|

市場調查報告書

商品編碼

1641766

全球模具複合材料市場(按樹脂類型、材料類型和最終用途行業分類)- 機會分析和行業預測,2024-2033 年Composites Materials in Tooling Market By Resin Type , By Material Type By End-Use Industry : Global Opportunity Analysis and Industry Forecast, 2024-2033 |

||||||

工具複合材料市場

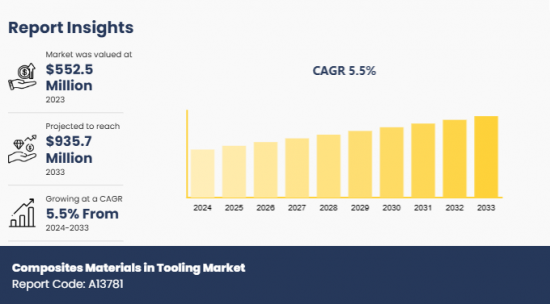

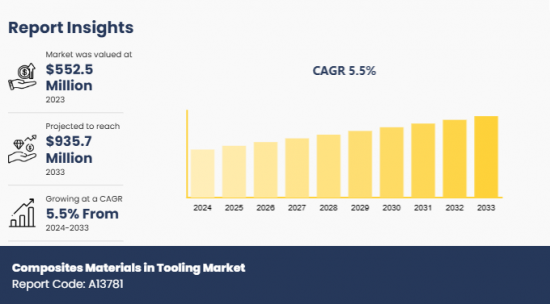

預計 2023 年工具複合材料市場價值將達到 5.525 億美元,到 2033 年將達到 9.357 億美元,2024 年至 2033 年的複合年成長率為 5.5%。

複合材料是由兩種或多種具有不同性質的部件組合而成的具有優異性能的元素。複合材料具有獨特的性能,例如高強度重量比、尺寸穩定性、耐腐蝕和耐熱性以及製造靈活性,可用於提高工具應用的性能並降低成本。工具中常用的複合材料包括玻璃纖維增強聚合物、金屬複合材料、碳纖維增強聚合物和陶瓷基質複合材料。

汽車和航太工業對輕量材料的需求不斷增加,這是工具複合材料市場發展的主要驅動力。此外,複合材料因其耐用性和耐磨性而提供的長期成本效益也刺激了其需求並推動了市場成長。市場上最近出現的趨勢是使用積層製造來銷售複合材料。這種製造技術可以很好地控制聚合物的成分和形態,有助於開發用於工具應用的複雜設計。

然而,複合材料在高衝擊應力或突然加載等極端條件下無法發揮良好的性能,限制了其使用並阻礙了市場發展。此外,缺乏處理複雜工具的高效勞動力嚴重限制了市場的成長。相反,由於許多製造業企業都努力將永續性納入其工作流程,因此工具複合材料市場預計將見證豐厚的利潤機會。據環保署稱,工業活動每年佔全球碳排放的 24%。複合材料透過提高耐熱性和促進機器的有效冷卻來延長工具壽命和提高能源效率。這會減少浪費和排放,預示著工具複合材料市場前景光明。

部分回顧

工具複合材料市場根據樹脂類型、材料類型、最終用途行業和地區進行細分。根據樹脂類型,市場分為環氧樹脂、聚氨酯和其他樹脂。依材料類型,分為金屬合金、鋼、矽膠、橡膠、玻璃纖維等。根據最終用途行業,市場分為航太、汽車、可再生能源和其他。根據地區,分析範圍涵蓋北美、歐洲、亞太地區、拉丁美洲以及中東和非洲。

主要發現

按樹脂類型分類,環氧樹脂在 2023 年佔據最高的市場佔有率。

按材料類型分類,玻璃纖維在 2023 年的市場上佔據顯著地位。

根據最終用途產業,航太業將在 2023 年佔據市場主導地位。

按地區分類,預計北美將在 2023 年創造最高收益。

此報告可進行客製化(可能需要支付額外費用和製定時間表)

