|

市場調查報告書

商品編碼

1478710

倒裝晶片/WLP製造與市場分析Flip Chip/WLP Manufacturing and Market Analysis |

||||||

在提高電子設備性能、可靠性和小型化的封裝技術進步的推動下,半導體產業不斷發展。這些封裝技術在小型化、增強功能和改進電氣性能方面具有獨特的優勢,使其成為現代電子系統的必備要素。

近年來,由於消費性電子、汽車、醫療保健和電信等各種最終用途行業對緊湊型和高性能電子設備的需求不斷增長,半導體倒裝晶片和 WLP 市場經歷了顯著增長。隨著對更小尺寸、更高功能和更高可靠性的需求不斷增長,倒裝晶片技術和 WLP 技術已成為應對這些課題的重要解決方案。

在快節奏的半導體製造領域,技術創新是進步的驅動力。在眾多先進封裝技術中,倒裝晶片和晶圓級封裝 (WLP) 已成為改變電子設備格局的關鍵技術。這些封裝技術專注於小型化、性能和功能,正在徹底改變半導體元件的整合方式,並為緊湊、高性能電子產品的新時代鋪平道路。

本報告對半導體倒裝晶片和 WLP 進行了全面研究,詳細分析了市場趨勢,包括主要趨勢、驅動因素、市場驅動因素和課題。它還關注技術進步、市場動態和競爭環境,旨在為利益相關者提供有價值的見解,並做出利用新興市場趨勢的決策。

目錄

第一章簡介

第二章執行摘要

第 3 章 倒裝晶片/WLP 問題與趨勢

- 介紹

- 晶圓凸塊

- 晶圓級封裝

- 焊盤重新分佈

- 晶圓凸塊成本

- 面板級封裝

第 4 章:光刻技術的問題與趨勢

- 問題

- 曝光系統

- 有競爭力的技術

第五章 UBM蝕刻問題與趨勢

- 介紹

- 技術問題和趨勢

- 批量蝕刻和單片蝕刻

第 6 章 金屬化問題與趨勢

- 介紹

- 濺鍍金屬化

- 電鍍

第七章市場分析

- 倒裝晶片和 WLP 市場驅動因素

- 市場機會

- 任務

- 倒裝晶片市場

- 光刻市場

- 氣相沉積市場

Introduction

The semiconductor industry is continually evolving, driven by advancements in packaging technologies that enhance performance, reliability, and miniaturization of electronic devices. Among these technologies, Flip Chip and Wafer-Level Packaging (WLP) have emerged as critical enablers of next-generation semiconductor devices. These packaging techniques offer unparalleled advantages in terms of size reduction, increased functionality, and improved electrical performance, making them indispensable in modern electronic systems.

The semiconductor Flip Chip and WLP market have witnessed significant growth in recent years, fueled by the growing demand for compact, high-performance electronic devices across various end-use industries such as consumer electronics, automotive, healthcare, and telecommunications. As manufacturers strive to meet the ever-increasing demands for smaller form factors, higher functionality, and greater reliability, Flip Chip and WLP technologies have become essential solutions for addressing these challenges.

This comprehensive report on semiconductor Flip Chip and WLP provides a detailed analysis of the market landscape, including key trends, drivers, challenges, and opportunities shaping the industry's trajectory. With a focus on technological advancements, market dynamics, and competitive landscape, this report aims to provide stakeholders with valuable insights to make informed decisions and capitalize on emerging market trends.

Key components of the report include:

Market Overview: An in-depth overview of the semiconductor Flip Chip and WLP market, including market size, growth drivers, and industry challenges. The report examines the current market landscape and provides forecasts for market growth and adoption trends over the forecast period.

Technology Landscape: A comprehensive analysis of Flip Chip and WLP technologies, including their principles, manufacturing processes, and key advancements. The report explores emerging trends such as fan-out wafer-level packaging (FOWLP), through-silicon vias (TSVs), and heterogeneous integration, highlighting their impact on the semiconductor packaging ecosystem.

Application Insights: An examination of key application areas driving the adoption of Flip Chip and WLP technologies across various industries, including consumer electronics, automotive electronics, healthcare devices, and telecommunications infrastructure. The report identifies growth opportunities and market trends in each application segment.

