|

市場調查報告書

商品編碼

1630244

歐洲金屬加工設備:市場佔有率分析、產業趨勢與統計、成長預測(2025-2030)Europe Metal Fabrication Equipment - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

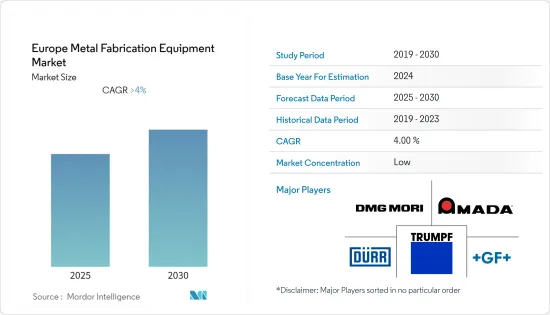

歐洲金屬加工設備市場預計在預測期內複合年成長率將超過 4%。

主要亮點

- 金屬工業和製造業的擴張、汽車和航太工業的擴張以及研發費用的增加等因素預計將在整個預測期內推動歐洲金屬加工設備市場的發展。歐洲的工業金屬加工產業也在不斷成長,因為該地區政府制定了支持該產業的政策。

- 歐洲金屬加工設備領域最重要的技術進步是工業4.0,其中包括資料分析、物聯網、積層製造和擴增實境。 AR 可用於培訓、品質保證、設計/原型、維護、操作、安全管理等。例如,擴增實境可以透過視覺化和簡化組裝、工具機轉換和逐步安裝過程來改進製造程序。

COVID-19 的營運挑戰和需求疲軟對歐洲金屬加工設備產業造成了相當大的打擊。預計在預測期內恢復到大流行前生產水準的時間會有所延遲。研究預測國內金屬需求將大幅下降,這種情況至少要到疫情結束後的 2023 年至 2024 年才會發生。

歐洲金屬加工設備市場趨勢

金屬加工產業不斷湧現的技術創新

- 自動化、積層製造和工業 4.0 正在受到歐洲金屬加工設備生產商的關注,因為該技術為金屬加工服務供應商提供了多種好處,包括提高業務效率。例如,最大的金屬零件製造設備製造商之一的通快公司正在將尖端雷射產品推向市場,其中包括被認為支持「綠色製造」理念的新型二極體雷射技術。

- 工業4.0的主要目標是自動化。隨著新技術進入市場,ICT技術正在更快地融入生產過程。組織、設備和其他製造資源變得更加數位化,從而導致「智慧工廠」的發展,其機器和流程持續連接,可提供高品質的成果。

- 工業4.0技術正在引領金屬加工設備製造領域的新生產方式、經營模式和產業的興起。這使得不斷改進生產過程成為可能。

- 機器人技術現已應用於金屬加工設備製造企業,並且已經發展到這些機器可以與團隊成員安全地一起業務的程度。協作機器人非常適合勞動密集或危險任務。此外,該領域29萬人的勞動力短缺問題也有望得到解決。儘管新型冠狀病毒肺炎 (COVID-19) 疫情導致更多人失業並引發了人們的關注,但協作機器人在金屬製造領域仍處於起步階段,並且正在迅速填補需要支援的空白。

此外,CNC工具機現已成為金屬製造業務的重要組成部分。金屬製造 CNC 部分的自動化可以減少過程中的一些重複,並隨著時間的推移提高生產力和效率。 2021-2021年及以後,隨著該領域的發展,數控自動化將繼續受到歡迎。

製造業和汽車業的需求不斷成長

- 在歐洲,金屬加工設備的主要最終用戶市場之一是汽車產業。世界汽車工業總產量的20%以上是在歐洲生產的。 2022年前三季度,歐盟生產了近800萬輛汽車,比2021年同期成長5.8%。

