|

市場調查報告書

商品編碼

1686203

越南塑膠:市場佔有率分析、行業趨勢和統計、成長預測(2025-2030 年)Vietnam Plastics - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

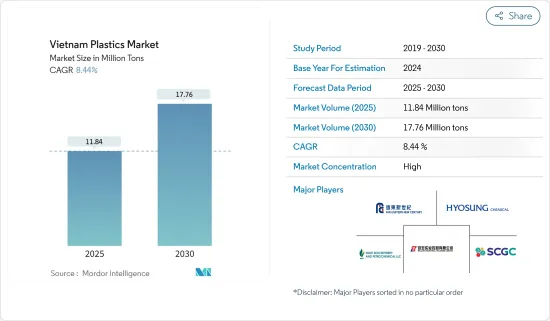

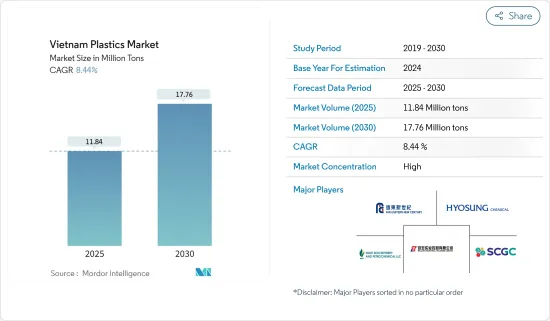

2025年越南塑膠市場規模預估為1,184萬噸,預計2030年將達到1,776萬噸,預測期(2025-2030年)複合年成長率為8.44%。

新冠肺炎疫情為越南市場帶來了負面影響。但隨著主要終端用戶產業復工,市場估計已恢復至疫情前的水準。

主要亮點

- 短期內,預計建設產業需求的增加將推動市場成長。

- 過度依賴原料和成品塑膠的進口預計會阻礙市場的成長。

- 預計增加的外國投資將為市場成長提供各種機會。

越南塑膠市場的趨勢

擠壓技術佔據市場主導地位

- 在越南,擠壓技術用於製造PVC、PE管、鋁和塑膠管、紡織品、PVC門、框架、屋頂和牆壁材料等產品。擠壓製程生產成本低,設置時間短。但精度一般,且主要適用於截面均勻的零件,不適用於複雜零件。

- 此技術主要用於建設活動,主要產品包括PVC、HDPE、PPR管道、型材、塑膠門窗、板材、家具等。

- 根據2020年塑膠工業發展規劃,塑膠工業將向減少包裝和消費塑膠比重、增加建築和技術塑膠比重的方向進行結構調整。

- 越南建築塑膠產業約佔整個塑膠產業的四分之一。建築和房地產行業的發展正在推動對塑膠建築產品的需求。

- 越南政府還計劃在 350 多個工業區建造 100 萬套經濟適用住宅。這些基礎設施建設計劃和不斷增加的工廠數量正在推動該國對建築和技術塑膠的強勁需求。

- 2022 年 4 月,越南領先的 PET 包裝營運商 Ngoc Nghia工業、服務和貿易股份公司 (NN) 被全球永續化學公司 Indorama Ventures Ltd (IVL) 收購。透過此次收購,IVL 將擴大其綜合 PET 產品供應範圍,向該國的主要跨國客戶供應產品,並鞏固其市場地位。

- 2022年9月,美國飲料公司可口可樂公司在越南推出完全回收的寶特瓶。該公司聲稱符合越南食品級 rPET 包裝法規和國際標準。

- 考慮到以上所有因素,擠壓技術可望佔領市場主導地位。

包裝領域佔據市場主導地位

- 包裝佔越南塑膠市場的最大佔有率。重量輕、耐熱、耐化學性和耐腐蝕性等因素使塑膠成為越南市場包裝的熱門選擇。

- 在包裝產業,塑膠用於醫療保健包裝、食品和飲料包裝、消費包裝商品、消費者和個人護理包裝、家居和花園等。

- 聚對苯二甲酸乙二醇酯(PET)是用於包裝的主要塑膠之一,主要用於食品和飲料行業。便攜性、設計靈活性、易於清洗、重量輕和防潮是 PET 適合用於包裝用途的一些特性。

- 此外,低操作危險、低毒性以及不含雙酚 A (BPA) 和重金屬也有利於 PET 在食品包裝行業的市場發展。

- 未來幾年,包裝產業的成長率將達到15%至20%,是越南成長最快的產業之一。目前,該行業有 900 多家工廠,其中約 70%位置南部,主要在胡志明市、平陽和同奈。

- 2022年3月,知名食品飲料公司利樂公司向平陽省一家價值1.412億美元的包裝材料工廠追加投資590萬美元,展現了對越南的信心。為了滿足越南和其他地區市場對無菌包裝日益成長的需求,新增投資將使該工廠的年產能從目前的115億包增加到165億包。

