|

市場調查報告書

商品編碼

1686219

丙烯酸-市場佔有率分析、產業趨勢與統計、成長預測(2025-2030)Acrylic Acid - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

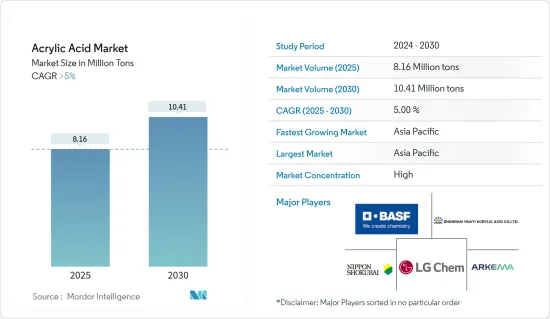

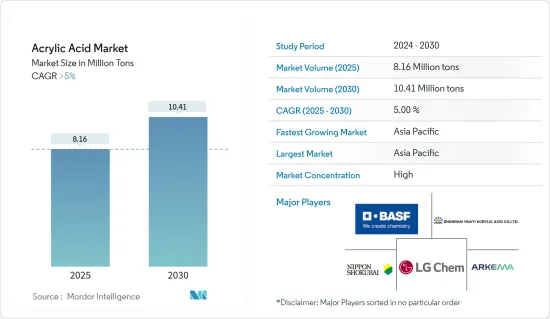

預計2025年丙烯酸市場規模為816萬噸,2030年將達到1,041萬噸,預測期內(2025-2030年)的複合年成長率將超過5%。

COVID-19疫情對市場產生了負面影響。然而,到 2021 年,人們對個人衛生和清潔環境的認知和意識不斷增強,導致對衣物洗護產品的需求增加。丙烯酸用於生產液體清潔劑,刺激了丙烯酸市場的需求。

主要亮點

- 短期內,丙烯酸基高吸水聚合物的應用範圍不斷擴大以及化學合成使用的增加預計將推動市場成長。

- 與丙烯酸相關的健康危害可能會阻礙市場成長。

- 預計在預測期內,對生物基聚合物的需求不斷成長將成為市場的成長機會。

- 亞太地區佔據了最大的市場佔有率,並可能在預測期內繼續主導市場。

丙烯酸市場趨勢

丙烯酸在油漆和被覆劑中的使用增加

- 丙烯酸用於生產丙烯酸酯,丙烯酸酯有多種用途,包括油漆和被覆劑。

- 丙烯酸用於建築塗料、汽車(OEM)和目標商標產品製造商塗飾(包括修補漆)和特殊應用塗料。

- 丙烯酸粉末塗料用作汽車車體的透明塗層。丙烯酸粉末塗料是許多應用的理想解決方案,但它們需要在高溫爐中固化。因此,它用途不廣泛(例如用於塗漆木材或塑膠)。

- 建築塗料用於粉刷建築物和住宅,以保護和裝飾表面。大多數都有特定用途,例如屋頂漆、牆面漆或甲板漆。無論用途如何,每種建築塗料都必須提供一定程度的裝飾性、耐用性和保護性。

- 大多數住宅都喜歡將自己喜歡的顏色用於客廳或臥室的牆壁。壓克力型塗料是首選,因為它們在顏色和色調方面提供了多種選擇。天花板大部分都漆成平面白色,可以反射房間的大部分環境光,讓居住者感到房間寬敞、放鬆。水經常會滲入地下室的乾牆。

- 2022 年 5 月,Grasim Industries(Aditya Birla Group)表示,計劃在 2025 會計年度向其塗料業務投資 1,000 億印度盧比(12.0947 億美元)。 2021 年 1 月,該公司宣布計劃在未來三年內投資 500 億印度盧比(6.0473 億美元)進軍塗料業務。該公司計劃於 2024 會計年度第四季運作一座年產能為 13.32 億公升(MLPA)的塗料廠。

