|

市場調查報告書

商品編碼

1687820

工業感測器:市場佔有率分析、行業趨勢和統計、成長預測(2025-2030 年)Industrial Sensors - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

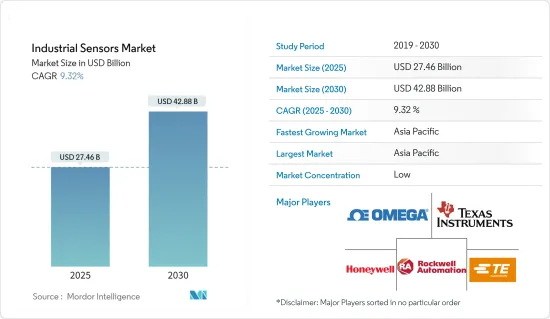

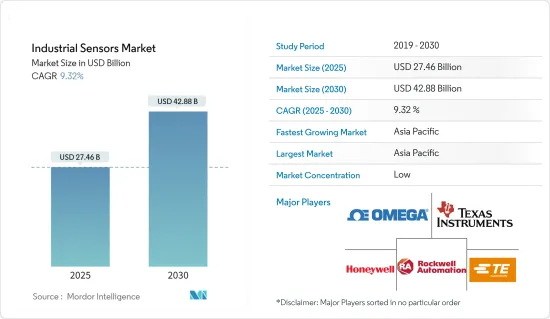

預計 2025 年工業感測器市場規模為 274.6 億美元,預計到 2030 年將達到 428.8 億美元,預測期內(2025-2030 年)的複合年成長率為 9.32%。

主要亮點

- 工業感測器在現代製造和生產過程中至關重要,可提供提高效率、安全性和生產力的許多好處。這些感測器的主要優點是它們能夠即時監測和收集資料。此功能使企業能夠快速追蹤績效指標,識別異常並做出明智的決策。感測器提供持續的回饋,使公司能夠微調流程、最大限度地減少停機時間並提高整體營運效率。

- 工業感測器在確保職場安全方面也發揮著至關重要的作用。透過監測溫度、壓力和氣體水平等環境參數,這些感測器可以在危險情況發生之前識別它們。例如,氣體洩漏感測器可以快速向工人發出警報,以便及時干預,防止事故發生並保護工人。

- 此外,這些感測器將開啟預測性維護的時代。透過檢查感測器的資料,公司可以識別機器的磨損情況,並在故障發生之前規劃維護。這種積極主動的策略不僅可以避免昂貴的維修,還可以延長設備的使用壽命,從長遠來看可以節省大量成本。

- 工業感測器也處於自動化和製造業採用智慧技術的前沿。蓬勃發展的物聯網 (IoT) 使感測器能夠與其他設備交互,從而創建互聯系統,從而增強流程自動化和資料共用。這種協同效應不僅簡化了營運,而且還增強了資源管理和能源效率,從而降低了營運成本。

- 工業自動化的激增正在推動工業感測器市場的發展。從機器人到流程自動化,隨著製造商尋求提高效率和降低營運成本,自動化技術正在獲得發展動力。在這些情況下,感測器至關重要,它提供即時資料,有助於決策並提高業務效率。隨著智慧工廠和工業 4.0 的發展勢頭日益強勁,對監控、控制和改進流程的感測器的需求比以往任何時候都高。

- 雖然感測器整合增強了工業自動化,但也有成本,限制了其在預算敏感型應用中的採用。此外,新產品開發所需的高額研發成本也是一個重大挑戰,特別是對於融資有限的中小型感測器製造商而言。這些製造商通常發現很難投入足夠的資源進行創新和保持市場競爭力所必需的廣泛研究和開發。因此,他們有可能落後於那些有財力大力投資新興科技的大公司。

工業感測器市場趨勢

影像感測器類型預計將佔據主要市場佔有率

- 工業影像感測器在各種工業環境中獲取視覺資料方面發揮關鍵作用。這些設備對於自動檢查、品管和監控系統至關重要。透過將光轉換為電子訊號,它們可以實現缺陷檢測、尺寸測量、物體識別和生產線監控。這些感測器主要用於製造業、汽車業、機器人和電子業等領域,是機器視覺系統的基礎,使自動化系統能夠解釋視覺資料並做出反應。

