|

市場調查報告書

商品編碼

1644650

亞太可程式邏輯控制器 (PLC):市場佔有率分析、產業趨勢與統計、成長預測(2025-2030 年)Asia-Pacific Programmable Logic Controller - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

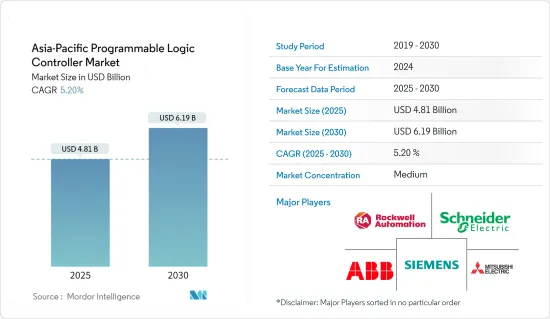

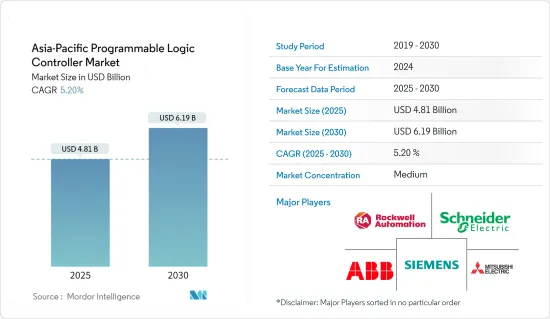

亞太地區可程式邏輯控制器 (PLC) 市場規模預計在 2025 年為 48.1 億美元,預計到 2030 年將達到 61.9 億美元,預測期內(2025-2030 年)的複合年成長率為 5.2%。

PLC 是控制自動化機械的主要計算系統。該系統還可以幫助檢測錯誤和缺陷並向技術人員發出警報。由於體積小,PLC 系統也比繼電器和開關盒等傳統系統更受歡迎。 PLC 的另一個優點是其多功能性,這是由於其可編程的特性,允許它們根據應用用於多種操作。

主要亮點

- 對於任何生產線來說,PLC 都至關重要,隨著第四次工業革命的進展,網際網路連接的感測器和系統正在與它們協同工作。例如,在生產巧克力或烘焙原料的食品和飲料製造工廠中,追蹤混合物中的所有化學物質並監測鍋爐故障等關鍵事件非常重要。近年來,機器人已經能夠直接處理精緻的食品。新型改進的夾持器技術和創新視覺系統的出現徹底改變了這個產業。例如,模仿人類觸覺的夾持技術的改進使得機器人能夠包裝水果和蔬菜。

- 工業控制系統的採用,以及許多公司提供多樣化的解決方案,正在推動印度市場的擴張,而印度市場則是由最近的技術創新定義的。例如,Delta電子銷售一系列自動化產品和解決方案,包括人機介面、感測器和機器人。 2021 年 3 月,ABB 印度公司報告稱,其在印度基於 PLC 的太陽能發電廠自動化方面已累積實現 5 吉瓦的里程碑。

- 日本正努力充分利用物聯網、人工智慧、巨量資料等第四次工業革命的技術創新,實現「社會5.0」。為了實現這一目標,政府建立了「互聯產業」。這是一個新的框架,期望工業透過連結現代生活的各個方面,包括人、機器、系統和商業,為社會問題開發創新的解決方案。這些政策可能會推動所研究的市場。

- 對於高壓操作設備的需求使得奈米 PLC 成為離散領域甚至小型企業的熱門選擇。由於在高電壓下易於控制,固定奈米 PLC 被用於轉換器、逆變器和其他基礎控制器等電子應用。此外,除了即時約束之外,PLC 能夠以出色的可靠性和性能執行一系列任務,再加上其承受極端溫度、濕度、振動和電氣噪音的能力,這些都促進了 PLC 在各種工業應用中的採用。

- 最近的冠狀病毒疫情對全球經濟造成了嚴重破壞,大大改變了許多行業的日常業務。隨著在家工作通訊協定的實施和就地避難令的持續,相關市場的參與者已經評估並重新評估了他們的網路事件準備和回應策略。對於部署工業控制系統 (ICS) (PLC) 來監控和控制關鍵設備和流程的企業來說尤其如此。