- 未來幾年,由於亞洲國家需求的增加,歐洲汽車產量預計將增加。生產更多車輛的需求可能會推動該地區的金屬加工設備市場。

- 汽車行業的公司正致力於簡化流程以節省成本和時間。我們也專注於在製造過程中使用最新技術,這增加了對六軸加工中心等最先進金屬加工工具的需求。

- 儘管該地區的四輪車產量因國內外市場需求的成長而大幅增加,但二輪車和三輪車的產量幾乎沒有成長。冷壓和熱壓與汽車的品質息息相關,除此之外沒有太大的需求。

- 汽車價格和生產水準的上漲正在推動汽車金屬衝壓產業的成長。汽車金屬衝壓製造商也預計鋁等輕質金屬市場在未來幾年將會成長。這是由於縮小動力傳動系統尺寸以使汽車更輕、更省油的趨勢日益成長。

- 汽車產業的進一步發展和投資預計歐洲汽車金屬衝壓產業的經濟影響將是巨大的。汽車引擎持續嚴重依賴鑄鋁、鈦、鍛鋼和鑄鐵等合金,支撐著歐洲金屬加工設備的成長。

歐洲金屬加工設備產業概況

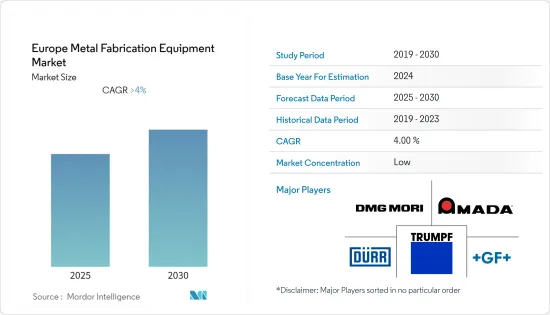

據觀察,歐洲金屬加工設備市場的競爭格局已鞏固,目前由幾家大公司主導市場。然而,他們面臨來自調查行業的區域競爭對手、中小企業和專業設備製造公司的激烈競爭。

汽車工業及其附屬行業是加工設備的最大買家,緊隨其後的是製造業。航太和國防等金屬製造市場關鍵產業的供需預計將在預測期內恢復。由於該地區工業部門的需求不斷成長以及某些行業的巨大市場,歐洲的金屬加工設備行業正在透過轉移製造設施來擴大規模。

TRUMPF GmbH+Co.KGm、Durr AG、Amada Europe、GF Machining Solutions 和 DMG MORI 是歐洲金屬加工設備市場上的領先公司。

其他領先公司包括 Schuler AG、GROB-WERKE GmbH、Bystronic Maschinen AG、Feintool International Holding AG、Mazak UK Limited、Okuma Europe、Reishauer AG、Starrag Group Holding AG、Gebr. Heller Maschinenfabrik GmbH、Bleighleigh Industrial 有 Meaileigh。 。

其他好處:

- Excel 格式的市場預測 (ME) 表

- 3 個月分析師支持

目錄

第1章簡介

- 研究成果

- 研究場所

- 調查範圍

第2章調查方法

第3章執行摘要

第4章市場動態

- 市場概況

- 市場促進因素

- 市場限制因素

- 市場機會

- 價值鏈/供應鏈分析

- 產業吸引力-波特五力分析

- 新進入者的威脅

- 買家/消費者的議價能力

- 供應商的議價能力

- 替代品的威脅

- 競爭公司之間的敵對關係

- 技術簡介

- COVID-19 對市場的影響

第5章市場區隔

- 按服務類型

- 加工

- 切割加工

- 焊接

- 成型

- 其他服務類型

- 按最終用戶產業

- 車

- 建造

- 航太

- 電力/電子

- 其他最終用戶產業

- 按地區

- 德國

- 英國

- 法國

- 其他歐洲國家

第6章 競爭狀況

- 市場集中度概覽

- 公司簡介

- TRUMPF GmbH+Co. KG

- Durr AG

- Amada Europe

- GF Machining Solutions

- DMG MORI

- Schuler AG

- GROB-WERKE GmbH

- Bystronic Maschinen AG

- Feintool International Holding AG

- Mazak UK Limited*

- 其他公司(Reishauer AG、Okuma Europe、Gebr. Heller Maschinenfabrik GmbH、Starrag Group Holding AG、Meusburger Georg Gmbh、Baileigh Industrial)

第7章 市場的未來

第8章附錄

The Europe Metal Fabrication Equipment Market is expected to register a CAGR of greater than 4% during the forecast period.

