|

市場調查報告書

商品編碼

1644471

美國印刷標籤:市場佔有率分析、行業趨勢、統計數據、成長預測(2025-2030 年)United States Print Label - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

價格

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

簡介目錄

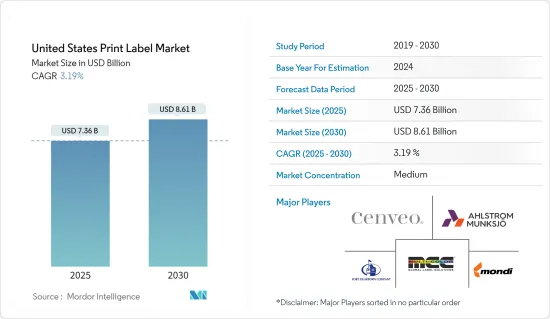

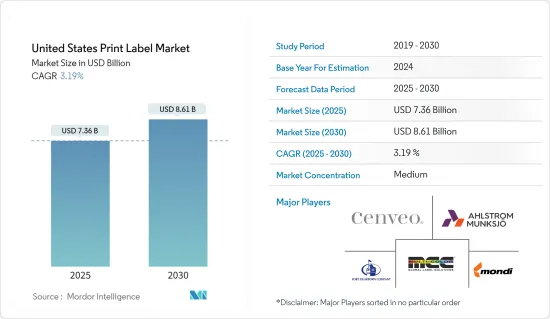

預計 2025 年美國印刷標籤市場規模為 73.6 億美元,到 2030 年將達到 86.1 億美元,預測期內(2025-2030 年)的複合年成長率為 3.19%。

主要亮點

- 新冠疫情為標籤數位印刷提供了機會。標籤是必需品供應鏈的一部分。它也是傳達訊息的重要工具。因此,市場對食品、衛生、藥品標籤和電子商務銷售相關的標籤資訊的需求日益增加。美國標籤產業在疫情爆發的第一個月發揮了至關重要的作用。在新冠肺炎疫情期間,美國標籤轉換器交貨了需求量大的印刷產品。

- 數位技術滿足了各個終端用戶產業的多種需求,並開發出了有吸引力的標籤設計,從而激發了潛在消費者的購買慾望。數位技術與現有標籤印刷技術的融合有望為各個領域帶來從小規模到大規模的巨大變化,從而改善整個市場。

- 此外,柔版印刷可望引領國內印刷標籤市場。隨著自動化程度的提高,客戶希望他們的產品能盡可能接近訂購時間交付。為了滿足需求,更快的交貨時間現在比以往任何時候都更重要。柔版印刷機提供連續印刷解決方案、更多軟體整合到印刷機和技術中以及耐用性,以便在更短的前置作業時間內滿足客戶需求。

- 柔版印刷是一種高速捲筒紙印刷技術,適用於大多數包裝和標籤應用。這種柔版印刷方法的最大優點是,它能夠在各種產品上快速、經濟、高品質地印刷標籤。柔版印刷版透過在橡膠或其他軟性材料上創建所需圖像的3D凸起圖像來創建柔版印刷。柔版印刷將品質、生產力和靈活性完美地融為一體,成為印刷標籤行業中最受歡迎的印刷方式。

- 由於客製印刷幾乎任何尺寸和數量的標籤,印刷標籤對於產品安全和促銷至關重要。先進的柔版印刷技術使品牌所有者能夠有效地推廣他們的產品並傳達有關產品的訊息,例如其產地和重要的營養資料,以及產品召回的重要追蹤資料。

- 柔版印刷成本較低,因此該平台擴大進入市場。創建個人化、限量版印刷標籤也變得更具吸引力。柔版印刷是一種使用軟性版(相對於固態版)的印刷技術。這是一種新的凸版印刷形式。

- 改進標籤轉換過程是一項持續且艱鉅的任務,因為很難跟上最新的技術進步。 UV LED 固化技術已成為各種印刷製程的重大突破。如今,它為標籤、標記、軟包裝和收縮套包裝應用的窄帶柔版印刷和套印上光提供了顯著的優勢。

- UV 固化油墨不僅可以提高印刷性能,還可以解決遷移問題,使其成為 UV 柔版食品包裝和標籤應用的理想選擇。太陽化學公司最近推出了 SolarVerse,一種色素豐富、黏度低、多用途的 UV 柔印基底濃縮液。

