|

市場調查報告書

商品編碼

1637850

機器狀態監測:市場佔有率分析、產業趨勢與統計、2025-2030 年成長預測Machine Condition Monitoring - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

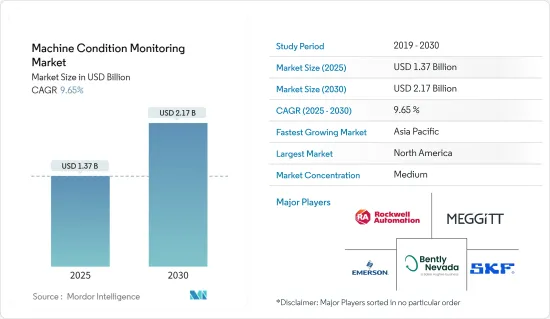

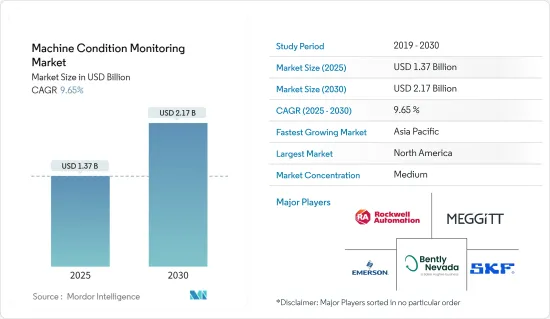

機器狀態監測市場規模在 2025 年估計為 13.7 億美元,預計到 2030 年將達到 21.7 億美元,預測期內(2025-2030 年)的複合年成長率為 9.65%。

預計在預測期內,工業 4.0 的日益普及、減少人為參與預測性維護的需求不斷成長以及對實施機器狀態監測解決方案的好處的認知不斷提高將推動機器狀態監測市場的發展。

主要亮點

- 工業 4.0 依靠自動化,包括即時資訊處理和電腦學習來實現工業工廠運作的現代化。這導致了電腦化生產技術的擴展,以提高營運效率,包括數位分析、自動化和商業物聯網。此外,工業4.0中預測管理的引入為許多行業帶來了巨大的前景。分析設備資料以確定和計劃維護並減少運作是機器健康管理過程的一部分。這些進步使得分析設備功能和預測故障情況成為可能。因此,有關機器狀態追蹤的知識的不斷成長有望開闢新的商業前景。

- 預計市場主要參與者的產品開發將促進市場成長。例如,2022年11月,透過診斷測試和服務(包括軟體)為電氣部門提供設備健康檢查的Doble工程公司宣布了一種針對中高壓電纜系統的新解決方案:Calisto電纜狀況監測。創新的Callisto電纜可實現安全可靠的電纜運行,降低故障可能性,降低整體營運和解決方案成本,並提供近乎即時的電纜健康狀況資訊。

- 自新冠疫情以來,對完全自主且極少人工監督的系統的需求推動了市場的發展,隨著全球經濟的逐步復甦和遠端操作需求的增加,市場也在不斷擴大。此外,由於對即時機器監控的需求不斷增加,工業 4.0 的日益採用可能會產生具有吸引力的市場發展前景。

- 然而,需要短期投資,而且狀態監控設備價格昂貴。此外,狀態監測感測器可能無法在某些環境中生存,且機器表現出不可預測的維護期,這對市場成長構成了挑戰。

機器狀態監測市場趨勢

汽車運輸快速成長

- 在全球範圍內,汽車產業是製造業的關鍵領域之一。隨著技術的快速進步,汽車變得越來越複雜。這種複雜性的增加會導致潛在的生產錯誤,從而增加了對持續機器狀態監控解決方案的需求。

- 汽車產業的市場相關人員正在競相簡化和升級其製造流程。生產線上安裝的各種馬達需要定期監控。馬達電壓模式分析方法有助於減少機器故障並延長機器壽命。汽車行業生產的汽車數量正在快速成長,預計將促進市場成長。例如,特斯拉2022年第三季的汽車產量為36.59萬輛。特斯拉的生產水準較上季成長超過41.5%,2022年第三季的年化成長率達到近53.9%。為了縮短製造週期並提高產量,汽車組裝廠的工廠車間必須採用相應的技術。

- 空氣處理系統和幫浦是汽車領域狀態監測最常見的應用。其他採用狀態監測的重要領域包括馬達和傳動部件的耐久性測試、風洞、可靠性測試的電氣故障和汽車測試台(人工道路)。

