|

市場調查報告書

商品編碼

1624593

亞太地區非破壞性檢測設備:市場佔有率分析、產業趨勢與統計、成長預測(2025-2030)APAC NDT Equipment - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

價格

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

簡介目錄

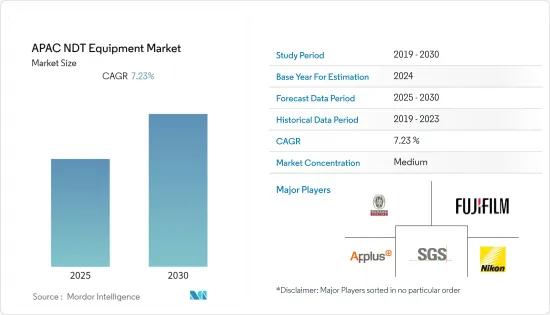

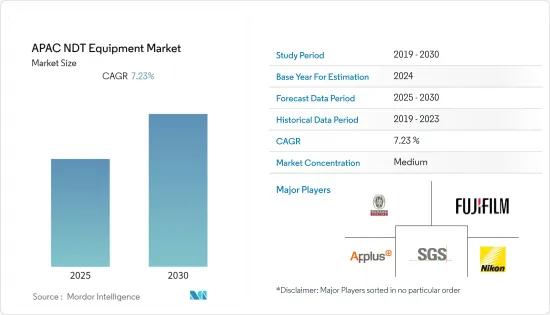

亞太地區非破壞性檢測設備市場預計在預測期間內年複合成長率為7.23%

主要亮點

- 大眾柴油引擎排放醜聞和中國牛奶醜聞(嬰兒奶粉中發現三聚氰胺)等安全違規行為導致新興經濟體加強了監管。這些違規行為顯示了獨立檢驗和認證服務的重要性。因此,法規和標準變得更加嚴格和複雜,導致對第三方的依賴增加,主要是在評估方面。

- NDT(無損檢測)設備無需拆卸和拆卸,可以節省大量時間。例如,涉及剝離(和更換)蒙皮的飛機維護和內部結構部件(例如翼肋)的檢查可以使用螢光檢查設備來執行。

- 當前無損檢測設備的市場趨勢是強大的即時資料擷取和需要即時即時回饋的全面擷取。 NDT 設備採用了新型感測器以及其他智慧、嵌入式的智慧多功能組件。

- 此外,電力和能源部門使用無損檢測設備來測試發電廠的多個組件。隨著世界各地發電廠和發電機組的增加,對無損檢測設備的需求預計將增加。例如,根據世界核能協會統計,截至2020年4月,中國已有47座運作核能發電廠,並計畫興建更多核電廠,並提供線上檢查和電站運作檢查服務。

- 此外,市場上的供應商正在透過併購策略擴大其足跡。例如,2020 年 2 月,Eddyfi/NDT 收購了 NDT Global。 Eddyfi Technologies 與 NDT Global 合併而成,是一家專注於 NDT 的創新商業測試和測量技術集團。該集團由高階技術業務部門組成,分為兩個不同的部門,包括非破壞性檢測設備和特定應用整合測試。

亞太地區無損檢測設備市場趨勢

嚴格的法規要求安全

- 世界各地的多個政府機構和區域機構已製定嚴格的措施,主要是為了確保建築物的安全。這些措施要求使用無損檢測和其他評估技術來執行一致性檢查。

- 這對於從有關當局獲得基礎設施計劃的建築許可證非常重要。這些檢查包括結構強度評估、消防安全和緊急通訊協定合規性測試。

- 制定安全措施的國際建築規範委員會(ICC)推出了一系列被稱為「國際規範」的示範建築規範。儘管這些代碼是為在美國使用而設計的,但它們已在其他地區廣泛採用。

- ICC1704標準要求焊接部門需要獲得NDT認證,以確保結構完整性。然而,在美國,區域組織被賦予制定自己的技術和工業標準的自主權。

- 無損檢測在國防和航太等先進應用中最為重要。在這些領域,出錯的可能性接近零,這就是為什麼政府機構採用 ASTM 和 ISO 標準來強制在基礎設施開發和維護中使用無損檢測技術。

- 在能源、材料科學和太空等關鍵領域,無損檢測被廣泛應用於確保零件的結構完整性。 ASTM、ISO、NAS等世界知名民間組織的角色不容忽視。這些組織制定無損檢測產業級政策,以定義一套無損檢測服務和設備製造商應遵循的實務和程序。