- 此外,紙膜的耐用性往往不如薄膜,如果在使用過程中沒有採取適當的措施,紙膜會隨著時間的推移而撕裂或起皺。然而,與環境法規相關的標籤也會阻礙印刷標籤市場的成長。如果標籤在回收時殘留在物品上,將會妨礙該物品的可回收性。例如,當回收一個貼有標籤的瓦楞紙箱時,高濕強度紙標籤不會阻止該箱子被回收,但如果使用薄膜代替高濕強度紙,則標籤可能無法回收。

美國印刷標籤市場的趨勢

感壓標籤佔據最大市場佔有率

- 感壓標籤(PSL) 由五層組成:襯裡、離型層、黏合劑、布料和麵漆,類似於高科技貼紙。 PSL 採用紙張、薄膜和箔作為主要標籤材料,並可使用多種油墨來產生Sharp Corporation、鮮豔的色彩。

- PSL 是最廣泛使用的標籤施用器之一,因為它不需要任何熱量、溶劑或水,只需輕輕或適度的壓力即可貼在產品表面上。據 Resource Label Group 及其所有子公司稱,PSL 佔據了市場上所有標籤的 80% 以上。

- 在傳統啤酒標籤市場這樣一個競爭激烈的市場中,讓您的標籤在眾多競爭對手中脫穎而出的最重要因素之一就是擁有獨特的外觀和感覺。因此,傳統的濕膠標籤由於其廣泛的裝飾可能性和優異的外觀正在迅速被感壓標籤和套管所取代。

- 在傳統的啤酒標籤領域,濕膠標籤更受青睞,因為它們極具成本效益,特別是對於更大、更持久的工作。另一方面,更多的裝飾可以增加標籤在擁擠的貨架上吸引注意力的機會。感壓標籤是濕膠標籤的一種具體而有效的替代品。感壓標籤採用具有金屬效果的反向印刷鏡面解決方案,具有更好的黏合性能和更多的裝飾選擇。這就是為什麼在美國企業發展的公司專注於滿足市場不斷變化的需求。

- 感壓標籤用於食品和飲料、製藥、消費品、個人護理和建設產業。為這些行業服務的供應商站在第一線,努力繼續生產和供應關鍵消費品和醫療保健產品的標籤材料。然而,由於競爭加劇以及印刷和裝飾技術的進步,原物料價格正在上漲。

飲料預計將佔據較大的市場佔有率

- 飲料是美國印刷標籤市場的主要終端用戶產業之一。這是由於飲料領域廣泛採用創新標籤和包裝以及健康飲料領域的市場不斷擴大。

- 預計到 2024 年,這個重要飲料類別的銷售額將超過 1,700 億美元。儘管在疫情期間,該國部分飲料細分市場的消費受到了影響,但新冠疫情的爆發擴大了許多細分市場的覆蓋範圍。

- 此外,中國擁有一些最大的碳酸飲料公司,能量飲料市場蓬勃發展,越來越多的公司採用新的包裝技術來吸引客戶。隨著美國消費者對健康的關注度日益提高,這些公司擴大在標籤上印製產品成分。此外,這些成分可能因品牌和特定能量飲料產品而異。

- 隨著葡萄酒市場的成長,標籤的需求變得至關重要。大多數葡萄酒標籤要么採用紙質標籤,要么採用薄膜標籤,即無標籤形式。此外,標籤的設計必須能夠承受其運輸、儲存和使用的環境。因此,該國釀酒廠的增加也將導致標籤印刷和製造的擴張。

- 隨著永續性在標籤供應鏈中變得越來越突出,我們可能會看到再生材料和可回收材料的使用量增加。潛在材料包括 PET、生質塑膠和厚可重複使用玻璃。隨著永續性在標籤供應鏈中變得越來越重要,我們可能會看到可回收標籤材料的使用量增加。此外,艾利丹尼森正在推廣多種永續性,包括回收再生用寶特瓶回收的 CleanFlake 黏合劑技術、ClearCut 黏合劑技術以及用於飲料標籤應用的各種紙張和薄膜布料。

- 飲料容器也將決定後續黏合劑的選擇。研究表明,玻璃容器所需的黏合劑與塑膠容器不同。紙和聚丙烯是飲料標籤最常用的兩種材料,其中大多數使用聚丙烯基材。該國的飲料業正在擴張,飲料標籤也在升級,這推動了該國的市場需求。

