|

市場調查報告書

商品編碼

1628815

拉丁美洲的 AMH 和儲存系統:市場佔有率分析、行業趨勢和成長預測(2025-2030 年)LA AMH and Storage Systems - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

價格

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

簡介目錄

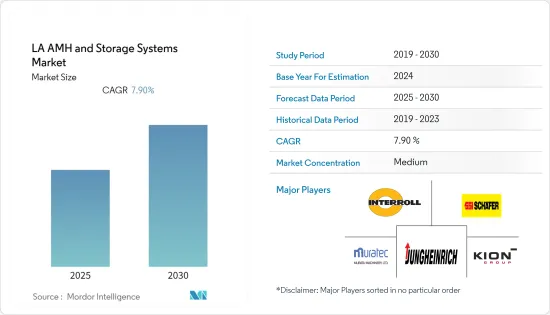

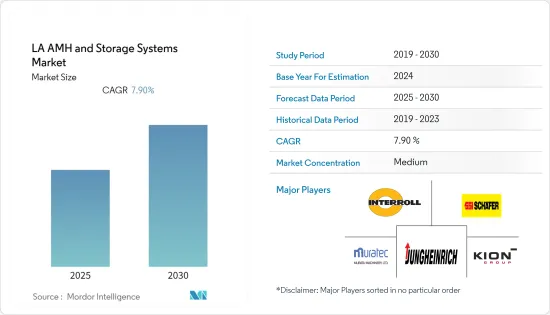

拉丁美洲 AMH 和儲存系統市場預計在預測期內複合年成長率為 7.9%

主要亮點

- 庫存單位 (SKU) 的快速成長使得批發商和經銷商難以就業務做出明智的決策。這一因素推動了對勞動力、設備和技術的更智慧使用的需求。推動自動化物料輸送系統需求的主要因素是降低成本、勞動效率和空間限制。

- 目前的市場狀況正在增加可用產品的數量,並增加對更頻繁和更小規模交付的需求。此外,自動導引車 (AGV) 和倉庫管理系統 (WMS) 等先進技術在食品和飲料倉儲和生產業務中不斷普及,為製造商帶來了多種好處。

- 受支援設施內自動化系統之間協作的工業 4.0 的啟發,拉丁美洲的倉庫經理現在正在尋求在公司範圍內實施自動化。透過在公司範圍內的部署,倉庫員工每天都可以使用 AGV,並透過與自動儲存和搜尋系統 (AS/RS) 以及倉庫管理系統通訊,促進與其他技術系統的整合。

- 拉丁美洲地區成長的主要驅動力是都市化進程的加速、電子商務銷售的增加以及技術提供者的強大存在。這些公司投資研發活動,提供創新解決方案,以便在競爭激烈的市場環境中生存。

拉丁美洲 AMH 和儲存系統市場趨勢

自動駕駛汽車預計將獲得顯著的市場佔有率

- 拖車/曳引機/拖車式 AGV 是物流業務的關鍵要素。它可以用於精細客製化的多種任務,例如倉庫半自動收集、原料運輸到生產線、最終產品運輸(裝卸)。然而,根據墨西哥汽車客車生產協會的數據,包括曳引機在內的大型車輛產量大幅下降至 65,080 輛。

- 此外,投資正在推動拉丁美洲地區的市場成長。例如,2020年10月,亞馬遜宣布投資1億美元在墨西哥開設新的物流倉庫,其中包括其在人口稠密的大都會區之外的第一個配送中心,以提供更快的送貨服務。新地點包括兩個履約中心,一個靠近北部城市蒙特雷,另一個靠近中部城市瓜達拉哈拉。此外,該公司正在向巴西擴張,最近在該國開設了第五個也是最大的履約中心,面積達 100,000平方公尺。所有這些投資預計將推動 AGV 在倉庫中的使用。

- 與大型製造商相比,需要處理較小負載的中型工業和實驗室的自動化蓬勃發展是推動單元貨載型 AGV 需求的主要因素。

- 此外,該地區不斷增加的研發支出和不斷增加的生產設施正在推動全球中端市場產業對自動化的需求,特別是在醫療保健和製藥業。

- 此外,該地區的消費者要求更快的交貨時間,增加了 AGV 在倉庫和配送中心的應用。此外,技術進步使 AGV 變得更好、更小,成本降低以及某些地區的勞動力短缺正在推動所研究市場的成長。

