|

市場調查報告書

商品編碼

1639437

工業機器人:市場佔有率分析、行業趨勢和統計、成長預測(2025-2030 年)Industrial Robotics - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

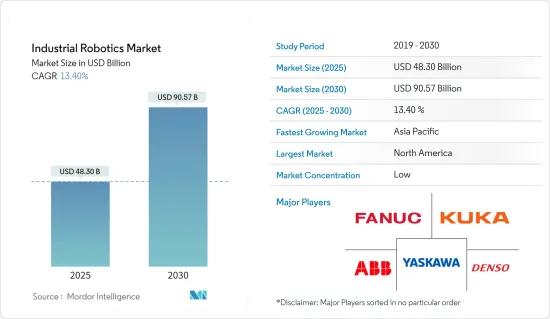

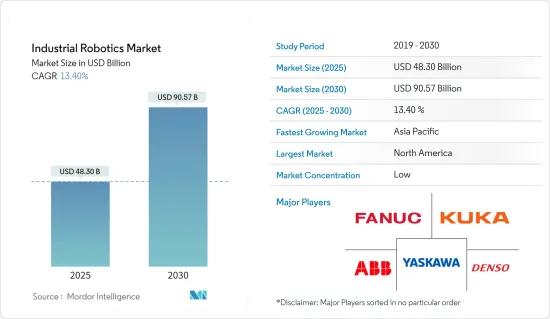

2025 年工業機器人市場規模預計為 483 億美元,預計到 2030 年將達到 905.7 億美元,預測期內(2025-2030 年)的複合年成長率為 13.4%。

主要亮點

- 工業機器人在製造業的工業自動化中發揮關鍵作用,現在工業中的許多核心業務都由機器人管理。隨著各地區經濟的成長,電子商務、電子、汽車等產業也蓬勃發展。

- 物聯網的日益普及以及各地區對機器人技術的投資對市場的成長做出了巨大貢獻。例如,《中國製造2025》的推出,旨在透過轉向注重品質和創新主導的製造業,全面升級中國工業。

- 最新的工業革命——工業 4.0 推動了協作機器人和人工智慧機器人等新技術的發展,工業界使用機器人來簡化許多流程、提高效率並消除錯誤。職場安全性的提高和生產能力的提高正在刺激產業進一步投資機器人系統。

- 到 2025 年,協作機器人預計將佔機器人總銷量的 34%(根據國際機器人聯合會 (IFR) 的數據),並將應用於塑膠、食品和消費品、半導體和電子、生命科學等行業,以及製藥。預計工業機器人的使用將變得更加廣泛。同樣引起關注的是蘋果工廠使用富士康機器人實現的自動化。半導體產業中的IC代工廠是影響當前市場需求的招募企業之一。

- 推動市場發展的關鍵因素包括對高品質產品的需求不斷成長(這需要對製造過程進行適當的端到端可視性)、對節能的需求以及對職場安全的日益關注。據監測北美工業機器人銷售情況的先進自動化協會 (A3) 稱,技術進步以及製造設施的持續成長也有望推動這一市場的發展。 2022年企業將訂購44,196台機器人,比2021年增加11%。

工業機器人市場趨勢

汽車業佔很大佔有率

- 在過去的 50 年裡,汽車產業已經在組裝上使用機器人完成各種製造工序。汽車製造商目前正在探索在更多工序中使用機器人。對於這樣的生產線,機器人更有效率、靈活、精確、可靠。這項技術使汽車產業成為機器人最重要的使用者之一,也是全球自動化程度最高的供應鏈之一。

- 此外,汽車製造過程中自動化程度的提高、人工智慧和數位化的參與是汽車產業對工業機器人需求增加的主要因素。

- 在當今的汽車產業,機器人技術的進步正在加速,以跟上正在發生的快速變化。機器人解決方案的模擬和虛擬試運行將最大限度地發揮當前汽車行業OEM、新興企業和供應商的工廠自動化優勢。

- 例如,歐洲第二大汽車製造商標致雪鐵龍集團正在利用 Universal Robots 的 UR10 協作機器人對其歐洲製造地進行現代化改造。根據瑞銀預測,2025年歐洲電動車銷量預計將達63億輛。

- 為了跟上汽車製造業不斷變化的格局,許多汽車產業公司都在採用工業機器人。例如,2022 年 1 月,華域汽車系統股份有限公司(以 HASCO 的名義開展業務)將與 ABB 集團在現有合作關係的基礎上成立合資企業,以「推進下一代智慧製造」。兩家公司聲稱,合資公司將使他們能夠進一步鞏固華域汽車在自動化解決方案領域的主導地位,從而使中國客戶受益。