- 印度油漆和塗料行業是印度各個終端用戶行業的重要晴雨表,對技術進步和宏觀經濟擴張做出了重大貢獻。近年來,該行業經歷了顯著成長,反映了更廣泛的行業趨勢。

- 根據《歐洲塗料》報道,印度塗料產業預計到 2023 年將達到近 95 億歐元(102.2 億美元),未來幾年將成長 14%。預計這將增加該國對特殊效果顏料的需求。

- 印度塗料產業預計將投資 3,500 億印度盧比(41.9 億美元)至 4,500 億印度盧比(52.9 億美元)。印度油漆和塗料行業的各種投資如下:

- 根據美國塗料協會預測,2023年美國建築塗料將佔整個市場的49%,其中OEM塗料佔30%,特殊用途塗料佔21%。 2023年,美國油漆和塗料產業產量估計約為13.1億加侖,預計2024年收益將超過13.4億加侖。

- 德國是歐洲主要的油漆和被覆劑生產國之一,擁有約300家油漆和印刷油墨製造商,其中許多是中小型企業。由於BASF、陶氏、貝克斯集團、Brillux、Altana Chemie、Meffert 和 Mankiewicz 等知名塗料製造商的總部均設在德國,預計該國的市場需求將會成長。

- 2023 年 6 月,奧地利油漆公司 Adler 開始在德國黑爾福德建造新的服務設施,耗資約 1,000 萬歐元(1,086 萬美元)。正式開幕和落成典禮計劃於 2025 年初舉行,預計施工將持續到 2024 年夏末。

- 總體而言,預計該地區對丙烯酸的需求將出現初步復甦,並呈現中高速成長。

亞太地區可望主導市場

- 由於中國、印度和日本等國家的需求旺盛,亞太地區佔據市場主導地位。

- 中國是亞太地區最大的丙烯酸消費國,預計預測期內其需求將會成長。在中國,建築和基礎設施領域的投資不斷增加也推動了對黏合劑、油漆和被覆劑的需求大幅成長。

- 中國是世界最大的個人衛生用品消費國之一。該國對個人衛生產品的需求受到大量嬰兒人口和不斷成長的可支配收入的推動,這推動了個人和衛生護理支出的增加。因此,預計丙烯酸市場在預測期內將會成長。

- 中國以其工業化和製造業而聞名,對油漆和被覆劑的需求十分廣泛。該國使用油漆和被覆劑的主要領域包括汽車、工業和建築。中國佔全球塗料市場的四分之一以上。根據中國塗料工業協會統計,近年來該產業實現了7%的成長率,推動了塗料用丙烯酸市場的發展。

- 中國有近1萬家塗料生產企業。全球大多數主要塗料製造商都在中國設有製造地,包括立邦塗料、阿克蘇諾貝爾、中國船舶塗料、PPG工業、BASF和艾仕得塗料。塗料公司在中國的投資日益增加。這可能會促進用於生產汽車油漆和被覆劑的丙烯酸市場的發展。

- 中國政府已啟動一項大規模建設計畫,其中包括在未來十年內將2.5億人遷移到新的特大城市。因此,丙烯酸可用於建築施工過程中各種用途的油漆和被覆劑中,改善建築物的性能。

- 預計到 2025 年,印度建築業規模將達到 1.4 兆美元。到 2030 年,預計將有 6 億人居住在城市中心,因此需要額外建造 2,500 萬套中高階住宅。根據國家投資計畫(NIP),印度已預算1.4兆美元用於基礎設施投資,其中24%用於可再生能源、道路、高速公路和城市基礎設施,12%用於鐵路。

