|

市場調查報告書

商品編碼

1640406

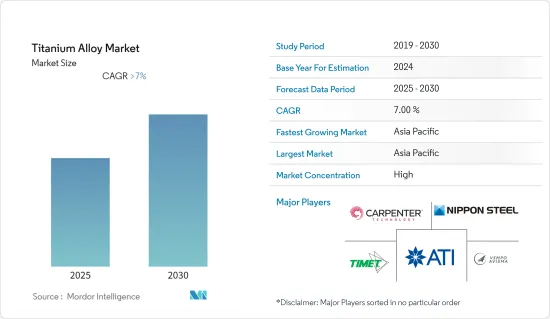

鈦合金 -市場佔有率分析、產業趨勢/統計、成長預測(2025-2030)Titanium Alloy - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

價格

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

簡介目錄

預計鈦合金市場在預測期內複合年成長率將超過7%。

儘管疫情對市場產生了負面影響,但該市場已於 2021 年恢復,預計在預測期內將進一步成長。

主要亮點

- 短期來看,鈦合金在航太領域的應用不斷擴大,以及戰車對鈦合金取代鋼和鋁的需求不斷增加,是市場成長的主要動力。

- 另一方面,合金的高反應活性在生產過程中需要特別小心。預計這將成為限制市場的因素。

- 此外,創新產品的開發預計在預測期內對市場來說是個好兆頭。

- 中國在亞太地區市場佔據主導地位,預計在預測期內將繼續佔據主導地位。這一優勢得益於化工、高階航太、汽車、醫療和環保領域的需求增加。

鈦合金市場趨勢

航太業對鈦合金的需求增加

- 鈦是航太工業最重要的原料之一。鈦合金在航太材料市場中佔據最大佔有率,其次是鋁合金。

- 考慮到原料的重量,鈦合金是航太工業中第三重要的原料。大約75%的高檔海綿鈦用於航太工業。用於飛機引擎、葉片、軸心和機身應用(起落架、緊固件、翼梁)。

- 此外,鈦合金可在從冰點以下到 600 攝氏度以上的惡劣溫度下使用,這使得它們可用於飛機引擎箱和其他應用。其高強度和低密度使其非常適合在飛機上使用。飛機領域,Ti-6Al-4V合金應用最多。

- 波音和空中巴士是世界頂尖的兩家公司,從事飛機、噴射機、直升機等製造。因此,這些企業是航太領域鈦合金的主要消費者。 2021年,空中巴士訂單。相較之下,波音公司收到的 771 架飛機訂單總額比 2020 年加倍。

- 此外,根據國際航空運輸協會(IATA)的數據,2020年全球商業航空公司收入為3,730億美元,預計2021年將達到4,720億美元,與前一年同期比較增26.7%。此外,預計到2022年將達到6,580億美元。這些因素可能會增加未來幾年航太零件製造對鈦合金的需求。

- 飛機製造商目前正在尋找加快生產的方法,以填補積壓訂單。例如,波音《2022-2041 年商業展望》預計,到 2041 年,全球新飛機交付總量將達到 41,170 架。截至 2019 年,全球飛機持有約為 25,900 架,到 2041 年可能會達到 47,080 架。

中國主導亞太

- 中國在亞太鈦合金市場佔據主導地位,由於化學、高階航太、醫療和環保領域的需求不斷增加,預計這種情況在預測期內將持續下去。

- 中國新疆新材和朝陽百盛新生產設施的推出預計將在提高鈦產量方面發揮重要作用。

- 中國航太工業對鈦合金的需求主要是由中國航太製造活動的成長所推動的。航太是該國的優先產業,政府正在投入巨額投資以提高國內製造能力。

- 中國的航太政策是進入航太研發生產頂級水準的最全面的嘗試之一。預計未來20年中國將成為全球最大的民航機銷售單一國家市場。例如,根據波音公司《2022-2041年商業展望》,到2041年,中國將交付約8,485架新飛機,市場服務價值將達5,450億美元。

- 此外,鈦在汽車工業中也用於連桿、引擎閥門、渦輪增壓器輪、排氣系統和懸吊彈簧等應用。無論從年銷量或製造產量來看,中國仍是全球最大的汽車市場。根據OICA(國際汽車製造商組織)預測,2021年中國汽車產量將達2,609萬輛,比2020年同期成長3%。

鈦合金產業概況

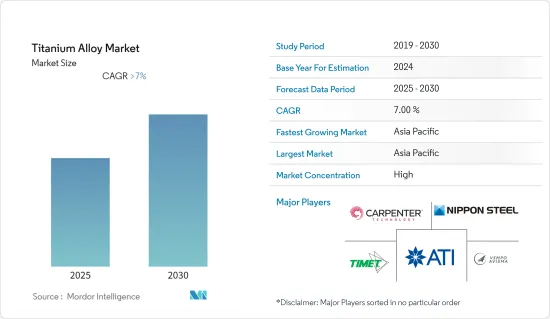

鈦合金市場細分為:主要企業(排名不分先後)包括 VSMPO-AVISMA Corporation、NIPPON STEEL CORPORATION、Allegheny Technologies Inc. (ATI)、TIMET (Precision Castparts Corp.) 和 CRS Holdings, LLC。