- 因此,由於上述方面,預計包裝領域將佔據市場主導地位。

越南塑膠產業概況

越南塑膠市場是一個集中市場,從事塑膠樹脂生產的參與者有限。市場的主要企業包括(不分先後順序)遠東新世紀、宜山煉油石化(NSRP)、曉星化學、億利實業控股有限公司和SCG化工公眾有限公司(TPC VINA)。

其他福利:

- Excel 格式的市場預測 (ME) 表

- 3 個月的分析師支持

目錄

第 1 章 簡介

- 調查前提條件

- 研究範圍

第2章調查方法

第3章執行摘要

第4章 市場動態

- 驅動程式

- 建築業需求不斷成長

- 其他促進因素

- 限制因素

- 過度依賴原料和塑膠成品的進口

- 對塑膠的環境擔憂以及新替代品的出現

- 產業價值鏈分析

- 波特五力分析

- 供應商的議價能力

- 買家的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭程度

- 原料分析

第5章 市場區隔

- 類型

- 傳統塑膠

- 聚乙烯

- 聚丙烯

- 聚苯乙烯

- 聚氯乙烯

- 工程塑膠

- 聚氨酯

- 氟樹脂

- 聚醯胺

- 聚碳酸酯

- 苯乙烯共聚物(ABS 和 SAN)

- 熱塑性聚酯

- 其他工程塑膠

- 生質塑膠

- 傳統塑膠

- 成型技術

- 吹塑成型

- 擠壓

- 射出成型

- 其他技術

- 應用

- 包裝

- 電氣和電子

- 建築和施工

- 汽車和運輸

- 家居用品

- 家具和床上用品

- 其他用途

第6章 競爭格局

- 併購、合資、合作、協議

- 市場排名分析

- 主要企業策略

- 公司簡介

- Agc Inc.

- Billion Industrial Holdings Limited

- Far Eastern New Century Corporation

- Hyosung Chemical

- Lyondellbasell Industries Holdings Bv

- Nan Ya Plastics Corporation

- Nsrp Llc

- Scg Chemicals Public Company Limited

- Toray Industries Inc.

- 越南石油天然氣集團

- Vietnam Polystyrene Co. Ltd

- Vinaplast

第7章 市場機會與未來趨勢

- 增加外國投資

- 其他機會

The Vietnam Plastics Market size is estimated at 11.84 million tons in 2025, and is expected to reach 17.76 million tons by 2030, at a CAGR of 8.44% during the forecast period (2025-2030).

The COVID-19 pandemic affected the Vietnamese market negatively. However, with the resumption of work in major end-user industries, the market is estimated to have reached pre-pandemic levels.

Key Highlights

- In the short term, the increasing demand from the construction industry is expected to drive market growth.

- Over-reliance on imports of raw materials and finished plastics is expected to hinder the growth of the market.

- An increase in foreign investments is expected to offer various opportunities for the growth of the market.

Vietnam Plastic Market Trends

Extrusion Technology to Dominate the Market

- In Vietnam, extrusion molding technology is used to make products such as PVC, PE pipe, aluminum and plastic pipe, fiber, PVC doors, frames, roofings, and wall coverings. An extrusion molding process involves lower production costs and faster setup time. However, it provides mediocre precision and is mostly suitable for uniform cross-section parts and not complex parts.

- This technology is used mainly in construction activities, and the main products include PVC, HDPE, PPR pipes, profile bars, plastic doors and windows, panels, and furniture.

- According to the plastic industry development plan of 2020, the plastics industry will be restructured toward reducing the proportion of packaging and consumer plastics and increasing the percentage of the construction and technical plastics segment.

- Vietnam's construction plastics segment accounts for around one-fourth of the total plastics industry. Developing the construction and real estate sector is boosting the demand for plastic construction products.

- In addition, the country's government aims to build a million affordable houses in more than 350 industrial zones. These infrastructural development projects and the increasing number of factories being installed are robustly increasing the demand for construction and technical plastics in the country.

- In April 2022, one of the top PET packaging businesses in Vietnam, Ngoc Nghia Industry - Service - Trading Joint Stock Company (NN), was acquired by Indorama Ventures Public Company Limited (IVL), a global sustainable chemical company. The acquisition will strengthen IVL's market position as it broadens its integrated PET product offering to significant multinational customers throughout the country.

- In September 2022, the US-based beverage company The Coca-Cola Company introduced fully recycled plastic bottles in Vietnam. The company claims to meet both Vietnamese regulations and international standards for food-grade rPET packaging.

- Based on the aforementioned aspects, extrusion technology is expected to dominate the market.