- 汽車領域對狀態監測的需求不斷成長,促使主要企業加強產品開發。例如,2022 年 4 月,OMRON推出了其創新的 K7TM 狀態監控系統,主要用於汽車和快速消費品領域的加熱設備。

預測期內歐洲將大幅成長

- 由於汽車、航太等終端使用產業的強勁發展,歐洲機器狀態監測市場預計在未來五年內將大幅成長。此外,ABB、SKF AB 和 Meggitt PLC 等主要製造商在該地區的存在將進一步促進市場成長。

- 攜帶式監控過程難以在遠端製造工廠中實施,從而增加了在線狀態監控的需求。此外,技術進步以及對即時警報和指標的需求正在推動許多終端使用領域擴大採用線上狀態監測流程。這促使主要參與者加大產品開發力道。例如,2021 年 6 月,ABB 宣布推出一項新型數位狀態監測服務,專注於輸送系統的預測性維護。預計這些發展將在預測期內推動機械狀態監測市場的成長。

- 該國擁有43個汽車組裝和生產廠,佔歐洲汽車生產能力的三分之一以上。該國生產的汽車有四分之三以上銷往國際市場。因此,預計高汽車產量將推動汽車產業對狀態監測解決方案的需求,從而在預測期內促進機器狀態監測市場的發展。例如,2022年4月,根據歐洲汽車工業協會(ACEA)的數據,2021年歐盟生產了約990萬輛乘用車。

- 智慧製造的發展始於機器自動化監控。智慧工廠中的設備透過基於物聯網的網路監視器連接,使機器能夠即時提取資料。連接機器系統提供有關設備性能的寶貴資訊,提高當前生產率並比較估計與實際生產率。根據ETNO預測,到2027年,汽車領域將有2.23億個活躍的物聯網(IoT)鏈接,整個歐洲將有1900萬個活躍的物聯網鏈接。因此,汽車產業智慧製造的部署正在增加,預計這將在預測期內推動區域市場的擴張。

機器狀態監測產業概況

機器狀態監測市場競爭適中,有多家參與者。該市場的一些參與者包括羅克韋爾自動化公司(Rockwell Automation, Inc)、美捷特公司(Meggitt PLC)、通用電氣本特利內華達公司(GE Bently Nevada)、艾默生電氣公司(Emerson Electric Co. ) 和SKF 集團。這些參與者正在採用產品發布、夥伴關係和合資企業等多種策略來增加客戶群並擴大產品系列。

- 2022 年 11 月-研華和 Actility 宣布推出一種基於 AI 的新型組合解決方案,以協助機器操作團隊進行機器預後診斷和狀態監控。這使得使用者可以同時檢查多個設備的狀態。

- 2022 年 9 月 - ABB 與荷蘭高成長公司、知名 ESA 技術供應商 Samotics 達成長期策略合作,以提供更好的狀態監測服務。我們利用彼此的優勢來更深入地了解設備健康和電力效率。

其他福利

- Excel 格式的市場預測 (ME) 表

- 3 個月的分析師支持

目錄

第 1 章 簡介

- 研究假設和市場定義

- 研究範圍

第2章調查方法與方法論

第3章執行摘要

第4章 市場洞察

- 市場概況

- 產業價值鏈分析

- 產業吸引力波特五力分析

- 新進入者的威脅

- 買家的議價能力

- 供應商的議價能力

- 替代品的威脅

- 競爭對手之間的競爭強度

- COVID-19 市場影響

第5章 市場動態

- 市場促進因素

- 透過預測性維護提高設備性能和生產力

- 預測性維護的需求不斷增加

- 工業 4.0 和製造業及製程工業的新興產業應用

- 市場挑戰

- 改裝的成本影響

- 全球宏觀經濟與地緣政治因素

第6章 市場細分

- 機器狀態監測

- 按類型

- 硬體

- 振動狀態監測裝置

- 熱成像設備

- 潤滑油分析

- 超音波發射監測

- 其他類型

- 軟體

- 服務

- 遠端監控服務

- 儀器維修服務

- 機器診斷服務

- 按類型

- 振動監測裝置

- 最終用戶產業

- 石油和天然氣

- 發電

- 工藝與製造

- 航太和國防

- 汽車與運輸

- 其他最終用戶產業(海洋、採礦、金屬等)

- 按地區

- 北美洲

- 美國

- 加拿大

- 歐洲

- 德國

- 英國

- 法國

- 其他歐洲國家

- 亞太地區

- 中國

- 日本

- 印度

- 其他亞太地區

- 世界其他地區

- 供應商市場佔有率分析

- 最終用戶產業

- 熱成像設備

- 按最終用戶產業

- 石油和天然氣

- 發電

- 工藝與製造

- 航太和國防

- 汽車與運輸

- 其他產業(海洋、採礦、金屬等)