- 因此,預測期內亞太地區很可能主導丙烯酸市場。

丙烯酸產業概況

丙烯酸市場本質上呈現整合態勢。市場的主要企業包括BASFSE、阿科瑪、日本觸媒、LG 化學和上海華誼丙烯酸。

其他福利

- Excel 格式的市場預測 (ME) 表

- 3個月的分析師支持

目錄

第1章 引言

- 調查前提條件

- 研究範圍

第2章調查方法

第3章執行摘要

第4章 市場動態

- 驅動程式

- 擴大高吸水性聚合物的應用

- 在化學合成上的應用日益廣泛

- 限制因素

- 丙烯酸的健康危害

- 價值鏈分析

- 波特五力分析

- 供應商的議價能力

- 買家的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭程度

第5章市場區隔

- 透過導數

- 丙烯酸甲酯

- 丙烯酸丁酯

- 丙烯酸乙酯

- 丙烯酸-2-乙基己酯

- 冰丙烯酸

- 高吸水性聚合物

- 按應用

- 油漆和被覆劑

- 黏合劑和密封劑

- 界面活性劑

- 衛生用品

- 紡織產品

- 其他用途

- 按地區

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 馬來西亞

- 泰國

- 印尼

- 越南

- 其他亞太地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 西班牙

- 北歐國家

- 土耳其

- 俄羅斯

- 其他歐洲國家

- 南美洲

- 巴西

- 阿根廷

- 哥倫比亞

- 南美洲其他地區

- 中東和非洲

- 沙烏地阿拉伯

- 卡達

- 阿拉伯聯合大公國

- 奈及利亞

- 埃及

- 南非

- 其他中東和非洲地區

- 亞太地區

第6章競爭格局

- 合併、收購、合資、合作和協議

- 市場佔有率(%)分析

- 主要企業策略

- 公司簡介

- Arkema

- BASF SE

- China Petroleum & Chemical Corporation(SINOPEC)

- Dow

- Formosa Plastics Corporation

- LG Chem

- Merck KGaA

- Mitsubishi Chemical Corporation

- NIPPON SHOKUBAI CO. LTD

- Sasol

- Shanghai Huayi Acrylic Acid Co. Ltd

- Satellite Chemical Co. Ltd

- Wanhua

第7章 市場機會與未來趨勢

- 對生物基聚合物的需求不斷增加

The Acrylic Acid Market size is estimated at 8.16 million tons in 2025, and is expected to reach 10.41 million tons by 2030, at a CAGR of greater than 5% during the forecast period (2025-2030).

The COVID-19 pandemic negatively impacted the market. However, in 2021, the demand for laundry care products increased due to the increased awareness and consciousness regarding personal hygiene and clean surroundings. Acrylic acid is used to produce liquid laundry detergent, stimulating the demand for the acrylic acid market.

Key Highlights

- Over the short term, the rising applications of acrylic acid-based super absorbent polymers and the increasing use of chemical synthesis are expected to drive the growth of the market.

- Health hazards associated with acrylic acid may hinder the growth of the market.

- The rising demand for bio-based polymers is likely to act as a growth opportunity for the market during the forecast period.

- The Asia-Pacific accounted for the largest market share, and it is likely to dominate the market during the forecast period.

Acrylic Acid Market Trends

The Usage of Acrylic Acid in Paints and Coatings is Increasing

- Acrylic acid is used to make acrylate esters, which are used in various applications, including paints and coatings.

- Acrylics are used in architectural coatings, finishes for products for original equipment manufacturers, including automotive (OEM) and refinishes, and special-purpose coatings.

- Acrylic powder coatings have been introduced as clear coats on car bodies. Although it is an ideal solution for many applications, curing is achieved at a high temperature in an oven. It is, therefore, not universally applicable (e.g., painting of wood and plastics).

- Architectural coatings are meant to protect and decorate surface features and are used to coat buildings and homes. Most are designated for specific uses, such as roof coatings, wall paints, or deck finishes. Each architectural coating must provide certain decorative, durable, and protective functions despite their use.

- Most homeowners prefer the color of their choice for the living room and bedroom walls. Acrylic paints are the preferred choice as they offer a wide variety of choices in terms of color and shade. A vast majority of ceilings are painted flat white so that they may reflect the majority of the ambient light in the room to make the resident feel that the room is spacious and relaxed. Basement masonry walls can often weep water.

