|

市場調查報告書

商品編碼

1640498

製造業物聯網 (IoT) -市場佔有率分析、產業趨勢與統計、成長預測(2025-2030 年)Internet-of-Things (IoT) In Manufacturing - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

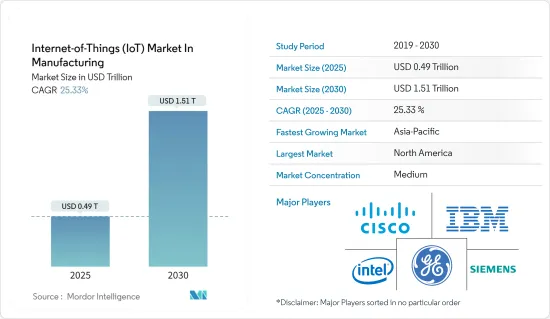

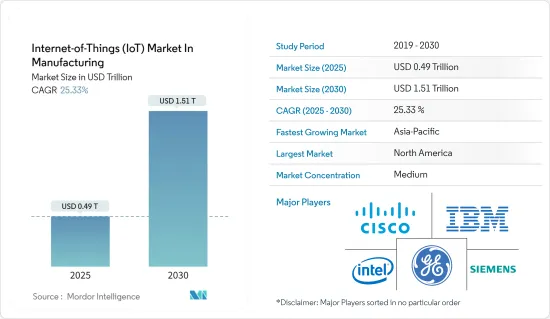

製造業物聯網 (IoT) 市場規模預計將從 2025 年的 4,900 億美元成長到 2030 年的 1.51 兆美元,預測期內(2025-2030 年)的複合年成長率為 25.33%。

在過去二十年中,對可追溯性和透明度的需求日益成長,使得公司對其產品生產過程的透明度更高。物聯網設備的資料收集和分析使製造商的整個流程變得無縫。

關鍵亮點

- 促進物聯網發展的因素包括更重視預防性維護、提高生產效率以及簡化製造基礎設施的管理。物聯網為製造商提供了前所未有的可視性、洞察力和控制力。透過簡化生產程序、減少停機時間、提高工作場所安全性和實現預測性維護,這項技術有可能徹底改變工業領域。

- 隨著生產車間、供應鏈和產品中聯網感測器數量的增加,製造商正在轉向新一代系統,其中機器、系統、資產和事物可以自動、即時地相互通訊。連網型設備的普及正在整個價值鏈的多個製造和供應鏈環節中得到應用。

- 製造業的物聯網可以幫助工廠的生產流程,因為物聯網設備可以自動追蹤開發週期並追蹤倉庫和庫存。這就是過去幾十年來物聯網設備投資激增的原因之一。製造業、物流業和運輸業中的物聯網預計將會成長。

- 物聯網被廣泛認為是一項將顯著改善製造業的先進技術。可整合所有工業領域的組件,包括感測器、處理單元、通訊和執行器。這種完全整合的智慧資訊物理系統將創造新的製造市場和商業性前景,為第四次工業革命鋪路。這給行業帶來了巨大可能性。

製造業物聯網 (IoT) 市場趨勢

供應鍊和物流管理應用推動市場成長

- RFID 和 GPS 等行動裝置和感測器的引入正在推動供應鏈在追蹤庫存和倉庫資產方面的重大轉變。

- 行動技術使企業能夠監控設備、庫存和業務。透過提供整個供應鏈的即時資料,資產智慧使公司能夠擴展其專業知識和能力。這些解決方案推動了運輸物流行業的發展,但當與物聯網 (IoT) 等實行技術相結合時,它們可以提供更多的資產智慧並幫助用戶做出更明智的決策。

- 物流中心、倉庫和貨場是供應鏈生態系統中最關鍵的部分。如果公司能夠提高這些組件的效能,它就能更有效率地業務。物流業將越來越依賴物聯網,倉庫將使用雲端來追蹤庫存、車輛和設備。大量透過 RFID 標籤連接起來的機器使這成為可能。包裹和托盤在本地層面進行交互,而公司伺服器則在全球範圍內持續監控它們的移動和進展。

- 使用RFID標籤等追蹤設備收集有關生產、有效期、製造日期、售後服務狀態和保固期的資訊,可以更有效地監控生產過程中的供應鏈。

- 根據SAS研究所的數據,英國從製造業獲益的潛力最大,物聯網為經濟帶來的收益約為40.32億英鎊。同樣,預計其他經濟體也將大力投資供應鏈自動化,加速整個製造業對物聯網的採用。

北美是最大的市場

- 製造業的物聯網市場主要由北美主導。該地區是美國和加拿大等新興經濟體的所在地,這些經濟體正在大力投資與市場相關的研發活動,從而幫助開拓新技術。作為行動性、巨量資料和物聯網等技術趨勢的早期採用者,製造商渴望將物聯網技術融入他們的流程中。

