|

市場調查報告書

商品編碼

1628777

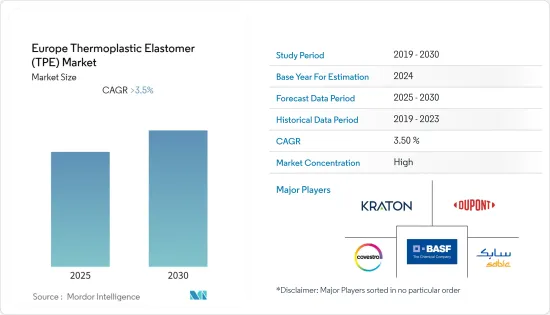

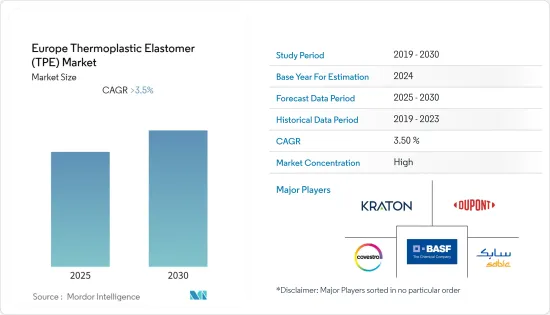

歐洲熱可塑性橡膠(TPE):市場佔有率分析、產業趨勢、成長預測(2025-2030 年)Europe Thermoplastic Elastomer (TPE) - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

預計歐洲熱可塑性橡膠市場在預測期內將維持3.5%以上的複合年成長率。

2020 年,COVID-19 影響了市場。由於汽車工業衰退以及政府封鎖導致建設業和汽車製造停止,歐洲熱可塑性橡膠市場遭受重創。熱可塑性橡膠用於製造墊圈、塑膠、管道、塗層、皮帶和軟管。然而,由於對基於熱可塑性橡膠的罩衣、手術單、手套和其他醫療用品的需求,市場在 2021 年復甦。

主要亮點

- 短期內,橡膠基工具手柄、管道、塑膠和墊圈等建築業材料對熱可塑性橡膠的需求不斷增加,預計將推動市場成長。

- 然而,熱可塑性橡膠應用的市場飽和預計將阻礙未來的市場成長。

- 對生物基熱可塑性橡膠不斷成長的需求可能會在未來幾年創造市場機會。

- 德國在市場上佔據主導地位,預計在預測期內仍將保持最高的複合年成長率。

歐洲熱可塑性橡膠市場趨勢

增加在汽車和運輸應用中的使用

- 熱可塑性橡膠(TPE) 用於汽車和電動車領域。這是因為熱可塑性橡膠結合了熱塑性塑膠的製造便利性和合成橡膠的彈性和耐用性。 TPE 具有低溫柔韌性、耐化學性、韌性,並且能夠成型為複雜形狀。

- TPE 可用於多種應用,包括密封件、軟管和管子、電纜以及內部和外部零件。 TPE 因其重量輕、柔韌且在惡劣氣候條件下耐用而被用於電動車的電纜、電線、軟管、管道、密封件、墊圈以及內部和外部部件。

- 汽車業對所用材料有非常嚴格的標準。材料必須在極端負載下保持尺寸穩定,並且在暴露於大溫差時不得變形。

- TPE 是一種比金屬更便宜的塑膠,可透過減輕重量來提高車輛能源效率,以較低的成本提供耐用性、耐腐蝕性、韌性、設計靈活性、彈性和卓越的性能。 TPE 的重量更輕,使得製造燃油效率更高的汽車成為可能。車重每減輕10%,消費量預計會降低5-7%。

- 汽車產業對輕質高性能聚合物的需求不斷增加,以實現更好的經濟性和設計靈活性,這推動了 TPE 市場的成長。高性能熱可塑性橡膠為製造商提供了設計優勢,並且堅固如鋼,有助於減輕重量並減少溫室氣體排放。

