|

市場調查報告書

商品編碼

1640357

亞太地區藥品包裝:市場佔有率分析、產業趨勢與成長預測(2025-2030)Asia Pacific Pharmaceutical Packaging - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

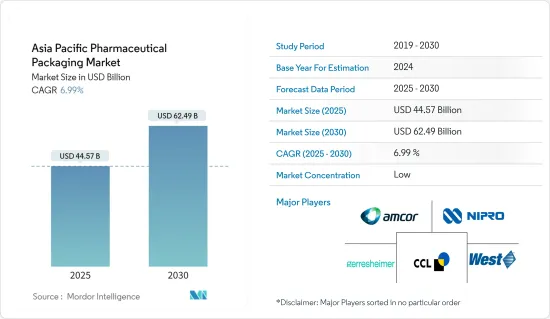

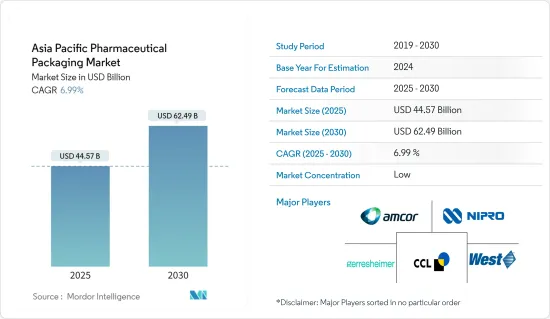

亞太地區藥品包裝市場規模預估至2025年為445.7億美元,預估至2030年將達624.9億美元,預測期間內(2025-2030年)複合年成長率為6.99%。

主要亮點

- 藥品包裝是容納、維護、保護和分發安全有效的藥品所必需的要素的集合,確保在藥品有效期之前隨時獲得安全有效的劑型。適當的包裝材料對於提供防篡改安全至關重要,這有助於阻止假藥的消費。此外,優質包裝材料必須符合嚴格的監管準則。

- 由於製藥業投資的增加,預計藥品包裝製造商將在亞太地區看到龐大的商機。對藥品的需求不斷成長以及製藥技術的進步直接推動了對玻璃瓶、安瓿和其他玻璃包裝解決方案的需求。隨著慢性病發病率持續上升以及 COVID-19 疫苗產量仍然很高,對初級包裝(尤其是玻璃容器)的需求預計將激增。

- 玻璃包裝預計將推動該地區藥品包裝領域的市場成長。製藥公司使用玻璃容器來包裝各種藥品,包括注射劑、口服固態、液體製劑和生技藥品。玻璃容器和包裝快速成長的因素包括藥品製造業務、特種藥品需求的增加以及醫療基礎設施的擴張。這一趨勢在中國、印度、日本和韓國等國家尤其明顯,這些國家的製藥業正經歷顯著成長,對玻璃包裝解決方案的需求也迅速增加。

- 預計塑膠瓶產業在未來幾年將經歷顯著成長。該地區 PET 的使用量正在穩步增加,與玻璃相比,重量減輕高達 90%,從而實現更具成本效益的運輸。目前,在製藥領域,由 PET 製成的塑膠瓶正在取代笨重而精緻的玻璃瓶,為各種液體提供可重複使用的包裝。製藥業塑膠 PET 技術的進步預計將提振市場前景。

- 此外,政府加強該地區製藥業的措施預計將推動市場擴張。例如,中國政府為促進國家醫療保健系統現代化而採取的措施預計將刺激藥品包裝行業的進步。此外,中國正在積極改善藥品包裝基礎設施和資源,同時增加藥品種類,這將為藥品包裝企業開闢新的途徑。

- 中國在全球醫藥市場的佔有率穩步提升,成為消費大國和全球醫藥產業和供應鏈的重要組成部分。近年來,在科學技術進步的推動下,製藥業的快速擴張預計將持續下去。 2023 年 12 月,丹麥製藥公司諾和諾德透露,計劃在 2026 年 6 月在該地區投資 4 億元人民幣(5,960 萬美元)新公司。這些重大發展預計將推動對藥品包裝服務的需求。

