|

市場調查報告書

商品編碼

1628814

泰國塑膠市場:佔有率分析、產業趨勢、成長預測(2025-2030)Thailand Plastics - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

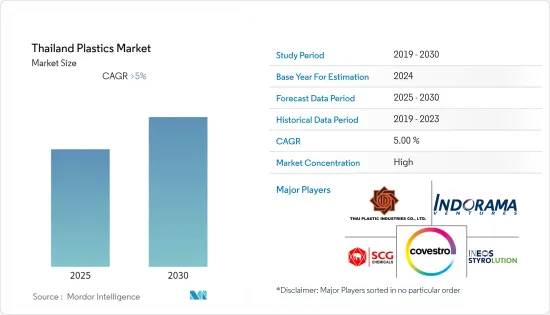

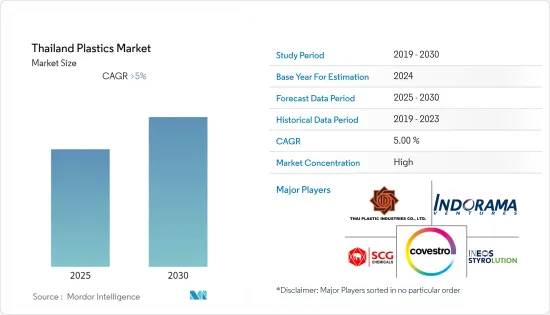

預計泰國塑膠市場在預測期內將維持5%以上的複合年成長率。

市場受到 COVID-19 的負面影響。供應鏈中斷導致塑膠產量減少。然而,自從限制解除以來,情況一直在穩定復甦。工業活動水準的上升可能會對所研究的市場產生正面影響。

主要亮點

- 從短期來看,建築領域塑膠使用量的增加以及食品和飲料包裝需求的增加是推動市場成長的因素。

- 另一方面,導致塑膠禁令的嚴格政府法規預計將阻礙預測期內的市場成長。

- 生物分解性塑膠投資的增加預計將在未來幾年為市場帶來機會。

泰國塑膠市場趨勢

聚對苯二甲酸乙二酯(PET)預計將主導市場

- 聚對苯二甲酸乙二醇酯 (PET) 樹脂以其優異的熔體流動性能、緊密的成型公差以及多腔模具的高生產率而聞名。由於其機械和電氣特性,PET 通常用於代替金屬用於馬達外殼、開關、感測器和其他電氣應用。

- PET和聚烯是塑膠包裝行業中使用最廣泛的材料。 PET 作為包裝材料的關鍵特性包括可回收性、強度和多功能性,這些特性推動了對這些產品的需求。

- 這些產品包括外帶容器、冷凍食品、蘇打水和果汁、番茄醬、瓶裝水、罐子、烘焙點心容器等。它也用於食品工業中的翻蓋、家常小菜容器、微波爐食品托盤等。

- PET 還具有出色的阻隔性,可保護和保存產品內容物。 PET 保留了碳酸飲料的碳酸化、果汁的維生素以及番茄醬的顏色。換句話說,PET 可以保護您的產品並使其不會妨礙貨架或垃圾桶。

- 2020年11月,全球最大的PET生產商泰國Indrama Ventures宣布投資15億美元,將塑膠回收再利用業務擴大兩倍,以提振對環保飲料製造商的需求。 Indrama 最近收購了回收聚對苯二甲酸乙二醇酯的公司。我們的目標是到 2025 年將目前每年約 25 萬噸的回收量擴大至 75 萬噸。 Indrama 每年向飲料業供應的 400 萬噸 PET 中,目標是回收材料佔 20% 左右。

- 2022年5月,一家名為ENVICCO Limited的泰國公司在泰國羅勇府Map Ta Phut新建了一家再生塑膠工廠,每年可生產約4.5萬噸再生聚對苯二甲酸乙二醇酯。預計這將提高PET在泰國塑膠市場的滲透率。

- 由於上述因素,預計在預測期內該國對 PET 的需求將會增加。

汽車產業主導市場

- 工程塑膠主要用於汽車工業。工程塑膠以其高性能而聞名,使汽車零件能夠滿足汽車行業的嚴格要求。在大多數情況下,工程塑膠用途廣泛,非常適合實現汽車產業所需的創新。此外,這些塑膠重量輕,可以降低燃料消耗。