亞太可程式邏輯控制器 (PLC) 市場趨勢

汽車產業正在推動顯著成長

- 在汽車領域,PLC 用於以靈活、耐用、易於可程式設計的控制器取代硬連線繼電器邏輯系統。例如。據日本汽車工業協會稱,日本汽車製造商預計2021年在海外生產汽車約1646萬輛,高於去年的1538萬輛。這比美國產量高出一倍以上。如此巨大的產量可能會為該地區所研究的市場創造成長機會。

- 成功整合汽車製造中的各個自動化階段將為供應鏈創造價值,從而帶來長期競爭力並降低價格。根據落基山研究所 (RMI) 和 NITI Aayog 的數據,到 2030 年,印度的電動車金融產業規模預計將達到 370 億印度盧比(500 億美元)。根據印度能源儲存聯盟的一項研究,到 2026 年,印度電動車市場預計將以 36% 的複合年成長率成長。

- 現代等品牌一直在大力投資智慧運輸解決方案,以保持領先於競爭對手。隨著汽車變得越來越聰明、連網程度越來越高,擁有專門從事機器人和人工智慧的公司將在長期內帶來巨大的資產。 2021年6月,現代汽車宣布從Softbank Corporation手中收購了波士頓動力公司的控股權。該交易對這家美國機器人開發商的估值為 11 億美元,現代持有80% 的股份,Softbank Corporation仍持有20% 的股份。這將使當地企業能夠開發新產品或將新功能融入現有產品以滿足客戶需求。

- 機器停機時間是影響汽車製造業效率的關鍵因素之一。根據 ISA.org(國際自動化協會)的資料,停機時間佔營運期間生產損失的 5-20%。使用自動化 PLC 系統可將機器停機時間從 20% 減少到 4%。減少系統停機時間的需求日益成長,推動了市場的成長。它的功能使得 PLC 比傳統的個人電腦 (PC) 和工作站領域更具獨特性。 PLC 可實現公司內部和公司之間的快速資料共用。這種快速的資料共用有助於減少停機時間,因為 PLC 可以自動化 FTP、Web 伺服器、國際資料庫和電子郵件傳輸。

- I/O 模組是一種與電腦(例如 PLC)之間傳輸資料的裝置。感測器和致動器等現場設備的增加增加了對 I/O 模組的需求。感測器訊號代表製程變數(例如液體流量),由輸入 I/O 模組轉換並存儲在 PLC 中。致動器從 I/O 模組接收操作訊號。

中國是推動市場發展的地區之一

- 該地區的公司正在開發新產品以滿足廣泛的客戶需求。例如,2021年7月,上海寶信軟體股份有限公司推出了自主研發的巨型可程式邏輯控制器(PLC)產品。寶信軟體自主研發的巨型PLC產品是工業控制系統的關鍵元件。經過10年的潛心研究,寶信終於掌握了精密控制、高速通訊的技術難題。

- 此外,該地區的公司正在增強產品系列,以滿足不同終端用戶的需求。例如,SINOVO PLC 是一種可程式邏輯記憶體控制器,在許多應用中使用。工具工具機、紡織、包裝、印刷、塑粒、造紙、製藥、石油、工業、電梯、提昇機、電纜、陶瓷、建築自控、風扇泵、車輛、軌道運輸、CNC工具工具機等系統與控制設備均採用SINOVO電氣產品。

- 所研究的市場受到工業生產和電腦及軟體投資的嚴重影響。這些 PLC 系統傳統上一直是製程和離散工廠自動化的基礎。工業 4.0 在各個工業領域的日益廣泛應用正在擴大所研究的市場。

- 工廠自動化的需求包括對自動化生產線和供應鏈的需求,這推動了工廠自動化產業的發展,並得到有利的投資支持。該國有多項投資,主要主要企業在該地區設立機構,創業投資向潛在的新興企業注入資金,以進一步促進所研究市場的成長。例如,2021 年 4 月,生產工業機器人的新興企業Yuibot 在由Softbank Corporation亞洲創投公司和其他公司主導的資金籌措中完成了 1,547 萬美元的投資。該公司 80% 的年收益來自中國,並計劃利用這筆資金資助研發。

- 2021年12月,中國發布智慧製造五年規劃,承諾2025年完成大規模製造業的數位化。依規劃,到2025年,中國70%以上的大型企業要數位化,在全國打造500家以上製造業示範基地。 《策略》也指出,智慧製造設備、工業軟體技術水準及市場競爭力明顯提升,市場滿足率分別達70%以上、50%以上。

