|

市場調查報告書

商品編碼

1626301

亞太地區安全繼電器和定時器:市場佔有率分析、產業趨勢、統計和成長預測(2025-2030)Asia Pacific Safety Relays and Timers - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

價格

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

簡介目錄

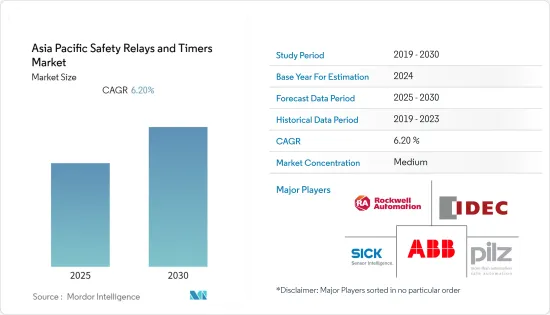

亞太地區安全繼電器和定時器市場預計在預測期內年複合成長率為 6.2%

主要亮點

- 安全繼電器是電子機械開關裝置,用於防止關鍵開關操作期間發生故障。繼電器設計用於隔離電路或用低功率訊號控制高功率電路。包裹在線圈中的磁芯、安裝在鐵軛上的可動銜鐵以及至少一組觸點組成了一個簡單的繼電器。當電流流過線圈時,它會產生一個磁場,驅動電樞,導致觸點移動並建立或斷開連接。

- 典型的繼電器利用線圈和金屬觸點的機械運動來打開和關閉負載。經過幾個操作週期後,金屬觸點可能會焊接閉合。在這種情況下,即使操作員按下急停按鈕,機器也會繼續運行,這對操作員來說是危險的。因此,許多國家和國際規範和安全標準禁止在危險機器中使用簡單繼電器和接觸器。

- 另一方面,安全繼電器具有設計為正向驅動的線圈和接點。強制驅動觸點系統可確保常開 (NO) 和常閉 (NC) 觸點不會同時開啟或關閉,從而消除了故障的可能性。有些安全繼電器內建監控裝置,可以提前偵測故障。

- 這些特性使安全繼電器適用於關鍵開關應用,例如緊急機器停止(E-stop)。如果開關或繼電器在此類應用中發生故障,則可能會發生機械或身體傷害。安全繼電器的其他用途包括安全門、雙手控制器、光柵和安全墊。

- 然而,由於原料價格波動,安全繼電器的設計和製造成本可能很高。此外,COVID-19 大流行擾亂了全球供應鏈,並導致原物料價格波動。

亞太地區安全繼電器和定時器市場趨勢

電力消耗增加推動市場成長

- 亞太地區的能源使用量正在穩定增加,電網的規模和複雜性也持續成長。對電力的需求正在迅速增加,特別是在工業領域。隨著該地區許多國家工業化的影響日益增強,改善現有電力基礎設施已成為主要驅動力。

- 作為回應,ABB 於 2021 年 5 月發布了 REX610,這是 Relion 產品系列的新成員,旨在支援安全、智慧和永續的電氣化。 REX610利用ABB經過驗證的可配置多功能繼電器和保護演算法,提供為所有基本配電應用提供最佳保護的解決方案,幫助保護電網、工業流程和人員,讓保護變得更加輕鬆。它也面向未來性,可以適應不斷發展的電網。隨著市場變化和需求變化,可以輕鬆添加、移除或更換模組,而無需更改整個繼電器。

- 此外,中東地區的發展,包括製造業向亞洲的轉移、中階被動收入的增加以及印度政府的「印度製造」宣傳活動,必將顯著增加該地區的電力消耗。此外,印度政府「人人有電」的目標正在促使該國增加電力供給能力。

- 印度統計與規劃部(MoSPI)公佈的資料顯示,2021年10月印度工業生產指數(IIP)與前一年同期比較去年同期成長3.2%。製造業生產與前一年同期比較%,發電量較上年成長3.1%。