超音波測試

- 超音波測試是一種體積測試方法,利用高頻聲波來測量材料的幾何和物理性能。將高頻聲波引入材料中以檢測表面和表面下缺陷。

- 超音波檢測可以檢測缺陷的存在和位置,並提供有關缺陷類型的資訊。透過金屬-氣體界面/金屬-液體界面的能量、聲波穿過樣品所需的時間以及聲束的衰減來檢測缺陷。

- 該檢驗用於所有主要行業的品管和材料檢驗,包括鑄件、鍛件、擠壓件、焊接接頭、鋼鐵製造和生產以及壓力容器、橋樑、汽車、機械和噴射引擎等結構的製造它用於。

- 超音波檢測的主要優點是它只需要接觸被測材料的一側,主要用於測試壓力設備、儲存槽和管道系統。超音波檢查是檢測裂縫和不完全熔合等嚴重平面故障的最佳方法。

- 此檢測技術具有深度滲透能力。超音波測試是一種檢測線性不連續性的高靈敏度方法。超音波檢測比 X 光檢測更快、更經濟。應用包括壁厚測量、腐蝕測繪、層壓檢查、缺陷檢測、密度測量和硬度測量。

- 超音波測試也可用於在製造和維護檢查過程中測量金屬零件的厚度。超音波測試用於測量壁厚、檢測隱藏的裂縫以及其他檢測影響結構完整性的異常情況。超音波檢測在建築構件中的廣泛使用增加了超音波檢測在工業品管中的重要性。

亞太地區非破壞性檢測設備產業概況

由於國內外眾多廠商的存在,亞太地區非破壞性檢測設備市場競爭非常激烈。市場是分散的,每個參與者都在價格、產品設計和產品創新等因素上競爭。

- 2021 年 3 月 - Intertek 宣布將其建築業務線擴展到加勒比海地區,並在波多黎各陶巴哈開設 Intertek-PSI。該設施將在整個加勒比地區提供岩地工程服務、環境諮詢和建築材料測試,提供以前僅在美國當地和加拿大提供的服務。

- 2021 年 4 月 - 尼康公司 (Nikon) 收購了 Morf3D Inc.,Morf3D Inc. 是金屬積層製造 (AM) 領域公認的先驅,專門從事航太、航太和國防工業的積層製造和工程,收購金額。

- 2021 年 5 月 - 尼康公司(Nikon)透過新的偏移 CT 重建演算法增強了其計量工業微焦點 X 光 CT 檢測解決方案,提供無與倫比的掃描速度和影像解析度。使用 X 光 CT 對鋁鑄件和電動車電池模組等大型零件進行無損品管,可在不犧牲解析度的情況下縮短檢查週期時間。這需要高X光強度或X光助焊劑。

- 2021 年 4 月 - 必維國際檢驗集團正在參與以科學為基礎的目標計劃。作為該組織的成員,必維國際檢驗集團的目標是將全球氣溫上升限制在比工業化前水準高 1.5°C 的範圍內。

其他好處

- Excel 格式的市場預測 (ME) 表

- 3 個月分析師支持

目錄

第1章簡介

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章市場洞察

- 市場概況

- 產業吸引力-波特五力分析

- 供應商的議價能力

- 消費者議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭公司之間敵對關係的強度

- COVID-19 市場影響評估

第5章市場動態

- 市場促進因素

- 嚴格的安全法規和檢驗服務業的成長預計將推動招聘

- 建設產業的需求不斷增加

- 市場限制因素

- 高更換率仍然是關鍵問題,新興地區不願採用新技術

- 市場機會

第 6 章 技術概覽

- 無損檢測設備產業的演變

- 產業價值鏈分析

第7章 市場區隔

- 技術類型

- X光檢查

- 超音波檢查

- 磁粉探傷

- 液體滲透檢測

- 目視檢查

- 渦流探傷

- 其他技術

- 最終用戶

- 石油和天然氣

- 電力/能源

- 建造

- 汽車/交通

- 航太/國防

- 其他最終用戶

- 國家名稱

- 中國

- 日本

- 印度

- 韓國

- 新加坡

- 印尼

- 其他(泰國、馬來西亞等)

第8章 競爭格局

- 公司簡介

- MISTRAS Group

- SGS Group

- Fujifilm Corporation

- Olympus Corporation

- Bureau Veritas SA

- GE Measurement and Control

- Nikon Metrology NV

- Intertek Group Plc.

