|

市場調查報告書

商品編碼

1458501

雙極電池技術發展現況及未來展望(2024年)<2024> Current Status and Future Outlook of Bipolar Battery Technology Development |

||||||

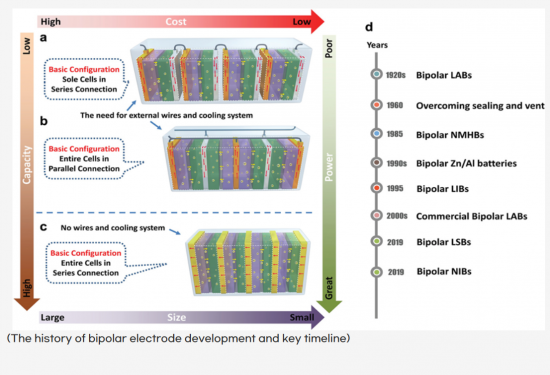

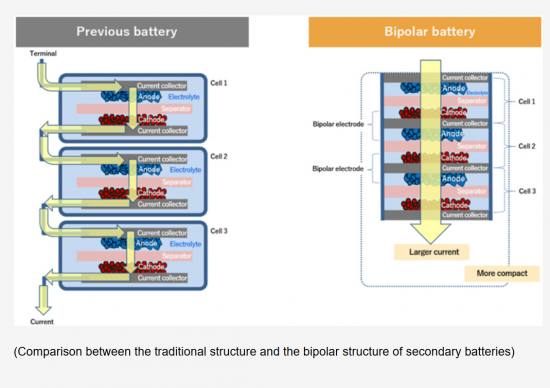

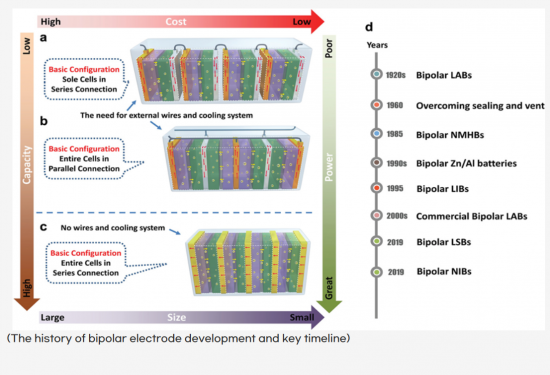

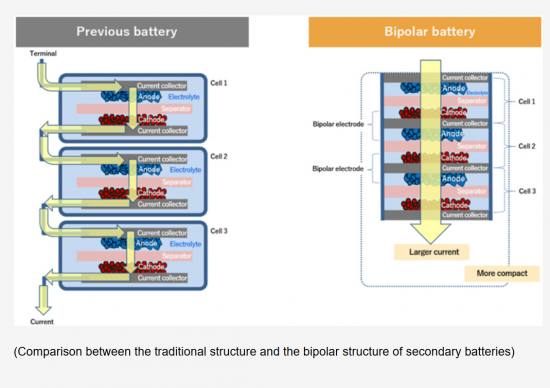

單電池二次電池由單極電極組成,集流體的兩側均由相同的電極材料製成,所有電極浸入相同的電解液中。由於每個電極均使用外部連接線並聯連接,因此電池系統包含大量惰性材料。結果,估計體積能量密度將損失約40%,重量能量密度將損失約20%。

雙極電池具有簡單的電池結構和形狀,因為它們不使用電連接器或其他配件。電池的體積接近各個單元電池的堆疊厚度乘以單元電池基板面積的總和,電池的重量相當於所有組件的總質量。雙極電池的容量等於單一單元電池的容量,但雙極電池的輸出電壓由串聯單元電池的數量乘以每個單元的電壓決定。

在電池中使用雙極電極顯著提高了體積和重量能量密度。此外,基於以應用為中心的設計,可以輕鬆調整電池形狀,以最大限度地利用目標裝置中的電池儲存空間。換句話說,透過減少電池體積和最小化BMS,可以透過最小化電池封裝材料的使用來同時追求提高能量密度和降低成本。這最終可能促使電動車在有限的電池空間中安裝更多電池,從而延長行駛里程。因此,雙極性電極的這些優點對於行動電子設備和電動車中使用的二次電池的設計非常有吸引力。