自動化和機器視覺系統的採用日益增多

- 隨著自動化的進步,特別是製造業和品管產業,對工業影像感測器的需求也不斷增加。這些感測器對於機器視覺系統至關重要,可以快速檢查產品缺陷,確保組裝的準確性並全面提高生產效率。此外,隨著工業 4.0 的到來和智慧工廠的興起,自動化環境中對這些感測器的需求只會成長。

- 根據國際機器人聯合會(IFR)預測,2023年全球工業機器人出貨量將達到約59.3萬台,較前一年大幅成長。預測到 2026 年出貨量將成長至約 718,000 台。

- 此外,2023 年 5 月,康耐視宣布推出 Advantage 182 視覺系統,這是一款由人工智慧驅動的解決方案,旨在簡化生命科學OEM 的定位、分類和檢查等複雜任務。為了滿足日益成長的需求,許多供應商正在推出新產品,凸顯影像感測器在先進工業機器人和機器視覺系統中的重要性。

- 在工業環境中,檢查已變得至關重要。影像感測器使工廠操作員能夠更快地檢查並更好地發現缺陷。例如,ams Osram 於 2023 年 1 月擴展了其 Mira 系列高靈敏度全球百葉窗CMOS 影像感測器,推出了 2.3mm x 2.8mm、0.5M 像素的 Mira050。

- 2024 年 4 月,OMNIVISION 推出了兩款專為機器視覺應用設計的新型 CMOS World 百葉窗 (GS) 影像感測器。該公司還成立了專門的機器視覺部門,主導工業自動化、機器人、物流條碼掃描和智慧型運輸系統(ITS)等領域的創新。

- 這些新推出的感測器因其影像處理性能而脫穎而出,適合需要高動態、高精度和快速響應時間的應用。 OG05B1B 擁有 500 萬像素 (MP) 解析度和 1/2.53 吋光學格式 (OF),而專為工廠自動化和 ITS 設計的 OG01H1B 則提供 1.5MP 解析度和 1/4.51 吋 OF。預計這些戰略舉措和進步將在可預見的未來推動該行業的成長。

預計亞太地區市場將大幅成長

- 中國迅速採用機器人取代人類工人預計將推動市場成長。在中國,製造效率依賴自動化,導致對確保機器人功能的感測器的需求激增。

- 日本正面臨日益嚴重的勞動力短缺問題,製造商開始轉向自動化、機器人和工業 4.0 解決方案等最尖端科技。經濟合作暨發展組織(OECD)強調了日本的人口挑戰。日本是世界上老化程度最高的國家,過去10年日本老齡人口減少了270多萬人。預測表明,到 2065 年,總勞動人口將下降 40%。因此,可以使用先進的製造技術來提高生產力和能源效率,同時減少產品缺陷。這種方法直接解決了勞動力短缺的問題,並擴大了自動化工廠對工業感測器的需求。

- 日本處於自動化工業革命的前沿,正迅速擁抱工業4.0。作為工廠自動化產品的製造地,日本不僅滿足國內需求,也供應亞太地區的其他市場。韓國的多元化產業進一步凸顯了其重要性,其中包括多家汽車製造公司、電子公司和食品加工公司。

- 韓國汽車業從最初的政府主導型發展成為大型跨國公司主導的產業。隨著起亞汽車、現代汽車、雷諾集團等產業領導企業的地位穩固,韓國汽車需求正走在持續成長的道路上。

- 在印度和東南亞,各領域的大量投資正在推動工業感測器需求的激增。

- 隨著東南亞汽車製造商對具有自動駕駛功能的電動車 (EV) 日益成長的需求做出反應,戰略夥伴關係變得至關重要。 2024 年 1 月,電動車充電器製造先驅、全球汽車巨頭的重要盟友 Exicom 與泰國能源創新公司 InnoPower Company Limited 簽署了分銷協議。此次合作將徹底改變泰國的電動車格局,InnoPower 現已銷售 Exicom 的 AC/DC 充電器。透過建立本地銷售和分銷網路,Exicom 將鞏固其在東南亞的地位。此外,感測器整合到生產線中預計將推動對具有更長檢測範圍的接近感測器的需求。