- 按地區

- 北美洲

- 美國

- 加拿大

- 歐洲

- 德國

- 英國

- 法國

- 其他歐洲國家(東歐和西歐國家)

- 亞太地區

- 中國

- 日本

- 印度

- 其他亞太地區

- 世界其他地區(拉丁美洲及中東及非洲)

- 供應商市場佔有率分析

- 按最終用戶產業

- 潤滑油分析儀

- 按最終用戶產業

- 石油和天然氣

- 發電

- 工藝與製造

- 航太和國防

- 汽車與運輸

- 其他產業(海洋、採礦、金屬等)

- 按地區

- 北美洲

- 美國

- 加拿大

- 歐洲

- 德國

- 英國

- 法國

- 其他歐洲國家

- 亞太地區

- 中國

- 日本

- 印度

- 其他亞太地區

- 世界其他地區(拉丁美洲及中東及非洲)

- 供應商市場佔有率分析

- 按最終用戶產業

第7章 競爭格局

- 公司簡介

- Meggitt Sensing Systems(Meggitt PLC)

- Rockwell Automation Inc.

- GE Bently Nevada

- Emerson Electric Co.

- SKF AB

- Bruuel & Kjaer Vibro

- FLIR Systems Inc.

- Fluke Corporation

- Nippon Avionics Co., Ltd.

- Thermo Fisher Scientific Inc.

- Perkin Elmer Inc.

- AMETEK Spectro Scientific

- Parker Kittiwake(PARKER HANNIFIN CORP.)

- Gastops Ltd

第8章投資分析

第9章:市場的未來

The Machine Condition Monitoring Market size is estimated at USD 1.37 billion in 2025, and is expected to reach USD 2.17 billion by 2030, at a CAGR of 9.65% during the forecast period (2025-2030).

Increasing adoption of industry 4.0, increasing demand for reducing human involvement in predictive maintenance, and rising awareness regarding the benefits of installing machine condition monitoring solutions are expected to drive the machine condition monitoring market over the forecast period.

Key Highlights

- Industry 4.0 relies on automation and computer learning, including real-time information processing, to modernize industrial plant operations. This has expanded computerized production technology to enhance operating efficiencies, including digital analytics, automation, and commercial IoT. Furthermore, implementing predictive management in Industry 4.0 provides substantial prospects for numerous industries. Analyzing equipment data to identify and plan maintenance and decrease outage is part of the machine condition management process. Such progress enables the analysis of equipment functioning and the prediction of breakdown scenarios. As a result, rising knowledge of machine status tracking is projected to open up new business prospects.

- Product developments by key players operating in the market are expected to contribute to market growth. For instance, in November 2022, Doble Engineering Company, which provides equipment health inspections for the electric sector via diagnostic tests and services, including software, introduced a new solution, Calisto cable condition monitoring, for moderate and higher voltage cable systems. The innovative Calisto cable provides safe and reliable cable operation, cutting the chance of failure, decreasing the overall cost of operations and solutions, and providing near-real-time information on cable health.

- Post COVID-19 requirement for fully autonomous systems with minimum human administration is propelling the market, which is expanding in line with the gradual recovery of the economies worldwide and the growth in demand for distant operations. Furthermore, the growing adoption of Industry 4.0 due to the increased need for real-time machine monitoring is likely to generate attractive market development prospects.

- However, short-term investment is required, and the equipment for condition monitoring is costly. Moreover, the condition monitoring sensors may not survive depending on the environment, and the machine exhibits unpredictable maintenance periods-such a factor challenges market growth.

Machine Condition Monitoring Market Trends

Automotive Transportation to Witness Significant Growth

- Globally, the automotive sector is one of the significant segments of the manufacturing industry. With rapid advances in technology, automobiles are becoming more complex. This increased complexity is leading to possible production errors, which in turn is increasing the need for continuous machine condition monitoring solutions.

- The automobile industry's market players are driven to streamline and upgrade their manufacturing processes. The various motors placed on the production lines need periodic monitoring. The motor voltage pattern analysis approach helps to reduce machine breakdowns and boost machine lifespan. The number of units manufactured in the vehicle industry is rapidly growing, which in turn is expected to contribute to market growth. For instance, Tesla Inc.'s 3rd quarter 2022 car manufacturing output was 365,900 units. Tesla's production level climbed by more than 41.5% quarter on quarter and reached nearly 53.9 % yearly in the third period of 2022. The technology on the car assembly facility's plant floor must be adequately serviced to provide an enhanced manufacturing cycle and output.