其他好處

- Excel 格式的市場預測 (ME) 表

- 3 個月分析師支持

目錄

第1章簡介

- 調查先決條件

- 調查範圍

第2章調查方法

第3章執行摘要

第4章市場動態

- 促進因素

- 擴大鈦合金在航太領域的應用

- 戰車對鈦合金替代鋼和鋁的需求增加

- 抑制因素

- 由於合金的高反應活性,在製造過程中需要特別小心

- 其他限制

- 產業價值鏈分析

- 波特五力分析

- 供應商的議價能力

- 消費者議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭程度

第5章市場區隔(市場規模(基於數量))

- 按微觀結構分

- 阿爾法和近阿爾法合金

- αBETA合金

- BETA合金

- 按最終用戶產業

- 航太

- 汽車/造船

- 化學

- 電力和海水淡化

- 其他

- 按地區

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 其他亞太地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 德國

- 英國

- 義大利

- 法國

- 歐洲其他地區

- 其他

- 南美洲

- 中東/非洲

- 亞太地區

第6章 競爭狀況

- 併購、合資、聯盟、協議

- 市場佔有率(%)**/排名分析

- 主要企業策略

- 公司簡介

- AMG Advanced Metallurgical Group NV

- ATI

- BRISMET

- CRS Holdings, LLC.

- Daido Steel Co., Ltd.

- Eramet

- Hermith GmbH

- Howmet Aerospace

- KOBE STEEL, LTD.

- M/s Bansal Brothers

- Mishra Dhatu Nigam Limited

- Perryman Company

- TIMET(Precision Castparts Corp.)

- Toho Titanium Co., Ltd.

- VSMPO-AVISMA Corporation

- Weber Metals(OTTO FUCHS COMPANY)

第7章市場機會與未來趨勢

- 創新產品開發

簡介目錄

Product Code: 52580

The Titanium Alloy Market is expected to register a CAGR of greater than 7% during the forecast period.

The pandemic had a negative effect on the market, which recovered in 2021 and is expected to grow further in the forecast period.

Key Highlights

- Over the short term, the market's growth is majorly driven by the growing usage of titanium alloys in the aerospace sector and increasing demand for titanium alloys for combat vehicles to replace steel and aluminum.

- On the flip side, the high reactivity of the alloy demands specialized care during production. This is expected to act as a restraint for the market.

- Furthermore, innovative product development will likely be an opportunity for the market during the forecast period.

- China dominates the market in the Asia-Pacific region, and it is expected to continue to do so during the forecast period. This dominance is attributed to the increasing demand from the chemical, high-end aerospace, automotive, medical, and environmental protection sectors.

Titanium Alloy Market Trends

Increasing Demand of Titanium Alloys in the Aerospace Industry

- Titanium is one of the most important raw materials for the aerospace industry. Titanium alloys account for the largest share of the aerospace raw material market, closely followed by aluminum alloys.

- Titanium alloys form the third-most important raw materials used in the aerospace industry when considering the weight of raw materials. Around 75% of the high-grade titanium sponge is used in the aerospace industry. It is used in aircraft engines, blades, shafts, and airframe applications (landing gear, fasteners, and wing beams).

- Furthermore, the ability of titanium alloys to operate at severe temperatures ranging from sub-zero to over 600°C makes them valuable in aircraft engine casings and other uses. They are perfect for usage in airframes due to their great strength and low density. The aircraft sector uses Ti-6Al-4V alloys the most.

- The top two companies in the world, Boeing and Airbus, are engaged in producing airplanes, jets, helicopters, etc. Therefore, these companies are the major consumers of titanium alloys in the aerospace industry. In 2021, Airbus took gross orders for 909 aircraft. In comparison, Boeing earned 771 gross orders, a twofold increase from 2020.

- Furthermore, according to the International Air Transport Association (IATA), the global revenue for commercial airlines was valued at USD 373 billion in 2020 and was estimated at USD 472 billion in 2021, registering a growth rate of 26.7% Y-o-Y. Furthermore, the revenue was expected to reach USD 658 billion by 2022. Such factors are likely to increase the demand for titanium alloy from aerospace parts manufacturing, in the years to come.

- Aircraft manufacturers are now looking for ways to accelerate production to fill order backlogs. For instance, according to the Boeing Commercial Outlook 2022-2041, the total global deliveries of new airplanes are estimated to be 41,170 by 2041. The global airplane fleet amounted to around 25,900 units as of the year 2019 and the fleet number is likely to reach 47,080 units by 2041.