雙極電極的另一個優點是電子電流垂直流過基板,基板的大橫截面積大大改善了電流密度和電流分佈。因此,透過使用雙極性電極,高速充電電池可以安全地運行,不會有任何安全問題。

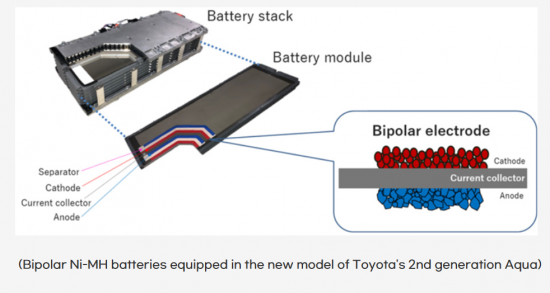

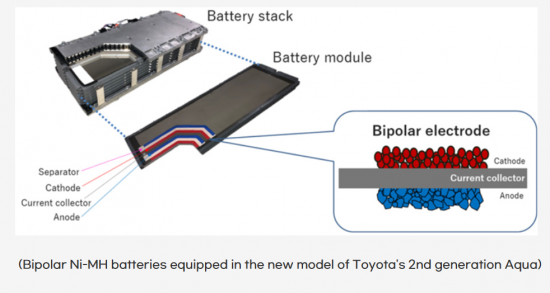

從Furukawa Electric的使用雙極電極的小型電池開始,近年來Toyota已將雙極鎳氫電池商業化,並將其安裝在 Aqua HEV 中。Toyota於2023年6月宣佈,計劃在2026年至2027年為大眾市場電動車生產雙極磷酸鐵鋰電池,並在2027年至2028年為未來電動車生產雙極鎳基鋰離子電池。此路線圖的目標是與高性能 LIB 相比,增加範圍並降低成本。

最近推出的Toyota Crown Countryman和LexusRX都配備了傳統鎳氫電池的改良版本,稱為雙極鎳氫電池。這與使用鋰離子電池的傳統趨勢背道而馳,尤其是在高階和節能車型。這一轉變標誌著該公司打算逐步擴大鎳氫電池在整個產品線中的使用,並代表了電池技術採用的策略性變化。

在本報告中,我們對雙極電池市場進行了研究和分析,並提供了近年來開始使用的雙極電極的發展趨勢和研發現狀的資訊。

目錄

第一章 二次電池用雙極性電極

- 電池結構優化需求

- 雙極電極

- 雙極電極的開發

- 雙極電極的應用

- 雙極鹼性電池

- 雙極鋰離子電池

- 雙極柱 LiB(Li-S、Na 離子)

- 課題與前景

第 2 章 雙極固態電池:設計、製造、電化學

- 概述

- 雙極板

- 雙極固態電池的製備及電化學性能

- 結果與未來展望

第三章 雙極固態電池:能量密度設計

- 概述

- 結果與討論

第4章 雙極固態電池:基於準固態電解質

- 準固態鋰垢複合材料

- 雙極固態LIB評估

- 雙極固態LIB的SEM分析

- 結論

第 5 章 雙極固態電池:基於硫化物電解質

- 概述

- 結果與討論

- 結論

第六章 雙極固態電池:多步驟印刷製造基地

- 概述

- 介紹

- 實驗

- 結果與討論

- 結論

第7章 雙極固態電池:FeOx-LFBO負極的應用

- 概述

- 介紹

- 實驗結果

- 結論

第 8 章 雙極 LFP/LTO 電池:用於微型/輕度混合動力汽車的 LIB

- 概述

- 介紹

- 實驗

- 結果與討論

- 結論

第9章 雙極鎳氫電池

- 概述

- 電池設計

- 晶圓電池應用

- 油電混合車應用

- 插電式混合動力汽車的應用

- 應用於公用事業

第10章 雙極高壓鈉離子電池

- 概述

- 介紹

- 實驗與方法

- 結果

第11章 雙極性全聚合物電池

- 全聚合物電池的特點

- 全聚合物電池的製作方法

- 全聚合物電池的特點

- 全聚合物電池的基本結構

- 將所有聚合物電池串聯堆疊

- 雙極全聚合物電池,安全性更高

- 核殼型電極材料

- APB Corporation的雙極型全聚合物電池

- 全聚合物電池的未來前景

第12章 雙極型鉛酸電池(Furukawa Electric Co., Ltd.)