- 歐洲汽車工業是全球汽車工業的主要部門,也是歐洲經濟的主要貢獻者。該行業的特點是悠久的工程和發明歷史、高技能的勞動力以及龐大的汽車市場。 2021年,歐洲汽車產業市場規模超過750億美元。

- 近年來,歐洲一直是全球電動車市場的主要企業,德國、法國和挪威等國家在電動車的採用和生產方面處於領先地位。根據歐盟統計局數據,2021年歐洲電動車出口額達125.3億美元,與前一年同期比較成長45%。

- 預計這些因素將在未來幾年推動該地區對熱可塑性橡膠的需求。

德國主導市場

- TPE(熱可塑性橡膠)是一種用於航太工業的聚合物材料,具有彈性、耐用性、柔韌性以及耐溫、耐化學品和耐紫外線的性能。 TPE 用於各種飛機應用,包括密封和緩衝、軟管和管道以及電氣和引擎零件。

- TPE 是一種高度通用的材料,兼具物理特性和易於加工性,使其適合在飛機上的各個區域使用。德國生產了全球超過 6% 的汽車和 12% 的飛機製造,增強了該地區的 TPE 市場。

- 德國擁有最大的汽車工業。據OICA稱,到2021年終,該國將生產33,086,692輛汽車。德國引領歐洲汽車市場,擁有約 40 個組裝和引擎生產廠,佔歐洲汽車總產量的三分之一。

- TPE(熱可塑性橡膠)因其耐溫、耐化學品和耐紫外線而被用於住宅行業。 TPE廣泛用於地板材料、屋頂、門窗、浴室設備等。它耐用、靈活且易於護理,適合住宅使用。根據聯邦統計局的數據,2021 年德國建築許可數量增加了 7%,達到 248,688 個(Destatis)。

- 因此,預計上述因素將在未來幾年對市場產生重大影響。

歐洲熱可塑性橡膠產業概況

歐洲熱可塑性橡膠市場因其性質而部分一體化。該市場的主要企業包括杜邦、BASF、科思創、科騰公司和沙烏地阿拉伯基礎工業公司。

其他好處:

- Excel 格式的市場預測 (ME) 表

- 3 個月分析師支持

目錄

第1章簡介

- 調查先決條件

- 調查範圍

第2章調查方法

第3章執行摘要

第4章市場動態

- 促進因素

- 建設產業的需求不斷增加

- 擴大暖通空調產業的應用

- 抑制因素

- 應用市場飽和

- 由於 COVID-19 的影響,情況不利

- 產業價值鏈分析

- 波特五力分析

- 供應商的議價能力

- 消費者議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭程度

第5章市場區隔

- 依產品類型

- 苯乙烯嵌段共聚物 (TPE-S)

- 熱塑性烯烴 (TPE-O)

- 合成橡膠合金(TPE-V 或 TPV)

- 熱塑性聚氨酯(TPU)

- 熱塑性共聚酯

- 熱塑性聚醯胺

- 按用途

- 汽車和交通

- 建築/施工

- 鞋類

- 電力/電子

- 醫療保健

- 家電

- 空調

- 黏合劑、密封劑、被覆劑

- 其他用途

- 按地區

- 德國

- 英國

- 義大利

- 法國

- 西班牙

- 其他歐洲國家

第6章 競爭狀況

- 併購、合資、聯盟、協議

- 市場佔有率(%)**/排名分析

- 主要企業策略

- 公司簡介

- Apar Industries Ltd

- Arkema

- Asahi Kasei Corporation

- BASF SE

- Covestro AG

- DSM

- DuPont

- Evonik Industries AG

- Exxon Mobil Corporation

- Grupo Dynasol

- Huntsman International LLC

- KRATON CORPORATION

- KURARAY CO. LTD

- LANXESS

- LG Chem

- LyondellBasell Industries Holdings BV

- Mitsubishi Chemical Corporation

- Mitsui Chemicals Inc.