- 汽車工業常用的塑膠包括聚丙烯、聚氨酯、聚氯乙烯和聚丁烯對苯二甲酸酯(PBT)。

- 聚丙烯是一種由丙烯製成的高度耐用的聚合物。聚丙烯具有耐化學性和耐用性,因此可用於各種汽車零件,從保險桿到電纜絕緣層再到地毯纖維。

- 聚氨酯具有很強的耐輻射、耐溶劑和耐環境磨損能力。這些特性使其適合多種應用,包括輪胎、座椅、懸掛刷等的生產。

- 熱塑性工程聚合物為汽車行業提供多種應用,包括生產高品質的儀表板組件、立柱飾件、汽車儀錶面板、輪罩、門襯、座椅靠背、把手、安全帶組件等。預計這將在預測期內提振受調查市場的需求。

- 塑膠也比金屬更經濟,並且透過減輕重量、耐用性、強度、設計靈活性、彈性、耐腐蝕性和高性能,有助於提高車輛的能源效率。還有一些塑膠具有優異的電絕緣性能。

- 泰國約有1,800家涉及汽車產業的公司,其中包括近30至40家大型公司、約700家一級汽車零件製造商以及超過1,000家二級和三級製造商。眾多大公司在泰國的存在不僅意味著汽車供應鏈龐大,也意味著汽車產業在未來幾年將進一步成長。

- 泰國工業聯合會(FTI)報告顯示,2022年11月泰國汽車產量年增近15%至約190,155輛,半導體短缺持續緩解,泰國生產的汽車數量增加這是過去 44 個月裡最好的。

- 此外,根據FTI的數據,2022年1月至11月泰國汽車產量達到近172萬輛,較去年同期成長約21%,大幅接近2022年約175萬輛的目標。預計 2022 年至 2025 年,泰國電動車市場的複合年成長率將達到約 22%。這可能會增加所研究市場的需求。

- 根據泰國國土交通旅遊部統計,2022年1月至4月泰國曼谷新增登記私家車數量約15.24萬輛。過去十年,泰國首都新登記的乘用車數量出現波動。 2021年及2020年曼谷新增私家車登記數量分別為269.83輛及292.3輛。

- 由於這些因素,預計泰國塑膠市場在預測期內將穩定成長。

泰國塑膠工業概況

泰國的塑膠市場已部分一體化。主要企業包括(排名不分先後)Indorama Ventures Public Company Limited、SCG Chemicals、INEOS Styrolution Group GmbH、COVESTRO AG 和 THAI PLASTIC INDUSTRIES。

其他好處

- Excel 格式的市場預測 (ME) 表

- 3 個月分析師支持

目錄

第1章簡介

- 調查先決條件

- 調查範圍

第2章調查方法

第3章執行摘要

第4章市場動態

- 促進因素

- 塑膠在建築和施工中的使用增加

- 食品和飲料包裝需求增加

- 抑制因素

- 嚴格的政府法規導致塑膠禁令

- 其他限制因素

- 價值鏈分析

- 波特五力分析

- 供應商的議價能力

- 買方議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭程度

第5章 市場區隔(以金額為準的市場規模)

- 種類

- 傳統塑膠

- 聚乙烯

- 聚丙烯

- 聚苯乙烯

- 聚氯乙烯

- 工程塑膠

- 聚對苯二甲酸乙二酯 (PET)

- 聚醯胺

- 聚碳酸酯

- 苯乙烯共聚物(ABS 和 SAN)

- 聚丁烯對苯二甲酸酯(PBT)

- 聚甲基丙烯酸甲酯(PMMA)

- 其他工程塑膠

- 生質塑膠

- 傳統塑膠

- 目的

- 包裝

- 電力/電子

- 建築/施工

- 汽車和交通

- 家具/寢具

- 其他

第6章 競爭狀況

- 併購、合資、聯盟、協議

- 市場佔有率(%)**/排名分析

- 主要企業策略

- 公司簡介

- Covestro AG

- HMC Polymers Thailand

- Indorama Ventures Public Company Limited

- INEOS Styrolution Group GmbH

- PTT Global Chemical Public Company Limited

- SCG Chemicals Co. Ltd

- Thai Plastic Industries Co. Ltd

第7章 市場機會及未來趨勢

- 增加生物分解性塑膠的投資

The Thailand Plastics Market is expected to register a CAGR of greater than 5% during the forecast period.

