|

市場調查報告書

商品編碼

1683518

北美正排量幫浦:市場佔有率分析、產業趨勢與統計、成長預測(2025-2030 年)NA Positive Displacement Pumps - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

價格

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

簡介目錄

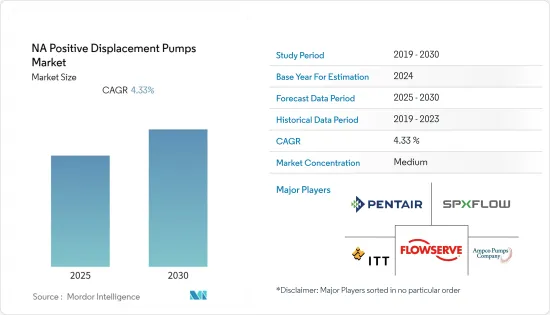

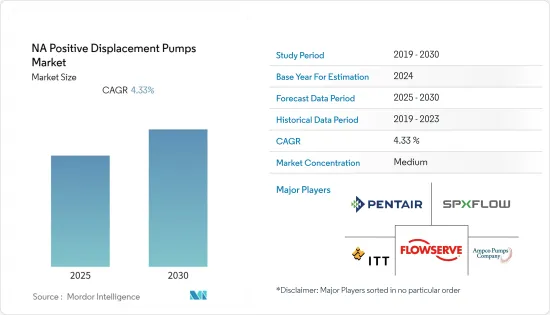

預計預測期內北美正排量幫浦市場的複合年成長率為 4.33%。

主要亮點

- 由於天然氣產量的增加,對石油和天然氣、化學品和發電等終端用戶行業的投資增加將對研究市場產生重大影響。該地區的國家,包括美國和加拿大,擁有豐富的石油蘊藏量並正在尋求開發油砂資源。

- 美國頁岩氣的蓬勃發展和穩定的油價正在推動正排量泵在化學、石油和天然氣行業的使用。此外,這些應用通常會面臨惡劣的條件,從而降低生產力,迫使石油和天然氣公司用先進技術取代現有設備。

- 此外,美國能源生產持續快速成長。例如,美國主要石油生產商之一埃克森美孚已宣布計劃擴大在西德克薩斯州二疊紀盆地的生產活動,最早在2024年實現100萬桶油當量的產量。

- 德克薩斯州的朱庇特管道和金德摩根的羅阿諾克擴建計劃等管道建設計劃計劃於 2021年終完工。這些計劃預計將在未來幾年推動美國對系統中正排量泵的巨大需求。

- 此外,美國也率先開展了各種太陽能計劃,並繼續成為新可再生能源技術的強國。美國能源部能源資訊署 (EIA) 估計,到 2020 年,美國電力部門的淨容量將達到約 1.07兆瓦,並預計未來將大幅增加,到 2050 年將達到約 1.7兆瓦。

北美正排量幫浦市場趨勢

食品飲料產業預計將大幅成長

- 在過去的幾十年裡,食品飲料行業經歷了從小型企業到中型企業再到大型企業的廣泛變化。食品加工的工業化催生了許多使用正排量幫浦的應用。正排量泵使在大氣條件下無法實現的過程成為可能。此外,它在處理氧氣敏感和熱敏感材料時還具有顯著的優勢。

- 此外,正排量幫浦在食品生產中具有許多優勢,包括平穩、無脈衝泵送和衛生性能。大轉子腔和防氣蝕端口使其非常適合廣泛的應用,包括高黏度流體和含有大顆粒的流體。

- 有些型號的設計具有特別嚴格的內部公差,這是透過使用特殊的防咬合內部合金來實現的。它們具有低滑移性能,可提高泵浦效率、改善衛生和生產性能以及設備壽命。

- 2022 年 6 月,NETZSCH Pumps North America, LLC 宣布推出 NOTOS Sanitary 2NSH 雙螺旋泵浦。 NOTOS 衛生級 2NSH 雙螺旋泵可在低壓和高壓下運行,在不影響品質的情況下保持產品的完整性和天然特性。該幫浦符合 FDA 要求,符合 3-A 衛生標準,可快速拆卸進行維護。

- 此外,多年來,食品和飲料加工公司一直致力於提高工廠效率,減少停機時間,並避免因人為錯誤造成的危險事故,增加了對工廠自動化的需求。工業中自動化程度的不斷提高是採用正排量幫浦的主要驅動力。

預計美國將佔較大市場佔有率

- 美國是北美最大的容積泵市場。隨著國內製造和加工行業(包括石油和天然氣、化學品、食品和飲料)以及大型用水和污水管理和發電行業的廣泛發展,對正排量泵的需求在過去幾年中不斷成長。