Competitive Analysis: A detailed assessment of the competitive landscape, including the profiles of leading players, their product portfolios, key strategies, and recent developments. The report provides insights into market positioning, competitive strengths, and potential growth strategies adopted by key players in the semiconductor Flip Chip and WLP market. Market Outlook and Opportunities: A forward-looking analysis of market trends, emerging opportunities, and future growth prospects in the semiconductor Flip Chip and WLP market. The report offers strategic recommendations for stakeholders to capitalize on market opportunities and mitigate potential risks.

Trends in Semiconductor Flip Chip/WLP (Wafer Level Packaging)

In the fast-paced world of semiconductor manufacturing, innovation drives progress. Among the myriad of advancements, Flip Chip and Wafer-Level Packaging (WLP) have emerged as pivotal technologies revolutionizing the landscape of electronic devices. With a focus on size reduction, enhanced performance, and increased functionality, these packaging techniques are reshaping the way semiconductor components are integrated, paving the way for a new era of compact, high-performance electronics. In this article, we delve into the latest trends shaping the semiconductor Flip Chip/WLP market, exploring the key drivers, innovations, and opportunities propelling this dynamic industry forward.

Market Growth and Expansion:

The semiconductor Flip Chip/WLP market is experiencing robust growth, driven by the escalating demand for smaller, more powerful electronic devices across a multitude of industries. With advancements in manufacturing processes and material technologies, Flip Chip and WLP solutions are increasingly being adopted in applications ranging from smartphones and wearables to automotive electronics and IoT devices. The market is poised for further expansion as manufacturers seek innovative packaging solutions to meet the evolving needs of modern electronic systems.

Technological Advancements:

Technological innovation lies at the heart of Flip Chip and WLP advancements. One of the key trends shaping the market is the adoption of fan-out wafer-level packaging (FOWLP), which offers significant advantages in terms of cost efficiency, miniaturization, and improved electrical performance. Additionally, through-silicon vias (TSVs) have emerged as a critical enabler of 3D integration, allowing for greater integration density and enhanced performance in semiconductor devices. Other notable trends include the development of heterogeneous integration techniques and the integration of advanced materials such as silicon photonics and gallium nitride (GaN) into packaging processes.

Application Diversification:

Flip Chip and WLP technologies are finding applications across a diverse range of industries, driving demand for specialized packaging solutions tailored to specific end-use requirements. In the consumer electronics sector, Flip Chip/WLP solutions are facilitating the development of smaller, more energy-efficient devices with enhanced functionality. In the automotive industry, these technologies are enabling the integration of advanced driver-assistance systems (ADAS), infotainment systems, and vehicle-to-everything (V2X) communication modules. Moreover, in the healthcare and telecommunications sectors, Flip Chip/WLP solutions are playing a crucial role in the development of next-generation medical devices, network infrastructure, and 5Genabled devices.

Market Dynamics and Competitive Landscape:

The semiconductor Flip Chip/WLP market is characterized by intense competition and rapid technological advancements. Leading players in the industry are investing heavily in research and development to stay ahead of the curve and gain a competitive edge. Moreover, strategic partnerships, mergers, and acquisitions are shaping the competitive landscape, driving consolidation and fostering innovation. As the market continues to evolve, collaboration between semiconductor manufacturers, packaging companies, and equipment suppliers will be crucial to unlocking new opportunities and driving growth.

Future Outlook and Opportunities:

Looking ahead, the future of the semiconductor Flip Chip/WLP market looks promising, with ample opportunities for innovation and growth. Continued advancements in packaging technologies, coupled with the proliferation of emerging applications such as artificial intelligence (AI), Internet of Things (IoT), and automotive electronics, are expected to drive demand for Flip Chip and WLP solutions. Moreover, as semiconductor devices become increasingly complex and heterogeneous, the need for advanced packaging solutions will only continue to grow, presenting new opportunities for market players to capitalize on.