亞太可程式邏輯控制器 (PLC) 產業概況

亞太地區可程式邏輯控制器(PLC)市場是一個中等競爭的市場。市場參與者正在透過合作、合併和大量的研發投資來創新先進的產品。

- 2022年1月-自動化專家ABB與中國主要汽車零件供應商華域汽車宣布成立合資企業,推動中國汽車產業下一代智慧生產。該合資企業將在兩家公司現有的成功夥伴關係關係的基礎上進一步發展,為華域汽車中國業務的靈活和永續汽車零件生產帶來重大發展。

- 2021年2月-Honeywell與山東電力建設公司(SEPCO)簽署契約,為薩勒曼國王國際海事工業和服務綜合體造船廠提供綜合控制、通訊、安全和安保系統。包括 ControlEdge 可程式邏輯控制器 (PLC)、資料集中器、安全管理器 SC 和 Experion 製程知識系統 (PKS) 監控和資料擷取 (SCADA) 系統。

其他福利:

- Excel 格式的市場預測 (ME) 表

- 3 個月的分析師支持

目錄

第 1 章 簡介

- 調查結果

- 調查前提

- 研究範圍

第2章調查方法

第3章執行摘要

第4章 市場洞察

- 市場概況

- 產業吸引力-波特五力分析

- 供應商的議價能力

- 買家的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭對手之間的競爭

- 價值鏈分析

- 評估新冠肺炎對市場的影響

第5章 市場動態

- 市場促進因素

- 汽車產業擴大採用可程式邏輯控制器 (PLC) 系統

製造業的技術進步

- 市場限制

- 部署成本高

第6章 市場細分

- 按類型

- 硬體和軟體

- 大型 PLC

- 奈米PLC

- 小型 PLC

- 中型PLC

- 軟體

- 其他類型

- 按服務

- 硬體和軟體

- 按最終用戶

- 食品、菸草、食物及飲料

- 車

- 化工和石化

- 能源與公共產業

- 紙漿和造紙

- 石油和天然氣

- 用水和污水處理

- 藥品

- 其他最終用戶產業

- 按地區

- 印度

- 中國

- 日本

- 其他亞太地區

第7章 競爭格局

- 公司簡介

- ABB Ltd

- Mitsubishi Electric Corporation

- Schneider Electric SE

- Rockwell Automation

- Siemens AG

- Honeywell International Inc.

- Omron Corporation

- Panasonic Corporation

- Robert Bosch GmbH

- Emerson Electric Co.(GE)

- Hitachi Ltd

- Toshiba International Corporation

第8章投資分析

第9章:未來市場展望

The Asia-Pacific Programmable Logic Controller Market size is estimated at USD 4.81 billion in 2025, and is expected to reach USD 6.19 billion by 2030, at a CAGR of 5.2% during the forecast period (2025-2030).

PLC is the primary computing system that controls automated machines. The system also helps detect any errors or flaws and alerts the technician. PLC systems are also preferred over traditional systems, like relays and switch boxes, due to their compact sizes. Another advantage of PLCs is their multi-functionality, owing to their programmable nature that can be used for multiple operations depending on the application.

Key Highlights

- PLCs are crucial to any production line, and as the fourth industrial revolution, more internet-connected sensors and systems are interfacing with PLCs. For instance, in a food and beverage manufacturing facility that produces ingredients for chocolate or baking, it is important to track all chemicals in a mixture and monitor critical events, such as a faulty boiler. In recent years it has become possible for robots to handle delicate food items directly. The arrival of new and improved gripper technology and innovative vision systems has transformed the industry. For instance, improvements in gripper technology that mimics human touch make it possible for robots to pack fruits and vegetables.

- The adoption of industrial control systems, with many businesses offering diverse solutions, has aided the market's expansion in India, defined by recent innovations. For example, Delta Electronics sells various automation products and solutions, such as human-machine interfaces, sensors, and robots. In March 2021, ABB India reported that it had attained a cumulative 5-gigawatt milestone in providing PLC-based solar plant automation in India.

- Japan intends to attain "Society 5.0" by fully leveraging the fourth industrial revolution's technology innovation, such as IoT, AI, and Big Data. To achieve this, the government established 'Connected Industries,' a new framework in which industries are expected to develop innovative solutions to societal problems by connecting many aspects of modern life, such as persons, machines, systems, and businesses. Such policies will drive the studied market.