巴西市場預計將顯著成長

- 隨著工業自動化任務的要求越來越高,COVID-19 的爆發增加了巴西對自主物料輸送的需求。同時,企業面臨勞動力短缺和實施新的社交距離要求的挑戰,這促使市場公司投資於產品創新。

- 該國正在進行各種擴張。例如,2020 年 1 月, 物料輸送 Clark Brasil 將總部遷至坎皮納斯技術中心。這項策略性舉措旨在建立巴西市場未來成長的能力,並在巴西建立生產設施。坎皮納斯位於聖保羅以北約100公里處,是重要的工商業中心,經濟活動廣泛。預計也將滿足該國對克拉克型物料輸送車輛不斷成長的需求。

- 此外,由於初始成本較高,受訪市場中的供應商提供了更靈活的輪播,以滿足客戶的特定要求。此類產品創新預計將推動 Carousel 在該地區的採用。

- 支持 Carousel 的供應商正在推動需求。例如,SSI Schaefer 提供的傳送帶每小時可執行 1,000 次揀選,儲存密度提高了 50%。 SSI 轉盤是處理小型零件和中低速產品的合適解決方案。這包括藥品、化妝品、電子元件、媒體、食品、標準尺寸小零件等。

- 促進托盤搬運的自動化物料輸送設備和車輛的推出預計也將對該地區各個倉庫的托盤適應性產生正面影響。然而,根據巴西汽車製造商協會的數據,2020年巴西生產了約95,000輛卡車,比2019年減少了19%,這可能會在相當長的時間內抑制市場。

拉丁美洲 AMH 和儲存系統產業概況

拉丁美洲 AMH 和儲存系統市場競爭中等,存在大量區域和全球公司。市佔率較大的主要廠商都在注重技術創新、併購、夥伴關係、擴大海外基本客群。公司正在利用策略合作措施來提高盈利。

- 2021 年 7 月 - S&H Systems 透過創新的 Interroll 交叉帶分類機和輸送機產品擴展了其自動化產品線,為倉庫業務提供多功能性。與 Interroll 的夥伴關係使 S&H 能夠為客戶提供更靈活和模組化的產品,使他們能夠在客戶主導的環境中提供選擇。

- 2020年8月,村田機械株式會社與Alpen簽約,打造首座3D機器人倉庫系統Alphabot。此外,阿爾彭集團主要的物流中心阿爾彭小牧物流中心將引進alphabot,以補充儲存能力,並將揀選、分類和包裝工作減少約60%。

其他好處

- Excel 格式的市場預測 (ME) 表

- 3 個月分析師支持

目錄

第1章簡介

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章市場洞察

- 市場概況

- 產業吸引力-波特五力分析

- 供應商的議價能力

- 消費者議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭公司之間敵對關係的強度

- COVID-19 對工業生態系的影響

第5章市場動態

- 市場促進因素

- 技術進步不斷推動市場成長

- 電子商務的快速成長導致倉庫自動化

- 工業 4.0 投資推動對 AMH 和儲存系統的需求

- 市場挑戰

- 缺乏技術純熟勞工

- 高資本要求

第6章 市場細分

- 依產品類型

- 軟體

- 硬體

- 服務

- 一體化

- 依設備類型

- 移動機器人

- 自動導引運輸車(AGV)

- 自動堆高機

- 自動拖車/曳引機/標籤

- 單元貨載

- 組裝

- 自主移動機器人(AMR)

- 自動化倉庫系統(ASRS)

- 固定飛彈

- 旋轉木馬

- 垂直升降模組

- 自動輸送機

- 腰帶

- 滾筒

- 調色盤

- 開賣

- 堆垛機

- 傳統的

- 機器人

- 分類系統

- 移動機器人

- 按最終用戶

- 飛機場

- 車

- 飲食

- 零售/倉庫/配送中心/物流中心

- 一般製造業

- 藥品

- 小包裹

- 電子/半導體製造

- 其他最終用戶

- 按國家/地區

- 巴西

- 阿根廷

- 墨西哥

- 哥倫比亞

- 秘魯

- 智利

第7章 競爭格局

- 公司簡介

- JBT Corporation

- KION Group AG

- SSI SCHEFER AG

- Daifuku Co. Limited

- Kardex Group

- Beumer Group GMBH & Co. KG

- Jungheinrich AG

- Murata Machinery Limited

- Interroll Group

- System Logistics

第8章投資分析

第9章市場的未來

簡介目錄

Product Code: 54941

The LA AMH and Storage Systems Market is expected to register a CAGR of 7.9% during the forecast period.