- 此外,美國供應商正在投資合作和收購策略,以增強其標籤解決方案並提高品牌知名度。例如,美國的Fort Dearborn 公司收購了 Wall 公司,後者是一家領先的切割堆疊、捲筒紙和收縮套筒標籤供應商。此次收購進一步加速了該公司在美國印刷標籤解決方案領域的成長,主要針對食品、飲料和家居用品領域。

美國印刷標籤產業概況

美國印刷標籤市場集中度較高,國內外都有許多大大小小的參與者。參與者正在採用產品創新、策略夥伴關係、業務擴張和併購等關鍵策略。主要市場發展包括:

- 2023 年 3 月美國圖形通訊公司泰勒宣布將在墨西哥蒙特雷開設一個新的標籤製造工廠。最新的開業將進一步幫助該公司滿足墨西哥工業公司對長效標籤日益成長的需求。

- 2023 年 10 月,All4Labels 將搬遷至墨西哥城的一個更大的工廠,並引入一系列新技術,作為擴大其在墨西哥和美國的激動人心的擴張計劃的一部分。 Almirall 表示,這五條新的印刷生產線將專注於感壓標籤和收縮套標,使該工廠的生產能力提高三倍。

其他福利:

- Excel 格式的市場預測 (ME) 表

- 3 個月的分析師支持

目錄

第 1 章 簡介

- 研究假設和市場定義

第2章調查方法

第3章執行摘要

第4章 市場動態

- 市場概況

- 市場促進因素

- 採用數位印刷技術生產的標籤需求不斷增加

- 醫療保健和化妝品領域的採用率很高

- 市場挑戰

- 缺乏能夠承受惡劣天氣條件的產品

- 生態系分析

- 產業吸引力-波特五力分析

- 新進入者的威脅

- 買家的議價能力

- 供應商的議價能力

- 替代品的威脅

- 競爭對手之間的競爭強度

- COVID-19 對美國印刷標籤市場的影響評估

第5章 市場區隔

- 按印刷過程

- 膠版印刷

- 凹版印刷

- 柔版印刷

- 螢幕

- 凸版印刷

- 電子照相術

- 噴墨

- 按標籤格式

- 濕膠標籤

- 感壓標籤

- 無底紙標籤

- 多部分追蹤標籤

- 套模標籤

- 收縮和拉伸套

- 按最終用戶產業

- 食物

- 飲料

- 衛生保健

- 化妝品

- 適合家庭使用

- 工業(汽車、工業化學品、耐用性和非耐用消費品)

- 後勤

- 其他最終用戶產業

第6章 競爭格局

- 公司簡介

- Fort Dearborn

- Multi Color Corporation

- Mondi Group

- Ahlstrom-munksjo Oyj

- Cenveo Corporation

- Avery Dennison Corporation

- Brady Corporation

- Westrock Company

- RR Donnelley & Sons Company

- Taylor Corporation

第7章:未來市場展望

簡介目錄

Product Code: 72261

The United States Print Label Market size is estimated at USD 7.36 billion in 2025, and is expected to reach USD 8.61 billion by 2030, at a CAGR of 3.19% during the forecast period (2025-2030).

Key Highlights

- The COVID pandemic has provided opportunities for digital printing in labeling. Labels are part of the supply chains of necessities. Additionally, they serve as an essential tool for conveying information. Hence, the market has witnessed an increased demand for food, hygiene, pharmaceutical labels, and labeling information related to e-commerce sales. Short runs on a regular and increasing basis have become the norm.The United States label industry played a key role in the initial month of the outbreak. The label converters in the US delivered printed products that were in high demand during the COVID-19 outbreak.

- Digital technology has met the multiple requirements of various end-user industries in developing attractive label designs to encourage potential consumers to make purchases. The integration of digital technology with the existing label printing techniques is expected to bring a massive change to all the small-scale and large-scale sectors, improving the overall market.

- Moreover, flexography printing is expected to drive the print label market in the country. With the rise in automation, customers want their products as close to the order time as possible. Faster turnaround times are becoming more vital than ever to meet demand. Flexographic printer with continuous print solutions, more software integrations into the presses and technologies, and durability would meet customer demand in shorter lead times.

- Flexography, a roll-feed high-speed printing technique, is appropriate for most packaging and label applications. The best thing about this flexography is that it makes it possible to print labels on a wide range of products quickly, affordably, and with excellent quality. A flexible printing plate creates a flexographic print by creating a three-dimensional relief of the desired image in rubber or another flexible material. Due to its excellent combination of quality, productivity, and flexibility, flexographic printing has become the most popular print generation in the print label industry.