- Due to the demand for high-voltage operating devices, Nano PLCs have also been a popular choice among discrete sectors and small businesses. Because of its simplicity of control at high voltages, fixed nano PLCs are employed in electronic applications like converters, inverters, and other base controllers. Furthermore, PLCs' ability to perform a single set of tasks with superior reliability and performance, except under real-time constraints, combined with their ability to withstand extreme temperatures, humidity, vibration, and electrical noise, has propelled PLCs' adoption in a variety of industrial applications.

- The recent coronavirus outbreak has been causing significant disruption to the global economy and has drastically changed how many industries operate daily. With work-from-home protocols implemented and shelter-in-place orders continue to propagate, allied market players evaluated and revised their preparedness and response strategies for cyber-incidents. This is particularly evident for players that have implemented industrial control systems (ICS) (PLC) to monitor and control critical equipment and processes.

APAC Programmable Logic Controller Market Trends

Automotive Industry Driving Significant Growth

- PLCs are used in the automotive sector to replace hard-wired relay logic systems with flexible, durable, and easily programmable controllers. For instance. According to Japan Automobile Manufacturing Association, In 2021, Japanese automakers are expected to produce roughly 16.46 million automobiles outside of Japan, up from 15.38 million in the previous year. This was more than double the amount produced in the United States. Such Huge production will create an opportunity for the studied market to grow in the region.

- Successful integration of different automation stages in the automobile manufacturing industry leads to value creation in the supply chain, which ensures a long-term competitive edge and price reduction for the domain. India's EV finance industry is expected to reach INR 3.7 lakh crore (USD 50 billion) by 2030, according to Rocky Mountain Institute (RMI) and NITI Aayog. According to a survey by the India Energy Storage Alliance, the EV market in India is expected to grow at a CAGR of 36% until 2026.

- A brand like Hyundai has been investing heavily in smart mobility solutions to stay ahead of its competitors. With cars becoming smarter and more connected, having a company specializing in robotics and AI can be a great asset in the long run. In June 2021, Hyundai Motor Company recently confirmed that they had bought a controlling interest in Boston Dynamics from SoftBank. According to the deal, the American robotics developer has been valued at USD 1.1 billion, and Hyundai has 80 % shares while SoftBank still owns 20%. This will provide local players to develop new products or incorporate new features in the existing products to cater to the need of the customer.

- Machine downtime is one of the significant factors that impact the automobile manufacturing efficiency of an industry. According to data from ISA.org ( International Society of Automation), it has been observed that downtime is responsible for 5-20% of the manufacturing losses incurred during operation. Machine downtime can be reduced from 20% to 4% by using automated PLC systems. The increased need for reducing system downtime is driving the growth of the market studied. Their capabilities make PLCs more exclusive than conventional personal computers (PCs) and workstation arenas. The PLCs can share data rapidly within and between companies. This rapid data sharing has helped reduce downtime as PLCs can automate the FTP and web servers, international databases, and email sending.

- I/O modules are devices that transfer data to or from a computer, such as a PLC. The growing field devices such as sensors and actuators drive the need for I/O modules. The sensor signal representing a process variable such as liquid flow is converted by an Input I/O module and stored in the PLC. The actuator receives an operating signal from an I/O module.

China is one of the Region Driving the Market

- The Firms in the region are developing new products to carter the wide range needs of the customer. For instance, in July 2021, Shanghai Baosight Software Co Ltd launched a huge programmable logic controller product that was created in-house. Baosight Software independently studied and created the huge PLC product, a crucial component in industrial control systems. Baosight has finally conquered the technology problems in precise control and high-speed communication after a decade of dedicated research.

- Furthermore, The companies in the region are enhancing their product portfolio to meet the demands of different end users. For Example, SINOVO PLC is a programmable logic memory controller with many applications. Machine tool, textile, package, printing, plastic cerement, paper-making, pharmacy, petroleum, chemical industry, elevator, hoisting machines, cables, ceramics, building automation, fan pumps, vehicles, rail transit, CNC machine tools, and other systems and control equipment all use SINOVO electric products.

- The market studied is strongly impacted by the industrial output and the investment funneled into computers and software. These PLC systems have traditionally been the foundation of process and discrete factory automation. The growing adoption of Industry 4.0 across the industrial verticals augmented the market studied.

