|

市場調查報告書

商品編碼

1640686

印度醫藥包裝:市場佔有率分析、行業趨勢和成長預測(2025-2030 年)India Pharmaceutical Packaging - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

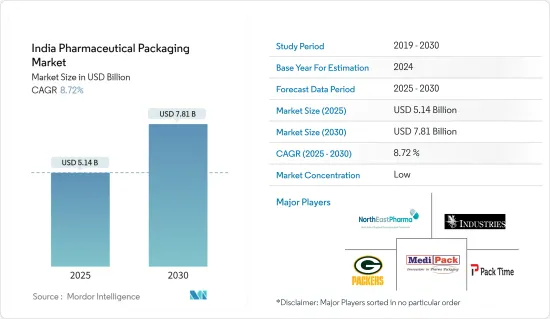

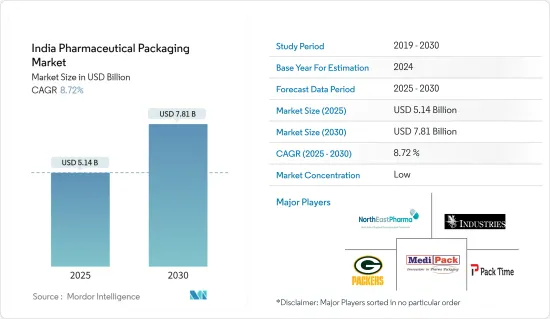

印度的醫藥包裝市場預計在 2025 年價值 51.4 億美元,預計到 2030 年將達到 78.1 億美元,預測期內(2025-2030 年)的複合年成長率為 8.72%。

藥品包裝採用專門設計用於安全運輸和儲存藥品的材料。這些材料是根據藥物特性選擇的,旨在保護、識別和維護封閉產品的完整性。包裝過程可確保藥品免受污染、物理損壞和環境條件等可能影響其功效和安全性的外部因素的影響。藥品包裝對於提供有關藥品的重要資訊(例如劑量說明和法規遵循詳細資訊)至關重要。

主要亮點

- 醫藥產品面臨各種危害,包括機械、化學、生物和氣候風險。藥品包裝有多種材料,包括塑膠、紙、玻璃和金屬,並適合多種給藥方式,包括口服、經皮、注射、局部、介入、鼻腔和眼科。

- 印度政府正在實施廣泛而持續的改革,以加強製藥業,並宣布了鼓勵外國直接投資(FDI)的政策。作為「自強不息印度」舉措的一部分,政府正在推出短期和長期措施來加強醫療保健體系。其中包括實施專門用於促進國內製藥和醫療設備製造業的生產連結獎勵計劃(PLI)。此外,印度正積極將自己定位為精神和健康旅遊目的地,發揮阿育吠陀和瑜伽的優勢。這些策略舉措將對所研究的市場產生重大影響。

- 由於人們越來越擔心其對生態系統和人類健康的影響,印度醫藥包裝市場受到越來越多的審查。推動製藥業的永續性不僅是為了減少碳排放,也是為了長期維護生態系統和公眾健康,尤其是在印度這樣的國家。有效應對這些環境挑戰的需求正在迅速增加對環保和永續藥品包裝解決方案的需求。

- 此外,供應商的議價能力直接影響價格和質量,從而決定價值鏈,並最終決定向消費者提供的產品和服務。隨著供應商實力增強,原物料成本增加,進而導致最終產品價格上漲。

- 印度製藥業已經因生產學名藥而聞名於全球。國內外對藥品的需求不斷成長,推動了對多樣化和先進包裝解決方案的需求。 COVID-19 疫苗的開發和分發需要專門的包裝解決方案,包括管瓶、注射器和低溫運輸包裝,以確保安全有效的交付。據印度衛生和家庭福利部稱,截至 2023 年 11 月 13 日,印度北方邦已接種了數量最多的新冠病毒疫苗。

印度醫藥包裝市場趨勢

塑膠產業推動市場成長

- 受衛生、安全和便利性的關注,印度醫療保健產業對軟性、一次性塑膠包裝的需求顯著成長。儘管許多行業出於對環境問題的考慮逐漸放棄使用一次性塑膠,但醫療保健行業卻是個例外,這主要是出於安全和衛生方面的考慮。這意味著該行業依賴一次性塑膠包裝,從而推動對塑膠包裝的需求。塑膠是用途廣泛的材料,例如 HDPE、PET 和 PP,由於其柔韌性、機械強度和穩定性等特性而被用於製藥業。