- Print Labels is crucial in product safety and promotions through flexible packaging attributed to on-demand printing in almost any size or quantity. Advanced flexographic printing techniques enable brand owners to efficiently promote their products and transmit information about them, including their origin, crucial nutritional data, and even crucial tracking data for a product recall.

- Due to the lower cost of flexo printing, its platforms have increasingly entered the market. Creating personalized, limited-run print labeling has also grown more appealing. Flexography is a printing technique that uses a flexible (rather than a solid) plate. It is a newer incarnation of relief printing.

- Enhancing the process of label converting is a continuous and demanding task due to the difficulty in keeping pace with the latest advancements in technology. UV LED curing technology has emerged as a significant breakthrough in various printing processes. It now provides significant advantages for narrow web flexographic printing and overprint varnishing for labels, tags, flexible packaging, and shrink-sleeve packaging applications.

- Apart from enhancing printing performance, UV cured inks are migration-compliant and, hence, ideal for UV flexo food packaging and label applications. Sun Chemical recently launched SolarVerse, a range of highly pigmented, low viscosity, multipurpose UV flexo base concentrates that are ideal for labeling food materials.

- Moreover, paper film stocks tend to be less durable than films, potentially ripping or wrinkling over time if proper care is not taken during the application process. However, labeling about environmental regulation will also hinder the growth of the print label market. If a label remains on an item during recycling, it will hinder the recyclability of the item. For example, when labeled corrugated boxes are recycled, wet strength paper labels do not hinder box recycling, but if the film is used instead of wet strength paper, the label could not have been recycled.

United States Print Label Market Trends

Pressure-sensitive Labels Accounts for the Largest Market Share

- Pressure-sensitive labels (PSL) consist of five individual layers, such as liner, release coat, adhesive, face stock, and topcoat, and are analogous to a high-tech sticker. A PSL can use paper, film, and foil as its primary label materials and can be used with a wide range of inks to produce sharp and bright colors.

- The PSL is one of the most widely used forms of label applicator, as it does not require any heat, solvent, or water to activate; it only takes light or moderate pressure to apply it to a product surface. According to the Resource Label Group and all subsidiaries, PSLs constitute more than 80% of all labels in the market.

- In a highly competitive market like the traditional world of beer labeling, one of the most important factors in making a label stand out from the crowd and the competition is having a unique look and feel. For this reason, traditional wet glue labels are quickly being replaced by pressure-sensitive labels or sleeves because of the various embellishment possibilities and the superior appearance.

- The traditional beer labeling world prefers wet glue labels because they are very cost-effective, especially for large-scale, long-lasting jobs. On the other hand, with more decoration, a label that stands out on a crowded shelf is more likely to be noticed. A concrete and effective alternative to wet glue labels is pressure-sensitive labels. Pressure-sensitive labels offer better adhesive properties and more decoration options on a reverse-printed mirror solution with metallic effects in advancements. This is why players operating in United States, focus on catering to the changing market needs.

- Pressure pressure-sensitive labels are used in the food and drink, pharmaceutical, consumer goods, personal care, and construction industries. Depending on the application, different adhesives may make pressure-sensitive labels permanent or reusable.The vendors serving these industries are working on the front line to continue producing and supplying label materials for critical consumer and healthcare products. However, the raw material prices are rising, coupled with increased competition and evolving printing and decorating technologies.

Beverage is Expected to Account For Significant Market Share

- The beverage is one of the primary end-user industries for the US print label market, owing to the high rate of adoption of innovative label and packaging in the beverage sectors and the growing market for the health drinks segment.

- Sales of significant beverage categories is expected to cross USD 170 billion by 2024. Although the consumption of some beverage segments in the country was affected during the pandemic, the scope of many segments expanded due to the COVID-19 outbreak.

- Furthermore, the country is home to some of the largest carbonated beverage companies, along with a strong market for energy drinks, which are increasingly adopting new packaging techniques to attract customers. These companies are also printing their ingredients on their labels, as health-related concerns are growing among US consumers, expanding the scope of printing. Also, these ingredients may vary between brands and specific energy drink products.

- With the growing wine market, the need for labeling is becoming crucial. Most of the wine labels use paper label look or no label look with film label. In addition, labels need to be designed to withstand the environment in which they are shipped, stored, and used. Therefore, the growing number of wineries in the country will also expand label printing and manufacturing.

