|

市場調查報告書

商品編碼

1636604

化學包裝:市場佔有率分析、產業趨勢與統計、成長預測(2025-2030)Chemical Packaging - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

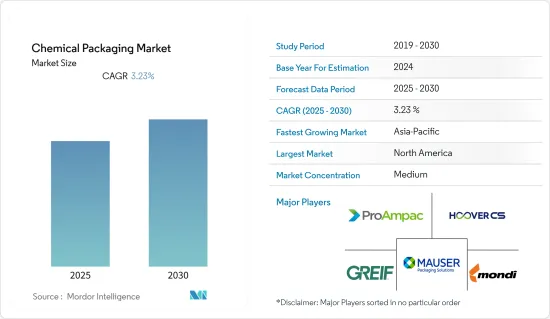

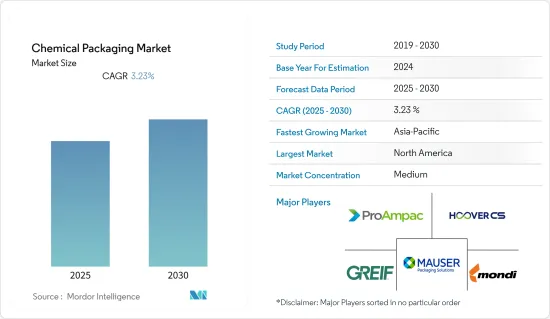

預計化學包裝市場在預測期內複合年成長率為3.23%

主要亮點

- 化學產品銷售的增加預計將增加全球透過傳統和線上零售商對化學包裝的需求。此外,化學品包裝桶和中型散裝容器(IBC)的需求正在增加,因為它們可以修復和重複使用,市場預計將擴大。

- 此外,各個地區都在專注於對化學品包裝實施嚴格的監管。考慮到危險品國際運輸的ADR歐洲協議,在其有關此類包裝的規定中表達了為危險品選擇適當包裝的重要性,並且IBC和大型包裝均規定不得損害或顯著削弱危險品物質,不得催化反應。隨著人們對包裝中常用化學物質(例如雙酚 A (BPA) 和全氟烷基物質和多氟烷基物質 (PFAS))的環境和健康影響的認知不斷增強,歐盟 (EU) 和美國預計將制定更嚴格的法規將在未來幾年內實施。這導致該地區化學品行業對強大包裝解決方案的需求增加。

- 一些新包裝滿足了安全問題並列出了更環保的足跡。傳統上,許多化學品製造商使用桶和桶來運輸他們的產品。儘管這些產品與競爭材料相比具有多種優勢,但新產品填補了市場上巨大的永續性空白。例如,盒中袋和工業散裝容器每個包裝可容納更多產品,並且折疊式,從而減少垃圾掩埋場和運輸成本。

- 中型散裝容器 (IBC) 是桶的替代品,不僅用於需要安全處理的產品,還用於 3 類、4 類、5 類和 9 類危險材料、可食用液體和潤滑劑等產品。工業,因為它可以安全地運輸各種固體或液體產品,包括油和精油等其他化學物質。

- 由於公眾越來越了解化學品包裝在降低化學品洩漏造成的死亡和財產損失風險方面的優勢,該市場正在不斷擴大。快速的都市化、全球化和現代化也是推動成長的因素。

- 然而,不斷變化的監管標準、原料成本的波動、廢物量的增加以及環境廢棄物法規的收緊預計將阻礙一些化學包裝產品的市場成長。

- 根據美國工業理事會 -19 的數據,有機化學品、無機化學品、塑膠樹脂、合成橡膠和人造纖維等基礎化學品在疫情初期全球產量增加了 1.4%。然而,特種化學品生產受到嚴重打擊,第一波疫情期間全球產量下降了11.2%,特別是被覆劑等特種化學品,下降了25.2%。

