|

市場調查報告書

商品編碼

1628788

北美泡殼包裝:市場佔有率分析、產業趨勢、成長預測(2025-2030)North America Blister Packaging - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

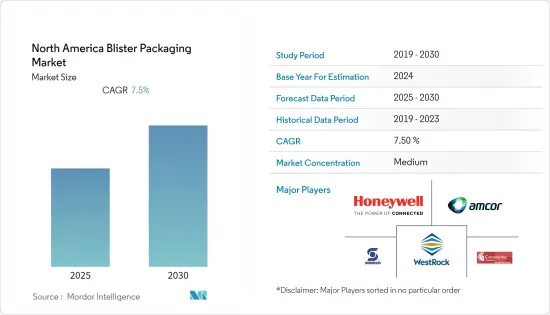

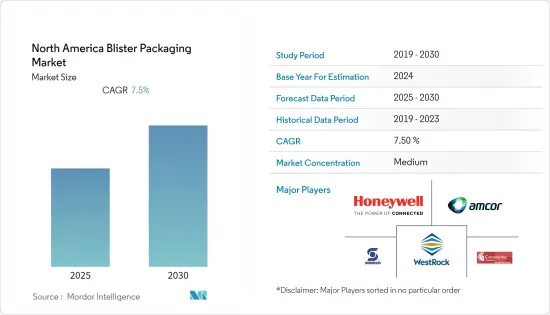

北美泡殼包裝市場預計在預測期內複合年成長率為 7.5%

主要亮點

- 泡殼包裝在北美地區正在溫和成長。泡殼包裝解決方案提供的高安全性正在推動需求。嚴格的法規以及製造商和消費者的需求導致泡殼包裝的使用增加。非處方藥的成長也重振了市場。

- 不斷上升的發病率和政府對假藥的嚴格監管迫使製藥公司生產包裝不同的藥品,這些藥品比繼續為患者提供符合其生產目的的藥品的基本需求更難模仿,壓力越來越大。推動市場的一個主要因素。泡殼包裝描述了防偽系統(例如鈔票認證系統)的一種有效方法。

- RFID(無線射頻識別標籤)等創新技術部署在泡殼中並在包裝外部貼上貼紙,有可能在整個供應鏈中提供個人安全,其使用量正在增加。只有當保護屏障被破壞並且分配和施用單一膠囊或錠劑時,才會發生泡殼內樣品的污染。

- 供應商也專注於環保泡殼包裝解決方案並推出紙質泡殼包裝。例如,2021 年 7 月,Hutamaki Oyj 推出了 Push Tab,這是醫療產業的紙本泡殼包裝解決方案。該產品經過 FSC 認證,旨在滿足受監管藥品包裝的嚴格安全要求。

北美泡殼包裝市場趨勢

藥品預計將顯著成長

- 製藥領域對泡殼包裝解決方案有不同的要求,例如與外部環境隔離、成本效益、高級保護、易於處理以及保存藥效等。這些包裝特別適合滿足嚴格的法規,並因其保護性能、成本效益、適應性和藥品包裝行業的需求而受到重視。

- 當藥物包裝在泡殼包裝中時,消費者知道他們的藥物和劑量,從而提高用藥依從性。泡殼的單位劑量特徵降低了錯誤劑量的風險。

- 零售層面的處方藥製備對於製藥技術人員和藥劑師來說是一個挑戰。在超級市場和藥局的開放環境中給藥可能會對敏感藥物在容器之間轉移時產生不利影響。泡殼包裝可以確保直接配送給客戶的過程。

- 雖然保護產品完整性仍然是藥品包裝的首要目標,但包裝產業的所有領域都在繼續努力降低包裝過程中的成本。

- 例如,Amcor 的 Polybar 阻隔薄膜系列涵蓋廣泛的防潮阻隔性,具有出色的抗壓性能,可確保為錠劑和膠囊等製藥應用提供最佳保護。我們使用 Aclar、COC、PE、PVC、PVdc 等材料。

- 此外,服務於固態製劑領域的製藥公司正在投資擴大北美的生產設施。例如,2020 年 9 月,Aphena Pharma Solutions 宣布擴建其位於田納西州庫克維爾的固態製劑部門。該公司的目標是為該工廠配備 24 條高速裝瓶線和 8 條熱成型泡殼包裝線。由此可見該地區對泡殼包裝的需求。

- 此外,根據歐洲製藥工業和協會聯合會的數據,2020 年北美佔藥品銷售額的 49%。這導致該地區對各種泡殼包裝的需求增加。

美國佔最大市場佔有率

- 嚴格的法規以及製造商和消費者的要求導致美國泡殼包裝的使用增加。製造商尋求透過根據這些監管標準製造產品來獲得稅收優惠。非處方藥的加速成長也刺激了市場。

- 多種慢性病正在推動美國對藥品的需求。藥品製造商推出並發明了具有先進功效的有效藥物。 FDA新藥認證數量也顯著增加。

- 在泡殼包裝過程中,單一錠劑或膠囊被密封在通常由熱成型塑膠或冷成型鋁製成的空腔內,鋁箔、薄膜或紙板等屏障可以保護藥物免受水分和氧氣等污染物的影響。此外,根據美國人口普查局的數據,到 2024年終,藥品製造業可能會達到 365,000 家。這進一步推動了該國的市場研究。