- Air-handling systems and pumps are the most common uses of condition monitoring in the automobile sector. Other critical areas wherein condition monitoring is employed include motor and transmission part endurance testing, wind tunnels, electrical breakdowns for reliability testing, automotive test benches (artificial roadways), and others.

- Increasing demand for condition monitoring in the automotive sector has led to increasing product development by key players. For instance, in April 2022, OMRON launched the innovative K7TM condition monitoring for heating equipment, which is utilized mainly in the automotive and FMCG sectors.

Europe to Grow Considerably Over The Forecast Period

- The machine condition monitoring market in Europe is anticipated to grow significantly over the next five years due to the presence of strong end-use industries such as automobile and aerospace. Furthermore, the presence of significant manufacturers across the region, including ABB, SKF AB, and Meggitt PLC, among others, will further contribute to market growth.

- Since portable monitoring processes are challenging to utilize in remote manufacturing plants, the need for online condition monitoring has increased. Furthermore, technological advancements and the need for real-time alerts and metrics have increased the adoption of online condition monitoring processes across numerous end-use sectors. This has led to increasing product developments by key players. For instance, in June 2021, ABB introduced a novel digital condition monitoring service designed specifically for conveyor system predictive maintenance. Such developments are expected to boost the Machine Condition Monitoring Market growth over the forecast period.

- The country homes 43 automobile assemblies and production plants, with more than 1/3rd of Europe's automobile production capacity. More than 3/4th of the cars produced in this country are destined for international markets. Thus, high automobile manufacturing will propel the need for condition-monitoring solutions in the automotive sector, boosting the market for machine condition monitoring over the forecast period. For instance, in April 2022, according to ACEA, around 9.9 million passenger vehicles were made in the European Union in 2021.

- Developing smart manufacturing begins with automated machine monitoring. Equipment in an intelligent factory is linked via IoT-enabled, web-based monitors that allow for real-time machine extracting data. The linked machine system provides useful information about equipment performance, improves current output, and compares estimated to real output ratios. According to ETNO, by 2027, there will be 223 million active Internet of Things (IoT) links in the automotive sector and 19 million businesses throughout Europe. Thus, increasing smart manufacturing deployment across the automobile industry is expected to boost regional market expansion over the forecast period.

Machine Condition Monitoring Industry Overview

The Machine Condition Monitoring Market is moderately competitive, with several players. Some of the players operating in the market include Rockwell Automation, Inc., Meggitt PLC, GE Bently Nevada, Emerson Electric Co., and SKF Group, among others. These players are adopting several strategies, such as product launches, partnerships, and joint ventures, among others, to increase their customer base and expand their product portfolios.

- November 2022 - Advantech and Actility have announced a novel combined AI-based solution to assist machine operation teams in implementing machine prognostics and condition monitoring. It enables users to check the status of several devices at the same time.

- September 2022 - ABB and Samotics, a high-growth scaleup business in the Netherlands and a prominent vendor of ESA technology have formed a long-term strategic cooperation to deliver better condition monitoring services. The method will use each company's strengths to provide more insights into equipment health and power efficiency.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH APPROACH AND METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Value Chain Analysis

- 4.3 Industry Attractiveness Porters Five Forces Analysis

- 4.3.1 Threat of New Entrants

- 4.3.2 Bargaining Power of Buyers

- 4.3.3 Bargaining Power of Suppliers

- 4.3.4 Threat of Substitute Products

- 4.3.5 Intensity of Competitive Rivalry

- 4.4 Impact of COVID-19 on the Market

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Increasing Equipment Performance and Productivity through Predictive Maintenance

- 5.1.2 Rising Predictive Maintenance Requirements

- 5.1.3 Industry 4.0 and Emerging Industrial Applications across Manufacturing and Process Industries