- 連網型設備和資料流已經應用於製造業。這有望降低基礎設施成本並縮短交貨時間。為了保持競爭力,製造商正在轉向物聯網和分析來營運和改善他們的業務。在美國,大約 35% 的製造商正在收集和使用智慧感測器產生的資料來增強其生產流程。

- 根據一項調查顯示,約有 34% 的製造商認為美國製造商應該在業務中實施物聯網。對於製造商來說,物聯網是一個結合軟體、雲端運算和分析工具的生態系統,將來自各種來源的原始資料轉化為有意義的預測,並以易於使用的介面顯示出來。未來五年,自動化領域的連網設備數量預計將增加50台。

- 北美憑藉其技術力、強大的基礎設施、多樣化的產業和支援生態系統,成為全球物聯網 (IoT) 製造領域最大的市場。隨著該地區在技術創新和數位轉型方面保持主導地位,物聯網在製造業的應用預計將繼續成長,進一步鞏固其作為全球最大物聯網市場的地位。

製造業物聯網 (IoT) 概述

製造業的物聯網 (IoT) 市場具有凝聚力和連貫性。隨著企業選擇物聯網作為其製造設備的推動者,工業 4.0 及更高層級的市場開始變得更具吸引力。此外,市場正趨向細分化。市場的主要企業包括思科系統公司、通用電氣、英特爾公司、IBM 公司、AT&T 公司、高通和西門子股份公司。

- 2022 年 6 月 - 領先的 LabOps Intelligence 技術平台 Elemental Machines 和下一代製造執行系統 (MES) 開發商 MasterControl 宣佈建立戰略夥伴關係,利用兩項最尖端科技消除手動資料收集的需要。製造商實現自動化、加強資料完整性、確保合規性並加速細胞和基因療法等先進生技藥品的生產。

- 2022 年 5 月 - 全球最大的 RFID 和數位 ID 解決方案供應商艾利丹尼森公司與物聯網先驅 WilIoT 達成戰略合作夥伴關係,將物聯網提升到新水平,並推進造福人類的全新物聯網解決方案和環境。

其他福利

- Excel 格式的市場預測 (ME) 表

- 3 個月的分析師支持

目錄

第 1 章 簡介

- 研究假設和市場定義

- 研究範圍

第2章調查方法

第3章執行摘要

第4章 市場洞察

- 市場概況

- 產業相關人員分析

- 產業吸引力-波特五力分析

- 供應商的議價能力

- 消費者議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭對手之間的競爭

第5章 市場動態

- 市場促進因素

- 資料分析的快速發展和技術進步

- 改善供應鏈管理和物流,降低營運成本

- 市場限制

- 缺乏標準化介面,限制整合和可擴展性

- 安全和隱私問題

- 機會

- 物聯網與巨量資料的結合對於智慧製造的未來至關重要

- COVID-19 對資料中心服務市場的影響

第6章 重大技術投入

- 雲端技術

- 人工智慧

- 網路安全

- 數位服務

- 產業政策

第7章 市場區隔

- 按軟體

- 應用程式安全

- 資料管理與分析

- 監控

- 網管

- 其他軟體

- 連結性別(定性分析)

- 衛星網路

- 蜂巢式網路

- RFID

- NFC

- Wi-Fi

- 其他連接

- 按服務

- 專業的

- 系統整合與部署

- 託管

- 其他

- 按用途(定性分析)

- 流程最佳化

- 預測性維護

- 資產管理

- 勞動力管理

- 緊急和事故管理

- 物流與供應鏈管理

- 庫存管理

- 按行業

- 車

- 食品和農業設備

- 工業設備

- 電子和通訊設備

- 化工及材料設備

- 其他最終用戶產業

- ***按地區

- 北美洲

- 美國

- 加拿大

- 歐洲

- 德國

- 英國

- 法國

- 西班牙

- 亞洲

- 中國

- 日本

- 印度

- 澳洲和紐西蘭

- 拉丁美洲

- 巴西

- 墨西哥

- 阿根廷

- 中東和非洲

- 阿拉伯聯合大公國

- 沙烏地阿拉伯

- 南非

- 北美洲

第8章 競爭格局

- 公司簡介

- Cisco Systems Inc.

- General Electric

- Intel Corporation

- IBM Corporation

- Verizon Communication Inc.

- AT&T Inc.

- Qualcomm

- Siemens AG

- Microsoft Corporation

- SAP SE

第9章投資分析

第10章 市場機會與未來趨勢

The Internet-of-Things Market In Manufacturing Industry is expected to grow from USD 0.49 trillion in 2025 to USD 1.51 trillion by 2030, at a CAGR of 25.33% during the forecast period (2025-2030).