Table of Contents

Chapter 1. Introduction

Chapter 2. Executive Summary

Chapter 3. Flip Chip/WLP Issues and Trends

- 3.1. Introduction

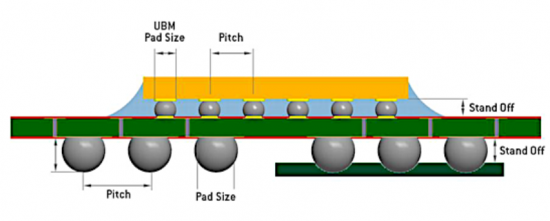

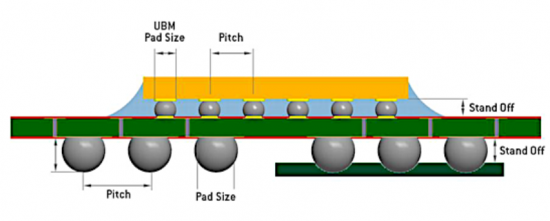

- 3.2. Wafer Bumping

- 3.2.1. Solder Bumps

- 3.2.1.1. Metallurgy

- 3.2.1.2. Deposition Of UBM

- 3.2.1.3. Sputter Etching

- 3.2.1.4. Photolithography

- 3.2.1.5. Solder Deposition

- 3.2.1.6. Resist Strip

- 3.2.1.7. UBM Wet Etch

- 3.2.1.8. Reflow

- 3.2.1.9. Flux Issues

- 3.2.2. Gold Bumps

- 3.2.2.1. Bump Processing

- 3.2.2.2. Bonding

- 3.2.2.3. Coplanarity

- 3.2.2.4. Conductivity

- 3.2.2.5. Thermal Properties

- 3.2.2.6. Size

- 3.2.2.7. Reliability

- 3.2.2.8. Cost Issues

- 3.2.3. Copper Pillar Bumps

- 3.2.4. Copper Stud Bumping

- 3.2.5. C4NP

- 3.2.1. Solder Bumps

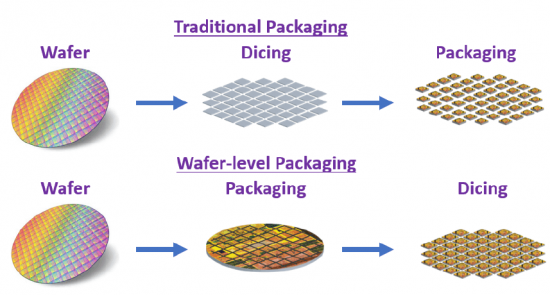

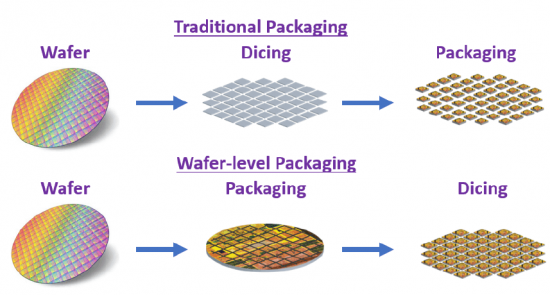

- 3.3. Wafer Level Packaging

- 3.4. Pad Redistribution

- 3.5. Wafer Bumping Costs

- 3.5.1. Wafer Redistribution And Wafer Bumping Costs

- 3.5.2. WLCSP Hidden Costs

- 3.5.3. WLCSP Cost Per Good Die

- 3.5.4. Wafer-Level Underfill Costs

- 3.6. Panel Level Packaging

Chapter 4. Lithography Issues And Trends

- 4.1. Issues

- 4.1.1. Technical Performance

- 4.1.2. Capital Investment

- 4.1.3. Cost Of Consumables

- 4.1.4. Throughput

- 4.1.5. Ease Of Use

- 4.1.6. Flexibility

- 4.1.7. Equipment Support

- 4.1.8. Resolution

- 4.1.9. Solder Bumping Capabilities

- 4.1.10. Gold Bumping Capabilities

- 4.2. Exposure Systems

- 4.2.1. Introduction

- 4.2.1.1. Reduction Steppers 4.