- 此外,這場大流行促使世界各地研究開發新冠肺炎 (COVID-19) 疫苗。例如,醫療保健巨頭強生公司於 2020 年 9 月啟動了臨床測試,並透過美國衛生與公眾服務部獲得了約 5 億美元的合作關係。

北美泡殼包裝產業概況

北美泡殼包裝市場適度細分。夥伴關係、併購和收購已成為市場上供應商生產最終用戶行業可接受的產品的重要策略,其中包裝材料經過嚴格的品質檢查,以確保它們不會污染內容物並影響健康。維持原料的持續流動仍是促進夥伴關係的挑戰。該市場的主要參與企業包括 Amcor Ltd、Westrock Company、Sonoco Products Company、Constantia Flexibles GmbH 和 Honeywell International Inc.。

- 2021 年 4 月 - Amcor 宣布對可回收聚乙烯基熱成型泡殼包裝進行客戶測試。這種新包裝旨在滿足高度專業化和監管的藥品包裝的嚴格要求,為最受歡迎的醫療包裝類型創造更永續的選擇。與市售包裝替代品相比,這項創新可減少高達 70% 的碳足跡。

- 2021 年 7 月 - Huthamaki 推出適用於醫療產業的紙質泡殼包裝「Pushtab」。該公司使用的紙張經過 FSC 認證,可取代由熱成型 PVC 或鋁製成的傳統推入式包裝,從而減少整個價值鏈對環境的影響。

其他好處

- Excel 格式的市場預測 (ME) 表

- 3 個月分析師支持

目錄

第1章簡介

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章市場洞察

- 市場概況

- 市場促進因素

- 老年人口增加與疾病傳播

- 產品創新,例如相對便宜的小型化

- 市場問題

- 法規的動態性和缺乏處理重負載的能力

- 產業吸引力-波特五力分析

- 供應商的議價能力

- 消費者議價能力

- 新進入者的威脅

- 競爭公司之間的敵對關係

- 替代品的威脅

- 評估 COVID-19 對泡殼包裝市場的影響

第5章市場區隔

- 按流程

- 熱成型

- 冷成型

- 按材質

- 塑膠薄膜

- 紙/紙板

- 鋁

- 其他

- 按最終用戶產業

- 消費品

- 藥品

- 工業的

- 其他

- 按國家/地區

- 美國

- 加拿大

第6章 競爭狀況

- 公司簡介

- Amcor PLC

- Westrock Company

- Constantia Flexibles GmbH

- Sonoco Products Company

- Klockner Pentaplast Group

- EI Du Pont De Nemours and Company

- Honeywell International Inc.

- The Dow Chemical Company

- Tekni-Plex Inc.

第7章 投資分析

第8章市場的未來

The North America Blister Packaging Market is expected to register a CAGR of 7.5% during the forecast period.

Key Highlights

- Blister packaging is witnessing moderate growth in the North American region. The high safety offered by blister packaging solutions is augmenting the demand for these solutions. The strict regulations and demand from manufacturers and consumers alike have led to growth in the usage of blister packages. Growth in over-the-counter drugs has also provided an impetus to the market.

- Growing pressure on pharmaceutical companies to manufacture medicines that are different in packaging and hard to imitate, surpassing the basic need of keeping it useful for the purpose it was produced, for it to be made available for patients, due to growth in diseases and stringent government regulations against counterfeit drugs, are among the significant factors propelling the market. Blister packaging provides an efficient method of anti-counterfeit systems, like banknote authentication systems and others.

- The use of innovative technologies in blisters, such as RFID (radio frequency identification tags), deployed with a seal applied outside the packaging, is increasing due to the potential to offer individual security throughout supply chains. Contamination of samples in blisters only occurs when the protective barrier is broken, when a single capsule or tablet is dispensed or administered.

- Vendors are also focusing on environmentally friendly blister packaging solutions and are introducing paper-based blister packaging. For instance, in July 2021, Hutamaki Oyj launched Push Tab, a paper-based blister solution for the healthcare industry. The product is certified by FSC and is designed to meet stringent safety requirements of regulated pharmaceutical packaging.

North America Blister Packaging Market Trends

Pharmaceutical is Expected to Witness a Significant Growth

- The pharmaceutical sector poses a different set of demands for blister packaging solutions, concerning insulation from external surroundings, cost-effectiveness, high levels of protection, and the ease of handling and retaining the effectiveness of the medicine. These packs are uniquely suited to meet stringent regulations and are highly valued for protective properties, cost-effectiveness, adaptability, and the pharmaceutical and packaging industry's requirements.

- When medicines are blister packaged, adherence is improved because consumers can keep track of their medications and dosage. The unit dosage feature of blisters reduces the risk of incorrect dosing.

- The retail-level preparation of prescription drugs is troubling pharmaceutical technicians or pharmacists. The administration of medicines in the open atmosphere of the supermarket and drug store may negatively affect sensitive medicines when they are transferred from container to container. Blister packaging can guarantee the process of distribution directly to the customer.