- 產品所含原料分析(%)

- 生產能力

- 投資機會

- 產品基準/產品規格及應用

- 產品生命週期

- 供應鏈分析與供應商利潤

- 新參與企業(按地區)

- 科技趨勢分析

- 經銷商利潤分析

- 打入市場策略

- 新產品開發/主要製造商產品矩陣

- 痛點分析

- 監管指南

- 根據客戶興趣客製的其他公司簡介

- 按國家或地區進行的額外分析 - 市場規模和預測

- 品牌佔有率分析

- 擴展公司簡介列表

- 歷史市場資料

- 導入/匯出分析/資料

- Excel 格式的主要企業詳細資料(包括位置、聯絡資訊、供應商/供應商網路等)

- 客戶/消費者/原料供應商名單-價值鏈分析

- 全球/地區/國家層面的公司市場佔有率分析

- 產品消費分析

- SWOT 分析

目錄

第 1 章 簡介

第 2 章執行摘要

第3章 市場狀況

- 市場定義和範圍

- 主要發現

- 重大投資機會

- 關鍵成功策略

- 波特五力分析

- 市場動態

- 驅動程式

- 限制因素

- 機會

第4章 模具複合材料市場(依樹脂類型)

- 市場概況

- 環氧樹脂

- 聚氨酯

- 其他

第 5 章 模具複合材料市場(依材料類型)

- 市場概況

- 金屬合金

- 鋼

- 矽

- 橡皮

- 玻璃纖維

- 其他

第6章 工具複合材料市場(依最終用途產業)

- 市場概況

- 航太

- 車

- 可再生能源

- 其他

第 7 章 模具複合材料市場(按地區)

- 市場概況

- 北美洲

- 主要市場趨勢和機遇

- 美國工具複合材料市場

- 加拿大工具複合材料市場

- 墨西哥的工具複合材料市場

- 歐洲

- 主要市場趨勢和機遇

- 法國工具複合材料市場

- 德國工具複合材料市場

- 義大利工具複合材料市場

- 西班牙工具複合材料市場

- 英國工具複合材料市場

- 其他歐洲國家工具複合材料市場

- 亞太地區

- 主要市場趨勢和機遇

- 中國工具用複合材料市場

- 日本工具複合材料市場

- 印度模具複合材料市場

- 韓國工具複合材料市場

- 澳洲工具複合材料市場

- 其他亞太地區工具複合材料市場

- 拉丁美洲、中東和非洲

- 主要市場趨勢和機遇

- 巴西工具複合材料市場

- 南非複合工具材料市場

- 沙烏地阿拉伯的工具複合材料市場

- 拉丁美洲其他地區、中東和非洲的複合材料工具市場

第8章 競爭格局

- 介紹

- 關鍵成功策略

- 前 10 家公司的產品映射

- 競爭儀錶板

- 競爭熱圖

- 2023年主要企業的定位

第9章 公司簡介

- Hexcel Corporation

- Toray Industries, Inc

- Solvay SA

- Huntsman Corporation

- Mitsubishi Chemical Holdings Corporation

- Owens Corning

- Teijin Limited

- Barrday Inc.

- SABIC

- Jushi Co., Ltd

Composites Materials in Tooling Market

The composites materials in tooling market was valued at $552.5 million in 2023 and is projected to reach $935.7 million by 2033, growing at a CAGR of 5.5% from 2024 to 2033.

Composite materials are elements with exceptional properties formed by the combination of two or more components with distinguished characteristics. Composites are used to improve the performance and reduce the costs of tooling applications via their unique attributes such as high strength-to-weight ratio, dimensional stability, corrosion & thermal resistance, and manufacturing flexibility. The common types of composite materials used in tooling include glass fiber-reinforced polymer, metal matrix composites, carbon fiber-reinforced polymer, and ceramic matrix composites.