- Applus Services, SA

- Acuren Inspection, Inc.(Rockwood Service Corporation)

- TEAM Inc.

- YXLON International Gmbh(COMET Group)

- TUV Rhineland AG

- Magnaflux Corp.

- NCS Testing Technology Co., Limited

- Zetec, Inc.

第9章投資分析

第10章投資分析市場的未來

簡介目錄

Product Code: 46732

The APAC NDT Equipment Market is expected to register a CAGR of 7.23% during the forecast period.

Key Highlights

- Safety breaches, such as Volkswagen's diesel emission scandal and the Chinese milk scandal (melamine found in infant milk formula), led to more stringent regulations in developing economies. Such breaches demonstrate the significance of independent inspection and certification services. It resulted in tougher and more complex regulations and standards and increased the dependability on third parties, primarily for assessment, thus, providing scope for independent TIC companies.

- NDT devices can save substantial time by eliminating the need for disassembly or dismantling. For instance, the maintenance of aircraft and the examination of internal structural components (like wing ribs), carried out by removing (and replacing) the outer skin, may be accomplished by radiographic inspection equipment.

- The current market trends in NDT equipment are robust live data capture and comprehensive capture, requiring instant real-time feedback. New sensors are being incorporated in NDT devices, along with other smart and multifunctional components that are intelligent and embedded.

- Furthermore, the power and energy sector uses NDT equipment to test several components of plants. The increasing number of plants and power units across the world is expected to drive the demand for NDT instruments. For instance, according to the World Nuclear Association, as of April 2020, China had 47 operable nuclear plants, and the country is planning to establish additional plants, along with in-line inspection and plant operation inspection services.

- Further, vendors in the market are expanding their foothold through the merger and acquisition strategy. For instance, in February 2020, Eddyfi/NDT acquired NDT Global. The combination of Eddyfi Technologies and NDT Global is an innovative and private test and measurement technology group that focuses on NDT. The group is composed of high-end technology business units operating in two different segments, such as NDT equipment and application-specific integrated inspections.

APAC Non-Destructive Testing Equipment Market Trends

Stringent Regulations Mandating Safety

- Several governmental agencies and regional bodies across the world formulated stringent measures, primarily for assuring the safety of buildings. These measures have mandated the use of NDT and other evaluation techniques for conducting fitness checks.

- This is important for gaining building clearances from concerned authorities for infrastructural projects. These checks include structural strength evaluation, fire safety, and emergency protocol compliance tests.

- The International Code Council (ICC), which engages in the formulation of safety measures, introduced a set of model building codes known as international codes. These codes were devised for use in the United States, but they are also widely employed in other regions.

- The ICC 1704 standard mandates the need for gaining NDT certification in the welding category to ensure structural integrity. However, in the United States, regional bodies are given autonomy for framing their own technical and industrial standards.

- NDT is of paramount importance in high-grade applications, such as defense and aerospace. In these sectors, the scope for error is close to zero, so governmental agencies adopted ASTM and ISO standards to mandate NDT techniques during the development and maintenance of infrastructure.

- Key areas, like energy, material science, and space, widely use NDT for ensuring the structural integrity of components. The role played by world-renowned private organizations, like ASTM, ISO, and NAS, cannot be overlooked, and these bodies have framed NDT industry-level policies for stipulating the set of practices and procedures to be followed by NDT service and equipment firms.

Ultrasonic testing

- Ultrasonic testing is a volumetric testing method that uses high-frequency sound waves to measure geometric and physical properties in materials. The high-frequency sound waves are introduced into the material to detect surface and sub-surface flaws.

- Using ultrasonic testing, the presence and location of flaws can be detected, and information about the type of flaw can be obtained. The flaws are detected from energy by the metal gas interfaces/metal liquid interfaces, the time of transit of the sound wave through the test piece, and attenuation of the beam of sound waves.

- This testing is used for quality control and materials testing in all major industries for the testing of castings, forgings, extruded components, weld joints, manufacturing and production of steel, fabrication of structures such as pressure vessels, bridges, motor vehicles, machinery, and jet engines.

- The major advantage of ultrasonic testing is that it only requires access to one side of the material being tested and is mainly used for the inspection of pressure equipment, tanks, and piping systems. Ultrasonic testing is the best method to detect critical planar breaks, such as cracking and incomplete fusion.

- This testing technology has deep penetration ability. Ultrasonic testing is a sensitive method for the detection of linear discontinuities. Ultrasonic testing is faster and economical compared to radiographic examination. It has applications such as wall thickness measurement, corrosion mapping, lamination testing, flaw detection, density measurement, and hardness measurement.

