|

市場調查報告書

商品編碼

1473268

半固態電池技術:發展及未來展望<2024> Semi-Solid Battery Technology: Development and Future Prospects |

||||||

各大電池製造商和汽車整車廠都計劃量產固態電池。然而,這些電池的大規模生產預計需要五到十年的時間。同時,由於半固態電池相對於傳統鋰離子電池(LiB)具有潛在的安全性、壽命和成本優勢,人們對半固態電池的興趣日益濃厚。由於這些期望,許多公司,尤其是中國的公司,都宣佈了大規模生產半固態電池的計畫。

半固態電池是介於液態電池和固態電池之間的中間產品。半固態電池在電池內加入一些電解質以增強介面。與液體電池相比,半固體電池可以最大限度地減少材料體系的變化,利用隔膜和液體電解質,並減少液體電解質的體積。這種減少可以提高電池的能量密度和安全性。此外,半固態電池的製造流程與傳統鋰離子電池技術和設備緊密相連。

在半固態電池中,添加液體可以增強複合材料中的離子傳輸,而不影響電子傳輸,並改善電極的電化學性能。這需要透過固/液界面的低電阻離子傳輸。最近的原位聚合技術已被用來透過固化半固體電池的原始液體成分來減少液體含量。

有機/無機複合固態電解質是最受歡迎的半固態電池形式之一,結合了有機和無機固態電解質的優點。這些複合材料通常由氧化物固體電解質和聚合物電解質組成,具有優異的拉伸強度和機械性能、良好的加工性能和足夠的離子電導率,使其適合大規模生產。

半固態電池發展主要由CATL、WeLion、Qingtao Energy、Ganfeng Lithium、Guoxuan、Farasis、Tailan等中國企業推動。此外,LGES、Factorial Energy、SES、ProLogium也在獨立或與汽車 OEM 廠商合作開發這項技術。

2023年上海車展上,CATL帶著期待已久的凝聚式電池亮相,引起了業界的關注。這項突破性技術採用高功率仿生凝聚電解質,並具有自適應微觀網路結構。這些技術創新提高了動態性能和鋰離子傳輸效率,使電池能量密度達到驚人的500Wh/kg,超過了傳統鋰離子電池。此外,CATL的創新也延伸到穩定性和產能,確保為未來電動車提供可靠且可擴展的解決方案。

固態電池的應用已經開始,NIO ET7搭載WeLion 360Wh/kg半固態電池,容量為150kWh,續航里程達到1145km,超過傳統電池。計劃於 2024 年 4 月開始量產。

根據SNE Research預測,2030年全球固態電池產能預計將達到約168GWh,2035年將達300GWh。預計整體電池市佔率將從2030年的約5.7%達到峰值,到2033年約6.55%,然後隨著固態電池的普及,到2035年再次下降至5.7%。

本報告分析了全球半固態電池的技術和市場趨勢,提供了半固態電池的概述、特點和分類,提供了與全固態電池的技術比較,並對其在電動車中的應用進行了展望(電動汽車)等。我們收集並提供未來技術發展和市場成長方向以及主要公司的核心專利等資訊。

本報告的好處:

- 1.半固態電池最新趨勢詳解

- 2.主要電池製造商和汽車整車廠詳細覆蓋

- 3.瞭解競爭格局:半固態電池與固態電池的比較

- 4.半固態電池發展歷程及現狀

- 5.半固態電池相關主要專利分析

目錄

第1章 半固態電池發展趨勢

- 全固態電池實際應用面臨的課題

- 全固態電池製造業不成熟

- 半固態電池:對產業鏈的影響

- 改進包裝流程:中間階段和後期階段

- 固體電解質膜形成工藝

- 核心材料系統創新

- 半固態電池成本降低

- 鋰金屬負極的用途

- 規模經濟的需要

- 半固態電池:主要優點

第2章 固態電池、半固態電池、混合電池的分類

- 固體電解質的類型

- 電解質體系的分類

- 固體電解質的分類:優點和缺點

- 混合電解質的類型

- 混合電解質特性

- 雜化無機聚合物複合電解質(IPC)

- 有機/無機雜化固體電解質

第3章 半固態電池用聚合物/無機複合電解質

- 概述

- 介紹

- 鋰離子電導率

- 電化學穩定性

- 抑制樹突

- 接觸穩定性

- 聚合物/無機複合電解質填料

- 聚合物/無機複合電解質的組成

- 惰性填料

- 活性填料

- 聚合物/無機複合電解質的合成

- 結論與總結

第4章 全固態電池與半固態電池詳細分析

- 全固態/半固態電池的優點(能量密度)

- 全固態/半固態電池的優點(安全性)

- 半固態電池的缺點

- 半固態電池的成本及未來前景

- 全固態電池/半固態電池相關政策:依國家劃分

- 依應用劃分的全固態/半固態電池市場

- 半固態電池的使用趨勢

- 氧化物固體電解質產能(分公司)

第5章 半固態電池:電動車的最佳解決方案?