- 包裝產業受到 COVID-19 大流行的嚴重影響。重點轉向感染疾病和疫苗減少了糖尿病和高血壓等治療領域成功的臨床試驗和研發工作。然而,在疫情期間,製藥業對各種疾病的藥品需求激增,導致包裝業務的大量投資。幸運的是,製藥業透過強調安全衛生包裝的需求來應對這場流行病,從而迅速復甦。

亞太地區藥品包裝市場趨勢

玻璃包裝預計將顯著成長

- 玻璃包裝被廣泛認為是包裝行業醫藥產品的主要選擇。它的受歡迎是由於它的永續性品質、惰性、不滲透性、可回收性以及在不影響品質的情況下重複使用的能力。由於藥物需求大幅增加,COVID-19 大流行進一步刺激了對玻璃包裝的需求。隨著世界各地的製藥商核准和分銷新藥和疫苗,玻璃包裝的使用預計將繼續擴大。

- 玻璃包裝主要作為藥品的主要包裝選擇,使其成為製藥業的首選。其主要原因是其具有永續性、惰性、不滲透性、可回收而不損失品質以及可重複使用等優點。玻璃容器作為主要包裝材料之一已廣泛應用於製藥領域。隨著慢性病盛行率的增加和 COVID-19 疫苗產量的持續增加,對初級包裝(尤其是玻璃容器)的需求預計將激增。

- 亞太地區慢性病盛行率的上升是推動藥品包裝市場擴張的關鍵因素。糖尿病、心血管疾病、癌症、呼吸系統疾病等疾病需持續用藥。因此,人們越來越需要各種藥品包裝解決方案,以最佳效率安全地儲存、保護和分發這些藥品。據世界衛生組織(WHO)稱,非傳染性疾病的增加導致該地區,特別是中東和非洲的慢性病負擔日益加重。

- Stoelzle 是一家初級包裝玻璃解決方案製造商,於 2023 年 11 月在 CPHI 巴塞隆納貿易展覽會上推出了其最新的環保 PharmaCos 系列。這個新的包裝解決方案系列採用了高比例的回收玻璃(73% 琥珀色玻璃和 38% 火石玻璃)和輕質瓶子設計。此外,這條新生產線是在製藥級設施中生產的,以滿足醫療產業的嚴格標準。供應商的此類重大創新預計將推動市場成長。

- 根據Bormioli Pharma介紹,目前市面上有多種專門針對II型和III型玻璃設計的再生玻璃產品。這些產品使用的材料來自外部供應鏈,並經過製藥用途認證。透過化學和機械加工,回收材料轉化為玻璃粉末,形成新生產週期的基礎。同時,Bormioli Pharma 正在積極進行低排放氣體反應器開發計劃。這些熔爐採用創新技術和工業流程,最大限度地減少我們的環境足跡。

- 此外,日本等國家的玻璃包裝技術市場預計將受到製藥商為提高藥品生產而增加投資的推動。一個著名的例子是武田公司於 2023 年 3 月宣布計劃投資約 1,000 億日圓(7.5 億美元)在大阪建造一座新的血漿衍生療法 (PDT) 生產設施。這項投資標誌著武田在日本有史以來最大規模的產能擴張。這座最先進的設施計劃於 2030 年投入運作,將是日本同類設施中最大的,並將顯著提高武田的等離子體製造能力。

印度預計將出現顯著成長

- 印度預計將成為藥品包裝市場成長最快的地區之一。近年來,由於技術創新和新療法的興起,藥品包裝領域經歷了顯著成長。 COVID-19 大流行的爆發凸顯了高效產品包裝和分銷的重要性。因此,人們越來越重視加速製造和分銷流程,包括包裝。因此,隨著對更快操作的需求不斷增加,包裝公司被迫快速創新。

- 印度預計將成為製藥業的主要企業,特別是在學名藥和具有成本效益的藥品生產領域。作為許多已開發國家學名藥的主要供應國,中國發揮著重要作用。學名藥生產和國際分銷的增加是推動印度醫藥包裝產業擴張的關鍵因素。此外,慢性病的快速增加和藥品生產業務投資的增加將導致市場需求大幅增加。

