 此外,2021年8月,海克斯康與印度中央製造技術實驗室(CMTI)合作建立了工業4.0卓越和體驗中心、智慧製造開發和演示單元(CMTI),這是一個工業4.0卓越和體驗中心位於印度班加羅爾的CMTI 中心)成立。

- 工業和發電應用預計將推動亞太地區計量服務市場的發展。計量服務用於各種發電應用,包括水平機械軸承、主軸、鑄件、渦輪機、頂部對準、渦旋箱形狀和組裝以及其他應用。

- 莫迪在另一場權衡會議上強調了印度在提高「印度製造」宣傳活動中提供的產品品質方面所做的努力,並呼籲政府提高區域產業的品管標準。 2021年1月,國家標準化與計量體系的建立,是成為未來產業區域和全球樞紐、各產業全球市場目標的重要支撐和組成部分。

工業測量設備產業概況

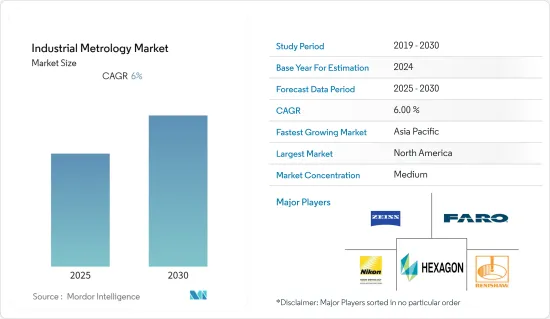

工業測量設備市場競爭激烈,參與企業眾多。市場集中度中等,主要企業採取產品創新、併購等策略。此外,每家公司都在採取多項成長和擴大策略,以獲得市場競爭優勢。

- 2022 年 8 月 - 3D 掃描和檢測解決方案領先開發商 LMI Technologies (LMI) 宣布正式發布其最新 4K+ 解析度智慧 3D 雷射線輪廓感測器 Gocator 2600 系列。這些工廠校準的感測器具有自訂光學裝置和強大的 9 兆像素成像器,適用於電池檢查、建築材料、汽車、橡膠和輪胎製造以及一般工廠自動化,每個配置文件有 4,200 個資料點,用於高解析度3D 掃描和檢查。

- 2022 年 3 月 - Hexagon AB 宣布收購 ETQ,後者是基於 SaaS 的品管系統 (QMS)、環境、健康和安全軟體以及合規管理軟體的供應商。該公司將作為海克斯康製造智慧部門的一部分運作。 ETQ Reliance 是 ETQ 的多租戶 QMS 軟體,為自動收集和分發製造品管資料、不合格報告和客戶回饋提供了資料骨幹。

其他好處

- Excel 格式的市場預測 (ME) 表

- 3 個月分析師支持

目錄

第1章簡介

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章市場洞察

- 市場概況

- 產業吸引力-波特五力分析

- 供應商的議價能力

- 買方議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭公司之間的敵對關係

- 產業價值鏈分析

- 評估 COVID-19 對工業測量設備市場的影響

第5章市場動態

- 市場促進因素

- 巨量資料分析的興起

- 採用雲端服務整合測量資料

- 新興國家對汽車的需求不斷成長

- 市場問題

- 安裝稱重設備高成本

- 缺乏有效處理稱重系統的專業知識

第6章 市場細分

- 按類型

- 硬體

- 軟體

- 按服務

- 按設備

- 三坐標測量機

- 光學數位轉換器和掃描儀

- 測量儀器

- X光/電腦斷層掃描器

- 自動光學檢定

- QR 圖裝置

- 按用途

- 逆向工程

- 品管和檢驗

- 繪圖和建模

- 其他

- 按最終用戶產業

- 航太/國防

- 車

- 製造業

- 半導體

- 其他

- 按地區

- 北美洲

- 歐洲

- 亞太地區

- 其他

第7章 競爭格局

- 公司簡介

- Hexagon AB

- Renishaw PLC

- FARO Technologies

- Nikon Metrology

- Carl Zeiss AG

- Jenoptik AG

- Perceptron

- Automated Precision Inc.

- KLA Corporation

- Applied Materials Inc.