- 半固態電池及其他電池

- 半固態電池MP產業鏈

- 正極/負極材料

- 固體電解質

- 電動汽車市場

- 市場分析(中國市場)

第6章 半固態鋰電池的發展:中間層的應用

- 分析總結

- 互動企業的角色

- 將 Ag-C 複合材料整合到 LLZTO 中

- 引入附加層

- 強化銀附著力

- 鋰金屬電池特性分析

- 電化學電池

- LLZTO的電化學性能

- Li-Ag-C/Ag/LLZTO/IL-LCO 電池

- 結論與討論

第7章 固態電池混合介面 (SLEI)

- SLEI(固液電解質界面)的定義

- 鋰離子電池和固態電池的區別

- 混合固體電解質/液體電解質(SE/LE)系統

- SLEI 和 SEI 的異同

- 氧化物混合系統

- 硫化物基混合系統

- 純溶劑的研究

- 液體電解質的電化學性質

第8章 使用準固態電解質的高效能鋰金屬電池:MOF(金屬有機框架)概述

- 分析總結

- 準固體電解質的生產

- CuBTC MOF 作為主體材料

- 準固體電解質的物理化學性質

- 準固態電解質與電極的相容性

- NCM-811//鋰軟包電池的電化學性能

- 結論

第9章 使用準固態電解質的鋰硫電池

- 鋰硫 (Li-S) 電池概述

- 固態鋰硫電池

- 工作原理

- 充電/放電曲線

- 離子傳導機制

- 技術問題

- 電解質材料設計策略

- 聚合物電解質的應用

- 凝膠/半固態聚合物電解質

- 固態聚合物電解質

- 無機固體電解質

- 硫化物固態電解質

- 氧化物固體電解質

- 混合電解質

- 無機-有機複合電解質

- 無機固液電解質

- 結論與展望

第10章 半固態電池產業發展趨勢

- 我國半固態電池現狀

- 中國全固態電池研發(R&D)

- 各公司投資狀況

- 中國固態電池前景

- 下一代電池的商業化

- 目前 LiB 改進的局限性

- 半固態電池的持續發展

- 提高對半固態電池的認識

- 固態電池生產(2026年後)

- 日本企業:延遲3-7年

- 全球半固態電池發展趨勢

- 正負極材料的發展趨勢

- 電池結構解模組化

- 半固態電池開始量產

第11章 半固態電池生產企業及企業

- LGES

- SK On

- WeLion

- BAK

- CATL

- NIO

- KAERI(Korea)

- ProLogium

- SES

- Factorial Energy

- KIERKorea)

- imec

- Qingtao Energy

- Ganfeng Lithium

- Yiwei Lithium Energy (EVE)

- Guoxuan Hi-Tech

- Farasis Energy

- SVOLT

- SEMCORP

- NGK

- Kyocera

- Talent New Energy

第12章 半固態電池市場展望

- 中國半固態電池產業現狀

- 半固態電池產業的歷史

- 中國半固態電池相關政策

- 中國電動車半固態電池需求展望

- 中國半固態電池市場滲透率

- 全球半固態電池市場展望

第13章 半固態電池專利分析

- Korea Institute of Energy Technology

- Qingtao New Energy

- LGES

- Arkema

- Global Graphene Group Inc.

- WeLion New Energy

- Ganfeng Lithium

- Sion Power

- Factorial Energy

- StoreDot

- SVOLT

參考

Major battery manufacturers and automotive OEMs are planning to mass-produce all-solid-state batteries. However, large-scale production of these batteries is expected to take 5-10 years. In the meantime, there's increasing interest in semi-solid-state batteries due to their potential safety, longevity, and cost advantages over conventional lithium-ion batteries (LiBs). This anticipation is driving many companies, especially in China, to announce mass production plans for semi-solid-state batteries.