化工包裝市場趨勢

材料進步可減輕重量並使用永續產品

- 由於世界各地對塑膠包裝廢棄物的日益關注,紙袋和生物分解性的袋子比塑膠袋和袋子更受青睞。這種情況促使各國政府採用生物分解性包裝等替代來源。美國人口僅佔全球的 4%,但排放的都市固態廢棄物(MSW) 卻佔全球的 2%。此外,據估計,美國每人每年排放約 106.2 公斤塑膠廢棄物。

- 在一些地區,新冠疫情促使各行業的企業重新使用一次性塑膠袋,而不是採用可重複使用的塑膠袋。結果,更多的化學公司停止使用可重複使用的容器,各州也開始暫時取消對塑膠購物袋的禁令。

- 向永續包裝解決方案的快速轉變進一步激勵袋子供應商以創新方式列出用於工業應用的可回收和永續袋子。例如,埃克森美孚提供各種高性能聚乙烯聚合物,包括埃奇得 XP 和埃克森美孚 HDPE,為差異化的永續重型袋子解決方案創造了機會。

- 此外,波蘭也是中東歐重要的化學工業國家。根據中央統計局統計,波蘭化工產業僱用了約30萬人,佔波蘭全部工業就業人數的11%。在波蘭化學工業的發展中,未來波蘭最大的突破是精製、石化和塑膠加工業的發展。這些趨勢可能會導致對袋子和麻袋的需求增加。

- 此外,根據波蘭中央統計局的數據,去年紙袋和麻袋的產量約為16.2萬噸,比上年的約15.5萬噸增加了4.52%。產值的增加表明紙袋和麻袋作為永續的選擇而受到青睞。

- 關注產品對環境的影響是既定的現象。人們對永續性的興趣重新燃起,並明確關注包裝。它反映在國家和地方政府的法規、消費者態度以及透過包裝傳達的品牌所有者的價值觀中。隨著永續性成為消費者的重要動力,品牌越來越重視能夠體現其對環境承諾的包裝材料和設計。

亞太地區佔主要市場佔有率

- 在亞太地區,由於工業發展、外國直接投資(FDI)增加和外匯升值,市場將擴大。此外,中國、印度等多個國家注重化學產品的生產和消費,增加了該地區化學包裝材料的需求和消費。

- 中國對鋼桶和中型散貨箱(IBC)的需求受到貿易活動支出增加和化學品包裝需求增加的推動。例如,中國的化學工業是全世界最收益的。過去二十年,該產業貢獻了全球化工市場成長的一半,也是中國經濟快速成長的重要推手。

- 危險化學品儲存和運輸過程中發生的事故數量不斷增加,預計將進一步推動中型散貨箱和鋼桶的消費,因為它們被認為是安全的包裝解決方案。此外,對防止化學品造成的健康風險以及在洩漏或浸出時暴露於外部環境的解決方案的需求不斷成長,繼續推動該地區的市場成長。

- 此外,隨著全球化學工業格局的變化,中國預計將透過技術創新和貿易來引領化學工業進入下一個發展階段,從而在國際市場上獲得優勢。

化工包裝行業概況

化學包裝市場競爭適中,由多個全球和地區參與企業組成。這些參與企業擁有重要的市場佔有率,並致力於在全球範圍內擴大基本客群。這些參與企業專注於研發活動、策略聯盟以及其他有機和無機成長策略,以在預測期內保持在市場環境中。

2022 年 11 月,Greif, Inc. 簽訂了一項具有約束力的協議,收購 Lee Container Corporation, Inc.。 Lee Container Corporation, Inc. 主要在化學品領域生產高性能阻隔容器和傳統吹塑成型容器。 Lee的收購加強了公司在油桶和小塑膠瓶領域的擴張力度,為公司帶來了新的成長引擎。