- 該地區對塑膠包裝類型的需求預計將大幅增加。對醫療用品和藥品的需求迅速成長正在推動印度塑膠藥品包裝的擴張。許多公司正在大力投資這項技術,以增加該地區的市場潛力。例如,2023年3月,西班牙包裝公司Inden Pharma打算透過與專門從事藥品塑膠包裝的奧地利ALPLApharma合作擴大在印度的業務。這些顯著的進步預計將推動市場成長。

- 根據InvestIndia的報告顯示,印度是全球最大的學名藥供應國,佔全球供應量的20%。此外,印度也是世界上最大的疫苗生產國。除美國外,印度還擁有最多符合美國食品藥物管理局(US FDA)制定標準的製藥廠。印度擁有 3,000 多家製藥公司和 10,500 多個生產設施,在製藥業擁有強大的網路和高技能的勞動力。此外,印度滿足全球約60%的疫苗需求,也是百白破、卡介苗和麻疹疫苗的主要供應國。藥品製造領域的廣泛能力必將刺激該地區的包裝業務市場。

- 此外,據InvestIndia稱,2018-22會計年度印度製藥業平均成長率為9.47%,達到423.4億美元,主要得益於出口增加和國內市場成長。據預測,2024年醫藥產業產值預計將達650億美元,2030年將達1,200億美元。為了確保永續成長,政府實施了各種舉措來促進研究和創新。作為 2047 年願景的一部分,政府的目標是按照 Vasudhaiva Kutumbakam 的原則,將印度打造成負擔得起的、創新的和高品質的藥品和醫療設備的全球領導者。此類重大發展預計將為包裝領域提供市場發展機會。

亞太地區藥品包裝產業概況

亞太地區藥品包裝市場與許多地區和全球參與企業競爭激烈。主要參與企業包括 Amcor Ltd.、West Pharmaceutical Services Inc.、CCL Industries Inc. 和 NIPRO Corporation。公司透過推出新產品和擴大生產單位來增加市場佔有率。我想宣布一些最近的趨勢。

- 2024 年 1 月,Loop Industries Inc. 成立,這是一家乾淨科技公司,其使命是透過生產 100% 再生聚對苯二甲酸乙二醇酯 (“PET”) 樹脂和聚酯纖維以及藥品包裝和醫療設備。

- 2023 年 6 月,CIncorporated 與 SGD Pharma 合作,在 Telangana 建立了一家最先進的工廠,生產用於藥品包裝的玻璃。據悉,兩家公司將共同投資超過50億印度盧比建造該工廠。與康寧的合作是改善加工技術和確保製藥業強大供應鏈的重要一步。兩家公司共同致力於幫助製藥商應對日益成長的產能和品質挑戰,並滿足全球對基本藥物不斷成長的需求。

其他好處

- Excel 格式的市場預測 (ME) 表

- 3 個月分析師支持

目錄

第1章簡介

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章市場動態

- 市場概況

- 產業價值鏈分析

- 產業吸引力-波特五力分析

- 供應商的議價能力

- 消費者議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭公司之間的敵對關係

- 市場促進因素

- 新興國家越來越多採用藥品包裝

- 市場限制因素

- 原料成本波動

第5章市場區隔

- 按材質

- 塑膠

- 紙板

- 玻璃

- 鋁箔

- 按類型

- 安瓿

- 泡殼包裝

- 塑膠瓶

- 注射器

- 管瓶

- 點滴

- 其他

- 按給藥方式分

- 口服藥品包裝

- 注射包裝

- 肺部藥物包裝

- 其他

- 按國家/地區

- 印度

- 日本

- 中國

- 澳洲

- 其他亞太地區

第6章 競爭狀況

- 公司簡介

- Amcor Ltd

- CCL Industries Inc.

- West Pharmaceutical Services Inc.

- Gerresheimer AG

- Schott AG

- NIPRO Corporation

- Wihuri Group

- Klockner Pentaplast Group

- Catalent Pharma Solutions Inc.

- Berry Global Group Inc.

第7章 投資分析

第8章市場的未來

The Asia Pacific Pharmaceutical Packaging Market size is estimated at USD 44.57 billion in 2025, and is expected to reach USD 62.49 billion by 2030, at a CAGR of 6.99% during the forecast period (2025-2030).