Semi-solid-state batteries serve as a transitional product between liquid-state and solid-state batteries. They incorporate a portion of electrolyte within the battery to enhance the interface. Compared to liquid-state batteries, semi-solid-state batteries necessitate minimal alterations to the material system, utilize separators and liquid electrolytes, and can decrease the volume of liquid electrolyte present. This reduction can enhance battery energy density and safety. Moreover, the manufacturing processes for semi-solid-state batteries closely align with traditional lithium-ion battery techniques and equipment.

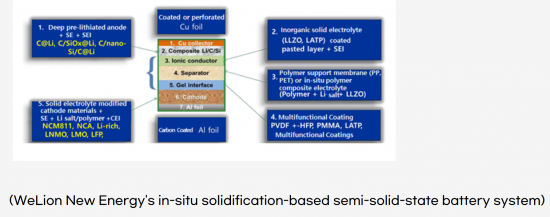

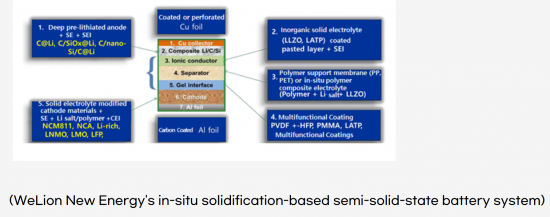

In semi-solid-state batteries, the addition of a liquid can enhance ion transport through the composite material without compromising electron transport, leading to improved electrochemical performance of the electrodes. This requires a low-resistance ion transport through the solid/liquid interface. Recent in-situ polymerization techniques have been employed to reduce the liquid content by solidifying the original liquid components of the semi-solid-state battery.

Organic-inorganic composite solid electrolytes, one of the most prevalent forms in semi-solid-state batteries, combine the advantages of both organic and inorganic solid electrolytes. These composite materials, typically consisting of oxide solid electrolytes and polymer electrolytes, exhibit exceptional tensile strength and mechanical properties, excellent processability, and adequate ion conductivity, making them suitable for large-scale production.

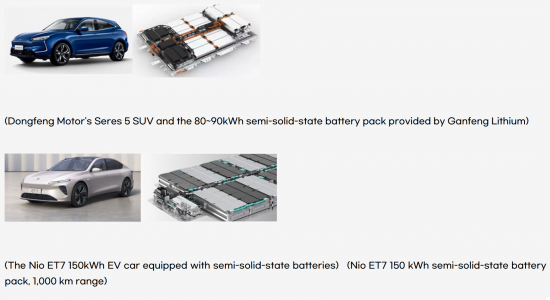

The development of semi-solid-state batteries is primarily being driven by Chinese companies, including CATL, WeLion, Qingtao Energy, Ganfeng Lithium, Guoxuan, Farasis, and Tailan. Additionally, LGES, Factorial Energy, SES, and ProLogium are also independently or collaboratively developing this technology with automotive OEMs.