- Ultrasonic testing can also be used to measure the thickness of metal sections during manufacturing and maintenance inspections. Ultrasonic testing is used to measure wall thickness, detect hidden cracks and other abnormalities affecting structural integrity. The widespread use of ultrasonic testing in construction components has augmented the importance of ultrasonic testing for industrial quality control.

APAC Non-Destructive Testing Equipment Industry Overview

The Asia Pacific NDT Equipment Market is highly competitive due to the presence of many domestic and international players. The market is fragmented, with the players competing in terms of price, product design, product innovation, etc.

- March 2021- Intertek announced the expansion of its Building and Construction business line to the Caribbean with Intertek-PSI opening in Tao Baja, Puerto Rico. From this facility, the Company will provide geotechnical services, environmental consulting, and construction materials testing throughout the Caribbean, bringing services to the region that have previously only been available through offices on the U.S. mainland and in Canada.

- April 2021- Nikon Corporation (Nikon) has acquired Morf3D Inc., a valued pioneer in metal additive manufacturing (AM) specializing in AM and engineering for the aerospace, space, and defense industries, for an undisclosed amount.

- May 2021- Nikon enhanced Metrology's industrial microfocus X-ray CT inspection solutions with a new offset CT reconstruction algorithm to deliver unrivaled scan speed and image resolution. Using X-ray CT for non-destructive quality control of larger components like aluminium castings or battery modules for electric vehicles will shorten the inspection cycle times without compromising resolution. One prerequisite for achieving this is high X-ray intensity or flux.

- April 2021- Bureau Veritas joined the Science-Based Targets project, a coalition of major companies committed to achieving the highest degree of climate commitment and paving the way to a net-zero future. Bureau Veritas commits to aligning climate goals to restrict global temperature rise to 1.5°C above pre-industrial levels as a member of this organization.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Consumers

- 4.2.3 Threat of New Entrants

- 4.2.4 Threat of Substitutes

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Assessment of the Impact of COVID-19 on the market

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Stringent safety regulations and growth in inspection services industry expected to drive adoption

- 5.1.2 Growing demand from the construction industry

- 5.2 Market Restraints

- 5.2.1 High replacement rate remains a key concern followed by reluctance to adopt new technologies in emerging regions

- 5.3 Market Opportunities

6 TECHNOLOGY SNAPSHOT

- 6.1 Evolution of the NDT equipment industry

- 6.2 Industry Value Chain Analysis

7 MARKET SEGMENTATION

- 7.1 Technology Type

- 7.1.1 Radiography Testing

- 7.1.2 Ultrasonic Testing

- 7.1.3 Magnetic Particle Testing*

- 7.1.4 Liquid Penetrant Testing

- 7.1.5 Visual Inspection

- 7.1.6 Eddy Current Testing*

- 7.1.7 Other Technologies

- 7.2 End-user

- 7.2.1 Oil & Gas

- 7.2.2 Power & Energy

- 7.2.3 Construction

- 7.2.4 Automotive & Transportation

- 7.2.5 Aerospace & Defense

- 7.2.6 Other End-users

- 7.3 Country

- 7.3.1 China

- 7.3.2 Japan

- 7.3.3 India

- 7.3.4 South Korea

- 7.3.5 Singapore

- 7.3.6 Indonesia

- 7.3.7 Others (Thailand, Malaysia, others)

8 COMPETITIVE LANDSCAPE

- 8.1 Company Profiles

- 8.1.1 MISTRAS Group

- 8.1.2 SGS Group

- 8.1.3 Fujifilm Corporation

- 8.1.4 Olympus Corporation

- 8.1.5 Bureau Veritas S.A.

- 8.1.6 GE Measurement and Control

- 8.1.7 Nikon Metrology NV

- 8.1.8 Intertek Group Plc.

- 8.1.9 Applus Services, S.A.

- 8.1.10 Acuren Inspection, Inc.(Rockwood Service Corporation)

- 8.1.11 TEAM Inc.

- 8.1.12 YXLON International Gmbh ( COMET Group)

- 8.1.13 TUV Rhineland AG

- 8.1.14 Magnaflux Corp.

- 8.1.15 NCS Testing Technology Co., Limited

- 8.1.16 Zetec, Inc.

9 Investment Analysis

10 Future of the market

02-2729-4219

+886-2-2729-4219