- 該地區製造、建設業和採礦活動的增加以及發電和消費量的增加預計將為安全繼電器和定時器市場提供利潤豐厚的機會。

各個最終用戶行業不斷成長的需求推動了市場

- 汽車繼電器用於整個汽車的線束和盒子模組,包括後部、前部、乘客、引擎區域、車身控制、動力傳動系統、車頂、座椅、車門和風扇模組。汽車繼電器的類型包括插入式、PCB式、高電流和高電壓,也包括汽車接觸器。隨著亞太地區汽車產量的增加,對安全繼電器的需求預計將會增加。

- 根據國際汽車工業協會(OICA)的數據,2020年中國乘用車產量為1,999萬輛,其次是日本,產量為696萬輛。此外,2019年亞太地區乘用車銷量為3,536萬輛,2020年為3,200萬輛。此外,對省油車的需求不斷成長以及車載電子技術的進步正在推動對汽車安全繼電器的需求。

- 此外,安全繼電器和定時器也用於控制、啟動和保護石油和天然氣領域的電路。工業定時器適用於物料輸送、工具機和各種加工機器的製程控制。

- 海上石油和天然氣探勘活動的大幅擴展導致該地區製程設備的部署大幅增加。根據貝克休斯統計,截至2021年10月,亞太地區共有190座石油和天然氣鑽井鑽機,其中70座為海上鑽機。

- 在化學和石化行業,安全繼電器擴大在泵送和儲存過程中使用。化工廠和石化廠的增加將推動安全繼電器和定時器市場。

亞太地區安全繼電器和定時器產業概況

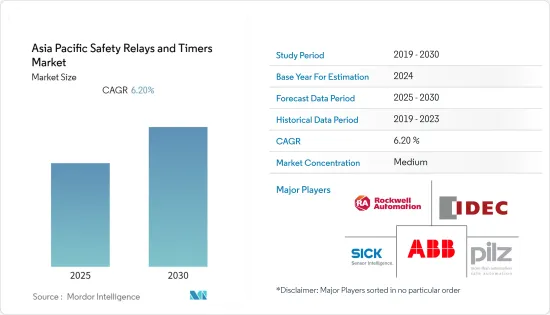

亞太安全繼電器和定時器市場競爭激烈,主要參與者包括羅克韋爾自動化、歐姆龍工業自動化、SICK AG、伊頓公司和西門子公司。技術進步和創新、策略聯盟和業務擴張預計將推動所研究的市場。

- 2021 年 10 月 - 施耐德電氣宣布與 Savant Power 合作開發一款遠端控制連網型繼電器,使住宅能夠更好地管理住宅能源使用情況。連接到電路斷流器的繼電器可控制住宅電力負載,包括在停電期間最大限度地提高備用電源的設定。透過為每個備用電源(電池、太陽能等)建立一個虛擬可配置的關鍵負載面板,您可以透過僅向關鍵電路發送電力來最大化可用電力,直到市電恢復為止。

- 2021 年 3 月 - IDEC Corporation 推出 HR5S 安全繼電器模組。這是 IDEC 安全設備系列的最新成員,旨在為設計師和OEM提供更高的最終用戶安全性,同時降低機器和設備成本並提高生產率,為您提供多種選擇。 HR5S 安全繼電器模組專為滿足 ISO 13849 2 類要求而設計。

其他好處

- Excel 格式的市場預測 (ME) 表

- 3 個月分析師支持

目錄

第1章簡介

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章市場洞察

- 市場概況

- 產業吸引力-波特五力分析

- 供應商的議價能力

- 消費者議價能力

- 新進入者的威脅

- 競爭公司之間的敵對關係

- 替代品的威脅

- 價值鏈分析

- COVID-19 對產業價值鏈的影響

- 評估 COVID-19 對產業的影響

第5章市場動態

- 市場促進因素

- 需要靈活的模組化設計

- 業界安全標準

- 整合功能要求

- 市場限制因素

- 市場競爭激烈

- 標準複雜度

第6章 市場細分

- 按類型

- 單功能安全繼電器

- 模組化和可配置的安全繼電器

- 透過聯繫

- 常閉、定時開啟 (NCTO)

- 常閉、時閉 (NCTC)

- 常開、時開(NOTO)

- 常開、時閉(NOTC)

- 按最終用戶

- 車

- 能源和電力

- 製造業

- 藥品

- 建造

- 半導體

- 石油和天然氣

- 其他最終用戶

- 按國家/地區

- 中國

- 日本

- 印度

- 澳洲

- 韓國

- 其他亞太地區

第7章 競爭格局

- 公司簡介

- Rockwell Automation, Inc.