Increase in requirement for lightweight materials in the automotive and aerospace industries is a significant driver of the composites materials in tooling market as the materials offer remarkable strength with their lightweight property. In addition, the long-term cost-effectiveness offered by composite materials due to their durability and resistance to wear & tear fuels their demand, which propels the market growth. A significant trend gaining prominence in the market in recent times is the utilization of additive manufacturing for the development of composites. This manufacturing technique offers exceptional control over the composition and geometry of polymers, facilitating the development of intricate designs for tooling applications.

However, the inability of composite materials to perform in extreme situations such as high-impact stresses or sharp loading conditions limits their usage and hampers the development of the market. Moreover, lack of efficient workforce to handle the composite tooling restrains the market growth notably. On the contrary, as several manufacturing industries are striving to adopt sustainability in their workflow, the composites materials in tooling market is anticipated to witness lucrative opportunities. According to the Environmental Protection Agency, industrial activities contribute 24% of global carbon emissions annually. Composites materials increase the lifespan & energy efficiency of tooling by enhancing the heat resistance and facilitating efficient cooling of machinery. This results in reduced wastage and low emissions, indicating a promising future for the composites materials in tooling market.

Segment Review

The composites materials in tooling market is segmented into resin type, material type, end-use industry, and region. On the basis of resin type, the market is divided into epoxy, polyurethane, and others. According to material type, it is classified into metal alloys, steel, silicon, rubber, fiberglass, and others. By end-use industry, it is categorized into aerospace, automotive, renewable energy, and others. Region wise, it is analyzed across North America, Europe, Asia-Pacific, and LAMEA.

Key Findings

On the basis of resin type, the epoxy segment held the highest market share in 2023.

According to material type, the fiberglass segment acquired a notable stake in the market in 2023.

By end-use industry, the aerospace segment dominated the market in 2023.

Region wise, North America was the highest revenue generator in 2023.

Competition Analysis

The major players in the global composites materials in tooling market include Hexcel Corporation, Toray Industries, Inc., Solvay S.A., Huntsman Corporation, Mitsubishi Chemical Holdings Corporation, Owens Corning, Teijin Limited, Barrday Inc., SABIC, and Jushi Co., Ltd. These major players have adopted various key development strategies such as business expansion, new product launches, and partnerships to strengthen their foothold in the competitive market.

Additional benefits you will get with this purchase are:

- Quarterly Update and* (only available with a corporate license, on listed price)

- 5 additional Company Profile of client Choice pre- or Post-purchase, as a free update.

- Free Upcoming Version on the Purchase of Five and Enterprise User License.

- 16 analyst hours of support* (post-purchase, if you find additional data requirements upon review of the report, you may receive support amounting to 16 analyst hours to solve questions, and post-sale queries)

- 15% Free Customization* (in case the scope or segment of the report does not match your requirements, 15% is equivalent to 3 working days of free work, applicable once)

- Free data Pack on the Five and Enterprise User License. (Excel version of the report)

- Free Updated report if the report is 6-12 months old or older.

- 24-hour priority response*

- Free Industry updates and white papers.

Possible Customization with this report (with additional cost and timeline, please talk to the sales executive to know more)

- Analysis of raw material in a product (by %)

- Manufacturing Capacity

- Investment Opportunities

- Product Benchmarking / Product specification and applications

- Product Life Cycles

- Supply Chain Analysis & Vendor Margins

- Upcoming/New Entrant by Regions

- Technology Trend Analysis

- Distributor margin Analysis

- Go To Market Strategy

- New Product Development/ Product Matrix of Key Players

- Pain Point Analysis

- Regulatory Guidelines

- Additional company profiles with specific to client's interest

- Additional country or region analysis- market size and forecast

- Brands Share Analysis

- Expanded list for Company Profiles

- Historic market data

- Import Export Analysis/Data

- Key player details (including location, contact details, supplier/vendor network etc. in excel format)

- List of customers/consumers/raw material suppliers- value chain analysis

- Market share analysis of players at global/region/country level

- Product Consumption Analysis

- SWOT Analysis

Key Market Segments

By Resin Type

- Epoxy

- Polyurethane

- Others

By Material Type

- Metal Alloys

- Steel

- Silicon

- Rubber

- Fiberglass

- Others

By End-Use Industry

- Aerospace

- Automotive

- Renewable Energy

- Others

By Region

- North America

- U.S.