- 全球首次商業化

- 用於長期儲能的ESS電池

第13章雙極LIB(Fraunhofer IKTS)

- 概述

- 雙極電池概念

- 濕式電極製造

- 隔板塗層

- 雙極電池,堆疊

- 雙極電池用捲繞箔 (SCHLENK)

第14章 雙極鎳氫電池(TOYOTA)

- 雙極電池特性

- 新電池技術

- TOYOTA的電池創新

- TOYOTA年表

- TOYOTA製造工藝

第15章 雙極電池專利

- TOYOTA:雙極鎳氫電池

- Hyundai Motor Company:雙極固態電池

- TOYOTA:雙極固態電池

- Samsung SDI:雙極電極和製造

- LG Chem:雙極電池

- LGES:雙極鋰離子電池

- KITECH:雙極固態電池

- ProLogium:水平複合進料結構

參考

A single-cell secondary battery consisted of monopolar electrodes, where both sides of the current collector are composed of the same electrode material, has all electrodes immersed in the same electrolyte. Since each electrode is connected in parallel using external connecting wires, a significant amount of inactive material has been integrated into the battery system. As a result, it is estimated that the volumetric energy density may experience a loss of approximately 40%, and the gravimetric energy density approximately 20%.

The bipolar battery features a simple cell configuration and shape as it does not utilize electrical connectors or other accessories. The volume of the battery is close to the product of the total stack thickness of the individual unit cells and the substrate area of the unit cell, while the weight of the battery is comparable to the total mass of all components. Although the capacity of the bipolar battery is equivalent to that of a single unit cell, the output voltage of the bipolar battery is determined by the number of unit cells connected in series and the voltage of each cell multiplied together.

Using bipolar electrodes in batteries significantly increases both volumetric and gravimetric energy density. Additionally, based on application-centric design, the battery shape can be easily adjusted to maximize the utilization of the battery storage space in the target device. In other words, the battery volume decreases, and by minimizing the BMS, energy density enhancement and cost savings can be simultaneously pursued through minimized use of cell packaging materials. This ultimately translates into the ability to install more batteries in limited electric vehicle battery mounting spaces, potentially leading to increased driving range. Therefore, these advantages of bipolar electrodes are highly attractive for the design of secondary batteries used in mobile electronic devices and electric vehicles.

Another advantage of bipolar electrodes is that electron flow occurs vertically through the substrate, and when the substrate's cross-sectional area is large, current density and distribution are significantly improved. Therefore, using bipolar electrodes allows fast-operating secondary batteries to function safely without any safety issues.

Starting with Furukawa Electric's compact batteries featuring bipolar electrodes, Toyota has recently commercialized bipolar Ni-MH batteries, which were applied to the Aqua HEV. In the announcement at June 2023, Toyota revealed a roadmap stating that they plan to produce bipolar LFP batteries for volume-grade EVs in 2026-2027 and bipolar Ni-based LIBs for future versions of EVs in 2027-2028. This roadmap aims to enhance driving range and reduce costs compared to performance versions of LIBs.

The recently released Toyota Crown Crossover and Lexus RX feature an improved version of the traditional Ni-MH battery, known as the bipolar Ni-MH. This marks a departure from the previous trend of using LIBs, especially in high-end and fuel-efficient models. This shift suggests an intention to gradually expand the use of Ni-MH batteries across the lineup, indicating a strategic change in battery technology adoption.

In this report, we have compiled the history of the development of bipolar electrodes, which have recently begun to be applied, as well as the current status of research and development. We have detailed each development to provide a comprehensive overview, making it easy to understand the overall situation.

