|

市場調查報告書

商品編碼

1550033

高電壓薄膜電容器:市場佔有率分析、產業趨勢、成長預測(2024-2029)High Voltage Film Capacitor - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2024 - 2029) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

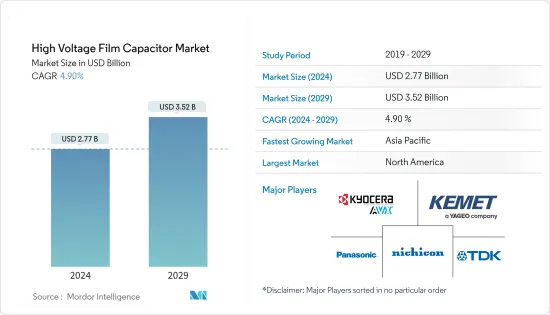

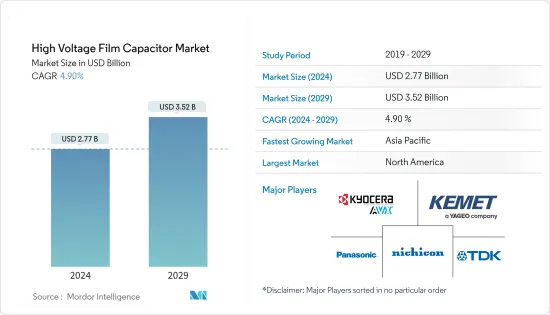

預計2024年高電壓薄膜電容器市場規模為27.7億美元,2029年將達35.2億美元,在預測期間(2024-2029年)複合年成長率為4.90%。

由於風能和太陽能等再生能源來源的採用日益增多,高電壓薄膜電容器市場正在見證成長,這需要高效的能源儲存和轉換系統。高電壓薄膜電容器因其穩定性、長壽命和高電壓耐受性而在這些系統中極為重要。此外,電動車、輸配電需求以及電容器技術的持續改進也是推動市場成長的因素。

主要亮點

- 高電壓薄膜電容器是在高電壓等級下儲存和釋放電能的電氣元件。它使用薄塑膠薄膜作為介電材料,並夾在金屬電極之間。高電壓薄膜電容器以其在高電壓應用中的高絕緣電阻、優異的穩定性和低性能劣化而聞名。

- 由於其高性能、耐用性和承受惡劣條件的能力,高電壓薄膜電容器是各種高壓和高功率應用的必備電容器。

- 高電壓薄膜電容器以其自癒特性而聞名,可以從部分擊穿中恢復。在金屬化薄膜電容器中,當發生擊穿時,擊穿周圍的一層薄金屬會蒸發,從而隔離故障並允許電容器繼續運作。

- 隨著電網現代化和高電壓直流 (HVDC) 輸電系統的擴展,對這些有助於提高遠距輸電效率和可靠性的電容器的需求不斷增加。根據IEA(國際能源總署)預測,2012年至2040年間,全球電力需求預計將成長近80%。電力基礎設施的擴建、現代化、數位化和分散化,以提高彈性,世界經濟論壇 (WEF) 等組織的計畫投資(未來 25 年為智慧電網撥款 7.6 兆美元)預計將改變全球各種市場動態設想。

- 此外,世界各地的公用事業公司擴大採用人工智慧和數位孿生等技術,再加上政府不斷加大的支持和舉措,正在吸引對智慧電網計劃的進一步投資。例如,2024 年 1 月,美國能源局宣布撥款 3,400 萬美元用於技術開發,以實現電網現代化、將電線埋入地下並更換老化的基礎設施。該計劃旨在透過最大限度地減少極端天氣造成的干擾、降低成本和加速可再生能源的採用,推進現代化和加強國家電網基礎設施的解決方案。

- 除了供應鏈中斷、能源價格、制裁、貿易限制、通膨上升等宏觀經濟因素的影響外,俄烏戰爭也為高電壓薄膜電容器市場帶來了充滿挑戰的環境。儘管中斷和成本上升仍然是主要挑戰,但對可再生能源和電動車的推動繼續推動需求,抵消了一些負面因素。

高電壓薄膜電容器市場趨勢

汽車領域預計將顯著成長

- 高電壓薄膜電容器在汽車工業中發揮重要作用,特別是在電動車、混合電動車和先進內燃機汽車中。這些電容器對於管理汽車電能流動和轉換的電力電子系統至關重要。

- 在電動車和混合動力車中,電池管理系統使用高電壓薄膜電容器來穩定電壓並管理電池充電和放電週期。這確保了電池組的最佳性能和使用壽命。

- 此外,ABS 和 ADAS 的持續採用也進一步推動了該細分市場的成長。隨著具有 ADAS 功能的車輛變得越來越複雜,它們的功率需求也會增加。高電壓薄膜電容器有助於管理這些電力需求,並為支援 ADAS 功能的感測器和處理器提供穩定、可靠的電力。