- The demand for factory automation includes the demand for automated production lines and supply chain and has driven it towards the factory automation sphere and has been supported by favorable investments. Several investments mark the country to further the growth of the studied market, with major key players expanding into the region and the injection of funds by venture capitalists into the emerging start-ups with potential. For instance, in April 2021, Youibot, a start-up company that makes industrial robots, closed an investment of USD 15.47 million in the funding round led by SoftBank Ventures Asia alongside others. The company generates 80% of its annual revenue in China and has plans to spend the raised funds on research and development.

- In a drive to boost the sector's technology and market competitiveness in a new phase of severe global competition in advanced manufacturing, In December 2021, China launched a five-year plan for smart manufacturing, promising that large manufacturers will complete digitalization by 2025. According to the plan, more than 70% of large-scale Chinese firms should be digitalized by 2025, and more than 500 demonstration manufacturing facilities will be created around the country. Also, according to the strategy, intelligent manufacturing equipment and industrial software's technological level and market competitiveness should be significantly increased, with market satisfaction rates exceeding 70% and 50%, respectively.

APAC Programmable Logic Controller Industry Overview

The Asia-Pacific Programmable Logic Controller Market is a moderately competitive market with significant players like ABB Ltd., Mitsubishi Electric Corporation, Schneider Electric SE, Rockwell Automation, etc. The players in the market are innovating advanced products through collaborations, mergers, and extensive R&D investments.

- January 2022- ABB, an automation expert, and HASCO, China's significant automotive components supplier, announced the formation of a joint venture to push China's automotive industry's next generation of smart production. The joint venture will build on the two businesses' current successful partnership, resulting in the vital development of highly flexible and sustainable car parts production within HASCO's China operations.

- February 2021- Honeywell agreed to offer integrated control, telecommunications, safety, and security systems to the King Salman International Complex for Maritime Industries and Services shipyard under a deal with SEPCO Electric Power Construction Corporation (SEPCO). ControlEdgeProgrammable Logic Controllers (PLCs), Data Concentrators, Safety Manager SCs, and Experion Process Knowledge System (PKS) Supervisory Control and Data Acquisition (SCADA) systems are all included.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Deliverables

- 1.2 Study Assumptions

- 1.3 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Bargaining Power Of Suppliers

- 4.2.2 Bargaining Power Of Buyers

- 4.2.3 Threat Of New Entrants

- 4.2.4 Threat Of Substitutes

- 4.2.5 Intensity Of Competitive Rivalry

- 4.3 Value Chain Analysis

- 4.4 Assessment of the Impact of Covid-19 on the Market

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Increased deployments of programmable logic controller system in automotive industry.

- 5.1.2

Technological advancements in manufacturing industry.

- 5.2 Market Restraints

- 5.2.1 High Cost of Adoption

6 MARKET SEGEMENATION

- 6.1 By Type

- 6.1.1 Hardware and Software

- 6.1.1.1 Large PLC

- 6.1.1.2 Nano PLC

- 6.1.1.3 Small PLC

- 6.1.1.4 Medium PLC

- 6.1.1.5 Software

- 6.1.1.6 Other Types

- 6.1.2 Services

- 6.1.1 Hardware and Software

- 6.2 By End User

- 6.2.1 Food, Tobacco, and Beverage

- 6.2.2 Automotive

- 6.2.3 Chemical and Petrochemical

- 6.2.4 Energy and Utilities

- 6.2.5 Pulp and Paper

- 6.2.6 Oil and Gas

- 6.2.7 Water and Wastewater Treatment

- 6.2.8 Pharmaceutical

- 6.2.9 Other End-user Industries

- 6.3 By Geography

- 6.3.1 India

- 6.3.2 China

- 6.3.3 Japan

- 6.3.4 Rest of Asia-Pacific

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 ABB Ltd

- 7.1.2 Mitsubishi Electric Corporation

- 7.1.3 Schneider Electric SE

- 7.1.4 Rockwell Automation

- 7.1.5 Siemens AG

- 7.1.6 Honeywell International Inc.

- 7.1.7 Omron Corporation

- 7.1.8 Panasonic Corporation

- 7.1.9 Robert Bosch GmbH

- 7.1.10 Emerson Electric Co. (GE)

- 7.1.11 Hitachi Ltd

- 7.1.12 Toshiba International Corporation