|

市場調查報告書

商品編碼

1640571

己二胺 -市場佔有率分析、產業趨勢與統計、成長預測(2025-2030 年)Hexamethylenediamine - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

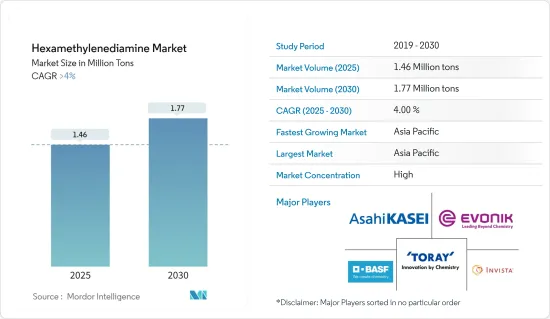

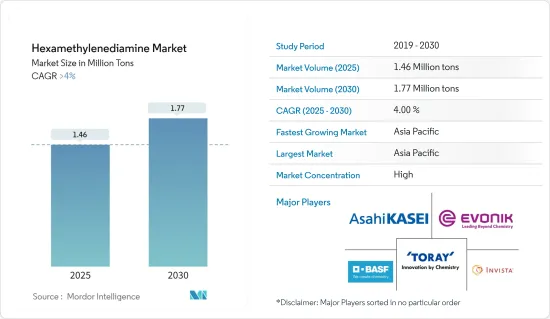

預計 2025 年己二胺市場規模為 146 萬噸,預計 2030 年將達到 177 萬噸,預測期內(2025-2030 年)的複合年成長率將超過 4%。

COVID-19疫情對己二胺市場產生了負面影響。由於多個國家實施全國封鎖以及社交距離措施導致勞動力短缺,汽車製造地停工,對己二胺市場造成了影響。然而,在疫情過後,由於紡織和汽車終端用戶產業的需求增加,己二胺市場已經順利復甦。

關鍵亮點

- 尼龍 6,6 樹脂消費量的增加以及汽車和紡織業對己二胺的需求增加預計將推動己二胺市場的發展。

- 在尼龍製造過程中使用蓖麻油作為替代原料預計會阻礙市場成長。

- 預計預測期內對生物基己二胺產品的需求不斷增加將為市場創造機會。

- 由於紡織和汽車終端用戶產業對六亞甲基二胺的需求不斷成長,預計亞太地區將佔據市場主導地位。

己二胺市場趨勢

紡織終端用戶產業主導市場

- 在尼龍66的生產過程中,需要大量消耗己二胺。尼龍 66 由兩種單體製成,即己二胺和己二酸,每個單體含有六個碳原子。尼龍66在紡織業中有著廣泛的應用。

- 尼龍66用於製造具有更好耐用性和抗撕裂性的織物。尼龍基織品有多種用途,可用於加固戶外裝備的紡織品。

- 亞太地區和歐洲是世界上最大的紡織品市場。歐盟委員會表示,歐盟的紡織生態系統創造了價值並提供了投資和創新的機會。紡織和服飾(T&C) 產業是歐洲規模最大、最多樣化的工業產業之一,僱用了 150 萬人。

- 據Apparel Resources稱,2022年,歐盟紡織品和服飾市場的銷售額將達到2,000億歐元(2,170億美元)。預計未來幾年這數字還會進一步增加。因此,紡織市場的擴張預計將推動該地區對己二胺的需求。

- 同樣,根據世界貿易組織 (WTO) 的數據,中國將在 2022 年成為世界最大的紡織品出口國,出口額約為 1,480 億美元。同樣,歐盟位居第二,出口額約 710 億美元。未來紡織品出口額可望進一步增加,推動目前研究市場的發展。

- 例如,在印度,自過去十年以來,紡織業的外國直接投資(FDI)不斷增加,導致紡織品產量增加,增加了植絨膠的使用。根據印度品牌資產基金會預測,到2025-26年,印度紡織服裝產業規模將達到1,900億美元。