- 印度政府正在透過各種法規和政策積極推動ADAS的採用。為了反映全球趨勢,我們預計將努力在新車中強制要求特定的 ADAS 功能。這種監管推動可能會加速這些技術的採用。

- 此外,汽車行業標準 145 要求在印度銷售的所有車輛必須安裝安全氣囊、SBR、ABS 和 SWS。最近推出的AIS 197:BNCAP(巴拉特新車評估計畫)制定了更嚴格的撞擊測試標準,將為ADAS成為強制性要求鋪平道路,預計將促進被動和主動式安全的採用。

亞太地區市場預計將顯著成長

- 工業擴張、可再生能源計劃、交通電氣化、消費性電子產品成長、智慧電網發展、技術進步、政府支持政策以及不斷成長的能源需求正在推動亞太地區高電壓薄膜電容器的成長。

- 過去幾年,中國已成為全球最大的汽車市場之一,並正在成為汽車技術強國。該國對技術進步持開放態度,這可能在未來幾年對汽車產業產生重大影響。此外,隨著工業4.0的到來,中國預計將在「中國製造2025」等計畫中實現自動化和工業領域的大規模成長。

- 此外,今年1月,中國比亞迪超越特斯拉,成為全球最大的純電動車製造商。這一激增是由中國對電動車的需求不斷成長推動的,中國銷售的汽車中有 40% 是電動車。亞太地區向電動車的轉變以及電動大眾交通工具系統的發展正在推動對高電壓薄膜電容器的需求。

- 印度的消費電子和通訊產業也正在經歷顯著成長。這些產業預計將為該國高電壓薄膜電容器市場的開拓創造有利的市場前景。 ICEA 預計,到 2025 年,印度筆記型電腦和平板電腦製造業的產值將達到 1,000 億美元。此外,據 IBEF 稱,印度的家用電器和消費電子產業預計將成長一倍以上,達到 211.8 億美元。

- 此外,印度通訊塔產業在過去七年中顯著成長了65%。 2022-2023 年通訊業的直接投資為 6.94 億美元,而 2021-2022 年為 6.68 億美元。

高電壓薄膜電容器產業概況

高電壓薄膜電容器市場競爭激烈,供應商規模各異。隨著企業繼續進行策略性投資以抵消當前的經濟放緩,預計市場將出現大量聯盟、併購和收購。該市場的一些主要企業包括 TDK Corporation、KYOCERA AVX、Kemet Corporation 和 Vishay Intertechnology。

- 2024 年 4 月 Kyocera AVX 推出兩款全新卡扣式電解電容器系列。 SNA系列和SNL系列在長壽命內實現了高可靠性、高耐壓和高CV性能。此外,這兩個系列均無鉛且符合 RoHS 標準,可在 -25度C 至 +105度C 的溫度範圍內使用,非常適合工業應用。

- 2024年4月,KEMET公司宣布發表R41P。 R41P 是一款 Y2/X1 薄膜電容器,其尺寸小(比 R41T 小 40%),使其在空間要求和成本優先的應用中特別有吸引力。因此,其THB值較低,高溫下使用壽命較短。此電容器系列適用於需要安全等級 Y2/X1 的「線對地」和「線上」應用中的電磁干擾 (EMI) 抑制濾波器。

其他好處:

- Excel 格式的市場預測 (ME) 表

- 3 個月分析師支持

目錄

第1章簡介

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章市場洞察

- 市場概況

- 產業吸引力-波特五力分析

- 新進入者的威脅

- 買家/消費者的議價能力

- 供應商的議價能力

- 替代品的威脅

- 競爭公司之間敵對關係的強度

- 產業價值鏈分析

- COVID-19副作用和其他宏觀經濟因素對市場的影響

第5章市場動態

- 市場促進因素

- 電動車需求不斷成長

- 智慧電網需求不斷成長

- 對節能技術的需求不斷增加

- 市場限制因素

- 原料取得困難

- 生產成本高

第6章 繞線式和疊片式分析

第7章 市場區隔

- 按最終用戶產業

- 車

- 航太/國防

- 石油和天然氣

- 驅動器和逆變器(非汽車)

- 其他最終用戶產業

- 按地區

- 北美洲

- 歐洲

- 亞太地區

- 澳洲/紐西蘭

- 拉丁美洲

- 中東/非洲

第8章 競爭格局

- 公司簡介

- TDK Corporation

- KYOCERA AVX Components Corporation

- Nichicon Corporation

- Kemet Corporation

- Panasonic Industry Co. Ltd

- Vishay Intertechnology nc.

