|

市場調查報告書

商品編碼

1640573

北美金屬罐:市場佔有率分析、行業趨勢和成長預測(2025-2030 年)North America Metal Cans - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

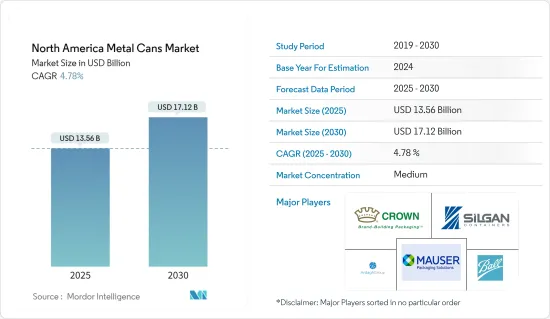

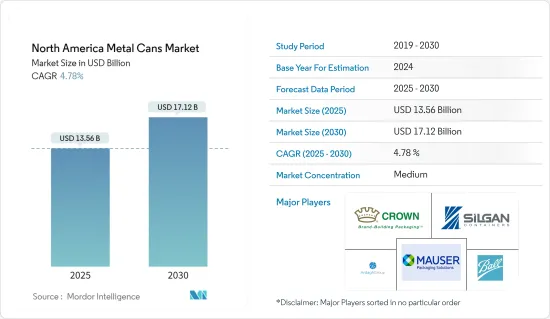

北美金屬罐市場規模預計在 2025 年為 135.6 億美元,預計到 2030 年將達到 171.2 億美元,預測期內(2025-2030 年)的複合年成長率為 4.78%。

食品和飲料行業佔金屬罐包裝市場的大部分佔有率,由於屬於必需品類別,在新冠疫情期間,該行業的需求量巨大。由於新冠肺炎疫情,全部區域實施了封鎖,導致消費習慣發生了重大變化。包裝食品、肉類、蔬菜和水果的需求正在增加。

主要亮點

- 金屬罐是該地區許多消費者忙碌生活方式的首選包裝解決方案之一,其最大優點是便利性。玻璃受到的限制主要是因為它容易破碎。此外,能量飲料的日益普及、新產品的推出、罐頭的經濟性和可回收性正在推動所研究市場的成長。

- 許多品牌正在推出新的能量飲料。例如,2020年,可口可樂北美公司推出了可口可樂品牌的首款能量飲料-可口可樂能量櫻桃(此口味僅在美國販售)。零卡路里版本將以 12 盎司 Sleek 罐裝形式在全國範圍內發售。

- 此外,根據美國鋁業協會和美國罐頭製造商協會(CMI)2020年的報告,美國鋁罐的產業回收率為55.9%,而消費者回收率為46.1%。此外,材料價值為1,210美元/噸。

- 該地區的化妝品行業也推動了金屬罐市場的成長,因為許多化妝品和個人護理製造商都傾向於使用金屬罐包裝他們的產品。例如,根據《Happi》雜誌的數據,2020 年美國主要除臭劑供應商聯合利華、寶潔和高露潔棕欖的銷售額分別為 3.2704 億美元、2.1979 億美元和 3849 萬美元. 以美元計。

- 食品和飲料行業在金屬罐包裝市場佔有較大佔有率,由於屬於必需品類別,在新冠疫情期間,該行業的需求巨大。根據 Store Brands 發布的 2020 年研究,在新冠疫情期間,美國的罐頭食品消費量增加了 96%。冷凍晚餐的消費量也增加了71%。

北美金屬罐市場趨勢

飲料預計將佔據較大的市場佔有率

- 金屬罐是飲料最廣泛使用的罐頭。由於方便攜帶,北美的罐裝葡萄酒、雞尾酒、烈酒和軟性飲料主要採用金屬罐包裝。金屬罐在飲料業的用途根據飲料的性質大致分為酒精飲料和非酒精飲料。啤酒等酒精飲料歷來使用金屬罐,而葡萄酒等其他類型的酒精飲料傳統上用玻璃瓶盛放,但擴大採用金屬罐。

- 此外,飲料罐製造商正在透過減少製造罐所需的規格來減輕重量。金屬罐可以承受包裝蘇打水所需的二氧化碳壓力。金屬罐還可以承受高達每平方英吋90磅的力量。這一因素使得罐頭成為飲料行業包裝的良好選擇。