- 此外,全球汽車產業的不斷發展也支持了汽車零件焊接、堆疊、零件插入、拾取和桶應用以及許多其他用途的工業機器人的發展。此外,2022 年 7 月,Yamaha馬達機器人公司宣布將在 Motek 2022 上展出其最新的先進自動化機器人。該公司將展示SCARA機器人、笛卡爾機器人、單軸機器人和LCMR200線性輸送機模組,突顯其速度、精確度和靈活性。

北美佔據主要市場佔有率

- 該地區的政府也正在採取舉措,協助開拓機器人市場的最新技術,以鼓勵機器人技術的採用。例如,美國聯邦政府啟動了國家機器人計畫(NRI)項目,以加強國內機器人製造能力並鼓勵該領域的研究活動。

- 2022年2月,美國鋼鐵公司與機器人及人工智慧工作室卡內基鑄造廠宣布達成戰略投資與合作關係。這兩家位於匹茲堡的新興企業將合作利用先進的機器人和人工智慧來加速和擴大工業自動化。利用這筆資金籌措,卡內基鑄造廠將在先進製造、工業機器人、整合系統、自主移動和語音分析等領域推廣和擴大其工業自動化機器人和人工智慧技術組合。

- 2022年3月,Kinova Robotics推出了加拿大首款工業協作機器人Link 6。 Link 6 是加拿大第一台採用自動化解決方案的協作工業機器人,可提高日常生產率,同時增強產品品質和一致性。 Link 6機械臂的開發和製造充分考慮了每個人的需求,無論您是經驗豐富的工業整合商還是沒有特定機器人專業知識的操作員,它都能提供長距離和高速度,從而縮短循環時間。 Kinova 的 Link 6 控制器提供市場上最高的處理能力和記憶體容量。它還支援可選的 GPU,使控制器能夠適應未來的 AI 解決方案,同時保持控制器的緊湊。

- 根據先進自動化協會(A3)統計,2021年第二季北美企業訂購了98.53億台機器人,較2020年大幅增加5,196台,帶來新的就業機會。此外,根據機器人工業協會 (RIA) 的數據,今年迄今為止工業機器人數量成長的最重要驅動力是汽車OEM為製程自動化購買的機器人數量增加了 83%。

工業機器人產業概況

工業機器人市場高度分散。工業 4.0 正在推動各個地區的數位化進程,為工業機器人市場提供了豐厚的機會。考慮到不時舉辦的機器人展覽會的數量,透明度很高。整體而言,現有參與者之間的競爭非常激烈。預計將會出現大公司和新興企業之間以創新為重點的收購和合作。市場的主要企業包括ABB和安川電機。該領域的主要發展包括:

- 2024 年 5 月:工業機器人製造商 ABB 在 Automate 2024 上推出其最新的模組化大型機器人。這些機械臂與先前發布的 IRB 5710-5720 和 IRB 6710-6740 型號一起,目前產品系列已拓展到 46 種型號。這些變體可以處理 70 至 620 公斤(約 150 至 1,350 磅)的承重能力。

- 2024 年 3 月,移動工業機器人推出最新產品-自主托盤搬運車 MiR1200。 MiR1200 托盤搬運車配備先進的 3D 視覺技術,旨在簡化勞力密集物料輸送。機器人可以動態調整其路徑,即使存在地板上鬆散的物體或頭頂上的障礙物等障礙物也能確保導航。

其他福利

- Excel 格式的市場預測 (ME) 表

- 3 個月的分析師支持

目錄

第 1 章 簡介

- 研究假設和市場定義

- 研究範圍

第2章調查方法

第3章執行摘要

第4章 市場洞察

- 市場概況

- 產業價值鏈分析

- 產業吸引力-波特五力分析

- 供應商的議價能力

- 買家的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭對手之間的競爭強度

- COVID-19 市場影響評估

第5章 市場動態

- 市場促進因素

- 更加重視職業安全

- 工業機器人新技術

- 市場限制

- 技術純熟勞工短缺

第6章 市場細分

- 按機器人類型

- 關節機器人

- 線性機器人

- 圓柱形機器人

- 並聯機器人

- SCARA機器人

- 其他機器人

- 按最終用戶產業

- 車

- 化學/製造

- 建造

- 電氣和電子

- 飲食

- 機械和金屬

- 藥品

- 其他終端用戶產業(橡膠、光學)

- 按地區

- 北美洲

- 美國

- 加拿大

- 歐洲

- 英國

- 法國

- 德國

- 亞洲

- 日本

- 中國

- 印度

- 韓國

- 澳洲和紐西蘭

- 拉丁美洲

- 中東和非洲

- 北美洲

第7章 競爭格局

- 公司簡介

- ABB Ltd.