2022 年 8 月,Mauser Packaging Solutions 宣布繼續擴大 Infinity 系列的產品生產範圍,同時投資於促進循環經濟的機械和軟體。最近,該公司投資了一台新型多層塑膠桶機,以加速其 Infinity 系列塑膠桶產品線中回收樹脂的使用。

其他好處

- Excel 格式的市場預測 (ME) 表

- 3 個月分析師支持

目錄

第1章簡介

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章市場洞察

- 市場概況

- 產業供應鏈分析

- 產業吸引力-波特五力分析

- 供應商的議價能力

- 買家/消費者的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭公司之間敵對關係的強度

- 評估 COVID-19 對化學包裝市場的影響

- 工業和製造業活動下降的影響

- 因應高成長市場的供給方挑戰

- 部分地區貿易活動變化

- 與區域市場相關的宏觀經濟因素等

- 涵蓋主要市場化工產業的現況與成長軌跡

- 化學包裝領域的關鍵創新與進步

第5章市場動態

- 市場促進因素

- 工業設施中對固定式中型散裝容器的需求不斷成長,推動了需求的成長

- 工業和製造業活動的復甦預示著市場成長

- 材料進步可減輕重量並使用永續產品

- 市場問題

- 由於依賴原物料價格而導致價格波動

- 加強環境廢棄物法規

第6章 市場細分

- 依產品類型

- 袋/麻袋

- 中型散裝容器(IBC)

- 桶和桶

- 軟性IBC及相關軟包裝產品

- 其他

- 按用途

- 通用化學品

- 特種化學品

- 石化

- 其他用途(高級化學品等)

- 按地區

- 北美洲

- 歐洲

- 亞太地區

- 拉丁美洲

- 中東/非洲

第7章 競爭格局

- 公司簡介

- Grief Inc.

- Mauser Packaging Solutions

- Mondi Group

- ProAmpac

- Environmental Packaging Technologies

- Hoover CS

- ALPLA-Werke Alwin Lehner GmbH & Co. KG

- SolvChem Custom Packaging

- Bulk-Pack Group

- LC Packaging Group

- Brainerd Chemicals Group

第8章投資分析

第9章市場的未來

The Chemical Packaging Market is expected to register a CAGR of 3.23% during the forecast period.

Key Highlights

- The increasing sales of chemicals are anticipated to stimulate the need for chemical packaging through traditional and online retailers globally. Additionally, due to their ability to be repaired or reused, the rising demand for drums and intermediate bulk containers (IBCs) in chemical packaging is anticipated to expand the market.

- Moreover, various regions are focusing on imposing stringent regulations for chemical packaging. The ADR European Agreement considering the International Carriage of Dangerous Goods expresses the importance of choosing the right packaging for dangerous goods in its provisions on such packaging, stating that IBCs and large packaging should not be harmed or significantly weakened by such dangerous goods and should not catalyze a reaction. As awareness of the environmental and health effects of commonly used chemicals in packaging, such as bisphenol-A (BPA) and per- and polyfluoroalkyl substances (PFAS), grows, the European Union and the United States are expected to enforce stricter regulations in the upcoming years. This drives the requirement for robust packaging solutions in the chemicals sector of the region.

- Several new packages satisfy the safety concerns and provide a greener footprint. Traditionally, many chemical manufacturers have used pails and drums to transport their products. While these products have several benefits over competitive materials, new products satisfy a significant market sustainability gap. For instance, bag-in-box and industrial bulk containers allow for more product-per-package and are collapsible, reducing landfill space and transportation costs.

- Intermediate bulk containers (IBCs), which are an alternative to drums, are particularly well suited to the chemical industry because they can safely transport a variety of solid or liquid products, including those that require safe handling as well as those that are classified as hazardous, like classes 3, 4, 5, and 9, as well as other chemicals, like edible liquids, lubricating, and essential oils.

- The market is expanding due to growing public knowledge of the advantages of chemical packaging, which lowers the risk of deaths and asset damage from chemical leaks. Rapid urbanization, globalization, and modernization are additional elements that promote growth.