- 金屬罐製造商正在提高北美的生產能力,以應對金屬罐短缺帶來的供應鏈中斷。 Ball 總裁預測,到 2023 年,需求將持續超過供應。飲料業對金屬罐的積極需求和成長引發了研究區域對該領域的多項投資。

- 例如,2021年9月,包裝公司鮑爾公司宣布將在拉斯維加斯投資2.9億美元建造新的鋁飲料包裝廠。該工廠將生產多種尺寸的罐頭。該工廠預計將於 2022 年底投入生產,全面運作後將創造 180 個製造業職缺。

- 此外,Ardagh Group 於 2020 年 10 月宣布將在其位於密西西比州的生產工廠安裝兩條新的高速飲料生產線。該公司宣布,這項投資旨在生產取得專利的、時尚的設計系列的一系列飲料,包括硬蘇打水、啤酒、能量飲料和茶。

美國佔最大佔有率

- 在這個市場,由於疫情導致罐頭短缺,許多公司正在現有工廠中增加新生產線,以提高生產力。例如,鮑爾公司於 2020 年 9 月宣布,將於 2021 年中期在賓夕法尼亞州匹茲頓開設一家鋁飲料包裝工廠,以服務北美市場,因為疫情導致北美家庭消費增加。該公司原計劃在2021年將產量擴大至60億罐。 Ball 計劃在 2021年終前開設兩家新工廠,並為其美國工廠增加兩條生產線。

- 疫情導致許多餐廳、酒吧關閉,罐裝酒精飲料銷量大幅增加。此外,許多飲料製造商已將產品轉向罐裝,這給鋁罐供應鏈帶來了壓力。為了滿足罐頭的需求,許多製造商正在開設工廠以滿足不斷成長的需求。

- 例如,2021年1月,皇冠控股在維吉尼亞亨利縣和巴西東南部的米納斯吉拉斯州投資了兩家新的飲料罐工廠。維吉尼亞的工廠將為多種類別的飲料供應罐,包括蘇打水、能量飲料、碳酸軟性飲料、茶、機能飲料、硬蘇打水、啤酒和雞尾酒。透過該工廠,該公司將擴大其北美供應網路,以滿足不斷成長的標準和特殊飲料罐市場的需求。

- 此外,皇冠控股於 2021 年 4 月宣布了在美國建立第三家飲料罐生產工廠的計畫。該工廠將生產蘇打水、能量飲料、碳酸軟性飲料、機能飲料和啤酒罐。

- CMI 的飲料罐和鋁罐板成員致力於實現雄心勃勃的美國回收目標,包括在 2030 年實現 70% 的回收率。這些新目標提高了鋁飲料罐的循環性,並向飲料製造商和消費者展示了該行業致力於確保鋁飲料罐仍然是市場上最永續的包裝。

北美金屬罐產業概況

北美金屬罐市場競爭適中。擁有較大市場佔有率的大公司正在各個地區擴大基本客群。此外,許多公司正在與多家公司製定策略合作計劃,以增加市場佔有率和盈利。市場的一些最新趨勢:

- 2021 年 3 月--鮑爾公司與西班牙領先的飲料公司 Damm 合作,在北美推出 ASI(鋁管理計畫)鋁罐,用於啤酒的儲存和包裝。預計這將有助於該公司提高銷售業績。

- 2021 年 2 月-Ardash Group 同意將其金屬包裝業務與 Gores Holdings V 合併,組成一家上市公司。根據協議,獨特目的收購公司Gores Holdings V將與Ardagh的金屬包裝部門合併,組成新公司Ardagh Metals。交易完成後,Ardagh 將保留 AMP 80% 的股份,並獲得高達 34 億美元的現金。此次交易包括來自Gores Holdings V的最高5.25億美元現金、由投資者主導的6億美元私募以及AMP籌集的約23億美元新債務。

其他福利:

- Excel 格式的市場預測 (ME) 表

- 3 個月的分析師支持

目錄

第 1 章 簡介

- 研究假設和市場定義

- 研究範圍

第2章調查方法

第3章執行摘要

第4章 市場洞察

- 市場概況

- 產業吸引力-波特五力分析

- 供應商的議價能力

- 買家的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭對手之間的競爭

- 產業價值鏈分析

- COVID-19 市場影響評估

第5章 市場動態

- 市場促進因素

- 金屬包裝回收率高

- 罐頭食品方便又便宜

- 市場限制

- 替代包裝解決方案的可用性

第6章 市場細分

- 依材料類型

- 鋁

- 鋼

- 按行業

- 食物

- 飲料

- 藥品

- 化妝品和個人護理

- 其他行業

- 按國家

- 美國

- 加拿大

第7章 競爭格局

- 公司簡介

- Crown Holdings Inc.