- Canada

- Mexico

- Europe

- France

- Germany

- Italy

- Spain

- UK

- Rest of Europe

- Asia-Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia-Pacific

- LAMEA

- Brazil

- South Africa

- Saudi Arabia

- Rest of LAMEA

Key Market Players:

- Hexcel Corporation

- Toray Industries, Inc

- Solvay S.A.

- Huntsman Corporation

- Mitsubishi Chemical Holdings Corporation

- Owens Corning

- Teijin Limited

- Barrday Inc.

- SABIC

- Jushi Co., Ltd

TABLE OF CONTENTS

CHAPTER 1: INTRODUCTION

- 1.1. Report Description

- 1.2. Key Market Segments

- 1.3. Key Benefits

- 1.4. Research Methodology

- 1.4.1. Primary Research

- 1.4.2. Secondary Research

- 1.4.3. Analyst Tools and Models

CHAPTER 2: EXECUTIVE SUMMARY

- 2.1. CXO Perspective

CHAPTER 3: MARKET LANDSCAPE

- 3.1. Market Definition and Scope

- 3.2. Key Findings

- 3.2.1. Top Investment Pockets

- 3.2.2. Top Winning Strategies

- 3.3. Porter's Five Forces Analysis

- 3.3.1. Bargaining Power of Suppliers

- 3.3.2. Threat of New Entrants

- 3.3.3. Threat of Substitutes

- 3.3.4. Competitive Rivalry

- 3.3.5. Bargaining Power among Buyers

- 3.4. Market Dynamics

- 3.4.1. Drivers

- 3.4.2. Restraints

- 3.4.3. Opportunities

CHAPTER 4: COMPOSITES MATERIALS IN TOOLING MARKET, BY RESIN TYPE

- 4.1. Market Overview

- 4.1.1 Market Size and Forecast, By Resin Type

- 4.2. Epoxy

- 4.2.1. Key Market Trends, Growth Factors and Opportunities

- 4.2.2. Market Size and Forecast, By Region

- 4.2.3. Market Share Analysis, By Country

- 4.3. Polyurethane

- 4.3.1. Key Market Trends, Growth Factors and Opportunities

- 4.3.2. Market Size and Forecast, By Region

- 4.3.3. Market Share Analysis, By Country

- 4.4. Others

- 4.4.1. Key Market Trends, Growth Factors and Opportunities

- 4.4.2. Market Size and Forecast, By Region

- 4.4.3. Market Share Analysis, By Country

CHAPTER 5: COMPOSITES MATERIALS IN TOOLING MARKET, BY MATERIAL TYPE

- 5.1. Market Overview

- 5.1.1 Market Size and Forecast, By Material Type

- 5.2. Metal Alloys

- 5.2.1. Key Market Trends, Growth Factors and Opportunities

- 5.2.2. Market Size and Forecast, By Region

- 5.2.3. Market Share Analysis, By Country

- 5.3. Steel

- 5.3.1. Key Market Trends, Growth Factors and Opportunities

- 5.3.2. Market Size and Forecast, By Region

- 5.3.3. Market Share Analysis, By Country

- 5.4. Silicon

- 5.4.1. Key Market Trends, Growth Factors and Opportunities

- 5.4.2. Market Size and Forecast, By Region

- 5.4.3. Market Share Analysis, By Country

- 5.5. Rubber

- 5.5.1. Key Market Trends, Growth Factors and Opportunities

- 5.5.2. Market Size and Forecast, By Region

- 5.5.3. Market Share Analysis, By Country

- 5.6. Fiberglass

- 5.6.1. Key Market Trends, Growth Factors and Opportunities

- 5.6.2. Market Size and Forecast, By Region

- 5.6.3. Market Share Analysis, By Country

- 5.7. Others

- 5.7.1. Key Market Trends, Growth Factors and Opportunities

- 5.7.2. Market Size and Forecast, By Region

- 5.7.3. Market Share Analysis, By Country