工業感測器產業概況

工業感測器市場分散,主要企業包括德州儀器公司、TE Connectivity 公司、Omega Engineering 公司、霍尼韋爾國際公司、羅克韋爾自動化公司、西門子股份公司和義法半導體公司。市場參與企業正在推出各種創新產品,以滿足消費者不斷變化的需求。此外,市場也建立了重要的聯盟和夥伴關係。市場參與者希望擴大影響力以滿足日益成長的工業感測器需求,而擴張和收購可能會推動未來的市場成長。

此外,隨著自動化在所有終端用戶行業中獲得認可,預計未來幾年市場將顯著成長。這提高了該行業的盈利。因此,新進入者的威脅很高。

其他福利:

- Excel 格式的市場預測 (ME) 表

- 3 個月分析師支持

目錄

第 1 章 簡介

- 研究假設和市場定義

- 研究範圍

第2章調查方法

第3章執行摘要

第4章 市場洞察

- 市場概況

- 產業價值鏈分析

- 產業吸引力-波特五力分析

- 供應商的議價能力

- 買家的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭對手之間的競爭強度

- COVID-19 和其他宏觀經濟因素將如何影響市場

- 技術簡介

第5章 市場動態

- 市場促進因素

- 物聯網的日益普及推動對感測元件的需求

- 更重視預測性維護和遠端監控

- 市場限制

- 成本和營運問題

第6章 市場細分

- 依感測器類型

- 流動

- 壓力

- 鄰近度(區域)

- 液位測量

- 溫度測量

- 影像

- 光電

- 其他感測類型

- 按最終用戶產業

- 化工和石化

- 礦業與金屬

- 力量

- 飲食

- 生命科學

- 航太和軍事

- 用水和污水

- 其他行業

- 按地區

- 北美洲

- 美國

- 加拿大

- 歐洲

- 德國

- 英國

- 法國

- 亞洲

- 中國

- 日本

- 韓國

- 澳洲和紐西蘭

- 拉丁美洲

- 中東和非洲

- 北美洲

第7章 競爭格局

- 公司簡介

- Texas Instruments Incorporated

- TE Connectivity Inc.

- Omega Engineering Inc.

- Honeywell International Inc.

- Rockwell Automation Inc.

- Siemens AG

- STMicroelectronics Inc.

- ams AG

- NXP Semiconductors NV

- Infineon Technologies AG

- Bosch Sensortec GmbH

- Sick AG

- ABB Limited

- Omron Corporation

第8章 限位開關分析

- 當前市場狀況

- 市場動態

第9章投資分析

第10章 市場機會與未來趨勢

The Industrial Sensors Market size is estimated at USD 27.46 billion in 2025, and is expected to reach USD 42.88 billion by 2030, at a CAGR of 9.32% during the forecast period (2025-2030).

Key Highlights

- In modern manufacturing and production processes, industrial sensors are indispensable, offering numerous advantages that boost efficiency, safety, and productivity. A key benefit of these sensors is their capability to monitor and gather real-time data. This feature empowers businesses to swiftly track performance metrics, identify anomalies, and make informed decisions. With sensors delivering continuous feedback, organizations can fine-tune processes, minimize downtime, and enhance overall operational efficiency.

- Industrial sensors also play a pivotal role in ensuring workplace safety. By monitoring environmental parameters like temperature, pressure, and gas levels, these sensors can preemptively identify hazardous situations. For example, gas leak sensors can promptly alert personnel, facilitating timely interventions that prevent accidents and safeguard workers.