- Ball Corporation

- Silgan Containers LLC

- Mauser Packaging Solutions

- Ardagh Group SA

- DS Containers Inc.

- CCL Container Inc.

- Independent Can Company

- Technocap Group

- Can-Pack SA

- Allstate Can Corporation

- Envases Group

第8章投資分析

第9章:未來市場展望

The North America Metal Cans Market size is estimated at USD 13.56 billion in 2025, and is expected to reach USD 17.12 billion by 2030, at a CAGR of 4.78% during the forecast period (2025-2030).

With a significant share in the metal can packaging market, the food and beverage industry is witnessing massive demand amidst the COVID-19 pandemic, as the industry falls under the essential commodity. The lockdown enforced across the region due to the COVID-19 pandemic has bought a significant change in consumption habits. There has been an increasing demand for packaged food products, meat, vegetables, and fruits.

Key Highlights

- Metal cans are one of the perfect packaging solutions for the on-the-go lifestyle of many consumers in the region, and their convenience is topping the benefits list. These can be easily transported or carried to festivals, beaches, and outdoor and sporting events, whereas glass is mainly restricted due to its breakability. In addition, the increasing popularity of energy drinks, the introduction of new products, and the price and recyclability of cans augment the studied market growth.

- Many brands are introducing new energy drinks. For instance, in 2020, Coca-Cola North America unveiled the first-ever energy drink under the Coke brand Coca-Cola Energy Cherry a flavor available exclusively in the United States. Their zero-calorie counterparts will be available nationwide in 12-oz. sleek cans.

- Furthermore, according to the Aluminum Association and Can Manufacturers Institute (CMI), 2020 report, the industry recycling rate of aluminum can account for 55.9% in the United States, and the Consumer recycling rate of aluminum can account for 46.1%. In addition, the value of material accounted for USD 1,210/tons.

- The cosmetic segment in the region is also driving the growth of the metal cans market in the area as many cosmetic and personal care manufacturers prefer metal cans packaging for their products. For instance, according to Happi Magazine, the unit sales of leading deodorant vendors such as Unilever, Procter, and Gamble, Colgate Palmolive in the United States in 2020 accounted for USD 327.04 million, USD 219.79 million, and USD 38.49 million, respectively.

- The food and beverage industry, with a major share in the metal, can packaging market, has witnessed huge demand amidst the COVID-19 pandemic, as the industry falls under the essential commodity. According to a 2020 survey published by Store Brands, the consumption of canned food due to the Covid-19 pandemic increased by 96% in the United States. Also, frozen dinners consumption also increased by 71%.

North America Metal Cans Market Trends

Beverage is Expected to Account For Significant Market Share

- Metal cans are most widely used for beverages. The most notable trend of canned wine, cocktails, hard drinks, and soft drinks is packaged in metal, driven by the need for portability in North America. The usage of metal cans in the beverage industry can be widely classified into alcoholic drinks and non-alcoholic drinks based on the nature of the beverage. Alcoholic beverages, such as beer, have historically used metal cans, while other kinds of liquor, like wine, traditionally served in glass bottles, are increasingly adopting metal cans.

- Moreover, beverage can manufacturers have reduced the weight by reducing the gauge required to fabricate the cans. Metal cans can support the carbonation pressure that is needed to package soda. Metal cans also resist forces up to 90 pounds per square inch. This factor makes the cans the favored choice for packaging in the beverage industry.

- Metal can manufacturers are increasing the production capacity in North America to address the supply chain disruption faced due to the shortage in metal cans. The President of the Ball Corporation has identified the demand to outstrip the supply until 2023. The aggressive demand and growth of metal cans in the beverage industry sparked multiple investments in the sector in the studied region.

- For instance, in September 2021, Packaging company Ball Corporation announced an investment of USD 290 million over the course of multiple years into a new aluminum beverage packaging plant in Las Vegas. The plant is expected to create a range of can sizes. The facility is scheduled to begin production in late 2022 and will create 180 manufacturing jobs when it is fully operational.

- Further, Ardagh Group announced in October 2020 that the two new high-speed beverages could manufacture lines in its production facility in Mississippi. The company announced that the investment is aimed to cater to the production of its patented sleek design line for various beverages, including hard seltzers, beer, energy drinks, and tea.

