|

市場調查報告書

商品編碼

1626314

中東和非洲的安全運動控制:市場佔有率分析、產業趨勢和成長預測(2025-2030)MEA Safety Motion Control - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

價格

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

簡介目錄

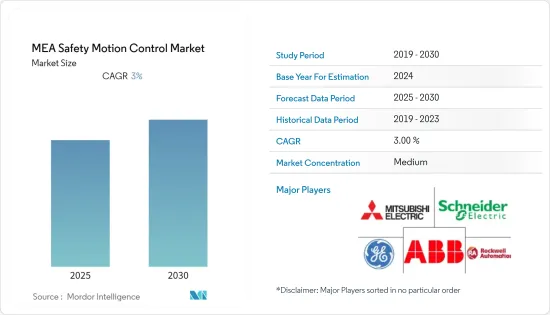

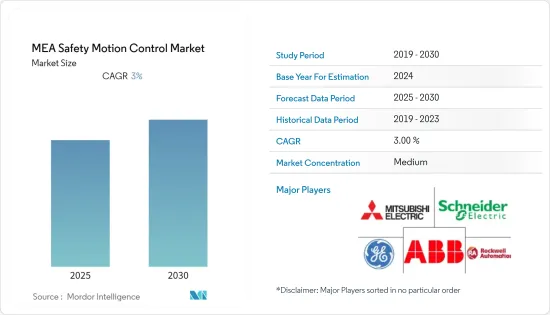

中東和非洲安全運動控制市場預計在預測期內複合年成長率為 3%

主要亮點

- 自動化解決方案的主要運動控制產品是運動控制器、驅動器、馬達和機器人。運動控制系統用於實現流程自動化,越來越多的公司開始採用機器人和輸送機系統,以在組裝和生產中實現更高的效率。因此,在這些應用中使用各種馬達來控制製程。

- 工業自動化和儲能法規的持續發展趨勢需要更安全的運動控制產品。供應商透過推出多種產品、收購基於工業物聯網軟體的公司以及建立合作夥伴關係,增加了對該領域的投資。

- 工業IoT(IIoT)的日益普及和智慧工廠數量的增加進一步推動了市場的成長。由於安全產品是智慧工廠的關鍵架構師,智慧工廠正成為安全運動控制產品的重要採用者。工業IoT也進一步增加了工業中對連網機器的需求和需求。僅這些連接的機器不足以實現純粹的數位轉型,因此組織正在開發一個無縫的人機生態系統來運行最佳化的端到端流程。

- 此外,倉庫自動化的成長趨勢以及數位雙胞胎運算、邊緣運算和預測製造等趨勢的成長也為先進安全運動控制設備開闢了空間。機器人已成為全球重要的自動化趨勢。機器人已成為先進汽車製造的關鍵組成部分。亞馬遜等公司也崛起,協作機器人、AGV等機器人也在製造業受到關注。

- COVID-19 大流行對世界各地的小型、中型和大型產業造成了經濟干擾。此外,各國的封鎖對許多製造業的打擊更加嚴重。因此,安全運動控制設備的需求在幾個細分領域中波動。然而,COVID-19 危機的影響迫使公司遵守嚴格的要求,以確保員工和機器的持續安全。結果,對自動化的需求激增。

中東和非洲安全運動控制市場趨勢

汽車產業需求龐大

- 隨著HCV和高階汽車製造和組裝流程的發展,汽車產業對安全運動控制系統的需求顯著增加。

- 在汽車產業,高階運動控制器用於控制生產過程中機械零件的運動。安全運動控制系統廣泛應用於引擎和駕駛員輔助系統等關鍵零件的製造。

- 汽車行業的所有重要供應商都依靠運動控制系統透過致動器和機械臂來最佳化其生產鏈。此外,在組裝和維護過程中擴大採用安全運動控制系統。

- 例如,安全控制系統廣泛應用於車輛組裝中,這是一個需要高精度和吞吐量的密集過程,以最少的資源執行重複性任務。

- 波灣合作理事會(GCC)汽車市場是該地區的主要市場之一。多年來我們實現了持續成長。該地區的主要市場是沙烏地阿拉伯,擁有最大的新車銷售和汽車零件行業。儘管該地區嚴重依賴日韓汽車製造商,但對於豪華汽車品牌來說,它也是一個充滿前景的市場。由於消費者可支配收入的增加,梅賽德斯、路虎探測車和保時捷等豪華汽車品牌開始在阿拉伯聯合大公國受到歡迎。同時,二手車市場和售後市場也不斷擴大。特別是,Covid-19大流行增加了全球經濟的不確定性,並導致人們重新考慮他們的支出。

- 2020年初,阿拉伯聯合大公國探索了進口豪華跑車的可能性,並很快考慮將自己建立為豪華跑車的生產基地。與波灣合作理事會其他次區域一樣,阿拉伯聯合大公國正在尋求企業實現經濟多元化並減少石油和天然氣收入。