- As sustainability becomes more of a presence in the labeling supply chain, there will be an increased use of recycled and recyclable materials. Top material choices will include PET, bioplastic, and thicker reusable glass. As sustainability becomes more critical in the labeling supply chain, they will likely see increased use of recyclable label materials. In addition, Avery Dennison promotes several technologies for sustainability, including its CleanFlake adhesive technology for PET bottle recycling, ClearCut Adhesive technology, and a variety of paper and film face stocks for beverage labeling applications.

- The beverage's container also dictates the subsequent adhesive choice. According to research, glass containers require a different adhesive than plastic containers. Paper and polypropylene are the two most common materials used for beverage labels, while most employ polypropylene substrates. The growing expansion of the beverage industry in the country as well as the launch of upgraded labels for beverages in the market boosted the market demand in the country.

- Further, the US vendors invest in collaboration and acquisition strategies to enrich their label solutions and increase brand awareness. For instance, US-based Fort Dearborn Company acquired Walle Corporation, a leading supplier of cut & stack, roll-fed, and shrink sleeve labels. This acquisition helped the company grow more in the printed label solutions in the US, primarily for the food, beverage, and household products segments.

United States Print Label Industry Overview

The United States print label market is moderately concentrated, owing to the presence of many large and small players in the market operating in the domestic and international market. Players are adopting key strategies, such as product innovation, strategic partnerships, expansions, and mergers and acquisitions. Some of the key developments in the market are:

- In March 2023: Taylor, a United States-based graphic communications company, announced the opening of its new label manufacturing facility in Monterrey, Mexico. The most recent opening would further aid the business in meeting the growing demand for long-lasting labels from industrial firms in Mexico.

- In October 2023: All4Labels moved to a new larger facility in Mexico City and is in the process of installing a host of new technologies as part of an impressive expansion plan to grow its presence in Mexico and the United States. The five new printing lines, focused on pressure-sensitive labels and shrink sleeves, will treble production capacity at the site, according to Almirall, while space remains for further press installations in the future

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Growing Demand for Labels Manufactured with Digital Print Technologies

- 4.2.2 High Adoption From Healthcare and Cosmetics Segment

- 4.3 Market Challenges

- 4.3.1 Lack of Products with Ability to Withstand Harsh Climatic Conditions

- 4.4 Industry Ecosystem Analysis

- 4.5 Industry Attractiveness - Porter's Five Forces Analysis

- 4.5.1 Threat of New Entrants

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Bargaining Power of Suppliers

- 4.5.4 Threat of Substitute Products

- 4.5.5 Intensity of Competitive Rivalry

- 4.6 Assessment of the Impact of COVID-19 on the US Print Label Market

5 MARKET SEGMENTATION

- 5.1 By Print Process

- 5.1.1 Offset Lithography

- 5.1.2 Gravure

- 5.1.3 Flexography

- 5.1.4 Screen

- 5.1.5 Letterpress

- 5.1.6 Electrophotography

- 5.1.7 Inkjet

- 5.2 By Label Format

- 5.2.1 Wet-glue Labels

- 5.2.2 Pressure-sensitive Labels

- 5.2.3 Linerless Labels

- 5.2.4 Multi-part Tracking Labels

- 5.2.5 In-mold Labels

- 5.2.6 Shrink and Stretch Sleeves

- 5.3 By End-user Industry

- 5.3.1 Food

- 5.3.2 Beverage

- 5.3.3 Healthcare

- 5.3.4 Cosmetics

- 5.3.5 Household

- 5.3.6 Industrial (Automotive, Industrial Chemicals, and Consumer and Non-consumer Durables)

- 5.3.7 Logistics

- 5.3.8 Other End-user Industries

6 COMPETITIVE LANDSCAPE

- 6.1 Company Profiles

- 6.1.1 Fort Dearborn

- 6.1.2 Multi Color Corporation

- 6.1.3 Mondi Group

- 6.1.4 Ahlstrom-munksjo Oyj

- 6.1.5 Cenveo Corporation

- 6.1.6 Avery Dennison Corporation

- 6.1.7 Brady Corporation

- 6.1.8 Westrock Company

- 6.1.9 R.R. Donnelley & Sons Company

- 6.1.10 Taylor Corporation

7 FUTURE OUTLOOK OF THE MARKET

02-2729-4219

+886-2-2729-4219