- SABIC

- Sirmax SpA

- Sumitomo Chemicals Co. Ltd

- The Lubrizol Corporation

第7章 市場機會及未來趨勢

- 對生物基熱可塑性橡膠的需求不斷成長

- 醫療產業應用不斷增加

The Europe Thermoplastic Elastomer Market is expected to register a CAGR of greater than 3.5% during the forecast period.

In 2020, COVID-19 affected the market. The European thermoplastic elastomer market suffered from declining automotive industries and the government-imposed lockdown, which halted construction and automotive manufacturing. Thermoplastic elastomers make gaskets, plastics, pipes, coatings, belts, and hoses. However, the market recovered in 2021 with the demand for gowns, drapes, gloves, and other thermoplastic elastomer-based medical items.

Key Highlights

- Over the short term, the increasing demand for thermoplastic elastomers in the construction industry materials, like rubber-based tool grips, pipes, plastics, and gaskets, is expected to drive the market's growth.

- However, market saturation in the applications of thermoplastic elastomers is expected to hinder the market's growth in the future.

- The growing demand for bio-based thermoplastic elastomers will likely create opportunities for the market in the coming years.

- Germany is expected to dominate the market and will likely witness the highest CAGR during the forecast period.

Europe Thermoplastic Elastomers Market Trends

Increasing Usage in the Automotive and Transportation Applications

- The automotive and electric vehicle sectors utilize thermoplastic elastomers (TPEs) because they combine the manufacturing convenience of thermoplastics with the elasticity and durability of elastomers. Due to their low-temperature flexibility, chemical resistance, toughness, and ability to be molded into complex shapes,

- TPEs are used for sealing, hoses and tubing, cables, interior and exterior components, and many more applications. TPEs are used in EVs for cables, wiring, hoses, tubing, seals, gaskets, and interior and exterior components due to their lightweight, flexibility, and durability in extreme climatic conditions.

- The automotive sector includes very rigorous standards for the materials utilized. Even when subjected to extreme loads, the materials must be dimensionally stable and not distort, even when subjected to wide temperature differences.

- TPEs are plastics that are less expensive than metals and help make automobiles more energy-efficient by lowering weight and providing durability, corrosion resistance, toughness, design flexibility, resiliency, and good performance at a low cost. TPE's reduced weight allows for more fuel-efficient automobiles. It is anticipated that every 10% reduction in vehicle weight results in a 5-7% reduction in fuel consumption.

- The growing demand for lightweight and high-performance polymers in the automotive industry to give better economy and design flexibility is driving the TPE market's rise. High-performance thermoplastic elastomers provide manufacturers with design advantages and equivalent strength to steel, which aids in weight reduction and greenhouse gas emissions control.

- The European automotive sector is a key segment of the worldwide automotive industry and a substantial contributor to the European economy. The sector is distinguished by a long history of engineering and invention, a highly skilled workforce, and a big automotive market. In 2021, Europe's automobile sector was worth more than USD 75 billion.

- In recent years, Europe is a major player in the global electric vehicle market, with nations such as Germany, France, and Norway leading the way in EV adoption and production. According to Eurostat, Europe's electric car exports in 2021 reached USD 12.53 billion, a 45% increase over the previous year.

- All the abovementioned factors are expected to augment the demand for thermoplastic elastomers in the region over the coming years.

Germany to Dominate the Market

- TPE (thermoplastic elastomer) is a type of polymer material utilized in the aerospace industry due to its elasticity, durability, flexibility, and resistance to temperature, chemicals, and UV light. TPEs are used in various airplane applications, such as sealing and cushioning, hoses and tubing, and electrical and engine components.

- TPE offers a versatile material with a combination of physical qualities and processing simplicity, making it suitable for usage in various regions of an airplane. Germany produces more than 6% of the world's automobiles and 12% of the world's aircraft manufacturing, bolstering the region's TPE market.