- 5.2 Market Challenges

- 5.2.1 Cost Implications in Line with Retrofits

- 5.2.2 Global Macroeconomic and Geopolitical Factors

6 MARKET SEGMENTATION

- 6.1 MACHINE CONDITION MONITORING

- 6.1.1 Type

- 6.1.1.1 Hardware

- 6.1.1.1.1 Vibration Condition Monitoring Equipment

- 6.1.1.1.2 Thermography Equipment

- 6.1.1.1.3 Lubricating Oil Analysis

- 6.1.1.1.4 Ultrasound Emission Monitoring

- 6.1.1.1.5 Other Types

- 6.1.1.2 Software

- 6.1.1.3 Services

- 6.1.1.3.1 Remote Monitoring Services

- 6.1.1.3.2 Instrumentation Maintenance Services

- 6.1.1.3.3 Machinery Diagnostics Services

- 6.1.1 Type

- 6.2 VIBRATION MONITORING EQUIPMENT

- 6.2.1 End User Industry

- 6.2.1.1 Oil and Gas

- 6.2.1.2 Power Generation

- 6.2.1.3 Process and Manufacturing

- 6.2.1.4 Aerospace and Defense

- 6.2.1.5 Automotive and Transportation

- 6.2.1.6 Other End-user Industries (Marine, Mining, Metal, etc.)

- 6.2.2 Geography

- 6.2.2.1 North America

- 6.2.2.1.1 United States

- 6.2.2.1.2 Canada

- 6.2.2.2 Europe

- 6.2.2.2.1 Germany

- 6.2.2.2.2 United Kingdom

- 6.2.2.2.3 France

- 6.2.2.2.4 Rest of Europe

- 6.2.2.3 Asia Pacific

- 6.2.2.3.1 China

- 6.2.2.3.2 Japan

- 6.2.2.3.3 India

- 6.2.2.3.4 Rest of Asia Pacific

- 6.2.2.4 Rest of the World

- 6.2.3 Vendor Market Share Analysis

- 6.2.1 End User Industry

- 6.3 THERMOGRAPHY EQUIPMENT

- 6.3.1 End User Vertical

- 6.3.1.1 Oil and Gas

- 6.3.1.2 Power Generation

- 6.3.1.3 Process and Manufacturing

- 6.3.1.4 Aerospace and Defense

- 6.3.1.5 Automotive and Transportation

- 6.3.1.6 Other End-user Verticals (Marine, Mining, Metal, etc.)

- 6.3.2 Geography

- 6.3.2.1 North America

- 6.3.2.1.1 United States

- 6.3.2.1.2 Canada

- 6.3.2.2 Europe

- 6.3.2.2.1 Germany

- 6.3.2.2.2 United Kingdom

- 6.3.2.2.3 France

- 6.3.2.2.4 Rest of Europe (Eastern Europe and Other Western European Countries)

- 6.3.2.3 Asia Pacific

- 6.3.2.3.1 China

- 6.3.2.3.2 Japan

- 6.3.2.3.3 India

- 6.3.2.3.4 Rest of Asia Pacific

- 6.3.2.4 Rest of the World (Latin America and Middle East and Africa)

- 6.3.3 Vendor Market Share Analysis

- 6.3.1 End User Vertical

- 6.4 LUBRICATING OIL ANALYSIS EQUIPMENT

- 6.4.1 End User Vertical

- 6.4.1.1 Oil and Gas

- 6.4.1.2 Power Generation

- 6.4.1.3 Process and Manufacturing

- 6.4.1.4 Aerospace and Defense

- 6.4.1.5 Automotive and Transportation

- 6.4.1.6 Other End-user Verticals (Marine, Mining, Metal, etc.)

- 6.4.2 Geography

- 6.4.2.1 North America

- 6.4.2.1.1 United States

- 6.4.2.1.2 Canada

- 6.4.2.2 Europe

- 6.4.2.2.1 Germany

- 6.4.2.2.2 United Kingdom

- 6.4.2.2.3 France

- 6.4.2.2.4 Rest of Europe

- 6.4.2.3 Asia Pacific

- 6.4.2.3.1 China

- 6.4.2.3.2 Japan

- 6.4.2.3.3 India

- 6.4.2.3.4 Rest of Asia Pacific

- 6.4.2.4 Rest of the World (Latin America and Middle East and Africa)

- 6.4.3 Vendor Market Share Analysis

- 6.4.1 End User Vertical

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Meggitt Sensing Systems (Meggitt PLC)

- 7.1.2 Rockwell Automation Inc.

- 7.1.3 GE Bently Nevada

- 7.1.4 Emerson Electric Co.

- 7.1.5 SKF AB

- 7.1.6 Bruuel & Kjaer Vibro

- 7.1.7 FLIR Systems Inc.

- 7.1.8 Fluke Corporation

- 7.1.9 Nippon Avionics Co., Ltd.

- 7.1.10 Thermo Fisher Scientific Inc.

- 7.1.11 Perkin Elmer Inc.

- 7.1.12 AMETEK Spectro Scientific

- 7.1.13 Parker Kittiwake (PARKER HANNIFIN CORP.)

- 7.1.14 Gastops Ltd