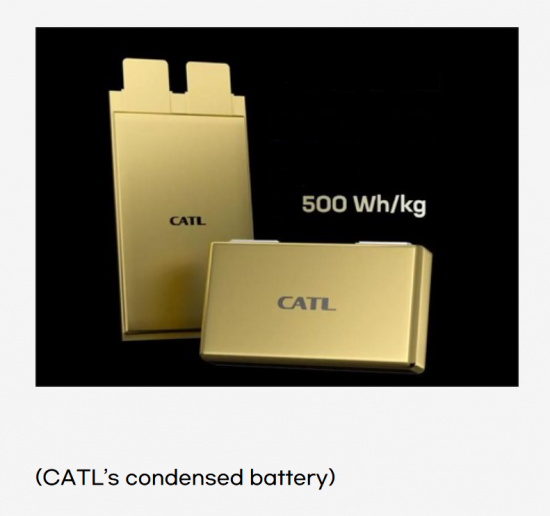

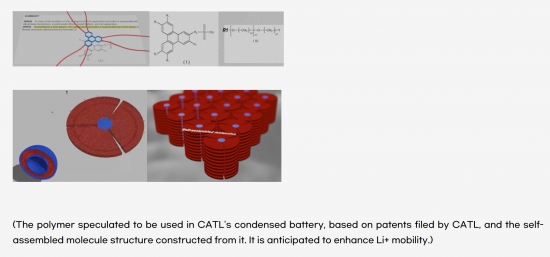

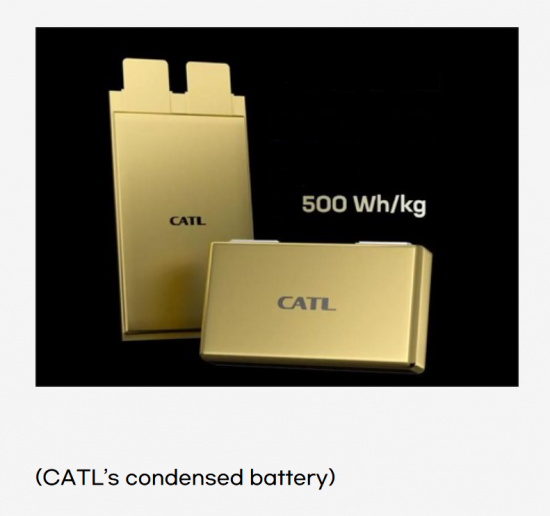

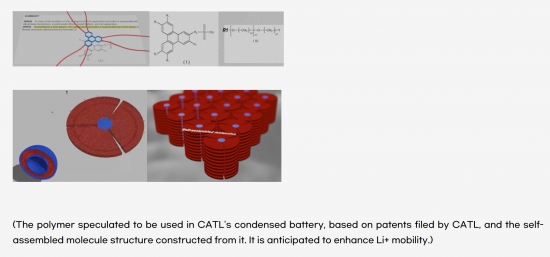

At the 2023 Shanghai Auto Show, CATL unveiled its highly anticipated Condensed Battery, grabbing industry attention. This groundbreaking technology utilizes a high-power bionic condensed electrolyte and features an adaptive micro-level network structure. These innovations enhance dynamic performance and lithium ion transport efficiency, resulting in an impressive cell energy density of 500 Wh/kg, surpassing conventional lithium-ion batteries. Moreover, CATL's innovation extends to stability and production capabilities, promising a reliable and scalable solution for electric vehicles in the future.

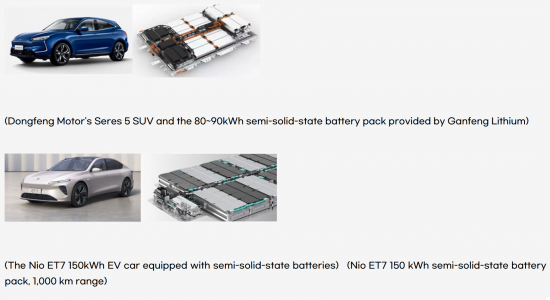

The application of solid-state batteries has already begun, and the NIO ET7 equipped with WeLion's 360Wh/kg semi-solid-state battery, boasting 150kWh, achieved a range of 1145km, surpassing conventional batteries. It's reported that mass production started in April 2024.

According to SNE Research, global solid-state battery production capacity is expected to reach approximately 168GWh by 2030 and 300GWh by 2035. In terms of overall battery market share, it is projected to peak at around 6.55% in 2033 from approximately 5.7% in 2030, before declining to 5.7% again by 2035 as solid-state batteries are widely adopted.

The strong points of this report are as follows.

- 1. Detailed coverage of recent trends surrounding semi-solid-state batteries

- 2. Detailed coverage of major battery manufacturers and automotive OEMs

- 3. Navigating the Competitive Landscape: Semi-Solid-State Batteries vs. Solid-State Batteries

- 4. The development history and current status of semi-solid-state batteries

- 5. Analysis of key patents related to semi-solid-state batteries

Table of Contents

1. Semi-Solid-State Battery Development Trends

- 1.1. Commercialization Challenges for All-Solid-State Batteries

- 1.1.1. Immaturity of All-Solid-State Battery Manufacturing

- 1.2. Semi-Solid-State Batteries: Impact on the Industrial Chain

- 1.2.1. Modifications to the Packaging Process: Intermediate and Rear Stages

- 1.2.2. Solid Electrolyte Film Formation Process

- 1.2.3. Innovation in Core Material Systems

- 1.2.3.1. Polymer Systems

- 1.2.3.2. Oxide Systems

- 1.2.3.3. Sulfide Systems

- 1.2.3.4. Costs

- 1.2.3.5. Electrolyte

- 1.2.3.6. Anode Material

- 1.2.3.7. Binders

- 1.2.3.8. Pre-lithiation

- 1.2.3.9. Separators

- 1.2.3.10. Dry Electrode Process (DBE)