- Protecting product integrity continues to be the primary goal of pharmaceutical packaging, but there is continued work on cost reduction in the packaging process in all areas of the packaging industry.

- For instance, The Polybar barrier films product families provided by Amcor cover a wide range of moisture barriers whilst also providing good crush resistance to ensure the best protection for pharmaceutical applications such as tablets and capsules. It uses materials such as Aclar, COC, PE, PVC, and PVdc, among others.

- Further, the pharmaceutical companies catering to solid dose division are investing in the expansion of manufacturing facilities in North America. For instance, in September 2020, Aphena Pharma Solutions announced the expansion of the solid dose division in Cookeville, Tennessee. The comany has aimed to equip the facility with 24 high-speed bottling lines and eight thermoform blister packaging lines. This indicates the demand for blister packaging in the region.

- Moreover, according to The European Federation of Pharmaceutical Industries and Associations, North America accounted for 49% of the pharmaceutical revenue in 2020 compared to other regions across the globe. This increases demand for various blister packaging in the region.

United States to Hold the Largest Market Share

- Strict regulations, demands from manufacturers and consumers alike have led to growth in the usage of blister packages in the United States. The manufacturers are looking to earn tax incentives by manufacturing products under these regulatory standards. The promotion of Growth in over-the-counter drugs and has also provided an impetus to the market.

- Various chronic diseases raised the demand for drugs in the United States. Drug manufacturers introduced and invented effective drugs with advanced efficacies. This market also witnessed significant growth in the number of newer drug approvals given by the FDA.

- Under the blister packaging process, individual tablets or capsules are sealed within their own cavity, usually made of thermo-formed plastic or cold-form aluminum, protecting the drug from contaminants such as moisture and oxygen by a barrier of foil, film, or paperboard. Also, according to US Census Bureau, the manufacturing of pharmaceutical products could reach 365 thousand by the end of 2024. This further drives the market studied in the country.

- Furthermore, the outbreak has increased the research across the world for developing a vaccine for COVID-19. For instance, the healthcare giant, Johnson & Johnson, started clinical trials in September 2020 and has received a nearly USD 500 million partnership via a US Department of Health and Human Services division.

North America Blister Packaging Industry Overview

The North America Blister Packaging Market is moderately fragmented. Partnership, mergers, and acquisitions have been a significant strategy for the vendors in the market for producing products that are acceptable in the end-user industry, where packaging materials undergo stringent quality tests not to contaminate the contents impact health. Maintaining a continuous flow of raw materials remain a challenge that prompts partnerships. Some of the major players in the market are Amcor Ltd, Westrock Company, Sonoco Products Company, Constantia Flexibles GmbH, Honeywell International Inc., among others.

- April 2021 - Amcor announced customer trials for recyclable Polyethylene-based thermoform blister packaging. The new packaging is designed to meet the stringent requirements of highly specialized and regulated pharmaceutical packaging and creates a more sustainable alternative for the most in-demand healthcare packaging type. This innovation also benefits from up to 70% reduction in its carbon footprint when compared to packaging alternatives on the market.

- July 2021 - Huthamaki launched Push Tab paper-based blister solution for the healthcare industry. The paper used by the comany is FSC certified and acts as an alternative to traditional push-through packaging made of thermoformed PVC and aluminum, thus reducing the environmental impact across the value chain.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Growing geriatric population and prevalence of diseases

- 4.2.2 Product innovations such as downsizing coupled with relatively low costs

- 4.3 Market Challenges

- 4.3.1 Dynamic nature of regulations and inability to support heavy goods

- 4.4 Industry Attractiveness - Porter's Five Forces Analysis

- 4.4.1 Bargaining Power of Suppliers

- 4.4.2 Bargaining Power of Consumers

- 4.4.3 Threat of New Entrants

- 4.4.4 Intensity of Competitive Rivalry

- 4.4.5 Threat of Substitutes

- 4.5 Assessment of the Impact of COVID-19 on Blister Packaging Market

5 MARKET SEGMENTATION

- 5.1 By Process

- 5.1.1 Thermoforming

- 5.1.2 Coldforming

- 5.2 By Material

- 5.2.1 Plastic Films

- 5.2.2 Paper and Paperboard

- 5.2.3 Aluminum

- 5.2.4 Other Materials

- 5.3 By End-User Industry

- 5.3.1 Consumer Goods

- 5.3.2 Pharmaceutical

- 5.3.3 Industrial

- 5.3.4 Other End-User Industries

- 5.4 By Country

- 5.4.1 United Sates

- 5.4.2 Canada

6 COMPETITIVE LANDSCAPE

- 6.1 Company Profiles

- 6.1.1 Amcor PLC

- 6.1.2 Westrock Company

- 6.1.3 Constantia Flexibles GmbH

- 6.1.4 Sonoco Products Company

- 6.1.5 Klockner Pentaplast Group

- 6.1.6 E.I. Du Pont De Nemours and Company

- 6.1.7 Honeywell International Inc.

- 6.1.8 The Dow Chemical Company

- 6.1.9 Tekni-Plex Inc.