CHAPTER 6: COMPOSITES MATERIALS IN TOOLING MARKET, BY END-USE INDUSTRY

- 6.1. Market Overview

- 6.1.1 Market Size and Forecast, By End-use Industry

- 6.2. Aerospace

- 6.2.1. Key Market Trends, Growth Factors and Opportunities

- 6.2.2. Market Size and Forecast, By Region

- 6.2.3. Market Share Analysis, By Country

- 6.3. Automotive

- 6.3.1. Key Market Trends, Growth Factors and Opportunities

- 6.3.2. Market Size and Forecast, By Region

- 6.3.3. Market Share Analysis, By Country

- 6.4. Renewable Energy

- 6.4.1. Key Market Trends, Growth Factors and Opportunities

- 6.4.2. Market Size and Forecast, By Region

- 6.4.3. Market Share Analysis, By Country

- 6.5. Others

- 6.5.1. Key Market Trends, Growth Factors and Opportunities

- 6.5.2. Market Size and Forecast, By Region

- 6.5.3. Market Share Analysis, By Country

CHAPTER 7: COMPOSITES MATERIALS IN TOOLING MARKET, BY REGION

- 7.1. Market Overview

- 7.1.1 Market Size and Forecast, By Region

- 7.2. North America

- 7.2.1. Key Market Trends and Opportunities

- 7.2.2. Market Size and Forecast, By Resin Type

- 7.2.3. Market Size and Forecast, By Material Type

- 7.2.4. Market Size and Forecast, By End-use Industry

- 7.2.5. Market Size and Forecast, By Country

- 7.2.6. U.S. Composites Materials in Tooling Market

- 7.2.6.1. Market Size and Forecast, By Resin Type

- 7.2.6.2. Market Size and Forecast, By Material Type

- 7.2.6.3. Market Size and Forecast, By End-use Industry

- 7.2.7. Canada Composites Materials in Tooling Market

- 7.2.7.1. Market Size and Forecast, By Resin Type

- 7.2.7.2. Market Size and Forecast, By Material Type

- 7.2.7.3. Market Size and Forecast, By End-use Industry

- 7.2.8. Mexico Composites Materials in Tooling Market

- 7.2.8.1. Market Size and Forecast, By Resin Type

- 7.2.8.2. Market Size and Forecast, By Material Type

- 7.2.8.3. Market Size and Forecast, By End-use Industry

- 7.3. Europe

- 7.3.1. Key Market Trends and Opportunities

- 7.3.2. Market Size and Forecast, By Resin Type

- 7.3.3. Market Size and Forecast, By Material Type

- 7.3.4. Market Size and Forecast, By End-use Industry

- 7.3.5. Market Size and Forecast, By Country

- 7.3.6. France Composites Materials in Tooling Market

- 7.3.6.1. Market Size and Forecast, By Resin Type

- 7.3.6.2. Market Size and Forecast, By Material Type

- 7.3.6.3. Market Size and Forecast, By End-use Industry

- 7.3.7. Germany Composites Materials in Tooling Market

- 7.3.7.1. Market Size and Forecast, By Resin Type

- 7.3.7.2. Market Size and Forecast, By Material Type

- 7.3.7.3. Market Size and Forecast, By End-use Industry

- 7.3.8. Italy Composites Materials in Tooling Market

- 7.3.8.1. Market Size and Forecast, By Resin Type

- 7.3.8.2. Market Size and Forecast, By Material Type

- 7.3.8.3. Market Size and Forecast, By End-use Industry

- 7.3.9. Spain Composites Materials in Tooling Market

- 7.3.9.1. Market Size and Forecast, By Resin Type

- 7.3.9.2. Market Size and Forecast, By Material Type