- 因此,預計預測期內紡織終端用戶產業將主導己二胺市場。

亞太地區佔市場主導地位

- 由於紡織、汽車和塑膠終端用戶產業的需求不斷增加,預計亞太地區將主導己二胺市場。

- 預計未來幾年紡織業對尼龍纖維的使用量的增加將推動該地區六亞甲基二胺市場的發展。由於中國紡織業的高速發展和汽車產業的持續投資,預計亞太地區將主導全球市場。

- 中國和孟加拉是該地區紡織品最大的市場。根據中國國家統計局預測,2022年中國紡織品產量將達382億米,去年同期為235億米。因此,預計紡織產品產量的增加將推動當前的研究市場。

- 孟加拉是該地區第二大紡織品市場。根據《2023年世界貿易統計評論》,2022年該國紡織品出口額達450億美元。該國在全球服飾出口中的佔有率將從上一年的 6.4% 增加到 2022 年的 7.9%。因此,紡織市場的成長可望帶動該國己二胺市場的發展。

- 隨著人們重視減輕汽車重量以提高燃油經濟性和減少排放氣體,汽車引擎蓋下零件對輕質複合尼龍樹脂的需求將會增加。中國是該地區最大的汽車製造國。根據國際汽車製造商協會(OICA)預測,2022年中國汽車產量將達2,702總合,與前一年同期比較去年同期成長3%。

- 同樣,印度已成為該地區第二大汽車製造國。 OICA預計2022年汽車產量將達545萬輛,較2021年的439萬輛成長24%。

- 此外,為了滿足印度日益成長的需求,各製造商已宣布擴張計劃,以增加其在印度的汽車生產能力。例如,MG Motor India 在 2023 年 1 月宣布將投資 1 億美元擴大生產能力,並在 2023年終前實現 70% 的成長。因此,汽車產量的增加預計將推動尼龍纖維市場並促進當前的研究市場。

- 總體而言,預計預測期內紡織和汽車終端用戶等行業的成長將推動該地區六亞甲基二胺市場的發展。

己二胺產業概況

己二胺市場本質上呈現部分整合狀態。市場的主要企業(不分先後順序)包括BASF SE、旭化成公司、贏創工業股份公司、東麗工業公司和英威達。

其他福利

- Excel 格式的市場預測 (ME) 表

- 3 個月的分析師支持

目錄

第 1 章 簡介

- 調查前提條件

- 研究範圍

第2章調查方法

第3章執行摘要

第4章 市場動態

- 驅動程式

- 尼龍66樹脂消耗量增加

- 汽車和紡織業對己二胺的需求不斷增加

- 其他促進因素

- 限制因素

- 尼龍生產中生物基原料的使用增加

- 其他限制因素

- 產業價值鏈分析

- 波特五力分析

- 供應商的議價能力

- 買家的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭程度

第5章 市場區隔(市場規模(基於數量))

- 應用

- 尼龍生產

- 塗料中間體

- 除生物劑

- 其他用途(硬化劑、潤滑劑等)

- 最終用戶產業

- 纖維

- 塑膠

- 汽車

- 其他最終用戶產業(油漆和塗料、石化產品等)

- 地區

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 其他亞太地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 德國

- 英國

- 義大利

- 法國

- 歐洲其他地區

- 南美洲

- 巴西

- 阿根廷

- 南美洲其他地區

- 中東和非洲

- 沙烏地阿拉伯

- 南非

- 其他中東和非洲地區

- 亞太地區

第6章 競爭格局

- 併購、合資、合作與協議

- 市場佔有率(%)**/排名分析

- 主要企業策略

- 公司簡介

- Alfa Aesar

- Asahi Kasei Corporation

- Ascend Performance Materials

- BASF SE

- DOW

- Evonik Industries AG

- Genomatica Inc.

- INVISTA

- Radici Partecipazioni SpA

- Shenma Industrial Co., Ltd.

- Solvay

- TORAY INDUSTRIES INC.

第7章 市場機會與未來趨勢

- 生物基己二胺產品需求不斷成長

- 其他機會

The Hexamethylenediamine Market size is estimated at 1.46 million tons in 2025, and is expected to reach 1.77 million tons by 2030, at a CAGR of greater than 4% during the forecast period (2025-2030).