- 印度政府正在實施廣泛而持續的改革,以加強製藥業。根據印度品牌股權基金會 (IBEF) 的數據,2023 會計年度印度政府在醫療保健方面的支出佔其 GDP 的 2.6%。預計2025年將達到GDP的2.5%。

- 在產品類型中,瓶類產品中,國內 HDPE 和寶特瓶的產量有所增加,而 HDPE(高密度聚苯乙烯)瓶憑藉其強度、彈性和耐化學性,已成為製藥行業的行業標準。預計這將對市場成長做出重大貢獻。高密度聚乙烯瓶因其強度、彈性和耐化學性已成為製藥業的行業標準。這些特性使其成為保護和儲存各種藥品的理想選擇,支持了塑膠瓶在市場上的廣泛使用。

- 塑膠包裝在印度製藥業非常受歡迎,因為這種產品類型可以透過添加劑進一步增強其固有性能,提高最終產品的抗氧、抗濕、抗紫外線性能。

瓶裝產品將成為印度市場成長最快的產品類別

- 液體藥品包裝用瓶的需求正在推動對玻璃、塑膠和其他基於材料的瓶包裝的需求。這些瓶子不僅可用於盛裝液體藥物,還可用於盛裝固態錠劑和凝膠錠劑。有多種尺寸適用於特定劑量和產品。它們有玻璃和塑膠兩種材質,如果按照說明存放,即使打開後也能保持其品質。

- 對可獲得、高品質的醫療保健,特別是對慢性病患者可負擔得起的醫療保健的追求,導致印度對永續瓶裝藥品包裝解決方案的需求日益成長。根據聯合國亞洲及太平洋經濟社會委員會(ESCAP)預測,到2023年,15至64歲人口將佔印度人口的68.9%。預計到 2050 年這群人將占到 67.0%。

- 高密度聚乙烯 (HDPE) 瓶的生產和供應可支持市場上瓶子部分的成長。這是因為瓶子可以在藥品保存期限內保護藥品免受污染和劣化,確保藥品的安全有效。印度對安全藥品包裝的需求持續成長。 HDPE 瓶因其能夠滿足藥品儲存和保護所需的嚴格標準而越來越受到認可。

- 寶特瓶因其產品保護、可視性和可客製化等用途和優點,已成為藥品包裝的首選。 寶特瓶具有環境永續,因為它們可回收利用,從而減少碳排放並節省資源。預計在預測期內,這些因素將推動印度製藥業使用寶特瓶進行包裝的增加。

印度醫藥包裝產業概況

印度醫藥包裝市場較為分散,主要由 Medipack Innovations Private Limited、Packtime Innovations Private Limited、North East Pharma Pack、NS Industries 和 AS Packers 等主要公司主導。這些公司正在利用策略合作措施來增加市場佔有率和盈利。然而,隨著技術進步和產品創新,中小企業透過贏得新合約和開拓新市場來擴大其市場佔有率。

其他福利

- Excel 格式的市場預測 (ME) 表

- 3 個月的分析師支持

目錄

第 1 章 簡介

- 研究假設和市場定義

- 研究範圍

第2章調查方法

第3章執行摘要

第4章 市場洞察

- 市場概況

- 產業吸引力-波特五力分析

- 供應商的議價能力

- 買家的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭程度

- 產業價值鏈分析

- 評估微觀經濟因素對市場的影響

第5章 市場動態

- 市場促進因素

- 環保意識增強,新監理標準的採用

- 印度慢性疾病患者急劇上升

- 市場限制

- 原料成本因供應商議價能力而波動

第6章 市場細分

- 依材料類型

- 塑膠

- 玻璃

- 其他材料類型

- 依產品類型

- 瓶子

- 管瓶/安瓿瓶

- 注射器

- 管子

- 瓶蓋和瓶塞

- 袋子和包包

- 標籤

- 其他產品類型

第7章 競爭格局

- 公司簡介

- Medipack Innovations Private Limited

- Packtime Innovations Private Limited

- North East Pharma Pack

- NS Industries

- AS Packers

- JK Print Packs

- West Pharmaceutical Packaging India Pvt. Ltd(West Pharmaceutical Services Inc.)