- 7.3.9.3. Market Size and Forecast, By End-use Industry

- 7.3.10. UK Composites Materials in Tooling Market

- 7.3.10.1. Market Size and Forecast, By Resin Type

- 7.3.10.2. Market Size and Forecast, By Material Type

- 7.3.10.3. Market Size and Forecast, By End-use Industry

- 7.3.11. Rest Of Europe Composites Materials in Tooling Market

- 7.3.11.1. Market Size and Forecast, By Resin Type

- 7.3.11.2. Market Size and Forecast, By Material Type

- 7.3.11.3. Market Size and Forecast, By End-use Industry

- 7.4. Asia-Pacific

- 7.4.1. Key Market Trends and Opportunities

- 7.4.2. Market Size and Forecast, By Resin Type

- 7.4.3. Market Size and Forecast, By Material Type

- 7.4.4. Market Size and Forecast, By End-use Industry

- 7.4.5. Market Size and Forecast, By Country

- 7.4.6. China Composites Materials in Tooling Market

- 7.4.6.1. Market Size and Forecast, By Resin Type

- 7.4.6.2. Market Size and Forecast, By Material Type

- 7.4.6.3. Market Size and Forecast, By End-use Industry

- 7.4.7. Japan Composites Materials in Tooling Market

- 7.4.7.1. Market Size and Forecast, By Resin Type

- 7.4.7.2. Market Size and Forecast, By Material Type

- 7.4.7.3. Market Size and Forecast, By End-use Industry

- 7.4.8. India Composites Materials in Tooling Market

- 7.4.8.1. Market Size and Forecast, By Resin Type

- 7.4.8.2. Market Size and Forecast, By Material Type

- 7.4.8.3. Market Size and Forecast, By End-use Industry

- 7.4.9. South Korea Composites Materials in Tooling Market

- 7.4.9.1. Market Size and Forecast, By Resin Type

- 7.4.9.2. Market Size and Forecast, By Material Type

- 7.4.9.3. Market Size and Forecast, By End-use Industry

- 7.4.10. Australia Composites Materials in Tooling Market

- 7.4.10.1. Market Size and Forecast, By Resin Type

- 7.4.10.2. Market Size and Forecast, By Material Type

- 7.4.10.3. Market Size and Forecast, By End-use Industry

- 7.4.11. Rest of Asia-Pacific Composites Materials in Tooling Market

- 7.4.11.1. Market Size and Forecast, By Resin Type

- 7.4.11.2. Market Size and Forecast, By Material Type

- 7.4.11.3. Market Size and Forecast, By End-use Industry

- 7.5. LAMEA

- 7.5.1. Key Market Trends and Opportunities

- 7.5.2. Market Size and Forecast, By Resin Type

- 7.5.3. Market Size and Forecast, By Material Type

- 7.5.4. Market Size and Forecast, By End-use Industry

- 7.5.5. Market Size and Forecast, By Country

- 7.5.6. Brazil Composites Materials in Tooling Market

- 7.5.6.1. Market Size and Forecast, By Resin Type

- 7.5.6.2. Market Size and Forecast, By Material Type

- 7.5.6.3. Market Size and Forecast, By End-use Industry

- 7.5.7. South Africa Composites Materials in Tooling Market

- 7.5.7.1. Market Size and Forecast, By Resin Type

- 7.5.7.2. Market Size and Forecast, By Material Type

- 7.5.7.3. Market Size and Forecast, By End-use Industry

- 7.5.8. Saudi Arabia Composites Materials in Tooling Market

- 7.5.8.1. Market Size and Forecast, By Resin Type

- 7.5.8.2. Market Size and Forecast, By Material Type