- 1.2.3.11. Industrialization Status of Semi-Solid Batteries

- 1.2.3.12. Gel-Type Solid Electrolyte

- 1.3. Reducing the Cost of Semi-Solid-State Batteries

- 1.3.1. Using Lithium Metal Anodes

- 1.3.2. Need for Economies of Scale

- 1.4. Semi-Solid State Batteries: Key Advantages

2. Classification of Solid-State, Semi-Solid-State, and Hybrid Batteries

- 2.1. Types of Solid Electrolytes

- 2.2. Classification of Electrolyte Systems

- 2.3. Classification of Solid Electrolytes and Their Pros and Cons

- 2.4. Types of Hybrid Electrolyte

- 2.5~7. Properties of Hybrid Electrolyte

- 2.8. Hybrid Inorganic Polymer Composite Electrolyte (IPC)

- 2.9~10. Organic-Inorganic Hybrid Solid-State Electrolyte

3. Polymer/Inorganic Composite Electrolytes for Semi-Solid-State Batteries

- 3.1. Overview

- 3.2. Introduction

- 3.2.1. Lithium Ion Conductivity

- 3.2.2. Electrochemical Stability

- 3.2.3. Dendrite Suppression

- 3.2.4. Contact Stability

- 3.3. Polymer/Inorganic Composite Electrolyte Fillers

- 3.3.1. Components of Polymer/Inorganic Composite Electrolytes

- 3.3.2. Inert Fillers

- 3.3.2.1. Oxide Fillers

- 3.3.2.2. Ferroelectric Fillers

- 3.3.2.3. Porous fillers

- 3.3.2.4. Other Inert Fillers

- 3.3.3. Active Fillers

- 3.3.3.1. Garnet-Type Solid Electrolytes

- 3.3.3.2. NASICON-Type Solid Electrolytes

- 3.3.3.3. Perovskite-Type Solid Electrolytes

- 3.3.3.4. Sulfide-Type Solid Electrolyte

- 3.3.4. Synthesis of Polymeric/Inorganic Complex Electrolytes

- 3.4. Conclusion and Summary

4. In-Depth Analysis of All/Semi-Solid-State Batteries

- 4.1. All/Semi-Solid-State Battery Advantage (Energy Density)

- 4.2. All/Semi-Solid-State Battery Advantage (Safety)

- 4.3. Semi-Solid-State Batteries Disadvantage

- 4.4. Semi-Solid-State Battery Costs and Future Outlook

- 4.5. All/Semi-Solid-State Battery Policies by Country

- 4.6. All/Semi-Solid-State Battery Application Market

- 4.7. Semi-Solid-State Battery Application Trends

- 4.8. Oxide Solid Electrolyte Production Capacity by Company

5. Semi-Solid-State Batteries: The Optimal Solution for EVs?

- 5.1. Semi-Solid-State Batteries vs. Other Batteries

- 5.2. Semi-Solid-State Battery Industry Chains

- 5.2.1. Cathode/Anode Materials

- 5.2.2. Solid Electrolytes

- 5.2.3. EV Market

- 5.2.4. Market Analysis (Chinese Market)

6. Quasi-Solid Lithium Battery Development: Interlayer Application

- 6.1. Research Overview

- 6.2. The Role of the Interplayer

- 6.3. Integrating Ag-C Composites into LLZTO

- 6.3.1. Introducing Additional Layers

- 6.3.2. Enhancement of Ag Adhesion

- 6.4. Analysis of Lithium Metal Cell Characteristics

- 6.4.1. Electrochemical Cell

- 6.4.2. .Electrochemical Performance of LLZTO

- 6.4.3. Li-Ag-C/Ag/LLZTO/IL-LCO Cell

- 6.5. Conclusion and Discussion

7. Solid-State Battery Hybrid Interface (SLEI)

- 7.1. Definition of SLEI(Solid-Liquid Electrolyte Interphase)