工業自動化的採用不斷增加,促進了市場需求。

- 由於各種最終用戶產業擴大採用自動化,中東和非洲已成為安全運動控制設備最重要的市場之一。該地區的能源挑戰也增加了先進工具的採用,促使許多公司投資機械安全設備,進一步推動市場成長。

- 為因應COVID-19導致的全球景氣衰退,中東和非洲工廠自動化和工業控制系統市場在2020年上半年見證了需求方的正面影響和供應方的混合影響。智慧工廠計畫將幫助製造商克服COVID-19 帶來的挑戰,包括減少勞動力、某些產品銷量減少、保持社交距離以及許多從事最終用戶行業(主要是製造業、汽車業)的公司因停工而關閉生產基地。

- 沙烏地阿拉伯於2018年啟動了一項價值70億美元的可再生能源計劃,以太陽能發電廠為主導。這是到 2023 年安裝 9.5 吉瓦太陽能和風能計畫的一部分。此類基礎設施的發展可能會提供工業控制和工廠自動化解決方案。

中東和非洲安全運動控制產業概況

安全運動控制市場高度分散。越來越參與企業正在透過策略併購以及與較小的參與企業結盟來擴大其在運動控制驅動市場的佔有率。近期趨勢如下。

- 2020 年 1 月 - 羅克韋爾公司宣布推出新型馬達保護斷路器,可節省空間、時間和成本。此斷路器經過 UL 認證,可用於集體安裝。這種安裝方式無需在每個馬達電路上安裝單獨的分支短路保護裝置,從而減少了面板空間、安裝和接線時間以及整體成本。

其他好處

- Excel 格式的市場預測 (ME) 表

- 3 個月分析師支持

目錄

第1章簡介

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章市場動態

- 市場概況

- 市場促進因素

- 工業安全標準

- 安全設備的需求

- 輕鬆設定和維護

- 靈活的自動化能力

- 市場限制因素

- 市場競爭加劇

- 產品成本增加

- 高資本要求

- 價值鏈/供應鏈分析

- 波特五力分析

- 新進入者的威脅

- 買方議價能力

- 供應商的議價能力

- 替代品的威脅

- 競爭公司之間敵對關係的強度

第5章市場區隔

- 元件類型

- 伺服驅動器

- 伺服馬達

- 致動器

- 其他

- 最終用戶產業

- 車

- 能源/電力

- 石油和天然氣

- 航太/國防

- 飲食

- 藥品

- 其他

- 地區

- 沙烏地阿拉伯

- 阿拉伯聯合大公國

- 南非

- 其他中東/非洲

第6章 競爭狀況

- 公司簡介

- Rockwell Automation

- ABB Ltd

- SIGMATEK Safety System

- ASTRE Engineering Tunisie

- Demero Automation Systems

- Schneider Electric SE

- General Electric Co.

- More Control

- SICK Group

- Siemens AG

第7章 投資分析

第8章市場的未來

簡介目錄

Product Code: 47259

The MEA Safety Motion Control Market is expected to register a CAGR of 3% during the forecast period.

Key Highlights

- Major motion control products for automation solutions are motion controllers, drives, motors, and robotics. Motion control systems are being used to automate processes, and more companies are turning to robotics and conveyor systems to achieve higher efficiency margins in assembly and production. Therefore, various motors are used in these applications to control the process.

- The ongoing trend in industrial automation and rules and regulations regarding energy reserves demands more safety motion control products. Vendors witnessed increasing investments in this arena via multiple product launches, acquiring IIoT software-based companies, and collaborations.

- The increasing adoption of Industrial IoT(IIoT) and the growing number of smart factories further expand the market's growth. Smart factories are becoming a significant adopter of safety motion control products, as safety products are the principal architect of smart factories. Besides, the industrial IoT further increased the need and demand for connected machines in the industries. These connected machines alone are not enough to accomplish pure digital transformation; hence, organizations are developing a seamless ecosystem of humans and machines, performing optimized, end-to-end processes.

- Additionally, The increasing trend of warehouse automation and growth in trends, such as digital twin, edge computing, and predictive manufacturing, is also developing space for advanced safety motion control devices. Robots have become a significant automation trend across the world. In advanced automotive manufacturing, robots have become a significant component. Companies like Amazon are also heavily increasing, and robots, like collaborative robots and AGVs, are also becoming the center of attraction in the manufacturing industry.

- COVID-19 pandemic has created economic turmoil for small, medium, and large-scale industries worldwide. Additionally, the country-wise lockdown has further hit many manufacturing industries. This has fluctuated the demand for safety motion control devices across some sectors. However, the impact of the COVID-19 crisis forced businesses to adhere to strict requirements to ensure the ongoing safety of their employees and their machines. As a result, the need for automation witnessed a sudden spike.

MEA Safety Motion Control Market Trends

Automotive Industry to Witness Huge Demand

- The demand for safety motion control systems in the automotive industry has seen a marked increase due to the developments in the manufacturing and assembly processes of HCV's and high-end motor vehicles.