- OMRON Corporation

- Sick AG

- Pilz GmbH & Co. KG

- Eaton Corporation PLC

- Siemens AG

- IDEC Corporation

- ABB Ltd

- TE Connectivity

- Altech Corporation

第8章投資分析

第9章 未來展望

簡介目錄

Product Code: 47140

The Asia Pacific Safety Relays and Timers Market is expected to register a CAGR of 6.2% during the forecast period.

Key Highlights

- Safety relays are electromechanical switching devices used to prevent failures during critical switching operations. Relays are designed to isolate circuits or control high-powered circuits with a low-power signal. A magnetic core encased in a wire coil, a movable armature attached to an iron yoke, and at least one set of contacts comprise a simple relay. When an electric current passes through the coil, it creates a magnetic field that activates the armature, causing the contacts to move to make or break a connection.

- A normal relay switches the load on and off using a wire coil and the mechanical movement of the metal contacts. After several operation cycles, the metal contacts may weld shut. If this happens, the machine will continue running if the operator presses the emergency stop pushbutton, which would be dangerous for the operator. As a result, many national and international norms and safety standards prohibit using simple relays or contactors on hazardous machines.

- Whereas safety relays have coils and contacts that are designed to be positively driven. A positively driven contact system ensures that the normally open (NO) and normally closed (NC) contacts can never be opened or closed simultaneously, eliminating the possibility of faulty operation. Some safety relays include built-in monitoring equipment to detect faults before they occur.

- Due to these characteristics, safety relays are appropriate for use in critical switching applications such as an emergency machine stop (E-stop). Mechanical or physical human damage could occur if a switch or relay fails to operate in one of these applications. The other applications for safety relays also include safety gates, two-hand control, light curtains, safety mats, etc.

- However, designing and manufacturing safety relays is could be expensive due to the fluctuations in prices of raw materials. Further, the COVID-19 pandemic has disrupted the supply chains globally, contributing to the volatility in raw materials prices.

APAC Safety Relays & Timers Market Trends

Increasing Power Consumption to Drive the Market Growth

- With the energy usage in the Asia Pacific region rising steadily, power distribution networks continue to grow in size and complexity. Electricity demand has soared, particularly in the industrial sector. With the rising influence of industrialization across many countries in the region, improving the existing electrical setup has gained considerable traction.

- In response, in May 2021, ABB is launched REX610, a new addition to its Relion product family designed to support safe, smart, and sustainable electrification. REX610 makes protecting grids, industrial processes, and people more effortless as it draws on ABB's heritage of configurable multifunctional relays and protection algorithms to create a solution that provides optimal protection for all basic power distribution applications. It is also futureproofed for an evolving grid. As the market shifts and requirements change, the modules can be easily added, removed, or replaced without changing the entire relay.

- Further, the shift of manufacturing industries to Asia, the growing dispensable income among the middle class, and the developments in South East Asia, including the 'Make in India' campaign by the Indian government, are bound to increase the power consumption of the region considerably. Further, the Indian government's aim of achieving 'Power for All' has sped up capacity addition in the country.

- According to the data released by the Ministry of Statistics & Programme (MoSPI), India's index of industrial production (IIP) grew by 3.2% in October 2021, as compared to the previous year. The manufacturing sector output jumped 2% y-o-y, and electricity generation grew 3.1% y-o-y in October 2021.

- The increasing manufacturing, construction, and mining activities, coupled with rising power generation and consumption in the region, are expected to provide lucrative opportunities for the safety relays and timers market.

The Rising Demand in Various End-user Industries to Drive the Market

- Automotive relays are used in harnesses and box modules throughout a vehicle, including rear and front, passenger and engine areas, body control, powertrain, roof, seat, door, and fan modules. The automotive relay types include plug-in, PCB, high-current, and high-voltage, including automotive contactors. With the increase in automotive production in the Asia Pacific region, the demand for safety relays is expected to rise.