Key Highlights

- Pharmaceutical packaging involves the assembly of elements required to enclose, maintain, safeguard, and distribute a secure and effective medicinal product, ensuring that a secure and effective dosage form is accessible at any given time prior to the drug product's expiration date. Appropriate packaging materials are essential for offering tamper-evident security, which aids in deterring the consumption of counterfeit medications. Furthermore, premium packaging materials must comply with rigorous regulatory guidelines.

- The pharmaceutical packaging manufacturers are anticipated to witness significant opportunities in Asia-Pacific, thanks to the increasing investments in the pharmaceutical sector. The rising demand for pharmaceutical drugs and advancements in pharmaceutical technology are directly contributing to the demand for glass bottles, ampules, and other glass packaging solutions. As chronic illnesses continue to rise and the production of COVID-19 vaccine doses remains substantial, the demand for primary packaging is expected to surge, specifically for glass containers.

- Glass packaging is expected to drive the market's growth in the region's pharma packaging sector. Pharmaceutical companies utilize glass containers to package a diverse array of pharmaceutical products, including injectable medications, solid oral pills, liquid formulations, and biologics. The rapid growth of glass packaging is driven by factors such as pharmaceutical manufacturing operations, the rising demand for specialty pharmaceuticals, and the expansion of healthcare infrastructure. This trend is particularly evident in countries like China, India, Japan, and South Korea, where pharmaceutical industries are experiencing significant growth, leading to a surge in demand for glass packaging solutions.

- The plastic bottles industry is projected to experience substantial growth in the coming years. The utilization of PET is steadily increasing in the region, resulting in a weight reduction of up to 90% compared to glass, thus enabling a more cost-effective transportation procedure. Presently, plastic bottles crafted from PET are extensively substituting bulky and delicate glass bottles in the pharmaceutical sector, providing reusable packaging for different liquids. The rising advancements in plastic PET technology for the pharmaceutical industry are anticipated to boost market prospects.

- Additionally, the government's initiatives to enhance the pharmaceutical sector in the area are anticipated to propel the market's expansion. For example, the measures implemented by the Chinese government to expedite the modernization of the nation's healthcare system are projected to stimulate the advancement of the pharmaceutical packaging industry. Moreover, China is proactively improving its pharmaceutical packaging infrastructure and resources while broadening its range of pharmaceutical products, potentially opening up new avenues for pharmaceutical packaging companies.

- China's presence in the global pharmaceutical market has been steadily growing, serving as both a major consumer and a vital component in the global pharmaceutical industry and supply chains. The rapid expansion of the pharmaceutical sector in recent years, driven by scientific and technological advancements, is projected to continue in the future. In December 2023, Danish pharmaceutical firm Novo Nordisk revealed its plan to invest CNY 400 million (USD 59.6 million) in a newly established company in the region by June 2026. These substantial developments are anticipated to drive the demand for pharmaceutical packaging services.

- The packaging industry experienced significant effects due to the COVID-19 pandemic. With a shift in focus toward infectious diseases and vaccines, there was a decrease in successful clinical trials and research and development activities in therapeutic areas like diabetes and hypertension. However, the pharmaceutical industry witnessed a surge in drug demand for various diseases during the pandemic, leading to substantial investments in the packaging business. Fortunately, the pharmaceutical industry quickly recovered by emphasizing the need for safe and hygienic packaging in response to the pandemic.

Asia Pacific Pharmaceutical Packaging Market Trends

Glass Packaging is Expected to Witness Significant Growth

- Glass packaging is widely considered the leading choice for pharmaceutical products in the packaging industry. Its popularity stems from its sustainable nature, inertness, impermeability, recyclability, and ability to be reused without compromising quality. The COVID-19 pandemic further fueled the demand for glass packaging as the need for medication significantly increased. With the approval and distribution of new drugs and vaccines by pharmaceutical manufacturers in various countries, the use of glass packaging is expected to continue expanding.

- Glass packaging is primarily provided as the main packaging option for pharmaceutical products and is one of the top choices in the pharmaceutical industry. This is mainly because it offers several advantages, including sustainability, inertness, impermeability, recyclability without any compromise in quality, and reusability. Glass containers have become widely utilized in the pharmaceutical sector as one of the primary packaging materials. As the prevalence of chronic diseases increases and the production of COVID-19 vaccine doses continues to rise, there is an anticipated surge in the demand for primary packaging, specifically glass containers.