- However, changing regulatory standards, fluctuations in raw material costs, growing waste levels, and increasing environment wastage regulations are expected to hamper some chemical packaging products' market growth.

- According to the American Chemistry Council, basic chemicals, including organic chemicals, inorganics chemicals, plastic resins, synthetic rubber, and manufactured fibers, witnessed a global production increase of 1.4% during the initial phases of the pandemic and have not seen a substantial impact due to COVID-19. However, the production of specialty chemicals took a significant hit as the global output declined by 11.2%, and especially for specialty chemicals, such as coatings, the show fell by 25.2% during the first wave of the pandemic, which negatively affected the usage of packaging in the specialty chemicals segment.

Chemical Packaging Market Trends

Material Advancements have Led to Lighter Weight Alternatives and Use of Sustainable Products

- Paper and biodegradable sacks are preferred over plastic sacks or bags due to the increasing concern over plastic packaging waste generated worldwide. The circumstances have led to governments adapting to alternative sources such as biodegradable packaging. The United States accounts for only 4% of the world's population and generates 2% of global Municipality Solid Waste (MSW). It is also stated that the United States produces about 106.2 kg of plastic waste per person per year.

- In some regions, COVID stimulated companies from various industries to bring back single-use plastic bags rather than accept reusable ones, mainly due to single-use plastics' ability to reduce the risk of potential viral transmission. Hence, an increasing number of chemical companies have suspended reusable containers, and states have begun to rescind plastic bag bans temporarily.

- The rapid shift toward sustainable packaging solutions further stimulates sack providers to innovate and provide recyclable or sustainable sacks for industrial purposes. For instance, ExxonMobil offers a range of performance PE polymers, including Exceed XP and ExxonMobil HDPE, among other products, to create several opportunities for differentiated, sustainable, heavy-duty sack solutions.

- Furthermore, Poland can be called a significant country in the chemical industry in Central and Eastern Europe. According to the Central Statistical Office, the chemical sector in Poland employs around 300,000 people, which accounts for 11% of employment in the entire industry within Poland. The most significant breakthrough in developing the chemical industry in Poland, which awaits the country in the coming years, is the development of refining, petrochemical, and plastics processing industries. Such a trend may lead to more demand for bags and sacks.

- Moreover, according to the Central Statistical Office of Poland, last year, the production of paper bags and sacks was valued at around 162,000 metric tons, a 4.52% rise in the output from the previous year, which was valued at about 155,000 metric tons. The increasing production value indicates the preference for bags and sacks made of paper as a sustainable option.

- Concern over the environmental impact of products is an established phenomenon. There has been a revived interest in sustainability explicitly focused on packaging. It is reflected in central government and municipal regulations, consumer attitudes, and brand owner values communicated via packaging. As sustainability has become a key motivator for consumers, brands increasingly focus on packaging materials and designs that show their environmental commitment.

Asia Pacific to hold significant market share

- The market will expand in the region due to rising industrial development, increasing foreign direct investment (FDI), and rising exchange rates. Additionally, several nations, like China and India, are concentrating more on manufacturing and consuming chemicals, increasing the demand for and consumption of chemical packaging materials in this region.

- The demand for steel drums and intermediate bulk containers (IBCs) in China is driven by increasing spending on trade activities and growing demand for chemical packaging. For instance, China's chemical industry has been the largest globally, given revenue generation. The sector has contributed to half of the growth of the world chemical market over the past two decades and has played an essential impetus in China's high economic growth.

- The growing incidents of storage and transportation of hazardous chemicals are further expected to foster the consumption of IBC and steel drums as they are perceived as safe packing solutions for such products. Additionally, the health risks posed by chemicals upon leakage and leaching, followed by the demand for a solution that prevents exposure to the external environment, continue to rise, driving the market's growth in the region.