- WIMA GmbH & Co. KG

第9章市場展望

The High Voltage Film Capacitor Market size is estimated at USD 2.77 billion in 2024, and is expected to reach USD 3.52 billion by 2029, growing at a CAGR of 4.90% during the forecast period (2024-2029).

The market for high-voltage film capacitors is witnessing growth due to the increasing adoption of renewable energy sources, such as wind and solar power, which require efficient energy storage and conversion systems. High-voltage film capacitors are crucial in these systems for their stability, long lifespan, and high voltage tolerance. Additionally, the demand for electric vehicles, power transmission and distribution, and the continuous improvements in capacitor technology are some of the factors that are driving market growth.

Key Highlights

- High-voltage film capacitors are electrical components that store and release electrical energy at high voltage levels. They are constructed using thin plastic films as the dielectric material sandwiched between metal electrodes. These capacitors are known for their high insulation resistance, stability, and ability to handle high-voltage applications without significant performance degradation.

- High-voltage film capacitors are favored for their high performance, durability, and ability to withstand harsh conditions, making them indispensable in a wide range of high-voltage and high-power applications.

- High-voltage film capacitors are known for their self-healing properties, which allow them to recover from partial dielectric breakdown. In metalized film capacitors, when a dielectric breakdown occurs, the thin metal layer around the breakdown evaporates, isolating the fault and allowing the capacitor to continue functioning.

- The increasing modernization of power grids and the expansion of high-voltage direct current (HVDC) transmission systems are driving the demand for these capacitors, as they help improve the efficiency and reliability of power transmission over long distances. According to the IEA (International Energy Agency), the world electricity demand is anticipated to increase by nearly 80% between 2012 and 2040. Expansion, modernization, digitization, and decentralization of the electricity infrastructure for improved resiliency and a planned investment from organizations such as the World Economic Forum (USD 7.6 trillion allocated for smart grids for the next 25 years) are expected to change various market dynamics in the global scenario.

- Further, utilities worldwide are increasingly adopting technologies like artificial intelligence and digital twinning, coupled with increased government support and initiatives, which are further attracting investments in smart grid projects. For instance, in January 2024, the US Department of Energy announced the development of technologies aimed at modernizing the electric grid, undergrounding power lines, and replacing aging infrastructure with USD 34 million in grants. The program is aimed at advancing solutions to modernize and boost the country's power grid infrastructure by minimizing extreme weather-related disruptions, lowering costs, and accelerating the adoption of renewable energy.

- The impact of macroeconomic factors such as supply chain disruptions, energy prices, sanctions, trade restrictions, and rising inflation, along with the Russia-Ukraine War, has created a challenging environment for the high-voltage film capacitor market. While disruptions and cost increases pose significant challenges, the ongoing push for renewable energy and electric vehicles continues to drive demand, providing some counterbalance to the negative factors.

High Voltage Film Capacitor Market Trends

Automotive Segment is Expected to Witness a Significant Growth Rate

- High-voltage film capacitors play a crucial role in the automotive industry, particularly in electric vehicles, hybrid electric vehicles, and advanced internal combustion engine vehicles. These capacitors are integral in power electronics systems that manage vehicles' flow and conversion of electrical energy.

- In EVs and HEVs, battery management systems use high-voltage film capacitors to stabilize voltage and manage the battery's charging and discharging cycles. This ensures the battery pack's optimal performance and longevity.

- Further, the increasing initiatives for adopting ABS and ADAS are further boosting the segment's growth. As vehicles become more advanced with ADAS features, the power requirements increase. High-voltage film capacitors help manage these power needs, providing stable and reliable power to sensors and processors that enable ADAS functionalities.

- The Indian government has been actively promoting the adoption of ADAS through various regulations and policies. Initiatives to mandate certain ADAS features in new cars are anticipated, mirroring global trends. This regulatory push is likely to accelerate the widespread adoption of these technologies.

- Further, Automotive Industry Standard 145 requires every vehicle sold in India to have airbags, SBR, ABS, and SWS. The recently introduced AIS 197: BNCAP (Bharat New Car Assessment Program), with its stricter crash testing norms, is expected to catalyze the uptake of passive and active safety, laying the groundwork for ADAS becoming a mandatory requirement.