The strong points of this report are as follows:

- 1. ailed coverage of recent technological trends related to bipolar batteries

- 2. ailed coverage of the development history and current status of bipolar battery developers

- 3. centrated coverage of the development status of bipolar batteries at Toyota Motor Corporation

- 4. lysis of bipolar battery's key patent

Table of Contents

1. Bipolar Electrodes for Secondary Batteries

- 1.1. The Necessity of Battery Structure Optimization

- 1.2. Bipolar Electrodes

- 1.3. Development of Bipolar Electrodes

- 1.3.1. History of Bipolar Electrode Development

- 1.3.2. Reduction in Weight, Size, and Cost

- 1.3.3. Improvement in Energy Density/Power Density

- 1.3.4. Requirements and Disadvantages of Bipolar Electrodes

- 1.4. Applications of Bipolar Electrodes

- 1.4.1. Bipolar Lead-Acid Batteries (LAB)

- 1.4.2. Improvement of Bipolar Lead-Acid Batteries

- 1.4.2.1. Surface Modification

- 1.4.2.2. Corrosion Prevention

- 1.4.3. Commercialization of Bipolar Lead-Acid Batteries

- 1.5. Bipolar Alkaline Batteries

- 1.5.1. Bipolar Ni-MH

- 1.5.2. Bipolar Al and Zn Batteries

- 1.6. Bipolar Lithium-Ion Batteries

- 1.7. Bipolar post-LiB(Li-S, Na-ion)

- 1.8. Challenges and Outlook

- 1.8.1. Substrate Materials

- 1.8.2. Electrode Materials

- 1.8.3. Electrolyte Materials

- 1.8.4. Engineering Technologies

- 1.8.5. Outlook of Bipolar Electrode

- 1.8.6. Hurdles to Commercialization

- 1.8.7. Other Bipolar Batteries

- 1.8.8. Bipolar Solid-State Batteries

2. Bipolar Solid-State Batteries: Design, Fabrication, and Electrochemistry

- 2.1. Overview

- 2.1.1. Advantages of Bipolar Solid-State Batteries

- 2.1.2. Technical Challenges of Bipolar Batteries

- 2.1.3. Requirements for Bipolar Materials

- 2.2. Bipolar Plates

- 2.3. Fabrication and Electrochemical Characteristics of Bipolar Solid-State Batteries

- 2.3.1. Free standing Lamination Bipolar Solid-State Batteries

- 2.3.2. Printing Bipolar Solid-State Batteries

- 2.4. Results and Future Outlook

3. Bipolar Solid-State Batteries: Design of Energy Density

- 3.1. Overview

- 3.2. Results and Discussion

- 3.2.1. SolidPAC demo

- 3.2.2. Comparison of Bipolar Stacking and Conventional Stacking

- 3.2.3. Sensitivity Analysis

- 3.2.4. Experimental Data Analysis

4. Bipolar Solid-State Batteries: Based on Quasi-Solid Electrolytes

- 4.1. Quasi-Solid Li-Glyme complex

- 4.2. Evaluation of Bipolar Solid-State LIBs

- 4.3. SEM Analysis of Bipolar Solid-State LIBs

- 4.4. Conclusion

5. Bipolar Solid-State Batteries: Based on Sulfide Electrolytes

- 5.1. Overview

- 5.2. Results and Discussion

- 5.2.1. Manufacturing and Characteristics of Cathode Layers

- 5.2.2. Manufacturing and Characteristics of Anode Layers

- 5.2.3. Manufacturing and Characteristics of Mono cells

- 5.2.4. Characteristics of Bipolar Stacked Solid-State Batteries

- 5.2.5. Comparison of Energy Densities in Bipolar Solid-State Batteries

- 5.3. Conclusion

6. Bipolar Solid-State Batteries: Based on Multistage Printing Manufacturing

- 6.1. Overview

- 6.2. Introduction

- 6.3. Experiment

- 6.3.1. Manufacturing of SWCNT-Coated Electrode Active Material

- 6.3.2. Fabrication of Printed Bipolar LIB

- 6.4. Results and Discussion

- 6.4.1. Solid Gel Composite Electrolyte(GCE)