- Yaskawa Electric Corporation

- Denso Corporation

- Fanuc Corporation

- KUKA AG

- Kawasaki Robotics

- Toshiba Corporation

- Panasonic Corporation

- Staubli Mechatronics Company

- Yamaha Robotics

- Epson Robots

- Comau SPA

- Adept Technologies

- Nachi Robotic Systems Inc.

第8章投資分析

第9章:未來市場展望

The Industrial Robotics Market size is estimated at USD 48.30 billion in 2025, and is expected to reach USD 90.57 billion by 2030, at a CAGR of 13.4% during the forecast period (2025-2030).

Key Highlights

- Industrial robots play a crucial role in manufacturing industrial automation, with many core operations in industries being managed by robots. With economic growth across regions, e-commerce, electronics, and the automotive industry, among others, have increased.

- Rising penetration of the IoT and investments in robotics across regions have been major contributors to the market's growth. For instance, the 'Made in China 2025' announcement aimed to broadly upgrade the Chinese industry by moving toward quality-focused and innovation-driven manufacturing.

- Industry 4.0, the newest industrial revolution, has fueled the development of new technologies, like collaborative robots, AI-enabled robots, etc., and has enabled industries to use robots to streamline many processes, increase efficiency, and eliminate errors. Increased workplace safety and improved production capabilities have further driven industries to invest in robotic systems.

- Owing to collaborative robots, which are estimated to account for 34% of the total robot sales in 2025 (according to the International Federation of Robots (IFR), the penetration of industrial robots is expected to rise across industries, such as plastics, food and consumer goods, semiconductors and electronics, life sciences, and pharmaceuticals. Another notable factory automation is expected at Apple's factories through Foxconn's robots. Semiconductor industry IC foundries have been among the adopters that have impacted the current market demands.

- Some of the major factors driving the market include rising demand for high-quality products (which need proper end-to-end visibility in the manufacturing process), the need for energy conservation, and rising focus on workplace safety. Incremental advancements in technology, coupled with a sustained increase in the development of manufacturing facilities, are also expected to drive this market, for instance, According to the Association for Advancing Automation (A3), which monitors industrial robot sales in North America. Companies ordered 44,196 robots in 2022, 11% more than in 2021.

Industrial Robotics Market Trends

Automotive Industry to Hold Major Share

- For the past 50 years, the automotive industry has used robots in its assembly lines for various manufacturing processes. Currently, automakers are exploring the use of robotics in more procedures. Robots are more efficient, flexible, accurate, and dependable for such production lines. This technology enables the automotive industry to remain one of the most significant robot users and possess one of the most automated supply chains globally.

- Furthermore, the growing adoption of automation in the automotive manufacturing process and the involvement of AI and digitalization are the primary factors increasing the demand for industrial robots in the automotive sector.

- In today's automotive industry, the advancement of robotics technology has accelerated to keep up with the rapid changes in the automotive industry. A robotics solution simulation and virtual commissioning will utilize the maximum benefits of factory automation for OEMs, startups, and suppliers in the present automotive industry.

- For instance, For instance, Europe's second-largest car manufacturer, PSA Group, modernizes its European manufacturing sites with Universal Robots' UR10 collaborative robots. According to UBS, around 6.3 billion electric vehicles are forecast to be sold in Europe in 2025.

- To cater to the changing landscape of automotive manufacturing, many players in the industry are adopting industrial robots. For instance, in January 2022, Huayu Automotive Systems Co., which does business as HASCO, and ABB Group announced that they have created a joint venture building on their existing relationship "to drive the next generation of smart manufacturing." The companies claimed that the joint venture would enable them to further develop HASCO's leading position with automated solutions that benefit customers in China.

- Further, the growing automotive sector worldwide supports the growth of industrial robotics for welding car parts, palletizing, part insertion, pick-and-pale applications, and many other uses. Moreover, in July 2022, Yamaha Motor Robotics announced to showcase of its latest robots for Advanced Automation at Motek 2022. The company will demonstrate SCARA, cartesian and single-axis robots, and the LCMR200 linear conveyor module, highlighting their speed, accuracy, and flexibility.

North America to Hold a Significant Market Share

- The government in the region is also encouraging the adoption of robotics by taking initiatives to support the development of modern technologies in the robotics market. For instance, the US federal government has commenced the National Robotics Initiative (NRI) program to bolster the capabilities of building domestic robots and encourage research activities in the field.

- In February 2022, United States Steel and Carnegie Foundry, a robotics and AI studio, announced a strategic investment and relationship. The two Pittsburgh-based startups will collaborate to accelerate and expand industrial automation powered by advanced robotics and artificial intelligence. Carnegie Foundry will use this funding to market and scale its industrial automation portfolio of robotics and AI technologies in advanced manufacturing, industrial robots, integrated systems, autonomous mobility, speech analytics, and other areas.