第8章投資分析

第9章市場的未來

簡介目錄

Product Code: 69398

The Industrial Metrology Market is expected to register a CAGR of 6% during the forecast period.

Key Highlights

- Furthermore, BMW has developed an innovative, fully automated inline measurement cell for quality control. This new inline multiple measurement cell streamlines this phase by integrating the measurement process into the production flow and can operate 24/7 if required. The inline measurement cell features four robots and a range of innovative measurement methods, including Laser Radar.

- The development of 3D measurement solutions, portable CMM, robot-mounted optical CMM scanners, cloud-based software application platforms, and dimensional metrology services led to high growth in the market. For instance, in October 2021, ZEISS confirmed the acquisition of Capture 3D, a prominent GOM 3D non-contact measuring solutions provider based in the USA. Capture 3D delivers 3D measurement solutions to help customers significantly improve product design, manufacturing, quality control, and production processes.

- The growing adoption of IoT-enabled sensors across the manufacturing value chain also brings advancements in the measuring process. In 2021, the Institute for Laser Technologies in Medicine and Metrology (ILM) at the University of Ulm developed a special sensor for short measurement times and environmental influences. It uses multi-wavelength digital holography, and allied implementation allows the collection of topographic data of an entire area for diffuse and specular reflective surfaces within one image.

- Furthermore, the COVID-19 pandemic and the measures taken by governments and businesses around the world have accelerated the digital transformation of industries. These measures include increased budgets for digital transformation projects. However, the pace of infrastructure evolution, which forms metrology as one of its core elements, has not been balanced.

- Due to the COVID-19 outbreak, the work environments were redesigned with fewer workers spending less time collaboratively due to physical-distancing requirements. This created an acute need for industries to be more agile. Hence, the demand for industrial metrology is expected to increase globally over the coming years. The worldwide impact of this virus is pushing virtual and online tools, which may further boost the growth of the industrial metrology market.

Industrial Metrology Market Trends

Automotive Industry is Expected to Hold the Largest Share

- The automotive sector is expected to witness a major evolution during the forecast period, as automobile manufacturing is quickly moving to automated facilities. The need for highly reliable and quality processes and the rising demand for electric vehicles are expected to drive major growth.

- According to India Investment Grid, the USD 74 Billion Automobile industry is expected to reach USD 300 Billion by 2026. In addition, India is also planning to host four large auto manufacturing hubs in Delhi-Gurgaon-Faridabad in the North and Mumbai-Pune-Nashik-Aurangabad in the West, Chennai- Bengaluru-Hosur in the South, and Jamshedpur-Kolkata in the East.

- Moreover, the rising need for inspection, measurement, and quality checks of various components in the automotive sector is driving growth. The automotive industry has increasingly used optical measurement systems and coordinate measuring machines (CMM) instead of conventional strain gauges, accelerometers, transducers, and extensometers to improve vehicles' safety and comfort. In addition, according to Scotiabank, 66.7 million cars were sold worldwide in 2021. and it has expected to rise by 66.9 million units in 2022, which will drive studied market growth in the future.

- Technological advancements in automobiles are resulting in an increased level of precision of components. Every seat, door, panel, and component in an automobile must be precision aligned to promote passenger safety, comfort, and satisfaction. The necessity of tolerance measurement to inspect and assess equipment alignment on machinery is also driving the demand for metrology services. Furthermore, production of electric vehicles with a 500 km range will begin in India in 2024, according to Ola Electric. The project is the largest automobile undertaking ever in India.

- The shift in preference from off-line quality inspection to near-line or in-line measurement techniques, enabling higher sampling rates and shorter inspection times in the automotive sector, is driving the growth of the industrial metrology market for the automotive industry.

Asia Pacific to Register the Fastest Growth

- The Asia Pacific is expected to account for the largest share in the industrial metrology market during the forecast period. The growth in the Asia-Pacific is attributed to the region's growing automotive and manufacturing sectors. Also, continuous technological advancements by regional companies are propelling the market's growth.

- Moreover, large funding from governments of various Asia-Pacific countries in R&D and extensive industrial bases are the major contributors to the regional industrial metrology market. China, South Korea, and Japan are the major countries contributing to the market growth in the region.