- Furthermore, these sensors usher in the era of predictive maintenance. By scrutinizing data from sensors, companies can pinpoint machinery wear and tear and scheduling maintenance before failures strike. This forward-thinking strategy not only curtails expensive repairs but also prolongs equipment lifespan, culminating in substantial long-term savings.

- Industrial sensors are also at the forefront of automation and the adoption of smart technologies in manufacturing. With the burgeoning Internet of Things (IoT), sensors can interact with other devices, forging an interconnected system that amplifies process automation and data sharing. This synergy not only streamlines operations but also bolsters resource management and energy efficiency, leading to reduced operational costs.

- The surge in industrial automation is propelling the industrial sensors market. As manufacturers chase heightened efficiency and leaner operational costs, automation technologies, from robotics to process automation, are gaining traction. In this landscape, sensors are vital, offering real-time data that sharpens decision-making and boosts operational efficiency. With the momentum towards smart factories and Industry 4.0, the appetite for sensors that can monitor, control, and refine processes is witnessing an unprecedented surge.

- While integrating sensors enhances industrial automation, it also incurs costs, restricting their adoption in budget-sensitive applications. Additionally, the substantial R&D expenses associated with new product development present a major challenge, particularly for small and medium-sized sensor manufacturers with limited cash flow. These manufacturers frequently find it challenging to dedicate adequate resources to extensive research and development, which is vital for innovation and maintaining market competitiveness. Consequently, they risk falling behind larger firms that have the financial capacity to invest significantly in emerging technologies.

Industrial Sensors Market Trends

Image Sensors Type Segment is Expected to Hold Significant Market Share

- Industrial image sensors play a crucial role in capturing visual data across various industrial environments. These devices are essential for automated inspections, quality control, and monitoring systems. By converting light into electronic signals, they facilitate defect detection, dimension measurement, object identification, and production line monitoring. While primarily used in sectors like manufacturing, automotive, robotics, and electronics, these sensors are fundamental to machine vision systems, allowing automated systems to interpret and respond to visual data.

Rising Adoption of Automation and Machine Vision Systems

- As industries, especially in manufacturing and quality control, increasingly embrace automation, the demand for industrial image sensors is on the rise. These sensors are pivotal to machine vision systems, enabling swift product inspections for defects, ensuring precision on assembly lines, and enhancing overall production efficiency. Furthermore, with the advent of Industry 4.0 and the rise of smart factories, the demand for these sensors in automated environments is set to grow.

- According to the International Federation of Robotics (IFR), global shipments of industrial robots hit around 593,000 units in 2023, showing a significant increase from the previous year. Forecasts suggest these shipments will climb to approximately 718,000 units by 2026.

- Additionally, in May 2023, Cognex unveiled its Advantage 182 vision system, an AI-driven solution designed for OEMs in the life sciences sector, aimed at simplifying complex tasks like location, classification, and inspection. Given the rising demand, many vendors are rolling out new products, underscoring the importance of image sensors in advanced industrial robots and machine vision systems.

- Inspections have gained paramount importance in industrial environments. With image sensors, factory operators can more adeptly spot defects during rapid inspections. For instance, in January 2023, ams OSRAM expanded its Mira family of high-sensitivity, global shutter CMOS image sensors by launching the 2.3mm x 2.8mm, 0.5Mpixel Mira050.

- In April 2024, OMNIVISION unveiled two state-of-the-art CMOS global shutter (GS) image sensors designed for machine vision applications. The company has also set up a specialized machine vision unit to lead innovations in areas like industrial automation, robotics, logistics barcode scanning, and intelligent transportation systems (ITS).

- These newly launched sensors stand out in imaging performance, particularly for applications that require high dynamics, precision, and quick responsiveness. The OG05B1B boasts a 5-megapixel (MP) resolution in a 1/2.53-inch optical format (OF), while the OG01H1B, designed for factory automation and ITS, offers a 1.5MP resolution in a 1/4.51-inch OF. Such strategic initiatives and advancements are anticipated to drive the segment's growth in the foreseeable future.