- In May 2022, Grasim Industries (Aditya Birla Group) planned to invest INR 10,000 crore (USD 1,209.47 million) in its paint business by FY 2025. In January 2021, the company announced plans to enter the paints business with INR 5,000 crore (USD 604.73 million) in the next three years. The company will likely commission a paint plant with a production capacity of 1,332 million liters per annum (MLPA) by Q4 FY 2024.

- The paints and coatings industry in India serves as a crucial barometer of the country's various end-user industries, significantly contributing to both technological advancements and macroeconomic expansion. In recent years, this sector has witnessed substantial growth, reflecting broader industry trends.

- According to European Coatings, the Indian paint industry amounted to nearly EUR 9.5 billion in 2023 (USD 10.22 billion), and it is expected to grow by 14% over the coming years. This is expected to increase the demand for special-effect pigments in the country.

- The Indian paint Industry is projected to invest INR 350,000 million (USD 4.19 billion) to INR 450,000 million (USD 5.29 billion) in capital expenditure. Various investments in the Indian paints and coating industry are as follows:

- According to the American Coatings Association, US architectural coatings accounted for 49% of the total market in 2023, while OEM and particular purpose coatings comprised 30% and 21%, respectively. In 2023, the production revenue of the paint and coatings industry in the United States was estimated at approximately 1.31 billion gallons, with forecasts predicting that production will exceed 1.34 billion gallons in 2024.

- Germany stands among the leading producers of paints and coatings in Europe, boasting approximately 300 manufacturers of paints and printing ink, many of which are small- and medium-sized enterprises. With prominent paint manufacturers such as BASF SE, Dow, Beckers Group, Brillux, Altana Chemie, Meffert, and Mankiewicz headquartered in Germany, the demand for the market is expected to escalate in the country.

- In June 2023, Adler, an Austrian paint company, commenced construction on its new service facility in Herford, Germany, with an investment of roughly EUR 10 million (USD 10.86 million). The official opening and inauguration are scheduled for early 2025, with construction set to continue until late summer 2024.

- Overall, the demand for acrylic acid is expected to witness moderate to high growth in the region after the initial recovery period.

The Asia-Pacific Region is Expected to Dominate the Market

- The Asia-Pacific dominated the market due to the high demand from countries like China, India, and Japan.

- China is the largest consumer of acrylic acid in the Asia-Pacific region, and its demand is expected to grow during the forecast period. The demand for adhesives, paints, and coatings in China is also increasing significantly due to the growing investments in the construction and infrastructure sectors.

- China is one of the major consumers of personal hygiene products globally. The country's demand for personal hygiene products is attributed to a large infant population and increasing disposable income, leading to increased spending on personal and hygiene care. Thus, the market for acrylic acid is expected to grow during the forecast period.

- China is known for its industrialization and manufacturing sector, where paints and coatings are widely required. Some of the major sectors where paints and coatings are used in the country are the automotive, industrial, and construction sectors, among others. China accounted for more than one-fourth of the global coatings market. According to the China National Coatings Industry Association, the industry has been registering a growth of 7% in recent years, driving the acrylic acid market in coatings application.

- Nearly 10,000 coatings manufacturers are located in China. Most leading global coating manufacturers, such as Nippon Paint, AkzoNobel, Chugoku Marine Paints, PPG Industries, BASF SE, and Axalta Coatings, have manufacturing bases in China. Paints and coatings companies have been increasingly growing investments in the country. This is likely to fuel the market for acrylic acid used to manufacture automotive paints and coatings.

- The Chinese government rolled out massive construction plans, including making provisions for the movement of 250 million people to its new megacities over the next ten years. Thus, this may create a major scope for acrylic acid in paints and coatings used in various applications during building construction, enhancing the building properties.

- India's construction Industry is projected to reach a value of USD 1.4 trillion by 2025. By 2030, an estimated 600 million people will live in urban centers, resulting in a need for 25 million additional mid and ultra-luxury units. Under the National Investment Plan (NIP), India has an infrastructure investment budget of USD 1.4 trillion, with 24% of the budget earmarked for renewable energy, roads and highways, urban infrastructure, and 12% for railways.