- 7.2. Difference between LIBs and All-Solid-State Batteries

- 7.3. Hybrid Solid Electrolyte/Liquid Electrolyte(SE/LE) Systems

- 7.4. Similarities and differences between SLEI and SEI

- 7.5. Oxide-Based Hybrid System

- 7.6. Sulfide-Based Hybrid System

- 7.6.1. Research on Pristine Solvents

- 7.6.2. Electrochemical Performance for Liquid Electrolytes

8. High-Efficiency Li Metal Batteries with Quasi-Solid Electrolytes (Introduction of MOFs)

- 8.1. Research Overview

- 8.2. Fabrication of Quasi-Solid Electrolytes

- 8.2.1. CuBTC MOF as a Host Material

- 8.2.2. Physicochemical Properties of Quasi-Solid Electrolytes

- 8.2.3. Compatibility of Quasi-Solid Electrolytes with Electrodes

- 8.2.4. Electrochemical Performance of NCM-811//Li Pouch Cells

- 8.3. Conclusion

9. Li-S Batteries with Quasi-Solid Electrolytes

- 9.1. Li-S Battery Overveiw

- 9.2. Solid-State Li-S Batteries

- 9.2.1. Operating Principle

- 9.2.2. . Charge/Discharge Profile

- 9.2.3. Ion Conduction Mechanisms

- 9.2.4. Technical Issues

- 9.3. Electrolyte Material Design Strategies

- 9.4. Polymer Electrolyte Applications

- 9.4.1. Gel/Quasi-Solid Polymer Electrolyte

- 9.4.2. Solid-Polymer Electrolyte

- 9.5. Inorganic Solid Electrolyte

- 9.5.1. Sulfide Solid Electrolyte

- 9.5.2. Oxide Solid Electrolyte

- 9.6. Hybrid Electrolyte

- 9.6.1. Inorganic-Organic Composite Electrolyte

- 9.6.2. Inorganic Solid-Liquid Electrolyte

- 9.7. Conclusion and Outlook

10. Semi-Solid-State Battery Industry Trends

- 10.1. The State of Semi-Solid-State Batteries in China

- 10.2. .All-Solid-State Battery R&D in China

- 10.3. Each Company's Investment Status

- 10.4. Outlook on All(Semi)-Solid-State Batteries in China

- 10.5. Commercialization of Next-Generation Batteries

- 10.5.1. Limitations in Improving Current LiBs

- 10.5.2. Continued Development of Semi-Solid-State Batteries

- 10.5.3. Growing Recognition of Semi-Solid-State Batteries

- 10.5.4. Solid-State Battery Production from 2026

- 10.5.5. Japanese Companies Lagging Behind by 3-7 Years

- 10.5.6. Global Trends in Semi-Solid-State-Batteries

- 10.5.7. Trends in Cathode/Anode Material Development

- 10.5.8. Demodularization of the Battery Structure

- 10.5.9. Mass Production of Semi-Solid-State Batteries Initiated

11. Semi-Solid-State Battery Manufacturers and Operations

- 11.1. LGES

- 11.2. SK On

- 11.3. WeLion

- 11.4. BAK

- 11.5. CATL

- 11.6. NIO

- 11.7. KAERI(Korea)

- 11.8. ProLogium

- 11.9. SES

- 11.10. Factorial Energy

- 11.11. KIERKorea)

- 11.12. imec

- 11.13. Qingtao Energy

- 11.14. Ganfeng Lithium

- 11.15. Yiwei Lithium Energy (EVE)

- 11.16. Guoxuan Hi-Tech

- 11.17. Farasis Energy

- 11.18. SVOLT

- 11.19. SEMCORP

- 11.20. NGK

- 11.21. Kyocera

- 11.22. Talent New Energy

12. Semi-Solid State Battery Market Outlook

- 12.1. Current Status of Semi-Solid-State Battery Industry in China

- 12.2. History of Semi-Solid-State Battery Industry

- 12.3. Policies for China's Semi-Solid-State Battery

- 12.4. China's Semi-Solid-State Battery Demand Outlook for EVs

- 12.5. Market Penetration Rate of Semi-Solid-State Batteries in China

- 12.6. Global Semi-Solid-State Battery Market Outlook

13. Patent Analysis of Semi-Solid-State Batteries

- 13.1. Korea Institute of Energy Technology

- 13.2. Qingtao New Energy

- 13.3. LGES

- 13.4. Arkema

- 13.5. Global Graphene Group Inc.

- 13.6. WeLion New Energy

- 13.7. Ganfeng Lithium

- 13.8. Sion Power

- 13.9. Factorial Energy

- 13.10. StoreDot

- 13.11. SVOLT