Key Highlights

- Throughout the forecast period, it is anticipated that factors such as the expanding metal and manufacturing industries, expanding automotive and aerospace sectors, and rising R&D expenditures would drive the European market for metal fabrication equipment. Europe's industrial metal fabrication industry is also growing because governments all over the region are putting in place policies that help the industry.

- The most important technological advancements in the metal fabrication equipment sector in Europe are Industry 4.0, including data analytics, the internet of things, additive manufacturing, and AR (augmented reality). AR can be used in training, quality assurance, design and prototyping, maintenance, operations, and safety management. For instance, by visualizing and streamlining assembly, machine tool change, and step-by-step installation processes, augmented reality (AR) can improve manufacturing operation procedures.

Due to COVID-19's operational challenges and poor demand, Europe's metal fabrication equipment sector took a considerable hit. A delayed return to pre-pandemic production levels was anticipated during the projected period. The study predicted a significant decline in domestic metal demand, which would not happen until at least 2023-2024 after the pandemic.

Europe Metal Fabrication Equipment Market Trends

Rising Technological Innovations in Metal Fabrication Industry

- As technologies offer several advantages, including increased operational efficiencies for the service providers of metal fabrication, automation, additive manufacturing, and industry 4.0 are gaining prominence among European producers of metal fabrication equipment. For example, Trumpf, one of the largest manufacturers of equipment for making metal parts, has put on the market cutting-edge laser products, such as new diode laser technology, which is thought to support the idea of "green production."

- The main aim of Industry 4.0 is automation. As new technologies hit the market, ICT technologies are being incorporated into production processes more quickly. Organizations, equipment, and other manufacturing resources are becoming more digitized, resulting in the development of "smart factories'' with continually connected machines and processes that provide high-quality outcomes.

- Industry 4.0 technology is leading to the rise of new production methods, business models, and industries in the metal fabrication equipment manufacturing sector. This makes it possible to continue to improve the production process.

- Robotics technology is now being used in the metal fabrication equipment production business, and it has advanced to the point where these machines can safely do duties alongside team members. Cobots, or collaborative robots, are perfect for laborious or hazardous activities. They might also lessen the 290,000-person labor shortfall in the sector. The COVID-19 pandemic, which forced even more people out of work and brought the situation into focus, showed that although cobots are still in their infancy in the metal manufacturing sector, they are rapidly filling a gap that needs to be supported.

Additionally, CNC machines are now a crucial component of the metal fabrication business. Automation in the CNC part of metal manufacturing can reduce some of the repetitiveness in this process, improving productivity and efficiency over time. After 2021-2021, CNC automation will continue to grow in popularity as the sector develops.

Growing Demand from the Manufacturing and Automotive Sectors

- In Europe, one of the key end-user markets for metal fabrication equipment is the automotive industry. More than 20% of all production in the automotive industry worldwide is produced in Europe. Nearly 8 million cars were produced in the European Union during the first three quarters of 2022, 5.8% higher than during the same time in 2021.

- In the coming years, the production volume of automobiles from Europe is anticipated to rise due to the growing demand from Asian nations. The need to make more cars is likely to drive the market for metal fabrication equipment in the region.

- Businesses in the automotive industry are focusing more on streamlining their processes to save money and time. They are also paying more attention to using the latest technologies in their manufacturing processes, which increases the demand for cutting-edge metal fabrication tools like a 6-axis machining center.