Key Highlights

- With the rapid growth in stock-keeping units (SKUs), wholesalers and distributors are finding it difficult to make informed decisions about the operations. This factor is driving the need for smarter usage of labor, equipment, and technology. The major factors driving the need for automated material-handling systems are cost savings, labor efficiency, and space constraints.

- In the current market landscape, there is an increase in the number of available products and demand for more frequent and smaller deliveries. Also, advanced technologies, like automatic guided vehicles (AGVs) and warehouse management systems (WMS), continued to increase in the food and beverage warehouses and production operations, providing several benefits to the manufacturers.

- Inspired by Industry 4.0, which supports collaboration between automated systems within facilities, warehouse managers in Latin America are now interested in incorporating enterprise-wide automation. The company-wide deployment will increase AGVs' accessibility to warehouse employees daily and encourage integration among other technological systems, as AGVs communicate with automated storage and retrieval systems (AS/RS) and warehouse management systems.

- The primary driving forces for the growth of the Latin America regional segment are the rising urbanization, rising e-commerce sales, and the significant presence of technology providers. These players are investing in research and development activities to offer innovative solutions to stay in the competitive market landscape.

Latin America AMH & Storage Systems Market Trends

Automated Guided Vehicle Expected to Witness Significant Market Share

- The tow/tractor/tug type of AGV is a key element in intralogistics operations. It can be used for multiple tasks with minor customizations, such as a semi-automatic pickup in warehouses, transporting raw materials to the production line, or dispatching end-products for transportation (loading and unloading). However, According to Asociacion Nacional de Productores de Autobuses, Camiones y Tractocamiones Mexico witnessed a significant decrease by 65.08 thousand production units in heavy production vehicles, including tractors.

- Further, the investments are driving the market growth in the Latin American region. For instance, In October 2020, Amazon announced a USD 100 million logistics investment in opening new warehouses in Mexico, including its first shipping centers outside the populous capital area, to offer faster deliveries. The new sites include two fulfillment centers, one near the northern city of Monterrey and another near the central city of Guadalajara. Additionally, the company is also striving to make inroads in Brazil, where it recently opened its fifth and biggest fulfillment center in the country, with 100,000 square meters. All these investments are expected to drive the utilization of AGV in the warehouse.

- The boom of automation in the medium-sized industries and laboratories that need to handle smaller loads, compared to the large-scale manufacturers, is the primary factor driving the demand for Unit load type of AGVs.

- Further, the continuously increasing R&D expenditure and the rising number of production establishments in the region are driving the demand for automation in the mid-range industries worldwide, especially in the healthcare and pharmaceutical sectors.

- Moreover, the consumers in the region seek shorter delivery times, increasing the application of AGV in warehouses and distribution centers. In, addition advancements in technology have made AGV's better and smaller; lower costs and shortage of labor in some places have fueled the growth of the market studied.

Brazil Expected to Witness Significant Growth in the Market

- Due to the outbreak of COVID-19, the need for autonomous material handling has been becoming more significant in Brazil as more demanding tasks in industrial automation increase. At the same time, companies are facing labor shortages and challenges in implementing new social distancing requirements, thereby driving the market players to invest in product innovation.

- The country is witnessing various expansions. For instance, in January 2020, Material Handling Clark Brazil relocated its corporate headquarters to the Campinas Technology Centre. The strategic step aims to future growth in the Brazilian market and builds capacity for establishing a production facility in Brazil. Campinas, about 100 kilometers north of So Paulo, is a significant industrial and commercial center with various economic activities. Also, the company is expected to meet the country's increasing demand for Clark materials handling vehicles.

- Moreover, due to the high initial cost, vendors in the market studied have been providing more flexible carousels to cater to client-specific requirements. Such innovations in terms of products are expected to boost the adoption of carousels in the region.

- The market vendors catering to carousels are driving demand. For instance, SSI Schaefer offers carousels that can perform 1,000 picks per hour and 50% higher storage density. The SSI Carousel is a suitable solution for handling small parts along with medium to slow-moving products. These include pharmaceutical products, cosmetics, electronics components, media, and food, along with standard-sized and small parts.