- High-end motion controllers are used in the automotive industry to control mechanical parts' movements in the production process. Safety motion control systems are extensively used to manufacture significant components, like engines and driver assistance systems.

- All the essential automotive suppliers rely on motion control systems to optimize their production chains through actuators and robotic arms. Furthermore, assembling and maintenance processes are also witnessing increased adoption of safety motion control systems.

- For instance, vehicle assembly (an exhaustive process requiring high precision and throughput) has been using safety control systems widely for performing repetitive tasks using minimal resources.

- The Gulf Cooperation Council (GCC) automotive market is one of the primary sectors of the region. It has achieved sustainable growth over the years. The region's primary market is Saudi Arabia, with the most significant new car sales and auto parts segment. The region is heavily dependent on Japanese and Korean automakers, but it is also a promising market for luxury car brands. Luxury car brands such as Mercedes, Range Rover, and Porsche have begun to gain popularity in the United Arab Emirates (UAE) due to rising consumer disposable income. Meanwhile, the market for used and aftermarket vehicles is also expanding, especially with the COVID-19 pandemic, which has led people to rethink their spending due to increased uncertainty in the global economy.

- In early 2020, the United Arab Emirates explored the possibility of importing luxury sports cars and considered establishing itself as a production base for luxury sports cars shortly. Like the other subregions of the Gulf Cooperation Council, the United Arab Emirates is considering ventures to diversify its economy and reduce its oil and gas revenues.

Increasing adoption of industrial automation to contribute to market demand.

- Due to the growing adoption of automation across the various end-user industries in the region, the Middle East and Africa is emerging as one of the most significant safety motion control devices. The energy concern in the region is also increasing the adoption of advanced tools and motivating many companies to invest in machine safety devices, further driving the growth market.

- Following the global economic recession led by COVID-19, the Middle Eastern and African factory automation and industrial control system market have witnessed positive impact from the demand side and mixed impact from the supply side in the first half of 2020. Smart factory initiatives have helped manufacturers overcome COVID-19 challenges and address issues such as workforce reductions, drops in sales for some specific products, social distancing, and extreme pressure to cut operational costs since most enterprises operating in the end-user industries (majorly manufacturing, automotive) had shuttered down their production sites due to lockdown restrictions.

- Saudi Arabia initiated USD 7 billion of renewable energy projects in 2018, with solar plants being the frontrunner. It is part of its plan to install 9.5 gigawatts of solar and wind capacity by 2023. such infrastructural developments are likely to provide for industrial controls and factory automation solutions.

MEA Safety Motion Control Industry Overview

The safety motion control market is highly fragmented. The increasing number of players are boosting their share of the motion control drive market through strategic mergers and acquisitions and partnerships with several small players. Some of the recent developments include:

- Jan 2020 - Rockwell Inc announced the launch of new motor protection circuit breakers that offer space, time, and cost savings. The circuit breakers are enabled by UL approval for use in group installation. This type of installation can reduce panel space, installation and wiring time, and overall costs, by eliminating the need for individual branch shortcircuit protective devices for each motor circuit.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Industry Safety Standards

- 4.2.2 Demand for Safe Equipment

- 4.2.3 Easy Set-up and Maintenance

- 4.2.4 Flexible Automation Functions

- 4.3 Market Restraints

- 4.3.1 High Market Competition

- 4.3.2 Rising Product Costs

- 4.3.3 High Capital Requirements

- 4.4 Value Chain / Supply Chain Analysis

- 4.5 Porters 5 Force Analysis

- 4.5.1 Threat of New Entrants

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Bargaining Power of Suppliers

- 4.5.4 Threat of Substitute Products

- 4.5.5 Intensity of Competitive Rivalry

5 MARKET SEGMENTATION

- 5.1 Component Type

- 5.1.1 Servo Drives

- 5.1.2 Servo Motors

- 5.1.3 Actuators

- 5.1.4 Others

- 5.2 End-User Industry

- 5.2.1 Automotive

- 5.2.2 Energy and Power

- 5.2.3 Oil and Gas

- 5.2.4 Aerospace and Defense

- 5.2.5 Food and Beverage

- 5.2.6 Pharmaceuticals

- 5.2.7 Other End-User Industries

- 5.3 Geography

- 5.3.1 Saudi Arabia

- 5.3.2 United Arab Emirates

- 5.3.3 South Africa

- 5.3.4 Rest of Middle East and Africa

6 COMPETITIVE LANDSCAPE

- 6.1 Company Profiles

- 6.1.1 Rockwell Automation

- 6.1.2 ABB Ltd

- 6.1.3 SIGMATEK Safety System

- 6.1.4 ASTRE Engineering Tunisie

- 6.1.5 Demero Automation Systems

- 6.1.6 Schneider Electric SE

- 6.1.7 General Electric Co.

- 6.1.8 More Control

- 6.1.9 SICK Group

- 6.1.10 Siemens AG

7 INVESTMENT ANALYSIS

8 FUTURE OF THE MARKET

02-2729-4219

+886-2-2729-4219