Asia-Pacific is Expected to Witness Significant Market Growth

- Industrial expansion, renewable energy projects, transportation electrification, consumer electronics growth, smart grid development, technological advancements, supportive government policies, and increasing energy demand propel the growth of high-voltage film capacitors in Asia-Pacific.

- China has been one of the world's largest automotive markets for the past years and is becoming a powerhouse for automotive technology. The country may considerably impact the automotive industry in the coming years as it is open to technological progress. Moreover, with the arrival of Industry 4.0, China is expected to see massive growth in the automation and industry sector, owing to schemes like "Made in China 2025."

- Further, in January of this year, China's BYD outpaced Tesla in becoming the world's largest producer of pure-electric vehicles. The surge is fuelled by rising EV demand in China, where 40% of vehicles sold are electric. This shift toward electric vehicles and the development of electric public transportation systems in Asia-Pacific are driving the demand for high-voltage film capacitors.

- The consumer electronics and telecommunication industries in India are also witnessing significant growth. These industries are expected to create a favorable market scenario for the development of the country's high-voltage film capacitor market. According to ICEA, India can achieve a value of USD 100 billion in the manufacturing of laptops and tablets by 2025. Furthermore, according to IBEF, the Indian appliances and consumer electronics industry is expected to more than double to reach USD 21.18 billion.

- Further, the Indian telecom tower industry has grown significantly by 65% over the past seven years. FDI in the telecommunication sector during 2022-2023 was USD 694 million compared to USD 668 million during 2021-2022.

High Voltage Film Capacitor Industry Overview

The high-voltage film capacitor market is highly competitive, with several vendors of different sizes. As organizations continue to invest strategically in offsetting the present slowdowns, the market is anticipated to encounter a number of partnerships, mergers, and acquisitions. The key companies operating in the market include TDK Corporation, KYOCERA AVX, Kemet Corporation, and Vishay Intertechnology.

- April 2024: Kyocera AVX released two new snap-in aluminum electrolytic capacitors series. The SNA and SNL Series deliver high reliability, high voltage, and high CV performance over long lifetimes. In addition, both series are lead-free compatible and RoHS compliant, rated for temperatures extending from -25°C to +105°C, and ideal for use in commercial and industrial applications, including frequency converters, solar inverters, power inverters, energy storage systems, and power supplies.

- April 2024: KEMET Corporation announced launching the R41P, a Y2/X1 film capacitor whose smaller size (40% smaller than the R41T) is particularly impressive in applications where space requirements and costs are prioritized. Accordingly, the component has a lower THB value and a shorter service life at high temperatures. This capacitor series is suitable for use in filters for suppressing electromagnetic interference (EMI) in "line-to-ground" and "across-the-line" applications that require safety classification Y2/X1.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumption and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Threat of New Entrants

- 4.2.2 Bargaining Power of Buyers/Consumers

- 4.2.3 Bargaining Power of Suppliers

- 4.2.4 Threat of Substitute Products

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Industry Value Chain Analysis

- 4.4 Impact of COVID-19 Aftereffects and Other Macroeconomic Factors on the Market

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Growing Demand for Electric Vehicles

- 5.1.2 Rising Demand for Smart Grids

- 5.1.3 Increasing Demand for Energy Efficient Technologies

- 5.2 Market Restraints

- 5.2.1 Limited Availability of Raw Materials

- 5.2.2 High Production Cost

6 ANALYSIS OF WOUND TYPE AND LAMINATE TYPE

7 MARKET SEGMENTATION

- 7.1 By End-user Industry

- 7.1.1 Automotive

- 7.1.2 Aerospace and Defense

- 7.1.3 Oil and Gas

- 7.1.4 Drives and Inverters (Non-automotive)

- 7.1.5 Other End-user Industries

- 7.2 By Geography

- 7.2.1 North America

- 7.2.2 Europe

- 7.2.3 Asia-Pacific

- 7.2.4 Australia and New Zealand

- 7.2.5 Latin America

- 7.2.6 Middle East and Africa

8 COMPETITIVE LANDSCAPE

- 8.1 Company Profiles

- 8.1.1 TDK Corporation

- 8.1.2 KYOCERA AVX Components Corporation

- 8.1.3 Nichicon Corporation

- 8.1.4 Kemet Corporation

- 8.1.5 Panasonic Industry Co. Ltd

- 8.1.6 Vishay Intertechnology nc.

- 8.1.7 WIMA GmbH & Co. KG