- The increasing prevalence of chronic diseases in the APAC region is a major factor driving the expansion of the pharmaceutical packaging market. Conditions such as diabetes, cardiovascular diseases, cancer, and respiratory ailments necessitate continuous medication. As a result, there is a rising need for diverse pharmaceutical packaging solutions to securely store, safeguard, and distribute these medications with optimal efficiency. As per the World Health Organization (WHO), the rise in noncommunicable diseases is contributing to the escalating burden of chronic illnesses in the region, especially in the SEA region.

- The primary packaging glass solutions manufacturer, Stoelzle, unveiled their latest eco-friendly PharmaCos line at the CPHI Barcelona trade show in November 2023. This new line of packaging solutions boasts a high percentage of recycled glass (73% in amber glass and 38% in flint glass) and lightweight bottle design. Additionally, the new line is produced in a pharmaceutical-grade facility to meet the strict standards of the healthcare industry. Such significant innovations by the vendors are expected to drive the market's growth.

- Bormioli Pharma states that currently, various recycled glass products are available specifically designed for type II and type III glass. These products utilize materials sourced from an external supply chain that is certified for pharmaceutical use. Through chemical and mechanical processing, the recycled materials can be transformed into glass powder, which serves as the foundation for the new production cycle. Simultaneously, Bormioli Pharma is actively involved in projects aimed at developing low-emission furnaces. These furnaces incorporate innovative technologies and industrial processes that minimize their environmental footprint.

- Moreover, the market for glass packaging techniques in countries like Japan will be driven by the increasing investments made by pharmaceutical vendors to enhance pharmaceutical production. A notable example is Takeda's announcement in March 2023, stating its plan to invest approximately JPY 100 billion (USD 0.75 billion) in constructing a new manufacturing facility for plasma-derived therapies (PDTs) in Osaka, Japan. This investment represents Takeda's largest-ever expansion of manufacturing capacity in Japan. The upcoming state-of-the-art facility, expected to be operational by 2030, will be the largest of its kind in the country and will significantly increase Takeda's plasma manufacturing capacity.

India is Expected to Witness Significant Growth

- India is expected to be one of the fastest-growing regions in the pharmaceutical packaging market. The pharmaceutical packaging sector has witnessed significant growth in recent years, driven by innovations and the rise of new treatments. The onset of the COVID-19 pandemic underscored the importance of efficient product packaging and distribution. As a result, there's a growing emphasis on accelerating both manufacturing and distribution processes, including packaging. Consequently, packaging firms are under mounting pressure to innovate swiftly, meeting the demand for faster operations.

- India is anticipated to emerge as a key player in the pharmaceutical sector, especially in the production of generic drugs and cost-effective medication. The country plays a vital role as a primary provider of generic medicines to numerous advanced nations. The rising output and international distribution of generic drugs are significant factors driving the expansion of the Indian pharmaceutical packaging industry. Additionally, the surge in chronic illnesses and the rise in investments in drug manufacturing operations will lead to a substantial increase in demand within the market.

- The region is anticipated to experience a notable increase in demand for plastic packaging types. The surge in the need for medical supplies and medications has propelled the expansion of plastic pharma packaging in India. Numerous companies are making substantial investments in this technology to enhance the region's market potential. For instance, in March 2023, Spanish packaging company Inden Pharma intended to broaden its operations in India through a partnership with Austria-based ALPLApharma, which specializes in plastic packaging for pharmaceuticals. These noteworthy advancements are projected to stimulate growth in the market.

- InvestIndia reports that India is the largest global provider of generic medicines, making up 20% of the global supply by volume. Additionally, India is the top producer of vaccines worldwide. Outside of the United States, India has the highest number of pharmaceutical plants that comply with the standards set by the US Food and Drug Administration (US FDA). With over 3,000 pharmaceutical companies and more than 10,500 manufacturing facilities, India possesses a robust network and a highly skilled workforce in the pharmaceutical industry. Moreover, India fulfills approximately 60% of the global demand for vaccines and is a major supplier of DPT, BCG, and Measles vaccines. These extensive capabilities in pharmaceutical manufacturing will undoubtedly stimulate the packaging business market in the region.