The market was negatively impacted by COVID-19. The production of plastics was reduced due to disruptions in the supply chain. However, the sector has been recovering well since restrictions were lifted. The rise in the level of industrial activities is likely to positively impact the studied market.

Key Highlights

- Over the short term, increasing usage of plastics in building and construction, and rising demand for food and beverage packaging, are some factors driving the market growth.

- On the flip side, stringent government regulations resulting in the plastic ban are expected to hinder market growth during the forecast period.

- Increasing investments in biodegradable plastics will likely create opportunities for the market in the coming years.

Thailand Plastic Market Trends

Polyethylene Terephthalate (PET) is Expected to Dominate the Market

- Polyethylene Terephthalate (PET) resins are known for their excellent melt flow characteristics, close molding tolerances, and high productivity from multi-cavity molds. Owing to its mechanical and electrical properties, PET is often used to replace metals in motor housings, switches, sensors, and other electrical applications.

- PET and polyolefins are the most widely used materials in the plastic packaging industry. Some of the significant properties of PET as a packaging material are recyclability, strength, and versatility, which drive the demand for these products.

- These products include take-out containers, frozen foods, carbonated drinks and juices, ketchup, bottled water, jars, and baked goods containers. They are also used in the food industry for clamshells, deli containers, and microwave food trays.

- PET also has excellent barrier properties that protect and preserve the product's contents. PET keeps the fizz in carbonated soft drinks, the vitamins in juices, and the color in ketchup intact. In other words, it protects products and keeps them on the shelves and out of the rubbish bin.

- Thailand's Indorama Ventures, the world's top producer of PET, in November 2020, announced spending USD 1.5 billion to triple its plastics recycling operations to increase the demand among green-minded beverage producers. Indorama has been acquiring companies that recycle polyethylene terephthalate in recent years. It aims to expand its recycling capacity to 750,000 tons a year by 2025 from the current roughly 250,000 tons. The goal is to have recycled materials account for around 20% of the 4 million tons of PET Indorama supplies to the beverage industry a year.

- In May 2022, a Thailand-based company named ENVICCO Limited started a new recycled plastic plant with the capacity to manufacture around 45,000 metric tons per year of recycled polyethylene terephthalate at Map Ta Phut, Rayong, Thailand. This will likely increase PET penetration in Thailand's plastics market.

- Owing to the abovementioned factors, the demand for PET will increase in the country over the forecast period.

Automotive Industry to Dominate the Market

- The automotive industry mainly uses engineering plastics as they are known for their high performance, thereby making the automotive parts compatible with the rigorous demands of the automotive sector. Mostly, engineering plastics are very versatile, which makes them suitable for achieving the needed innovation in the automotive industry. Moreover, these plastics are lightweight, which reduces fuel consumption.

- Some of the widely used plastics in the automotive industry include polypropylene, polyurethane, Polyvinyl chloride, Polybutylene Terephthalate (PBT), and others.

- Polypropylene is a very durable polymer that is manufactured from propylene. Owing to its chemical resistance and durability, polypropylene is used in various automotive components ranging from bumpers to cable insulation to carpet fibers.

- Polyurethanes are exceptionally resistant to radiation, solvents, and environmental wear. Owing to these qualities, they are well-suited for different applications, including the manufacturing of tires, seating, suspension brushes, etc.

- Thermoplastic-engineered polymers serve the automotive industry in different applications, such as the production of high-quality dashboard components, pillar trim, automotive instrument panels, wheel covers, door liners, seat backs, handles, and seat belt components, among others. This is expected to boost the demand for the studied market over the forecast period.

- Plastics are also more economical than metals and help to make automobiles energy-efficient by reducing weight, and offering durability, toughness, design flexibility, resiliency, corrosion resistance, and high performance. Some plastics also exhibit good electrical insulation properties.