- 6.4.2. Fabrication and Characteristics of Printed Electrodes

- 6.4.3. GCE and Electrode Paste Control

- 6.4.4. Mechanical Flexibility and Thermal Stability

- 6.5. Conclusion

7. Bipolar Solid-State Batteries: Application of FeOx-LFBO Anode

- 7.1. Overview

- 7.2. Introduction

- 7.3. Experiment Results

- 7.3.1. Synthesis and Characteristics of FeOx-LFBO

- 7.3.2. Electrochemical Performance of FeOx-LFBO Anode

- 7.3.3. Mechanism Analysis

- 7.3.4. Electrochemical Performance of Cu-free LIB

- 7.4. Conclusion

8. Bipolar LFP/LTO Batteries: LIBs for Micro/Mild Hybrid

- 8.1. Overview

- 8.2. Introduction

- 8.3. Experiments

- 8.4. Results and Discussion

- 8.4.1. LFP, LTO

- 8.4.2. 15Wh Bipolar Battery

- 8.4.3. Safety

- 8.5. Conclusion

9. Bipolar Ni-MH Batteries

- 9.1. Overview

- 9.2. Battery Design

- 9.3. Application of Wafer Cells

- 9.4. Application in HEVs

- 9.5. Application in PHEVs

- 9.6. Application in Utility

- 9.6.1. High-Power Bipolar Batteries

- 9.6.2. High-Energy Bipolar Batteries

10. Bipolar High-Voltage Na-ion Batteries

- 10.1. Overview

- 10.2. Introduction

- 10.2.1. Monopolar 48V Battery System

- 10.2.2. Commercialization Issues of Bipolar Batteries

- 10.3. Experiment and Method

- 10.4. Results

- 10.4.1. Bipolar Batteries with Liquid Electrolytes

- 10.4.2. nS mP(Series-Parallel) Bipolar Batteries

- 10.4.3. Na-ion Bipolar Batteries with Above 5V

- 10.4.4. Custom Cell Voltage Profile Design

11. Bipolar All Polymer Batteries

- 11.1. Characteristics of All Polymer Batteries

- 11.1.1. Advantages of All Polymer Batteries

- 11.1.2. Disadvantages of All Polymer Batteries

- 11.1.3. Energy Density of All Polymer Batteries

- 11.1.4. Manufacturers of All Polymer Batteries

- 11.1.4.1. Kawasaki Heavy Industries

- 11.1.4.2. JFE Chemical

- 11.1.4.3. Teijin

- 11.1.4.4. Gunze/Sanyo Chemical Industries

- 11.2. Manufacturing Methods of All Polymer Batteries

- 11.3. Characteristics of All Polymer Batteries

- 11.3.1. Voltage Increase by Stacking

- 11.3.2. Elimination of Drying Process

- 11.3.3. Improve of Production Speed

- 11.4. Basic Structure of All Polymer Batteries

- 11.5. All Polymer Batteries Stacked in Series

- 11.6. Safety-Enhanced Bipolar All Polymer Batteries

- 11.7. Core-Shell Type Electrode Materials

- 11.8. Bipolar All Polymer Batteries by APB Corporation

- 11.9. Future Outlook of All Polymer Batteries

12. Bipolar Lead-Acid Batteries (Furukawa Electric Co., Ltd.)

- 12.1. World's First Commercialization

- 12.1.1. Structure and Challenges of Bipolar Lead-Acid Batteries

- 12.1.2. Overcoming Challenges with Metal/Polymer Materials

- 12.2. ESS Batteries for Long-Term Power Storage

13. Bipolar LIBs (Fraunhofer IKTS)

- 13.1. Overview

- 13.2. Concept of Bipolar Batteries

- 13.3. Wet Process Electrode Manufacturing

- 13.4. Separator Coating

- 13.5. Bipolar Cells and Stacks

- 13.6. Roll Clad Foil for Bipolar Battery (SCHLENK)

14. Bipolar Ni-MH Batteries (TOYOTA)

- 14.1. Characteristics of Bipolar Batteries

- 14.2. New Battery Technologies

- 14.3. Battery Innovation by TOYOTA

- 14.4. Timeline of TOYOTA

- 14.5. Manufacturing Process by TOYOTA

15. Bipolar Battery Patents

- 15.1. TOYOTA: Bipolar Ni-MH Batteries

- 15.2. Hyundai Motor Company: Bipolar Solid-State Batteries

- 15.3. TOYOTA: Bipolar Solid-State Batteries

- 15.4. Samsung SDI: Bipolar Electrodes and Manufacturing

- 15.5. LG Chem: Bipolar Batteries

- 15.6. LGES: Bipolar LIBs

- 15.7. KITECH: Bipolar Solid-State Batteries

- 15.8. ProLogium: Horizontal Composite Electric Supply Structure