- The region's production of four-wheelers has significantly increased in response to rising demand from domestic and international markets, whereas manufacturing of two- and three-wheelers has grown very little. Cold pressing and hot pressing have a lot to do with how well cars are made, and there isn't much other demand for them.

- Rising automobile pricing and production levels are driving growth in the automotive metal stamping sector. Also, manufacturers of automotive metal stamping expect the market for lightweight metals like aluminum to grow in the coming years. This is because of the growing trend of downsizing powertrains to make cars lighter and get better gas mileage.

- Additional development and investment in the automobile sector The economic impact of the European automobile metal stamping sector is anticipated to be significant. Vehicle engines continue to employ a lot of alloys like cast aluminum, titanium, forged steel, and cast iron, which has helped the growth of metal fabrication equipment in Europe.

Europe Metal Fabrication Equipment Industry Overview

The competitive landscape of the European metal fabrication equipment market is observed to be somewhat consolidated, with a few of the major players currently dominating the market. However, they are up against fierce competition from regional competitors, small and medium-sized businesses, and firms that specialize in making specialized equipment in the industry under investigation.

The automotive industry and its auxiliary sectors are the biggest buyers of fabrication equipment, closely followed by manufacturing companies. Throughout the forecast period, demand and supply for key industries in the metal fabrication market, such as aerospace and defense, are anticipated to pick up. Companies were driven to relocate their manufacturing facilities to expand the European metal fabrication equipment industry due to growing demand in the region's industrial sectors and sizable marketplaces for several industry verticals.

TRUMPF GmbH + Co. KGm, Durr AG, Amada Europe, GF Machining Solutions, and DMG MORI are some of the leading players operating in the European metal fabrication equipment market.

Some other major players in the market are Schuler AG, GROB-WERKE GmbH, Bystronic Maschinen AG, Feintool International Holding AG, Mazak U.K. Limited, Okuma Europe, Reishauer AG, Starrag Group Holding AG, Gebr. Heller Maschinenfabrik GmbH, Baileigh Industrial, Meusburger Georg Gmbh, etc.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Deliverables

- 1.2 Study Assumptions

- 1.3 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS & DYNAMICS

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.3 Market Restraints

- 4.4 Market Opportunities

- 4.5 Value Chain/Supply Chain Analysis

- 4.6 Industry Attractiveness - Porter's Five Forces Analysis

- 4.6.1 Threat of New Entrants

- 4.6.2 Bargaining Power of Buyers/Consumers

- 4.6.3 Bargaining Power of Suppliers

- 4.6.4 Threat of Substitute Products

- 4.6.5 Intensity of Competitive Rivalry

- 4.7 Technological Snapshot

- 4.8 Impact of COVID-19 on the Market

5 MARKET SEGMENTATION

- 5.1 Service type

- 5.1.1 Machining

- 5.1.2 Cutting

- 5.1.3 Welding

- 5.1.4 Forming

- 5.1.5 Other Service Types

- 5.2 End-user Industries

- 5.2.1 Automotive

- 5.2.2 Construction

- 5.2.3 Aerospace

- 5.2.4 Electrical and Electronics

- 5.2.5 Other End-user Industries

- 5.3 Geography

- 5.3.1 Germany

- 5.3.2 UK

- 5.3.3 France

- 5.3.4 Rest of the Europe

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration Overview

- 6.2 Company Profiles

- 6.2.1 TRUMPF GmbH + Co. KG

- 6.2.2 Durr AG

- 6.2.3 Amada Europe

- 6.2.4 GF Machining Solutions

- 6.2.5 DMG MORI

- 6.2.6 Schuler AG

- 6.2.7 GROB-WERKE GmbH

- 6.2.8 Bystronic Maschinen AG

- 6.2.9 Feintool International Holding AG

- 6.2.10 Mazak U.K. Limited*

- 6.3 Other Companies (Reishauer AG, Okuma Europe, Gebr. Heller Maschinenfabrik GmbH, Starrag Group Holding AG, Meusburger Georg Gmbh, Baileigh Industrial)