- 2020年11月,全球容積幫浦製造商Wilo SE宣布將在美國威斯康辛州開設新廠,預計將提振該地區的容積幫浦市場。

- 此外,核能和可再生能源在美國也呈現崛起趨勢。太陽能正在獲得大量投資,這就是我們看到太陽能淨發電量增加的原因。該地區依靠水電等可再生能源進行大規模發電,這將推動該地區的研究市場。

- 美國也是一些標誌性的發電工程的所在地。華盛頓州哥倫比亞河上的大古力水壩是該州最大的水力發電發電工程之一,可滿足該州約三分之二的電力需求。

- 此外,通用電氣再生能源公司也與美國政府簽訂了兩份水電合約。一處是諾斯菲爾德山抽水蓄能發電廠,另一處是太平洋天然氣電力公司的卡里布一號水力發電廠。

北美正排量幫浦產業概況

北美正排量幫浦市場相當分散,有數家地區性和全球性參與者。主要企業包括 Ampco Pumps Company Inc.、Flowserve Corporation 和 ITT Inc. 該市場的主要企業正在推出創新的新產品並建立夥伴關係和聯盟以獲得競爭優勢。

- 2022 年 3 月 - 阿特拉斯·科普柯同意收購 LEWA GmbH 及其子公司以及 Geveke BV 及其子公司。 LEWA 是隔膜計量泵、製程泵和容積泵的領先製造商。

- 2021 年 5 月 - CDI Energy Products 宣布開發並推出針對離心幫浦和正排量泵浦應用的專有先進熱塑性聚合物複合材料。

其他福利:

- Excel 格式的市場預測 (ME) 表

- 3 個月的分析師支持

目錄

第 1 章 簡介

- 研究假設和市場定義

- 研究範圍

第2章調查方法

第3章執行摘要

第4章 市場洞察

- 市場概況

- 產業吸引力-波特五力分析

- 供應商的議價能力

- 消費者議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭對手之間的競爭

- 產業價值鏈分析

- COVID-19 產業影響分析

第5章 市場動態

- 市場促進因素

- 擴大 MEMS 技術的應用

- 該地區對水處理設施的需求不斷增加

- 市場挑戰

- 高成本、相容性問題

第6章 市場細分

- 按容積泵類型

- 隔膜

- 活塞

- 齒輪

- 長袍

- 漸進腔

- 擰緊

- 葉片

- 蠕動

- 按最終用戶產業

- 石油和天然氣

- 化學

- 飲食

- 用水和污水

- 藥品

- 力量

- 其他

- 按國家

- 美國

- 加拿大

第7章 競爭格局

- 公司簡介

- Ampco Pumps Company Inc.

- Flowserve Corporation

- ITT Inc.

- Pentair PLC

- SPX Flow Inc.

- Xylem Inc.

- Liquidyne Process Technologies, Inc.

- Springer Pumps, LLC.

- Titan Manufacturing, Inc.

- Dickow Pump Co.

- Centec LLC

第8章投資分析

第9章:市場的未來

簡介目錄

Product Code: 91325

The NA Positive Displacement Pumps Market is expected to register a CAGR of 4.33% during the forecast period.

Key Highlights

- The increasing investments in the end-user industries, such as oil and gas, chemical, and power generation, significantly impact the studied market due to the increasing natural gas production. Countries in the region, such as the United States and Canada, have abundant oil reserves and try to utilize their oil sands resources.

- The boom of shale gas in the United States and the stabilizing oil prices are driving the usage of positive displacement pumps in the chemical and oil and gas industries. Additionally, these applications are often exposed to harsher conditions, resulting in low productivity, driving the oil and gas companies to replace existing equipment with advanced technologies.

- Moreover, energy production in the United States continues to expand rapidly. For instance, ExxonMobil, one of the major oil producers in the country, announced its plans to increase the production activity in the Permian Basin of West Texas by producing around 1 million bpd oil equivalent as early as 2024.

- Pipeline construction projects such as Jupiter Pipeline in Texas and Roanoke Expansion Project by Kinder Morgan are some of the projects destined to be completed by the end of 2021. These projects are also expected to create a considerable demand for positive displacement pumps, as a part of systems, in the United States over the next few years.

- Further, the United States also pioneered various solar energy projects and remained a powerhouse in new renewable energy technologies. The US Department of Energy's Energy Information Administration (EIA) estimated that the net capacity of the electric power sector in the country was estimated to be around 1.07 terawatts in 2020 and was expected to increase significantly in the future to reach approximately 1.7 terawatts by 2050.

North America Positive Displacement Pumps Market Trends

Food & Beverage Segment is Expected to Witness Significant Growth

- In recent decades the food and beverage industry witnessed widespread changes from small to middle and large firms. The industrialization of food processing created several applications that use positive displacement pumps. It enables processes that can not otherwise be performed under atmospheric conditions. Furthermore, it offers a great advantage in processing oxygen and heat-sensitive materials.