- Hence, due to these factors, the Asia-Pacific region is likely to dominate the acrylic acid market during the forecast period.

Acrylic Acid Industry Overview

The acrylic acid market is consolidated in nature. Some major players in the market include BASF SE, Arkema, NIPPON SHOKUBAI CO. LTD, LG Chem, and Shanghai Huayi Acrylic Acid Co. Ltd.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Drivers

- 4.1.1 Increasing Applications of Super Absorbent Polymers

- 4.1.2 Increasing Usage in Chemical Synthesis

- 4.2 Restraints

- 4.2.1 Health Hazards of Acrylic Acid

- 4.3 Industry Value Chain Analysis

- 4.4 Porter's Five Forces Analysis

- 4.4.1 Bargaining Power of Suppliers

- 4.4.2 Bargaining Power of Buyers

- 4.4.3 Threat of New Entrants

- 4.4.4 Threat of Substitute Products and Services

- 4.4.5 Degree of Competition

5 MARKET SEGMENTATION (Market Size in Volume)

- 5.1 By Derivative

- 5.1.1 Methyl Acrylate

- 5.1.2 Butyl Acrylate

- 5.1.3 Ethyl Acrylate

- 5.1.4 2-Ethylhexyl Acrylate

- 5.1.5 Glacial Acrylic Acid

- 5.1.6 Superabsorbent Polymer

- 5.2 By Application

- 5.2.1 Paints and Coatings

- 5.2.2 Adhesives and Sealants

- 5.2.3 Surfactants

- 5.2.4 Sanitary Products

- 5.2.5 Textiles

- 5.2.6 Other Applications

- 5.3 By Geography

- 5.3.1 Asia-Pacific

- 5.3.1.1 China

- 5.3.1.2 India

- 5.3.1.3 Japan

- 5.3.1.4 South Korea

- 5.3.1.5 Malaysia

- 5.3.1.6 Thailand

- 5.3.1.7 Indonesia

- 5.3.1.8 Vietnam

- 5.3.1.9 Rest of Asia-Pacific

- 5.3.2 North America

- 5.3.2.1 United States

- 5.3.2.2 Canada

- 5.3.2.3 Mexico

- 5.3.3 Europe

- 5.3.3.1 Germany

- 5.3.3.2 United Kingdom

- 5.3.3.3 France

- 5.3.3.4 Italy

- 5.3.3.5 Spain

- 5.3.3.6 NORDIC Countries

- 5.3.3.7 Turkey

- 5.3.3.8 Russia

- 5.3.3.9 Rest of Europe

- 5.3.4 South America

- 5.3.4.1 Brazil

- 5.3.4.2 Argentina

- 5.3.4.3 Colombia

- 5.3.4.4 Rest of South America

- 5.3.5 Middle East and Africa

- 5.3.5.1 Saudi Arabia

- 5.3.5.2 Qatar

- 5.3.5.3 United Arab Emirates

- 5.3.5.4 Nigeria

- 5.3.5.5 Egypt

- 5.3.5.6 South Africa

- 5.3.5.7 Rest of the Middle East and Africa

- 5.3.1 Asia-Pacific

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers, Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Market Share (%) Analysis

- 6.3 Strategies Adopted by Leading Players

- 6.4 Company Profiles

- 6.4.1 Arkema

- 6.4.2 BASF SE

- 6.4.3 China Petroleum & Chemical Corporation (SINOPEC)

- 6.4.4 Dow

- 6.4.5 Formosa Plastics Corporation

- 6.4.6 LG Chem

- 6.4.7 Merck KGaA

- 6.4.8 Mitsubishi Chemical Corporation

- 6.4.9 NIPPON SHOKUBAI CO. LTD

- 6.4.10 Sasol

- 6.4.11 Shanghai Huayi Acrylic Acid Co. Ltd

- 6.4.12 Satellite Chemical Co. Ltd

- 6.4.13 Wanhua

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 Increasing Demand for Bio-based Polymers