- Further, in August 2021, Hexagon partnered with India's Central Manufacturing Technology Institute (CMTI) to establish a Smart Manufacturing Development and Demonstration Cell (SMDDC), an Industry 4.0 Centre of Excellence and Experience Centre, at the CMTI premises in Bengaluru, India.

- The industrial and power generation applications are expected to drive the metrology services market in Asia-Pacific. Metrology services are used in different power generations, including horizontal machine bearing, main shaft, casting, turbines, tops-off alignment, scroll case geometry and assembly, and other applications.

- In additional Metrology Conclave, Narendra Modi emphasized the country's operation toward improving the quality of products supplied under the Make In India campaign, government participation has been extended concerning improving quality control standards within regional industries. In January 2021, at the Nationgn. Establishing a national standardization and metrology system is a key supporter and essential part of the goal to become a regional and global hub for future industries and a global market for various industries.

Industrial Metrology Industry Overview

The industrial metrology market is competitive, owing to the presence of many players. The market is moderately concentrated, with the major players applying strategies like product innovations and mergers and acquisitions. Also, companies are involved in several growth and expansion strategies to gain a competitive advantage in the market.

- August 2022 - LMI Technologies (LMI), a major developer of 3D scanning and inspection solutions, has announced the official release of its latest Gocator 2600 Series of 4K+ resolution smart 3D laser line profile sensors. These factory pre-calibrated sensors come modified with custom optics and a powerful 9-megapixel imager to deliver 4200 data points per profile for high-resolution 3D scanning and inspection across broad fields of view in applications such as battery inspection, building materials, automotive, rubber and tire production, and general factory automation.

- March 2022 - Hexagon AB has announced the acquisition of ETQ, a SaaS-based quality management system (QMS), environment, health and safety software, and compliance management software. The company will operate as part of Hexagon's Manufacturing Intelligence division. ETQ's multitenant QMS software, ETQ Reliance, provides the data backbone for automating the collection and delivery of manufacturing quality control data, nonconformance reports, and customer feedback.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porters Five Forces Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Buyers

- 4.2.3 Threat of New Entrants

- 4.2.4 Threat of Substitutes

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Industry Value Chain Analysis

- 4.4 Assessment of Impact of COVID-19 on the Industrial Metrology Market

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Rise in Big Data Analytics

- 5.1.2 Adoption of Cloud Services to Integrate the Metrological Data

- 5.1.3 Rising Demand for Automobiles in Developing Countries

- 5.2 Market Challenges

- 5.2.1 High Cost of Setting Up Metrology Facility

- 5.2.2 Lack of Expertise for Efficient Handling of Metrological Systems

6 MARKET SEGMENTATION

- 6.1 By Type

- 6.1.1 Hardware

- 6.1.2 Software

- 6.1.3 Services

- 6.2 By Equipment

- 6.2.1 Coordinate Measuring Machine

- 6.2.2 Optical Digitizer and Scanner

- 6.2.3 Measuring Instrument

- 6.2.4 X-Ray and Computed Tomography

- 6.2.5 Automated Optical Inspection

- 6.2.6 2D Equipment

- 6.3 By Application

- 6.3.1 Reverse Engineering

- 6.3.2 Quality Control & Inspection

- 6.3.3 Mapping and Modelling

- 6.3.4 Other Applications

- 6.4 By End User Industry

- 6.4.1 Aerospace and Defense

- 6.4.2 Automotive

- 6.4.3 Manufacturing

- 6.4.4 Semiconductor

- 6.4.5 Other End User Industries

- 6.5 By Geography

- 6.5.1 North America

- 6.5.2 Europe

- 6.5.3 Asia Pacific

- 6.5.4 Rest of the World

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Hexagon AB

- 7.1.2 Renishaw PLC

- 7.1.3 FARO Technologies

- 7.1.4 Nikon Metrology

- 7.1.5 Carl Zeiss AG

- 7.1.6 Jenoptik AG

- 7.1.7 Perceptron

- 7.1.8 Automated Precision Inc.

- 7.1.9 KLA Corporation

- 7.1.10 Applied Materials Inc.

8 INVESTMENT ANALYSIS

9 FUTURE OF THE MARKET

02-2729-4219

+886-2-2729-4219