- According to The International Organization of Motor Vehicle Manufacturers (OICA), China produced 19.99 million passenger cars in 2020, followed by Japan with 6.96 million. Further, the number of passenger cars sold in the Asia Pacific region totaled 35.36 million in 2019 and 32 million in 2020. Also, the rising demand for fuel-efficient vehicles, and technological advancements in-vehicle electronics, are driving the demand for safety relays in automobiles.

- Further, safety relays and timers are used in controlling, starting, and protecting circuits in the oil and gas sector. The industrial timers are suitable for material handling, machine tools, and process control in various process machines.

- Due to the significant expansion in offshore oil and gas exploration activities, the deployment of process equipment has significantly increased in the region. According to Baker Hughes, the Asia Pacific region had 190 oil and gas rigs as of October 2021, of which 70 were offshore rigs.

- Safety relays are increasingly being used during pumping and storage in the chemical and petrochemical industries. Increasing chemical and petrochemical plants boosts the safety relays and timers market.

APAC Safety Relays & Timers Industry Overview

The Asia Pacific Safety Relays and Timers Market is moderately competitive and consists of prominent players like Rockwell Automation, OMRON Industrial Automation, SICK AG, Eaton Corp., Siemens AG, Etc. Technological advancements and innovations, coupled with strategic collaborations and expansions, are expected to drive the studied market.

- October 2021 - Schneider Electric announced a partnership with Savant Power to develop a remote-controlled connected relay to enable homeowners better manage their residential energy use. When connected to a circuit breaker, the relay would provide control of residential power loads, including configurations to maximize backup power in the event of an outage. By constructing a virtual configurable critical load panel for each backup power source (battery, solar, etc.), available power can be maximized by sending it to only crucial circuits until the utility power is restored.

- March 2021 - IDEC Corporation launched the HR5S safety relay module, a new addition to IDEC's family of safety devices that offers designers and OEMs more options to provide better end-user safety while cutting costs and improving productivity of machines and equipment. The HR5S safety relay module is explicitly designed to meet ISO 13849 Category 2 requirements.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHT

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Consumers

- 4.2.3 Threat of New Entrants

- 4.2.4 Intensity of Competitive Rivalry

- 4.2.5 Threat of Substitutes

- 4.3 Industry Value Chain Analysis

- 4.4 COVID-19 Impact on Industry Value Chain

- 4.5 Assessment of the Impact of COVID-19 on the Industry

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Need for Flexible Modular Designs

- 5.1.2 Industry Safety Standards

- 5.1.3 Integrated Functionality Requirements

- 5.2 Market Restraints

- 5.2.1 High Market Competition

- 5.2.2 Complexity of Standards

6 MARKET SEGMENTATION

- 6.1 By Type

- 6.1.1 Single-Function Safety Relays

- 6.1.2 Modular & Configurable Safety Relays

- 6.2 By Contacts

- 6.2.1 Normally Closed, Time Open (NCTO)

- 6.2.2 Normally Closed, Time Closed (NCTC)

- 6.2.3 Normally Open, Time Open (NOTO)

- 6.2.4 Normally Open, Time Closed (NOTC)

- 6.3 By End-users

- 6.3.1 Automotive

- 6.3.2 Energy and Power

- 6.3.3 Manufacturing

- 6.3.4 Pharmaceutical

- 6.3.5 Construction

- 6.3.6 Semiconductors

- 6.3.7 Oil and Gas

- 6.3.8 Other End-user Applications

- 6.4 By Country

- 6.4.1 China

- 6.4.2 Japan

- 6.4.3 India

- 6.4.4 Australia

- 6.4.5 South Korea

- 6.4.6 Rest of Asia Pacific

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Rockwell Automation, Inc.

- 7.1.2 OMRON Corporation

- 7.1.3 Sick AG

- 7.1.4 Pilz GmbH & Co. KG

- 7.1.5 Eaton Corporation PLC

- 7.1.6 Siemens AG

- 7.1.7 IDEC Corporation

- 7.1.8 ABB Ltd

- 7.1.9 TE Connectivity

- 7.1.10 Altech Corporation

8 INVESTMENT ANALYSIS

9 FUTURE OUTLOOK

02-2729-4219

+886-2-2729-4219