- Moreover, positive displacement pumps offer many benefits in food production, including smooth, pulse-free pumping and hygienic performance. Large rotor fluid cavities and anti-cavitation ports make them ideal for a wide range of applications, including highly viscous fluids and fluids containing large particles.

- Some pump models are designed with particularly tight internal tolerances, facilitated through the use of special non-galling internal alloys. These offer low slip performance, increasing pumping efficiency and improving sanitary and production performance and unit longevity.

- In June 2022, NETZSCH Pumps North America, LLC, announced the introduction of the NOTOS Sanitary 2NSH Twin Screw Pump, which is ideal for meeting the food and beverage requirements industries. It can work at both low and high working pressures; the NOTOS Sanitary 2NSH Twin Screw Pump maintains product integrity and natural properties without any quality loss. The FDA-compliant pump meets 3-A Sanitary Standards and can be disassembled quickly for easy maintenance.

- Further, over the years, food and beverage processing companies made consistent efforts to increase plant efficiency, reduce downtime, and avoid hazardous accidents caused due to human error, thus leading to a rise in the demand for plant automation. The increasing adoption of automation in the industry is a major driver for implementing positive displacement pumps.

United States is Expected to Account for a Significant Market Share

- The United States is the largest market for positive displacement pumps in North America. The presence of a wide range of domestic manufacturing and processing industries, such as oil and gas, chemicals, and food and beverages, along with huge water and wastewater management and power generation sectors, has augmented the demand for positive displacement pumps over the past several years.

- In November 2020, Wilo SE, a global manufacturer of positive displacements, announced the opening of its new factory in Wisconsin, United States, which will boost the market for positive displacement pumps in the region.

- Moreover, nuclear and renewable energy sources are increasing in the United States. Solar energy is witnessing significant investments; thus, an increase in the solar net electricity generation can be observed. The region relies on renewable energy like hydropower for large-scale power generation, which will drive the studied market in the region.

- The United States is also home to some of the iconic hydropower projects. Grand Coulee Dam, built across the Columbia River in Washington, has been one of the best hydropower projects and generates around two-thirds of the electricity requirement for the state.

- Further, GE Renewable Energy signed an agreement with the US government for two hydropower contracts. One is for the Northfield Mountain pumped hydro storage station and the other for PG&E's Caribou One hydropower station.

North America Positive Displacement Pumps Industry Overview

The North America Positive Displacement Pumps Market is moderately fragmented with the presence of several regional and global companies. Some of the key players are Ampco Pumps Company Inc., Flowserve Corporation, ITT Inc., etc. Key players in this market are introducing new innovative products and forming partnerships and collaborations to gain competitive advantages.

- March 2022 - Atlas Copco agreed to acquire LEWA GmbH and subsidiaries and Geveke BV and subsidiaries. LEWA is a significant manufacturer of diaphragm metering, process, and positive displacement pumps.

- May 2021 - CDI Energy Products announced the development and launch of its newest proprietary thermoplastic polymer composite material aimed at applications in centrifugal and positive displacement pumps.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumption and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Consumers

- 4.2.3 Threat of New Entrants

- 4.2.4 Threat of Substitutes

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Industry Value Chain Analysis

- 4.4 Impact Analysis of COVID-19 on the Industry

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Increasing Popularity of MEMS Technology

- 5.1.2 Increasing demand of water treatment facilities in the region

- 5.2 Market Challenges

- 5.2.1 High Cost and Compatibility Issues

6 MARKET SEGMENTATION

- 6.1 Type of Positive Displacement Pump

- 6.1.1 Diaphragm

- 6.1.2 Piston

- 6.1.3 Gear

- 6.1.4 Lobe

- 6.1.5 Progressive Cavity

- 6.1.6 Screw

- 6.1.7 Vane

- 6.1.8 Peristaltic

- 6.2 End-user Industries

- 6.2.1 Oil & Gas

- 6.2.2 Chemicals

- 6.2.3 Food & Beverage

- 6.2.4 Water & Wastewater

- 6.2.5 Pharmaceutical

- 6.2.6 Power

- 6.2.7 Others

- 6.3 Country

- 6.3.1 United States

- 6.3.2 Canada

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Ampco Pumps Company Inc.

- 7.1.2 Flowserve Corporation

- 7.1.3 ITT Inc.

- 7.1.4 Pentair PLC

- 7.1.5 SPX Flow Inc.

- 7.1.6 Xylem Inc.

- 7.1.7 Liquidyne Process Technologies, Inc.

- 7.1.8 Springer Pumps, LLC.

- 7.1.9 Titan Manufacturing, Inc.

- 7.1.10 Dickow Pump Co.

- 7.1.11 Centec LLC

8 INVESTMENT ANALYSIS

9 FUTURE OF THE MARKET

02-2729-4219

+886-2-2729-4219