- In March 2022, Kinova Robotics introduced Link 6, Canada's first industrial collaborative robot. Link 6 is Canada's first industrial collaborative robot, with automation solutions that increase daily productivity while enhancing product quality and consistency. The Link 6 robotic arm is developed and constructed with any user in mind, both for experienced industrial integrators and operators with no particular robotic expertise, achieving quick cycle times through longer reach and fast movements. The Link 6 controller from Kinova has the market's most processing power and memory capacity. It supports an optional GPU, making it ready for use with future AI solutions while keeping the controller compact.

- Association for Advancing Automation (A3), companies in North America ordered 9,853 million robots in the second quarter of 2021, which is a significant increase compared to 2020, with 5,196 sales, leading to new job opportunities. Further, according to Robotic Industries Association (RIA), the most critical driver of the year-to-date increase in industrial robots was an 83% growth in units purchased by automotive OEMs for process automation.

Industrial Robotics Industry Overview

The industrial robotics market is highly fragmented. Industry 4.0, with digitalization initiatives across regions, provides lucrative opportunities in the industrial robots market. The degree of transparency is high, considering the number of robotic trade exhibits across conducted areas occasionally. Overall, the competitive rivalry among existing players is high. The acquisitions and collaboration of large companies with startups are predicted, focusing on innovation. A few major players in the market are ABB and Yaskawa. Some of the key developments in the area are:

- May 2024: ABB, an industrial robot manufacturer, unveiled its latest modular large robots at Automate 2024. These robot arms, in conjunction with the previously released IRB 5710-5720 and IRB 6710-6740 models, now present a lineup of 46 variants. These variants are capable of managing payloads ranging from 70 to 620 kilograms (approximately 150 to 1,350 pounds).

- March 2024: Mobile Industrial Robots has unveiled its latest product, the MiR1200 autonomous pallet jack. Equipped with advanced 3D vision technology, the MiR1200 Pallet Jack is designed to streamline labor-intensive materials handling. This robot can adapt its route dynamically, ensuring navigation even in the presence of obstacles, such as loose objects on the floor or overhead hindrances.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHT

- 4.1 Market Overview

- 4.2 Industry Value Chain Analysis

- 4.3 Industry Attractiveness - Porter's Five Forces Analysis

- 4.3.1 Bargaining Power of Suppliers

- 4.3.2 Bargaining Power of Buyers

- 4.3.3 Threat of New Entrants

- 4.3.4 Threat of Substitutes

- 4.3.5 Intensity of Competitive Rivalry

- 4.4 Assessment of the Impact of COVID-19 on the Market

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Increased Emphasis on Workplace Safety

- 5.1.2 Emerging Technologies in Industrial Robots

- 5.2 Market Restraints

- 5.2.1 Lack of Skilled Workforce

6 MARKET SEGMENTATION

- 6.1 By Type of Robot

- 6.1.1 Articulated Robots

- 6.1.2 Linear Robots

- 6.1.3 Cylindrical Robots

- 6.1.4 Parallel Robots

- 6.1.5 SCARA Robots

- 6.1.6 Other Types of Robot

- 6.2 By End-user Industry

- 6.2.1 Automotive

- 6.2.2 Chemical and Manufacturing

- 6.2.3 Construction

- 6.2.4 Electrical and Electronics

- 6.2.5 Food and Beverage

- 6.2.6 Machinery and Metal

- 6.2.7 Pharmaceutical

- 6.2.8 Other End-user Industries (Rubber, Optics)

- 6.3 By Geography

- 6.3.1 North America

- 6.3.1.1 United States

- 6.3.1.2 Canada

- 6.3.2 Europe

- 6.3.2.1 United Kingdom

- 6.3.2.2 France

- 6.3.2.3 Germany

- 6.3.3 Asia

- 6.3.3.1 Japan

- 6.3.3.2 China

- 6.3.3.3 India

- 6.3.3.4 South Korea

- 6.3.4 Australia and New Zealand

- 6.3.5 Latin America

- 6.3.6 Middle East and Africa

- 6.3.1 North America

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 ABB Ltd.

- 7.1.2 Yaskawa Electric Corporation

- 7.1.3 Denso Corporation

- 7.1.4 Fanuc Corporation

- 7.1.5 KUKA AG

- 7.1.6 Kawasaki Robotics

- 7.1.7 Toshiba Corporation

- 7.1.8 Panasonic Corporation

- 7.1.9 Staubli Mechatronics Company

- 7.1.10 Yamaha Robotics

- 7.1.11 Epson Robots

- 7.1.12 Comau SPA

- 7.1.13 Adept Technologies

- 7.1.14 Nachi Robotic Systems Inc.