United States Accounts for the Largest Share

- Many companies in the market are adding new lines to existing plants and are making productivity enhancements because of the can shortage issues due to the pandemic. For instance, in September 2020, Ball Corporation announced that it would open an aluminum beverage packaging plant in Pittston, Pennsylvania, by mid-2021 to serve the North American market as the at-home consumption grows due to the pandemic. The company initially planned a 6 billion can output expansion by 2021. Ball Corporation is looking forward to opening two new plants and adding two production lines to the United States facilities by the end of 2021.

- Many restaurants and bars were closed with the pandemic, due to which canned alcoholic beverages witnessed a significant increase in sales. Also, many beverage manufacturers shifted their products into cans, which has put a strain on the aluminum can supply chain. To cater to the demand for cans, many manufacturers have been opening facilities to meet this ever-growing demand.

- For instance, in January 2021, Crown Holdings invested in the two new beverage can plant in Henry Country, Virginia, and Minas Gerais State, Southeast Brazil. The plant in Virginia will be supplying beverage cans to serve various categories, including sparkling water, energy drinks, carbonated soft drinks, tea, functional beverages, hard seltzers, beer, and cocktails. The company expands its North American supply network with the plant to address the growing standard and specialty beverage cans market.

- Additionally, in April 2021, Crown Holding unveiled its plan to build its third new beverage can production facility in the United States. The plant will produce cans for sparkling waters, energy drinks, carbonated soft drinks, functional beverages, beers, among other beverages.

- Can Manufacturers Institute (CMI) beverage can manufacturer and aluminum can sheet producer members are committing to achieving ambitious U.S. recycling rate targets, including a 70% recycling rate by 2030. These new targets will improve the circularity of the aluminum beverage can while demonstrating to beverage companies and consumers the industry's dedication to ensuring the aluminum beverage can remain the most sustainable package on the market.

North America Metal Cans Industry Overview

The North America Metal Cans market is moderately competitive. The major players with a significant share in the market are expanding their customer base across various regions. In addition, many companies are forming strategic and collaborative initiatives with multiple companies to increase their market share and profitability. Some of the recent developments in the market are:

- March 2021 - Ball Corporation, along with the partnered company Damm, one of the leading beverage companies in Spain, introduced ASI's(The aluminum stewardship initiative) aluminum cans for storage and packaging of beer in North America. This is expected to increase the sales performance of the company.

- February 2021 - Ardagh Group agreed to merge its metal packaging business with Gores Holdings V, creating a publicly listed company. The agreement will see Gores Holdings V, a unique purpose acquisition company, merge with Ardagh's metal packaging division to form the newly created Ardagh Metal. Ardagh will retain an 80% stake in AMP and receive up to USD 3.4 billion in cash when the transaction completes. The deal includes up to USD 525 million in cash from Gores Holdings V and USD 600 million in a private placement led by investors, along with approximately USD 2.3 billion of new debt raised by AMP.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Buyers

- 4.2.3 Threat of New Entrants

- 4.2.4 Threat of Substitutes

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Industry Value Chain Analysis

- 4.4 Assessment of COVID -19 Impact on the Market

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 High Recyclability Rates of Metal Packaging

- 5.1.2 Convenience and Lower Price Offered by Canned Food

- 5.2 Market Restraints

- 5.2.1 Presence of Alternate Packaging Solutions

6 MARKET SEGMENTATION

- 6.1 By Material Type

- 6.1.1 Aluminum

- 6.1.2 Steel

- 6.2 By End-user Vertical

- 6.2.1 Food

- 6.2.2 Beverage

- 6.2.3 Pharmaceuticals

- 6.2.4 Cosmetic and Personal Care

- 6.2.5 Other End-user Verticals

- 6.3 By Country

- 6.3.1 United States

- 6.3.2 Canada

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Crown Holdings Inc.

- 7.1.2 Ball Corporation

- 7.1.3 Silgan Containers LLC

- 7.1.4 Mauser Packaging Solutions

- 7.1.5 Ardagh Group S.A.

- 7.1.6 DS Containers Inc.

- 7.1.7 CCL Container Inc.

- 7.1.8 Independent Can Company

- 7.1.9 Technocap Group

- 7.1.10 Can-Pack SA

- 7.1.11 Allstate Can Corporation

- 7.1.12 Envases Group