- Moreover, with the landscape of the chemical industry changing globally, China is expected to drive its chemical industry to the next stage of development by taking the lead by leveraging technology innovation and trade and prevailing in the international market.

Chemical Packaging Industry Overview

The chemical packaging market is moderately competitive and consists of several global and regional players. These players account for a considerable market share and focus on expanding their client base worldwide. These players focus on R&D activities, strategic alliances, and other organic and inorganic growth strategies to stay in the market landscape over the forecast period.

In November 2022, Greif, Inc. entered into a binding agreement to acquire Lee Container Corporation, Inc., for a purchase price of USD 300 million, excluding tax benefits, with an estimated net present value of roughly USD 30 million. Lee Container Corporation, Inc. manufactures high-performance barrier and conventional blow-molded containers, primarily in the chemicals segment. The Lee purchase strengthens its dedication to expanding the jerrycan and small plastic bottle footprint and gives its company a new growth engine.

In August 2022, Mauser Packaging Solutions announced that the company continues expanding the number of items it can produce under the Infinity Series while investing in machinery and software that promote the circular economy. The business most recently invested in a new multi-layer plastic drum machine to facilitate the usage of recycled resin in the company's Infinity Series plastic drum product line.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Supply Chain Analysis

- 4.3 Industry Attractiveness - Porter's Five Forces Analysis

- 4.3.1 Bargaining Power of Suppliers

- 4.3.2 Bargaining Power of Buyers/Consumers

- 4.3.3 Threat of New Entrants

- 4.3.4 Threat of Substitute Products

- 4.3.5 Intensity of Competitive Rivalry

- 4.4 Assessment of the Impact of COVID-19 on the Chemical Packaging Market

- 4.4.1 Effect of Decline in Industrial and Manufacturing Activity

- 4.4.2 Supply-side Challenges in Catering to High-growth Markets

- 4.4.3 Changes in Trade Activity in a Few Regions

- 4.4.4 Macro-economical Factors Pertinent to Regional Markets, Among Others

- 4.5 Coverage on the Current Scenario and Growth Trajectory of the Chemicals Sector in the Major Markets

- 4.6 Key Innovations and Advancements in the Chemical Packaging Domain

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Growing Demand for Fixed IBC's in Industrial Establishments to Drive Demand

- 5.1.2 Recovery in Industrial and Manufacturing Activity Augurs Well for the Market Growth

- 5.1.3 Material Advancements have Led to Lighter Weight Alternatives and Use of Sustainable Products

- 5.2 Market Challenges

- 5.2.1 Price Variance due to Dependence on Raw Material Prices

- 5.2.2 Rising Environmental Wastage Regulations

6 MARKET SEGMENTATION

- 6.1 By Product Type

- 6.1.1 Bags and Sacks

- 6.1.2 Intermediate Bulk Containers (IBC)

- 6.1.3 Pails and Drums

- 6.1.4 Flexible IBCs and Related Flexible Packaging Products

- 6.1.5 Other Product Types

- 6.2 By Application

- 6.2.1 Commodity Chemicals

- 6.2.2 Specialty Chemicals

- 6.2.3 Petrochemicals

- 6.2.4 Other Applications (Advanced Chemicals, etc.)

- 6.3 By Geography

- 6.3.1 North America

- 6.3.2 Europe

- 6.3.3 Asia-Pacific

- 6.3.4 Latin America

- 6.3.5 Middle East & Africa

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Grief Inc.

- 7.1.2 Mauser Packaging Solutions

- 7.1.3 Mondi Group

- 7.1.4 ProAmpac

- 7.1.5 Environmental Packaging Technologies

- 7.1.6 Hoover CS

- 7.1.7 ALPLA-Werke Alwin Lehner GmbH & Co. KG

- 7.1.8 SolvChem Custom Packaging

- 7.1.9 Bulk-Pack Group

- 7.1.10 LC Packaging Group

- 7.1.11 Brainerd Chemicals Group