With the increasing demand in the last two decades for traceability and transparency, companies have started making the processes involved in the production of their products transparent. Data collection and analysis through IoT devices make the whole process seamless for manufacturers.

Key Highlights

- Some of the drivers that have fueled the IoT's growth include a greater emphasis on preventative maintenance, increased production effectiveness, and streamlining the management of manufacturing infrastructure. Manufacturers have unprecedented visibility, insight, and control thanks to the IoT. By streamlining production procedures, cutting downtime, enhancing workplace safety, and enabling predictive maintenance, this technology has the potential to transform the industrial sector completely.

- As the number of networked sensors in production, the supply chain, and products grows, manufacturers are moving into a new generation of systems that let machines, systems, assets, and things talk to each other automatically and in real time.The pervasiveness of connected devices is finding applicability across multiple manufacturing and supply chain segments throughout the value chain.

- IoT in manufacturing can help the flow of production in a plant because IoT devices automatically track development cycles and keep track of warehouses and stock. It is one of the reasons that investments in IoT devices have skyrocketed over the past few decades. IoT in manufacturing, logistics, and transportation will grow.

- IoT is widely recognized as a advanced technology that significantly improves the manufacturing sector. It can integrate every industrial sector's components, including sensors, processing units, communication, and actuation devices. This fully integrated smart cyber-physical system creates new manufacturing markets and commercial prospects and sets the path for the fourth industrial revolution. It creates significant potential for the industrial industry.

Internet of Things (IoT) in Manufacturing Market Trends

Supply Chain and Logistics Management Application to Spur Growth in the Market Studied

- There has been a substantial change in the supply chain with the adoption of mobile devices and sensors, including RFID and GPS, to track inventory and warehouse assets.

- Mobile technologies allow businesses to monitor equipment, inventory, and business operations. By giving them real-time data across their entire supply chain, asset intelligence enables enterprises to boost their expertise and capacity. Although these solutions have helped the transportation and logistics industries advance over time, combining them with enabling technologies like the Internet of Things (IoT) can provide even more asset intelligence and help users make more educated decisions.

- Distribution centers, warehouses, and yards are the most important ecosystem parts of the supply chain.If a business is able to improve the performance of these components, the effectiveness of its operations will also improve. The logistics industry would increasingly rely on IoT, and warehouses would use the cloud to track their inventory, cars, and equipment. Numerous machines connected via RFID tags make this possible. The packages and pallets would interact with one another on a local level, while a company-based server would continuously monitor their movements and travel progress on a global level.

- Improved inventory management is a major outcome of IoT adoption in the manufacturing industries, made possible by the availability of real-time object visibility and the capability to track and maintain inventories.Using tracking devices, like RFID tags, to collect information about production, expiration dates, manufacture dates, after-sales status, and warranty periods could make supply chain monitoring during manufacturing more effective.

- According to the SAS Institute, the United Kingdom may benefit the most from the manufacturing sector, with IoT accounting for approximately GBP 4,032 million of the total economy. Similarly, other economies are expected to invest heavily in the automation of the supply chain, thereby driving IoT adoption in the overall manufacturing sector.

North America to be the Largest Market

- North America mainly dominates the market for IoT in manufacturing. This region has developed economies, like the United States and Canada, which heavily invest in R&D activities related to the market, thus contributing to the development of new technologies. With the early adoption of trending technologies like mobility, big data, and IoT, manufacturers are eager to integrate IoT technologies into their processes.

- Connected devices and data flow are already finding applications in manufacturing. Therefore, accelerated deliveries can now be expected as the infrastructure cost is reduced. In order to stay competitive, manufacturers are leveraging IoT and analytics to run and improve businesses. In the United States, about 35% of manufacturers collect and use data generated from smart sensors to enhance manufacturing processes.

- According to a study, around 34% of the manufacturers believe that US manufacturers must adopt IoT in their operations. For manufacturers, IoT has become an ecosystem where software, cloud computing, and analytics tools are combined to turn raw data from different sources into meaningful predictions and present them in easy-to-use interfaces. By next five years, the number of connected devices in the automation sector is expected to increase by 50.

- North America's technological prowess, solid infrastructure, variety of industries and supportive ecosystem have helped it take the lead as the world's largest market for the manufacturing sector of Internet of Things (IoT). The use of IoT in manufacturing is anticipated to continue to grow as the region maintains its dominance in technical innovation and digital transformation, further strengthening its position as the world's largest IoT market,

Internet of Things (IoT) in Manufacturing Industry Overview

The Internet-of-Things (IoT) market in manufacturing is cohesive and coherent. The market after Industry 4.0 has started to be more attractive, as companies are opting for IoT as enablers in their manufacturing units. Moreover, the market is inclined toward fragmentation. Some of the key players in the market are Cisco Systems Inc., General Electric, Intel Corporation, IBM Corporation, AT&T Inc., Qualcomm, and Siemens AG, among others.