Packaging Segment to Dominate the Market

- Packaging accounts for the largest share of the Vietnamese plastics market. Factors like light weight and thermal, chemical, and corrosion resistance make plastics a viable choice for packaging purposes in the Vietnamese market.

- In the packaging industry, plastics are used for healthcare packaging, food and beverage packaging, consumer packaged goods, consumer and personal care packaging, and in the home and garden.

- Polyethylene terephthalate (PET) is one of the majorly used plastics for packaging purposes, mostly in the food and beverage industry. Portability, design flexibility, ease of cleaning, light weight, and protection against moisture are a few properties of PET that make them suitable for packaging purposes.

- In addition, low handling hazards, low toxicity, absence of Bisphenol A (BPA), and heavy metals favor the PET market for the food packaging industry.

- With a growth rate of 15% to 20% in the upcoming years, the packaging industry is one of Vietnam's fastest-growing sectors. Over 900 factories are currently in operation in the sector, with approximately 70% of them located in the Southern region, primarily in Ho Chi Minh City, Binh Duong, and Dong Nai.

- In March 2022, Tetra Pak, a well-known F&B company, with an additional USD 5.9 million investment into its USD 141.2 million packaging material factory in the province of Binh Duong, proved its confidence in Vietnam. To meet the growing demand for aseptic packages in Vietnam and other regional markets, the additional investment will increase the factory's annual output from the current 11.5 billion to 16.5 billion packages.

- Thus, based on the aforementioned aspects, the packaging segment is expected to dominate the market.

Vietnam Plastic Industry Overview

The Vietnamese plastics market is a consolidated market with a limited number of players engaged in the production of plastic resins. Some of the key players in the market include Far Eastern New Century, Nghi Son Refinery and Petrochemical (NSRP), Hyosung Chemicals, Billion Industrial Holdings Limited, and SCG Chemicals Public Company Limited (TPC VINA), among others (not in any particular order).

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Drivers

- 4.1.1 Growing Demand from the Construction Sector

- 4.1.2 Other Drivers

- 4.2 Restraints

- 4.2.1 Over-reliance on Imports of Raw Materials and Finished Plastics

- 4.2.2 Environmental Concerns of Plastics and the Availability of New Substitutes

- 4.3 Industry Value Chain Analysis

- 4.4 Porter's Five Forces Analysis

- 4.4.1 Bargaining Power of Suppliers

- 4.4.2 Bargaining Power of Buyers

- 4.4.3 Threat of New Entrants

- 4.4.4 Threat of Substitute Products and Services

- 4.4.5 Degree of Competition

- 4.5 Raw Material Analysis

5 MARKET SEGMENTATION (Market Size in Volume)

- 5.1 Type

- 5.1.1 Traditional Plastics

- 5.1.1.1 Polyethylene

- 5.1.1.2 Polypropylene

- 5.1.1.3 Polystyrene

- 5.1.1.4 Polyvinyl Chloride

- 5.1.2 Engineering Plastics

- 5.1.2.1 Polyurethanes

- 5.1.2.2 Fluoropolymers

- 5.1.2.3 Polyamides

- 5.1.2.4 Polycarbonates

- 5.1.2.5 Styrene Copolymers (ABS and SAN)

- 5.1.2.6 Thermoplastic Polyesters

- 5.1.2.7 Other Engineering Plastics

- 5.1.3 Bioplastics

- 5.1.1 Traditional Plastics

- 5.2 Technology

- 5.2.1 Blow Molding

- 5.2.2 Extrusion

- 5.2.3 Injection Molding

- 5.2.4 Other Technologies

- 5.3 Application

- 5.3.1 Packaging

- 5.3.2 Electrical and Electronics

- 5.3.3 Building and Construction

- 5.3.4 Automotive and Transportation

- 5.3.5 Housewares

- 5.3.6 Furniture and Bedding

- 5.3.7 Other Applications

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers and Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Market Ranking Analysis

- 6.3 Strategies Adopted by Leading Players

- 6.4 Company Profiles

- 6.4.1 Agc Inc.

- 6.4.2 Billion Industrial Holdings Limited

- 6.4.3 Far Eastern New Century Corporation

- 6.4.4 Hyosung Chemical

- 6.4.5 Lyondellbasell Industries Holdings Bv

- 6.4.6 Nan Ya Plastics Corporation

- 6.4.7 Nsrp Llc

- 6.4.8 Scg Chemicals Public Company Limited

- 6.4.9 Toray Industries Inc.

- 6.4.10 Vietnam Oil And Gas Group

- 6.4.11 Vietnam Polystyrene Co. Ltd

- 6.4.12 Vinaplast

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 Increase in Foreign Investments

- 7.2 Other Opportunities