- Moreover, InvestIndia states that the Indian pharmaceutical industry experienced an average growth rate of 9.47% from FY18 to FY22, reaching USD 42.34 Billion, mainly due to increased exports and a growing domestic market. Forecasts suggest that the pharma sector is expected to reach a value of USD 65 billion in 2024 and USD 120 billion in 2030. To ensure sustained growth, the government has implemented various initiatives to promote research and innovation. As part of its vision for 2047, the government aims to establish India as a global leader in producing affordable, innovative, and high-quality pharmaceuticals and medical devices, in line with the principle of Vasudhaiva Kutumbakam. Such significant developments will provide market opportunities in the packaging sector.

Asia Pacific Pharmaceutical Packaging Industry Overview

The Asia-Pacific pharmaceutical packaging market is competitive, with many regional and global players. Some major players are Amcor Ltd, West Pharmaceutical Services Inc., West Pharmaceutical Services Inc., CCL Industries Inc., and NIPRO Corporation. Companies are increasing their market share by launching new products and expanding production units. Some of the recent developments are:

- January 2024: Loop Industries Inc., a clean technology company whose mission is to accelerate a circular plastics economy by manufacturing 100% recycled polyethylene terephthalate ("PET") plastic and polyester fiber, and Bormioli Pharma, an international player in pharmaceutical packaging and medical devices, launched an innovative pharmaceutical packaging bottle manufactured with 100% recycled virgin quality Loop PET resin.

- June 2023: CIncorporated partnered with SGD Pharma to establish a state-of-the-art facility for producing pharmaceutical packaging glass in Telangana. It was reported that the two companies would collectively invest more than INR 500 crore in setting up this facility. This collaboration with Corning is a significant move in advancing converting technology within the pharmaceutical sector and ensuring a robust supply chain. By working together, these companies aim to assist pharmaceutical manufacturers in addressing the growing challenges related to capacity and quality, as well as meeting the rising global demand for essential medications.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumption and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Market Overview

- 4.2 Industry Value Chain Analysis

- 4.3 Industry Attractiveness - Porter's Five Forces Analysis

- 4.3.1 Bargaining Power of Supplier

- 4.3.2 Bargaining Power of Consumers

- 4.3.3 Threat of New Entrants

- 4.3.4 Threat of Substitute Products

- 4.3.5 Intensity of Competitive Rivalry

- 4.4 Market Drivers

- 4.4.1 Increasing Adoption of Pharmaceutical Packaging in Emerging Economies

- 4.5 Market Restraints

- 4.5.1 Fluctuations in Raw Material Cost

5 MARKET SEGMENTATION

- 5.1 By Material

- 5.1.1 Plastic

- 5.1.2 Paper and Paper Board

- 5.1.3 Glass

- 5.1.4 Aluminum Foil

- 5.2 By Type

- 5.2.1 Ampoules

- 5.2.2 Blister Packs

- 5.2.3 Plastic Bottles

- 5.2.4 Syringes

- 5.2.5 Vials

- 5.2.6 IV fluids

- 5.2.7 Other Types

- 5.3 By Drug Delivery Mode

- 5.3.1 Oral Drug packaging

- 5.3.2 Injectable Drug packaging

- 5.3.3 Pulmonary Drug Packaging

- 5.3.4 Other Drug Delivery Modes

- 5.4 By Country

- 5.4.1 India

- 5.4.2 Japan

- 5.4.3 China

- 5.4.4 Australia

- 5.4.5 Rest of Asia-Pacific

6 COMPETITIVE LANDSCAPE

- 6.1 Company Profiles

- 6.1.1 Amcor Ltd

- 6.1.2 CCL Industries Inc.

- 6.1.3 West Pharmaceutical Services Inc.

- 6.1.4 Gerresheimer AG

- 6.1.5 Schott AG

- 6.1.6 NIPRO Corporation

- 6.1.7 Wihuri Group

- 6.1.8 Klockner Pentaplast Group

- 6.1.9 Catalent Pharma Solutions Inc.

- 6.1.10 Berry Global Group Inc.