- Germany includes the largest automobile industry. According to OICA, the country produced 33,08,692 vehicles by the end of 2021. Germany leads the European automotive market, with around 40 assembly and engine production plants contributing to one-third of Europe's total automobile production.

- TPE (thermoplastic elastomer) is employed in the housing industry because of its resilience to temperature, chemicals, and UV radiation. TPEs are widely utilized in flooring, roofing, windows & doors, and bathroom fixtures. They are suitable for house use because they combine durability, flexibility, and ease of upkeep. According to the Federal Statistical Office, building permits in Germany increased by 7% in 2021 to 248,688 permits (Destatis).

- Therefore, the above factors are expected to significantly impact the market in the coming years.

Europe Thermoplastic Elastomers Industry Overview

The European thermoplastic elastomer market is partially consolidated in nature. The key players in the market include DuPont, BASF SE, Covestro AG, KRATON CORPORATION, and SABIC.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Drivers

- 4.1.1 Growing Demand from the Construction Industry

- 4.1.2 Growing Applications in the HVAC Industry

- 4.2 Restraints

- 4.2.1 Market Saturation in Applications

- 4.2.2 Unfavorable Conditions Arising due to the Impact of COVID-19

- 4.3 Industry Value Chain Analysis

- 4.4 Porter's Five Forces Analysis

- 4.4.1 Bargaining Power of Suppliers

- 4.4.2 Bargaining Power of Consumers

- 4.4.3 Threat of New Entrants

- 4.4.4 Threat of Substitute Products and Services

- 4.4.5 Degree of Competition

5 MARKET SEGMENTATION

- 5.1 Product Type

- 5.1.1 Styrenic Block Copolymer (TPE-S)

- 5.1.2 Thermoplastic Olefin (TPE-O)

- 5.1.3 Elastomeric Alloy (TPE-V or TPV)

- 5.1.4 Thermoplastic Polyurethane (TPU)

- 5.1.5 Thermoplastic Copolyester

- 5.1.6 Thermoplastic Polyamide

- 5.2 Application

- 5.2.1 Automotive and Transportation

- 5.2.2 Building and Construction

- 5.2.3 Footwear

- 5.2.4 Electrical and Electronics

- 5.2.5 Medical

- 5.2.6 Household Appliances

- 5.2.7 HVAC

- 5.2.8 Adhesives, Sealants, and Coatings

- 5.2.9 Other Applications

- 5.3 Geography

- 5.3.1 Germany

- 5.3.2 United Kingdom

- 5.3.3 Italy

- 5.3.4 France

- 5.3.5 Spain

- 5.3.6 Rest of Europe

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers and Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Market Share (%)**/Ranking Analysis

- 6.3 Strategies Adopted by Leading Players

- 6.4 Company Profiles

- 6.4.1 Apar Industries Ltd

- 6.4.2 Arkema

- 6.4.3 Asahi Kasei Corporation

- 6.4.4 BASF SE

- 6.4.5 Covestro AG

- 6.4.6 DSM

- 6.4.7 DuPont

- 6.4.8 Evonik Industries AG

- 6.4.9 Exxon Mobil Corporation

- 6.4.10 Grupo Dynasol

- 6.4.11 Huntsman International LLC

- 6.4.12 KRATON CORPORATION

- 6.4.13 KURARAY CO. LTD

- 6.4.14 LANXESS

- 6.4.15 LG Chem

- 6.4.16 LyondellBasell Industries Holdings BV

- 6.4.17 Mitsubishi Chemical Corporation

- 6.4.18 Mitsui Chemicals Inc.

- 6.4.19 SABIC

- 6.4.20 Sirmax SpA

- 6.4.21 Sumitomo Chemicals Co. Ltd

- 6.4.22 The Lubrizol Corporation

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 Growing Demand for Bio-based Thermoplastic Elastomers

- 7.2 Increasing Applications in the Medical Industry