The COVID-19 pandemic negatively affected the market for hexamethylenediamine. The nationwide lockdowns in several countries and the labor shortage due to social distancing measures resulted in the suspension of manufacturing sites for automotive vehicles, which affected the market for hexamethylenediamine. However, post-COVID pandemic, the market for hexamethylenediamine recovered well due to increasing demand from textile and automotive end-user industries.

Key Highlights

- The increasing consumption of Nylon 66 resins and the rising demand for hexamethylenediamine in the automotive and textile industries are expected to drive the market for Hexamethylenediamine.

- The usage of castor oil as an alternative raw material for the nylon production process is expected to hinder market growth.

- The increasing demand for bio-based hexamethylenediamine products is expected to create opportunities for the market during the forecast period.

- The Asia-Pacific region is expected to dominate the market due to the rising demand for hexamethylenediamine from textile and automotive end-user industries.

Hexamethylenediamine Market Trends

Textile End-User Industry to Dominate the Market

- A high amount of hexamethylenediamine produced is consumed for the manufacturing of nylon 66. Nylon 66 is made of two monomers, each containing six carbon atoms, hexamethylenediamine and adipic acid. The nylon 66 is widely used in the textile industry.

- Nylon 66 is used to manufacture fabric materials that provide better durability and tearing resistance. The nylon-based fabrics are used for various applications and reinforcement for outdoor equipment textiles.

- Asia-Pacific and Europe are the largest markets for textiles across the globe. According to the European Commission, The EU's textiles ecosystem generates value and opens up opportunities for investment and innovation. Textiles and clothing (T&C) is one of Europe's largest and most diversified industrial sectors, with a workforce of 1.5 million.

- According to Apparel Resources, in 2022, the textile and clothing market in the European Union registered EUR 200 billion (USD 217 billion) in revenue. It is further expected to increase in the coming years. Thus, the increasing market for textile products is expected to drive the demand for hexamethylenediamine in the region.

- Similarly, according to the World Trade Organization, in 2022, China was the top-ranked global textile exporter, with a value of approximately USD 148 billion. Similarly, the European Union ranked in second place, with an export value of around USD 71 billion. The export value of textiles is further expected to increase in the coming years, thereby driving the current studied market.

- For instance, in India, with an increase in foreign direct investment (FDI) in the textile industry from the past decade, the production of textiles is increasing, thus resulting in increased use of flock adhesives. According to the Indian Brand Equity Foundation, India's textile and apparel industry is expected to reach USD 190 billion by 2025-26.

- Thus, the textile end-user industry segment will dominate the market for hexamethylenediamine during the forecast period.

Asia-Pacific to Dominate the Market

- The Asia-Pacific region is expected to dominate the market for hexamethylenediamine due to rising demand from the textile, automotive, and plastics end-user industries.

- The increasing usage of nylon fibers is increasing in the textile industry expected to drive the market for hexamethylenediamine in the region through the years to come. Asia-Pacific is expected to dominate the global market, owing to the highly developed textile sector in China, coupled with continuous investments in the automotive sectors.

- China and Bangladesh are the largest markets for Textiles in the region. According to the National Bureau of Statistics of China, the textile production volume in China accounted for 38.2 billion meters in 2022, compared to 23.5 billion meters during the same period in the previous year. Thus, the increase in the production volume of textiles is expected to drive the current studied market.

- Bangladesh is the second-largest market for textiles in the region. According to the World Trade Statistical Review 2023, the country exported textiles worth USD 45 billion in the year 2022. The country's share in global clothing exports increased to 7.9% in the year 2022, as compared to 6.4 % registered in the previous year. Thus, the growth in the textile market will drive the market for hexamethylenediamine in the country.

- The focus on reducing vehicle weight for greater fuel efficiency and lower emissions will increase the demand for lightweight composite nylon resins in automotive under-the-hood components. China is the largest automotive vehicle manufacturer in the region. According to OICA (The Organisation Internationale des Constructeurs d'Automobiles), automotive vehicle production in China reached a total of 27.02 million units in 2022, an increase of 3% over the previous year for the same period.