- There are around 1,800 companies in Thailand in the automotive segment, which includes nearly 30 to 40 major players, about 700 Tier 1 automotive part manufacturers, and more than 1,000 Tier 2 and 3 producers. The presence of many major companies in the country not only signifies a vast automotive supply chain but also that the automotive industry is primed for further industry growth in the coming years.

- Car production in Thailand increased by nearly 15% year-on-year (Y-o-Y) to around 190,155 units in November 2022, which is the highest in the last 44 months, as the shortage of semiconductors continued to ease, according to the report of the Federation of Thai Industries (FTI).

- Furthermore, as per the FTI, the total number of car production in Thailand for the first 11 months of 2022 reached nearly 1.72 million units, registering a year-on-year growth of around 21%, and very close to the 2022 target of about 1.75 million units. The EVs market in Thailand is likely to register a CAGR of around 22% from 2022 to 2025. This is likely to boost the demand for the market studied.

- As per the Department of Land Transport (Thailand), around 152.4 thousand new private cars were registered in Bangkok, Thailand, from January to April 2022. The number of new registrations for passenger cars in the capital city of Thailand has fluctuated over the past 10 years. The number of new private cars registered in Bangkok in 2021 and 2020 was 269.83 and 292.3, respectively.

- Due to all such factors, the market for plastics in Thailand is expected to have steady growth during the forecast period.

Thailand Plastic Industry Overview

The plastics market in Thailand is partially consolidated in nature. The major companies include Indorama Ventures Public Company Limited, SCG Chemicals Co. Ltd, INEOS Styrolution Group GmbH, COVESTRO AG, and THAI PLASTIC INDUSTRIES CO. LTD, among others (not in any particular order).

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Drivers

- 4.1.1 Increasing Usage of Plastics in Building and Construction

- 4.1.2 Rising Demand from Food and Beverage Packaging

- 4.2 Restraints

- 4.2.1 Stringent Government Regulations Resulting in Plastic Ban

- 4.2.2 Other Restraints

- 4.3 Industry Value Chain Analysis

- 4.4 Porter's Five Forces Analysis

- 4.4.1 Bargaining Power of Suppliers

- 4.4.2 Bargaining Power of Buyers

- 4.4.3 Threat of New Entrants

- 4.4.4 Threat of Substitute Products and Services

- 4.4.5 Degree of Competition

5 MARKET SEGMENTATION (Market Size in Value)

- 5.1 Type

- 5.1.1 Traditional Plastics

- 5.1.1.1 Polyethylene

- 5.1.1.2 Polypropylene

- 5.1.1.3 Polystyrene

- 5.1.1.4 Polyvinyl Chloride

- 5.1.2 Engineering Plastics

- 5.1.2.1 Polyethylene Terephthalate (PET)

- 5.1.2.2 Polyamides

- 5.1.2.3 Polycarbonates

- 5.1.2.4 Styrene Copolymers (ABS and SAN)

- 5.1.2.5 Polybutylene Terephthalate (PBT)

- 5.1.2.6 Polymethyl Methacrylate (PMMA)

- 5.1.2.7 Other Engineering Plastics

- 5.1.3 Bioplastics

- 5.1.1 Traditional Plastics

- 5.2 Application

- 5.2.1 Packaging

- 5.2.2 Electrical and Electronics

- 5.2.3 Building and Construction

- 5.2.4 Automotive and Transportation

- 5.2.5 Furniture and Bedding

- 5.2.6 Other Applications

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers and Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Market Share (%)**/Ranking Analysis

- 6.3 Strategies Adopted by Leading Players

- 6.4 Company Profiles

- 6.4.1 Covestro AG

- 6.4.2 HMC Polymers Thailand

- 6.4.3 Indorama Ventures Public Company Limited

- 6.4.4 INEOS Styrolution Group GmbH

- 6.4.5 PTT Global Chemical Public Company Limited

- 6.4.6 SCG Chemicals Co. Ltd

- 6.4.7 Thai Plastic Industries Co. Ltd

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 Increasing Investments in Biodegradable Plastics