- Huhtamaki India Ltd(Huhtamaki Oyj)

- SGD Pharma India Ltd(SGD Pharma)

- Uflex Limited

- Amcor Flexibles India Pvt. Ltd(Amcor PLC)

- Essel Propack Ltd

- Parekhplast India Limited

- Regent Plast Pvt. Ltd

- Graham Blow Pack Pvt. Limited

- Hoffmann Neopac AG

- 供應商市場佔有率分析

第8章投資分析

第9章:市場的未來

The India Pharmaceutical Packaging Market size is estimated at USD 5.14 billion in 2025, and is expected to reach USD 7.81 billion by 2030, at a CAGR of 8.72% during the forecast period (2025-2030).

Pharmaceutical packaging uses materials designed to transfer and store pharmaceutical drugs safely. These materials are selected based on the drugs' characteristics, aiming to safeguard, identify, and maintain the integrity of the enclosed product. The packaging process ensures that the drugs are protected from external factors such as contamination, physical damage, and environmental conditions, which could potentially compromise their efficacy and safety. Pharmaceutical packaging is crucial in providing essential information about the drug, including dosage instructions and regulatory compliance details.

Key Highlights

- Pharmaceutical drugs face various hazards, spanning mechanical, chemical, biological, and climatic risks. They are packaged using multiple materials, including plastics, paper, glass, and metal, and tailored to different delivery methods, such as oral, pulmonary, injectable, transdermal, topical, interventional, nasal, and ocular.

- The Indian government has implemented extensive and ongoing reforms to bolster the pharmaceutical industry, unveiling policies to foster foreign direct investments (FDI). As part of the Aatmanirbhar Bharat Abhiyaan initiative, the government has introduced a range of short- and long-term measures to fortify the health system. These include implementing Production-linked Incentive (PLI) schemes specifically designed to enhance domestic pharmaceutical and medical device manufacturing. Moreover, India is actively positioning itself as a destination for spiritual and wellness tourism, leveraging its strengths in Ayurveda and yoga practices. These strategic moves are poised to impact the market studied significantly.

- The pharmaceutical packaging market in India is under increasing scrutiny for its impact on ecosystems and human health, given the escalating environmental concerns. The push for sustainability in the pharmaceutical industry is not just about reducing its carbon footprint but also about safeguarding ecosystems and public health for the long haul, especially in a country like India. The demand for eco-friendly and sustainable pharmaceutical packaging solutions is growing rapidly, driven by the need to address these environmental challenges effectively.

- Moreover, supplier bargaining power directly impacts pricing and quality, thereby dictating the value chain and, ultimately, the products and services delivered to consumers. As a supplier's power grows, so do the costs of raw materials, subsequently elevating the final product's price tag.

- The Indian pharmaceutical industry was already a major global player known for its generic drug manufacturing. The increasing demand for pharmaceutical products both domestically and internationally drove the need for diverse and advanced packaging solutions. The development and distribution of COVID-19 vaccines required specialized packaging solutions, including vials, syringes, and cold chain packaging, to ensure safe and effective delivery. According to the Ministry of Health and Family Welfare (India), the Indian state of Utter Pradesh reported the highest number of administered doses of the vaccine against the coronavirus as of November 13, 2023.

India Pharmaceutical Packaging Market Trends

Plastic Segment to Witness Major Market Growth

- The healthcare industry in India is witnessing a notable surge in the demand for flexible single-use plastic packaging, driven by a heightened emphasis on hygiene, safety, and convenience. While many industries are moving away from single-use plastics due to environmental concerns, healthcare is an exception, primarily due to safety and hygiene. This signifies the industry's reliance on single-use plastic packaging and drives the demand for plastic packaging. Plastic is a highly versatile material, including HDPE, PET, and PP, and is used in the pharmaceutical industry due to its flexibility, mechanical strength, and stability characteristics.

- The Indian government has implemented extensive and ongoing reforms to bolster the pharmaceutical industry. According to the India Brand Equity Foundation (IBEF), the Indian government spent 2.6% of the country's GDP on healthcare in the financial year 2023. Government healthcare spending is anticipated to be 2.5% of the GDP in the financial year 2025.