China to Dominate the Asia-Pacific Region

- China dominates the titanium alloy market in the Asia-Pacific region, which is expected to continue during the forecast period, owing to the increasing demand from the chemical, high-end aerospace, medical, and environmental protection sectors.

- The launch of new production facilities by Xinjiang New Material Co. Ltd and Chaoyang Baisheng Co. Ltd in China is expected to have a major role in boosting the production rate of titanium.

- The demand for titanium alloy in the aerospace industry in China is mainly driven by the growing manufacturing activities of the aerospace industry in the country. Aerospace is a priority industry for the country, with the government investing huge amounts to increase its domestic manufacturing capabilities.

- The Chinese aerospace policy represents one of the most comprehensive attempts to enter the top levels of aerospace development and production. China is expected to be the world's largest singlecountry market for civil aircraft sales over the next 20 years. For instance, in China, according to the Boeing Commercial Outlook 2022-2041, around 8,485 new deliveries will be made by 2041 with a market service value of USD 545 billion.

- Furthermore, titanium is used in the automotive industry for applications in connecting rods, engine valves, turbo charger wheels, exhaust systems, and suspension springs, among others. China continues to be the world's largest automotive market by both annual sales and manufacturing output. According to OICA (The Organisation Internationale des Constructeurs d'Automobiles), the vehicle production of China reached a total of 26.09 million units in 2021 which is an increase of 3% over 2020 for the same period.

Titanium Alloy Industry Overview

The titanium alloy market is partially fragmented. The major companies (not in particular order) include VSMPO-AVISMA Corporation, NIPPON STEEL CORPORATION, Allegheny Technologies Inc. (ATI), TIMET (Precision Castparts Corp.), and CRS Holdings, LLC.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Drivers

- 4.1.1 Growing Usage of Titanium Alloys in the Aerospace Sector

- 4.1.2 Increasing Demand for Titanium Alloys for Combat Vehicles to Replace Steel and Aluminum

- 4.2 Restraints

- 4.2.1 High Reactivity of Alloy Demands Specialized Care During Production

- 4.2.2 Other Restraints

- 4.3 Industry Value Chain Analysis

- 4.4 Porter's Five Forces Analysis

- 4.4.1 Bargaining Power of Suppliers

- 4.4.2 Bargaining Power of Consumers

- 4.4.3 Threat of New Entrants

- 4.4.4 Threat of Substitute Products and Services

- 4.4.5 Degree of Competition

5 MARKET SEGMENTATION (Market Size in Volume)

- 5.1 By Microstructure

- 5.1.1 Alpha and Near-alpha Alloy

- 5.1.2 Alpha-beta Alloy

- 5.1.3 Beta Alloy

- 5.2 By End-user Industry

- 5.2.1 Aerospace

- 5.2.2 Automotive and Shipbuilding

- 5.2.3 Chemical

- 5.2.4 Power and Desalination

- 5.2.5 Other End-user Industries

- 5.3 By Geography

- 5.3.1 Asia-Pacific

- 5.3.1.1 China

- 5.3.1.2 India

- 5.3.1.3 Japan

- 5.3.1.4 South Korea

- 5.3.1.5 Rest of Asia-Pacific

- 5.3.2 North America

- 5.3.2.1 United States

- 5.3.2.2 Canada

- 5.3.2.3 Mexico

- 5.3.3 Europe

- 5.3.3.1 Germany

- 5.3.3.2 United Kingdom

- 5.3.3.3 Italy

- 5.3.3.4 France

- 5.3.3.5 Rest of Europe

- 5.3.4 Rest of the World

- 5.3.4.1 South America

- 5.3.4.2 Middle-East and Africa

- 5.3.1 Asia-Pacific

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers and Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Market Share(%)**/Ranking Analysis

- 6.3 Strategies Adopted by Leading Players

- 6.4 Company Profiles

- 6.4.1 AMG Advanced Metallurgical Group N.V.

- 6.4.2 ATI

- 6.4.3 BRISMET

- 6.4.4 CRS Holdings, LLC.

- 6.4.5 Daido Steel Co., Ltd.

- 6.4.6 Eramet

- 6.4.7 Hermith GmbH

- 6.4.8 Howmet Aerospace

- 6.4.9 KOBE STEEL, LTD.

- 6.4.10 M/s Bansal Brothers

- 6.4.11 Mishra Dhatu Nigam Limited

- 6.4.12 Perryman Company

- 6.4.13 TIMET (Precision Castparts Corp.)

- 6.4.14 Toho Titanium Co., Ltd.

- 6.4.15 VSMPO-AVISMA Corporation

- 6.4.16 Weber Metals (OTTO FUCHS COMPANY)

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 Innovative Product Development

02-2729-4219

+886-2-2729-4219