- Similarly, India has become the second-largest automotive vehicle manufacturer in the region. According to OICA, the total production volume of automotive vehicles reached 5.45 million units in 2022, indicating a growth of 24% as compared to 4.39 million units registered in 2021.

- Furthermore, to meet the growing demand in India, various manufacturers have announced their expansion plans to increase the production capacity of automotive vehicles in the country. For instance, in January 2023, MG Motor India announced to invest USD 100 million to expand capacity and register a growth of 70% by the end of 2023. Thus, an increase in automotive vehicle production is expected to drive the market for nylon fibers, thereby driving the current studied market.

- Overall, the growth in industries such as textile and automotive end-user industries is likely to drive the market for hexamethylenediamine in the region during the forecast period.

Hexamethylenediamine Industry Overview

The hexamethylenediamine market is partially consolidated in nature. Some of the major players in the market (not in any particular order) include BASF SE, Asahi Kasei Corporation, Evonik Industries AG, TORAY INDUSTRIES INC., and INVISTA, among others.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Drivers

- 4.1.1 Increasing Consumption of Nylon 66 Resins

- 4.1.2 The Rising Demand for Hexamethylenediamine in Automotive and Textile Industries

- 4.1.3 Other Drivers

- 4.2 Restraints

- 4.2.1 Increased Usage of of Bio-based Raw Materials for Nylon Production

- 4.2.2 Other Restraints

- 4.3 Industry Value Chain Analysis

- 4.4 Porter's Five Forces Analysis

- 4.4.1 Bargaining Power of Suppliers

- 4.4.2 Bargaining Power of Buyers

- 4.4.3 Threat of New Entrants

- 4.4.4 Threat of Substitute Products and Services

- 4.4.5 Degree of Competition

5 MARKET SEGMENTATION (Market Size in Volume)

- 5.1 Application

- 5.1.1 Nylon Production

- 5.1.2 Intermediate for Coatings

- 5.1.3 Biocides

- 5.1.4 Other Applications (Curing Agents, Lubricants, etc.)

- 5.2 End-user Industry

- 5.2.1 Textile

- 5.2.2 Plastics

- 5.2.3 Automotive

- 5.2.4 Other End-user Industries (Paints and Coatings, Petrochemicals, etc.)

- 5.3 Geography

- 5.3.1 Asia-Pacific

- 5.3.1.1 China

- 5.3.1.2 India

- 5.3.1.3 Japan

- 5.3.1.4 South Korea

- 5.3.1.5 Rest of Asia-Pacific

- 5.3.2 North America

- 5.3.2.1 United States

- 5.3.2.2 Canada

- 5.3.2.3 Mexico

- 5.3.3 Europe

- 5.3.3.1 Germany

- 5.3.3.2 United Kingdom

- 5.3.3.3 Italy

- 5.3.3.4 France

- 5.3.3.5 Rest of Europe

- 5.3.4 South America

- 5.3.4.1 Brazil

- 5.3.4.2 Argentina

- 5.3.4.3 Rest of South America

- 5.3.5 Middle East and Africa

- 5.3.5.1 Saudi Arabia

- 5.3.5.2 South Africa

- 5.3.5.3 Rest of Middle East and Africa

- 5.3.1 Asia-Pacific

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers and Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Market Share (%)**/Ranking Analysis

- 6.3 Strategies Adopted by Leading Players

- 6.4 Company Profiles

- 6.4.1 Alfa Aesar

- 6.4.2 Asahi Kasei Corporation

- 6.4.3 Ascend Performance Materials

- 6.4.4 BASF SE

- 6.4.5 DOW

- 6.4.6 Evonik Industries AG

- 6.4.7 Genomatica Inc.

- 6.4.8 INVISTA

- 6.4.9 Radici Partecipazioni SpA

- 6.4.10 Shenma Industrial Co., Ltd.

- 6.4.11 Solvay

- 6.4.12 TORAY INDUSTRIES INC.

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 Increasing Demand for Bio-Based Hexamethylenediamine Products

- 7.2 Other Opportunities