- June 2022 - Elemental Machines, a leading LabOps Intelligence technology platform, and MasterControl, a developer of a next-generation manufacturing execution system (MES), announced a strategic partnership utilizing two cutting-edge technologies to assist bio manufacturers in automating manual data collection, enhancing data integrity, guaranteeing compliance, and accelerating production for advanced biologics like cell and gene therapies.

- May 2022- The world's largest supplier of RFID and digital ID solutions, Avery Dennison Corporation, and the Internet of Things pioneer, Wiliot, announced a strategic alliance to expand the IoT to the next level and usher in a new era of IoT that benefits people and the environment.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Stakeholder Analysis

- 4.3 Industry Attractiveness - Porter's Five Forces Analysis

- 4.3.1 Bargaining Power of Suppliers

- 4.3.2 Bargaining Power of Consumers

- 4.3.3 Threat of New Entrants

- 4.3.4 Threat of Substitute Products

- 4.3.5 Intensity of Competitive Rivalry

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Rapid Growth and Technological Advancements in Data Analytics

- 5.1.2 Improved Supply Chain Management and Logistics at Lower Operational Costs

- 5.2 Market Restraints

- 5.2.1 Lack of Standardized Interfaces and Limited Integration and Scalability

- 5.2.2 Security and Privacy Issues

- 5.3 Opportunities

- 5.3.1 Intersection of IoT and Big Data Essential to the Future of Smart Manufacturing

- 5.4 Impact of COVID-19 on Data Center Services Market

6 KEY TECHNOLOGY INVESTMENTS

- 6.1 Cloud Technology

- 6.2 Artificial Intelligence

- 6.3 Cyber Security

- 6.4 Digital Services

- 6.5 Industry Policies

7 MARKET SEGMENTATION

- 7.1 By Software

- 7.1.1 Application Security

- 7.1.2 Data Management and Analytics

- 7.1.3 Monitoring

- 7.1.4 Network Management

- 7.1.5 Other Software

- 7.2 By Connectivity (Qualitative Analysis)

- 7.2.1 Satellite Network

- 7.2.2 Cellular Network

- 7.2.3 RFID

- 7.2.4 NFC

- 7.2.5 Wi-Fi

- 7.2.6 Other Connectivities

- 7.3 By Services

- 7.3.1 Professional

- 7.3.2 System Integration and Deployment

- 7.3.3 Managed

- 7.3.4 Other Services

- 7.4 By Application (Qualitative Analysis)

- 7.4.1 Process Optimization

- 7.4.2 Predictive Maintenance

- 7.4.3 Asset Management

- 7.4.4 Workforce Management

- 7.4.5 Emergency and Incident Management

- 7.4.6 Logistics and Supply Chain Management

- 7.4.7 Inventory Management

- 7.5 By End-user Vertical

- 7.5.1 Automotive

- 7.5.2 Food and Agriculture Equipment

- 7.5.3 Industrial Equipment

- 7.5.4 Electronics and Communication Equipment

- 7.5.5 Chemicals and Materials Equipment

- 7.5.6 Other End-user Verticals

- 7.6 ***By Geography

- 7.6.1 North America

- 7.6.1.1 United States

- 7.6.1.2 Canada

- 7.6.2 Europe

- 7.6.2.1 Germany

- 7.6.2.2 United Kingdom

- 7.6.2.3 France

- 7.6.2.4 Spain

- 7.6.3 Asia

- 7.6.3.1 China

- 7.6.3.2 Japan

- 7.6.3.3 India

- 7.6.3.4 Australia and New Zealand

- 7.6.4 Latin America

- 7.6.4.1 Brazil

- 7.6.4.2 Mexico

- 7.6.4.3 Argentina

- 7.6.5 Middle East and Africa

- 7.6.5.1 United Arab Emirates

- 7.6.5.2 Saudi Arabia

- 7.6.5.3 South Africa

- 7.6.1 North America

8 COMPETITIVE LANDSCAPE

- 8.1 Company Profiles

- 8.1.1 Cisco Systems Inc.

- 8.1.2 General Electric

- 8.1.3 Intel Corporation

- 8.1.4 IBM Corporation

- 8.1.5 Verizon Communication Inc.

- 8.1.6 AT&T Inc.

- 8.1.7 Qualcomm

- 8.1.8 Siemens AG

- 8.1.9 Microsoft Corporation

- 8.1.10 SAP SE