- 4.2.1.2. Full-Field Projection

- 4.2.1.3. Mask Aligners

- 4.2.1.4. 1X Steppers

- 4.2.1.5. 2X Steppers

- 4.2.1. Introduction

- 4.3. Competitive Technologies

- 4.3.1. Inkjet Printing

- 4.3.2. Stencil/Screen Printing

- 4.3.3. Electroless Metal Deposition

Chapter 5. UBM Etch Issues And Trends

- 5.1. Introduction

- 5.2. Technology Issues And Trends

- 5.2.1. Process Flow

- 5.2.2. Etch Process

- 5.2.3. Etch Chemistry

- 5.3. Batch Versus Single-Wafer Etching

Chapter 6. Metallization Issues and Trends

- 6.1. Introduction

- 6.2. Sputtering Metallization

- 6.2.1. Gold Bump

- 6.2.2. Solder Bumping

- 6.2.2.1. T I / Cu and TiW / Cu

- 6.2.2.2. Al / NiV / Cu

- 6.2.2.3. T i / N i (V) and TiW / Ni ( V )

- 6.2.2.4. Cr / Cr-Cu / Cu

- 6.2.3. Copper Bumping

- 6.3. Electrodeposition

Chapter 7. Market Analysis

- 7.1. Market Drivers For Flip Chip And WLP

- 7.2. Market Opportunities

- 7.3. Challenges

- 7.4. Flip Chip Market

- 7.4.1. Market Dynamics

- 7.4.2. Market Forecast

- 7.5. Lithography Market

- 7.5.1. Aligners Vs. Steppers

- 7.5.2. Market Analysis

- 7.6. Deposition Market

List of Tables

- 3.1. Common UBM Stacks For Solder And Gold Bumping

- 3.2. Solder Bumping Guidelines

- 3.3. Gold Bumping Guidelines

- 3.4. Copper Bumping Guidelines

- 3.5. Comparison Of Solder Bumping Processes

- 3.6. ITRS Pin Counts For Different Applications

- 3.7. Pillar-WLP CSP Guidelines

- 3.8. Pad Redistribution Guidelines

- 4.1. Key Challenges For WLP Lithography

- 4.2. Lithography Tools By Vendor

- 5.1. UBM Film Etchants

- 5.2. Advantages Of Spin Processing

- 6.1. Common UBM Stacks For Gold And Solder Bumping

- 7.1. WLP Demand by Device (Units)

- 7.2. WLP Demand by Device (Wafers)

- 7.3. Worldwide Lithography Forecast

- 7.4. Cost Of Ownership Of 1x Versus 2x Steppers

- 7.5. Worldwide Forecast For Deposition Tools

List of Figures

- 3.1. C4 Chip Connections

- 3.2. Wafer Bump Technology Roadmap

- 3.3. Comparison Of Copper Pillar, Flip Chip, And WLP

- 3.4. Solder Bumping Process

- 3.5. Three Process Flows For Solder Bumping

- 3.6. Gold Bumping Process

- 3.7. Cost Per Gold Bumped Wafer

- 3.8. Copper Stud Bump

- 3.9. Breakdown Of Stud Bumping Costs

- 3.10. C4NP Process Description

- 3.11. Pillar-WLPCSP Process

- 3.12. Pad Redistribution Process

- 4.1. Laser-Projection Imaging

- 4.2. Solder Jet Technology

- 4.3. Principle Of Screen Printing

- 4.4. Principle Of Inkjet Printing

- 4.5. Electroless Under Bump Metallization

- 5.1. Electroplated Solder Bumping Process

- 7.1. WLP Applications

- 7.2. Wire Bond versus Flip Chip

- 7.3. Flip Chip and Wire Bond Equipment Forecast

- 7.4. Growth in Copper Wire Bonding

- 7.5. Flip Chip Market By Number of Devices

- 7.6. Flip Chip Market By Number of Wafers

- 7.7. WLP Market by Device - 2014

- 7.8. WLP Market by Device - 2020

- 7.9. Device Shipment Forecast WLP Vs Flip Chip

- 7.10. Device Shipment Forecast FIWLP Vs FOWLP

- 7.11. Historic Lithography Market Shares

- 7.12. Lithography Market Share Growth

- 7.13. ECD Market Shares

- 7-14. Sputtering Market Shares