- 7.5.8.3. Market Size and Forecast, By End-use Industry

- 7.5.9. Rest of LAMEA Composites Materials in Tooling Market

- 7.5.9.1. Market Size and Forecast, By Resin Type

- 7.5.9.2. Market Size and Forecast, By Material Type

- 7.5.9.3. Market Size and Forecast, By End-use Industry

CHAPTER 8: COMPETITIVE LANDSCAPE

- 8.1. Introduction

- 8.2. Top Winning Strategies

- 8.3. Product Mapping Of Top 10 Player

- 8.4. Competitive Dashboard

- 8.5. Competitive Heatmap

- 8.6. Top Player Positioning, 2023

CHAPTER 9: COMPANY PROFILES

- 9.1. Hexcel Corporation

- 9.1.1. Company Overview

- 9.1.2. Key Executives

- 9.1.3. Company Snapshot

- 9.1.4. Operating Business Segments

- 9.1.5. Product Portfolio

- 9.1.6. Business Performance

- 9.1.7. Key Strategic Moves and Developments

- 9.2. Toray Industries, Inc

- 9.2.1. Company Overview

- 9.2.2. Key Executives

- 9.2.3. Company Snapshot

- 9.2.4. Operating Business Segments

- 9.2.5. Product Portfolio

- 9.2.6. Business Performance

- 9.2.7. Key Strategic Moves and Developments

- 9.3. Solvay S.A.

- 9.3.1. Company Overview

- 9.3.2. Key Executives

- 9.3.3. Company Snapshot

- 9.3.4. Operating Business Segments

- 9.3.5. Product Portfolio

- 9.3.6. Business Performance

- 9.3.7. Key Strategic Moves and Developments

- 9.4. Huntsman Corporation

- 9.4.1. Company Overview

- 9.4.2. Key Executives

- 9.4.3. Company Snapshot

- 9.4.4. Operating Business Segments

- 9.4.5. Product Portfolio

- 9.4.6. Business Performance

- 9.4.7. Key Strategic Moves and Developments

- 9.5. Mitsubishi Chemical Holdings Corporation

- 9.5.1. Company Overview

- 9.5.2. Key Executives

- 9.5.3. Company Snapshot

- 9.5.4. Operating Business Segments

- 9.5.5. Product Portfolio

- 9.5.6. Business Performance

- 9.5.7. Key Strategic Moves and Developments

- 9.6. Owens Corning

- 9.6.1. Company Overview

- 9.6.2. Key Executives

- 9.6.3. Company Snapshot

- 9.6.4. Operating Business Segments

- 9.6.5. Product Portfolio

- 9.6.6. Business Performance

- 9.6.7. Key Strategic Moves and Developments

- 9.7. Teijin Limited

- 9.7.1. Company Overview

- 9.7.2. Key Executives

- 9.7.3. Company Snapshot

- 9.7.4. Operating Business Segments

- 9.7.5. Product Portfolio

- 9.7.6. Business Performance

- 9.7.7. Key Strategic Moves and Developments

- 9.8. Barrday Inc.

- 9.8.1. Company Overview

- 9.8.2. Key Executives

- 9.8.3. Company Snapshot

- 9.8.4. Operating Business Segments

- 9.8.5. Product Portfolio

- 9.8.6. Business Performance

- 9.8.7. Key Strategic Moves and Developments

- 9.9. SABIC

- 9.9.1. Company Overview

- 9.9.2. Key Executives

- 9.9.3. Company Snapshot

- 9.9.4. Operating Business Segments

- 9.9.5. Product Portfolio

- 9.9.6. Business Performance

- 9.9.7. Key Strategic Moves and Developments

- 9.10. Jushi Co., Ltd

- 9.10.1. Company Overview

- 9.10.2. Key Executives

- 9.10.3. Company Snapshot

- 9.10.4. Operating Business Segments

- 9.10.5. Product Portfolio

- 9.10.6. Business Performance

- 9.10.7. Key Strategic Moves and Developments