- The launch of automated material handling equipment and vehicles, which increases the ease of handling pallets, is also expected to positively impact the adaptability of pallets by various warehouses in the region. However, In 2020, according to Associacao Nacional dos Fabricantes de Veiculos Automotores, approximately 95 thousand trucks were produced in Brazil, a decrease of 19% compared to 2019, which could restrain the market for a considerable period.

Latin America AMH & Storage Systems Industry Overview

The Latin America Automated Material Handling and Storage Systems Market is moderately competitive, with a considerable number of regional and global players. The major vendors with a prominent share in the market are focusing on innovations, mergers and acquisitions, partnerships, and expanding customer base across foreign countries. The companies are leveraging on strategic collaborative initiatives to increase their profitability.

- July 2021 - S&H Systems expanded their automation product line with innovative Interroll crossbelt sorter and conveyor products that provide versatility for warehouse operations. The partnership with Interroll enables S&H to offer more flexible and modular products to clients, providing them with options in a customer-driven environment.

- August 2020 - Murata Machinery Ltd signed a contract with Alpen Co. Ltd to construct the first 3D robot warehousing system, alphabot. Further, alphabot will be introduced at the Alpen Komaki Distribution Center, one of Alpen Group's main distribution centers, to complement its storage capacity and reduce picking, sorting, and packaging operations by approximately 60%.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Consumers

- 4.2.3 Threat of New Entrants

- 4.2.4 Threat of Substitutes

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Impact of COVID-19 on the Industry Ecosystem

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Increasing Technological Advancements Aiding Market Growth

- 5.1.2 Rapid Growth in E-commerce Leading to Warehouse Automation

- 5.1.3 Industry 4.0 Investments Driving the Demand for Automated Material Handling and Storage Systems

- 5.2 Market Challenges

- 5.2.1 Unavailability for Skilled Workforce

- 5.2.2 High Capital Requirements

6 MARKET SEGMENTATION

- 6.1 By Product Type

- 6.1.1 Software

- 6.1.2 Hardware

- 6.1.3 Services

- 6.1.4 Integration

- 6.2 By Equipment Type

- 6.2.1 Mobile Robots

- 6.2.1.1 Automated Guided Vehicle(AGV)

- 6.2.1.1.1 Automated Forklift

- 6.2.1.1.2 Automated Tow/Tractor/Tug

- 6.2.1.1.3 Unit Load

- 6.2.1.1.4 Assembly Line

- 6.2.1.2 Autonomous Mobile Robots(AMR)

- 6.2.2 Automated Storage and Retrieval System(ASRS)

- 6.2.2.1 Fixed Asile

- 6.2.2.2 Carousel

- 6.2.2.3 Vertical Lift Module

- 6.2.3 Automated Conveyor

- 6.2.3.1 Belt

- 6.2.3.2 Roller

- 6.2.3.3 Pallet

- 6.2.3.4 Overhead

- 6.2.4 Palletizer

- 6.2.4.1 Conventional

- 6.2.4.2 Robotic

- 6.2.5 Sortation System

- 6.2.1 Mobile Robots

- 6.3 By End-User

- 6.3.1 Airport

- 6.3.2 Automotive

- 6.3.3 Food and Beverage

- 6.3.4 Retail/Warehousing/Distribution Centers/Logistic Centers

- 6.3.5 General Manufacturing

- 6.3.6 Pharmaceuticals

- 6.3.7 Post and Parcel

- 6.3.8 Electronics and Semiconductor Manufacturing

- 6.3.9 Other End-Users

- 6.4 By Country

- 6.4.1 Brazil

- 6.4.2 Argentina

- 6.4.3 Mexico

- 6.4.4 Colombia

- 6.4.5 Peru

- 6.4.6 Chile

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 JBT Corporation

- 7.1.2 KION Group AG

- 7.1.3 SSI SCHEFER AG

- 7.1.4 Daifuku Co. Limited

- 7.1.5 Kardex Group

- 7.1.6 Beumer Group GMBH & Co. KG

- 7.1.7 Jungheinrich AG

- 7.1.8 Murata Machinery Limited

- 7.1.9 Interroll Group

- 7.1.10 System Logistics

8 INVESTMENT ANALYSIS

9 FUTURE OF THE MARKET

02-2729-4219

+886-2-2729-4219