- Among product types, the bottle segment is anticipated to contribute significantly to the market's growth in line with the growth of HDPE and PET bottle production in the country and the emergence of HDPE (high-density polyethylene) bottles as the industry standard in the pharmaceutical industry due to their strength, resilience, and chemical resistance. These qualities make them perfect for safeguarding and storing a variety of medical supplies, supporting the growth of plastic bottle usage in the market.

- The material's intrinsic properties can be further improved through additives, improving performance and properties to act against oxygen, moisture, and UV radiation to the finished product, making plastic packaging a highly preferable type of packaging in the Indian pharmaceutical industry.

Bottles to be the Fastest-growing Product Segment in the Indian Market

- The demand for bottles for liquid pharmaceutical product packaging fuels the demand for glass, plastic, and other material-based bottle packaging. These bottles can be used for more than liquid medicines, solid pills, and gel tablets. They come in various sizes tailored to the specific dosage or product. Available in both glass and plastic, they maintain quality even after opening, provided they are stored as directed.

- The push for accessible, high-quality healthcare, especially for chronic diseases, at affordable rates is fueling the need for sustainable bottle pharmaceutical packaging solutions in India. According to the United Nations Economic and Social Commission for Asia and the Pacific (ESCAP), individuals aged between 15 and 64 constituted 68.9% of India's population in 2023. This demographic is projected to account for a share of 67.0% by 2050.

- The production and availability of HDPE-based bottles can support the growth of the bottles segment in the market because bottles ensure that medications remain safe and effective throughout their shelf life, shielding them from contamination and degradation. The demand for safe pharmaceutical packaging continues to grow in India. HDPE bottles are increasingly recognized for their ability to meet the rigorous standards required for storing and protecting medicinal products.

- PET plastic bottles have become the favored choice for pharmaceutical packaging owing to their applications and advantages in offering product protection, visibility, and customization. PET bottles can be environmentally sustainable due to their recyclability, reduced carbon footprint, and resource conservation. These factors are expected to support their increasing usage for packaging in the Indian pharmaceutical industry during the forecast period.

India Pharmaceutical Packaging Industry Overview

The Indian pharmaceutical packaging market is fragmented and dominated by significant players like Medipack Innovations Private Limited, Packtime Innovations Private Limited, North East Pharma Pack, NS Industries, and AS Packers. These companies leverage strategic collaborative initiatives to increase their market share and profitability. However, with technological advancements and product innovations, mid-size to smaller companies are growing their market presence by securing new contracts and tapping new markets.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Buyers

- 4.2.3 Threat of New Entrants

- 4.2.4 Threat of Substitutes

- 4.2.5 Degree of Competition

- 4.3 Industry Value Chain Analysis

- 4.4 Assessment of the Impact of Microeconomic Factors on the Market

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Rising Awareness of Environmental Issues and Adoption of New Regulatory Standards

- 5.1.2 Surging Number of Chronic Disease Cases in India

- 5.2 Market Restraints

- 5.2.1 Fluctuations in Raw Material Costs Due to Suppliers' Bargaining Power

6 MARKET SEGMENTATION

- 6.1 By Material Type

- 6.1.1 Plastic

- 6.1.2 Glass

- 6.1.3 Other Material Types

- 6.2 By Product Type

- 6.2.1 Bottles

- 6.2.2 Vials and Ampoules

- 6.2.3 Syringes

- 6.2.4 Tubes

- 6.2.5 Caps and Closures

- 6.2.6 Pouches and Bags

- 6.2.7 Labels

- 6.2.8 Other Product Types

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Medipack Innovations Private Limited

- 7.1.2 Packtime Innovations Private Limited

- 7.1.3 North East Pharma Pack

- 7.1.4 N S Industries

- 7.1.5 A S Packers

- 7.1.6 JK Print Packs

- 7.1.7 West Pharmaceutical Packaging India Pvt. Ltd (West Pharmaceutical Services Inc.)

- 7.1.8 Huhtamaki India Ltd (Huhtamaki Oyj)

- 7.1.9 SGD Pharma India Ltd (SGD Pharma)

- 7.1.10 Uflex Limited

- 7.1.11 Amcor Flexibles India Pvt. Ltd (Amcor PLC)

- 7.1.12 Essel Propack Ltd

- 7.1.13 Parekhplast India Limited

- 7.1.14 Regent Plast Pvt. Ltd

- 7.1.15 Graham Blow Pack Pvt. Limited

- 7.1.16 Hoffmann Neopac AG

- 7.2 Vendor Market Share Analysis