Asia Pacific Expected to Witness Significant Growth in the Market

- China's swift embrace of robots to supplant human workers is poised to propel market growth. As manufacturing efficiency hinges on automation in China, the demand for sensors ensuring robot functionality is set to surge.

- Japan's pressing workforce shortages are steering manufacturers towards cutting-edge technologies, including automation, robotics, and Industry 4.0 solutions. The Organisation for Economic Co-operation and Development (OECD) highlights Japan's demographic challenges: the nation boasts the world's oldest population and has seen a decline of over 2.7 million in the last decade. Projections indicate a staggering 40% drop in the total workforce by 2065. Consequently, leveraging advanced manufacturing technologies not only boosts productivity and energy efficiency but also curtails product defects. This approach directly addresses workforce shortages, amplifying the demand for industrial sensors in automated factories.

- Japan stands at the forefront of the automated industrial revolution, rapidly embracing Industry 4.0. As a manufacturing nexus for factory automation products, Japan not only caters to its domestic needs but also supplies to other markets across the Asia-Pacific. The nation's significance is further underscored by its diverse industries, including multiple automobile manufacturers, electronics, and food processing.

- South Korea's automotive sector, now a global heavyweight, has evolved from its humble, government-controlled beginnings to a landscape dominated by multinational giants. With industry leaders like Kia Corporation, Hyundai Motor Company, and Renault Group firmly established, South Korea is on a trajectory of sustained automobile demand growth.

- Significant investments across diverse sectors are fueling a burgeoning demand for industrial sensors in India and Southeast Asia.

- As Southeast Asian automotive manufacturers navigate the surging demand for electric vehicles (EVs) with automated driving features, strategic partnerships are becoming pivotal. In January 2024, Exicom, a trailblazer in EV charger manufacturing and a vital ally to global automotive giants, inked a distribution deal with Thailand's energy innovation firm, InnoPower Company Limited. This collaboration is set to reshape Thailand's EV landscape, with InnoPower distributing Exicom's AC/DC chargers. By establishing a local sales and distribution network, Exicom fortifies its foothold in Southeast Asia. Furthermore, as production lines meld human workers with sensors, the appetite for proximity sensors boasting extended sensing ranges is anticipated to rise.

Industrial Sensors Industry Overview

The industrial sensors market is fragmented, with several prominent players like Texas Instruments Incorporated, TE Connectivity Inc., Omega Engineering Inc., Honeywell International Inc., Rockwell Automation Inc., Siemens AG, and STMicroelectronics Inc. The market players are launching various innovative products that cater to consumers' evolving requirements. Further, the market has been registering significant collaborations and partnerships. Expansions and acquisitions among the market players to expand their presence to address the increasing demand for industrial sensors would fuel future market growth.

Furthermore, the market is expected to grow at a significant rate in the future due to the increasing acceptance of automation across all end-user industries being captured. This is improving industry profitability. Thus, the threat of new entrants is high.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Value Chain Analysis

- 4.3 Industry Attractiveness - Porter's Five Forces Analysis

- 4.3.1 Bargaining Power of Suppliers

- 4.3.2 Bargaining Power of Buyers

- 4.3.3 Threat of New Entrants

- 4.3.4 Threat of Substitute Products

- 4.3.5 Intensity of Competitive Rivalry

- 4.4 Impact of COVID-19 and Other Macroeconomic Factors on the Market

- 4.5 Technology Snapshot

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Growing Adoption of IoT Leading to Demand for Sensing Components

- 5.1.2 Growing Emphasis on the Use of Predictive Maintenance and Remote Monitoring

- 5.2 Market Restraints

- 5.2.1 Cost and Operational Concerns

6 MARKET SEGMENTATION

- 6.1 By Sensor Type

- 6.1.1 Flow

- 6.1.2 Pressure

- 6.1.3 Proximity (Area)

- 6.1.4 Level Measurement

- 6.1.5 Temperature

- 6.1.6 Image

- 6.1.7 Photoelectric

- 6.1.8 Other Sensing Types

- 6.2 By End User Vertical

- 6.2.1 Chemical and Petrochemicals

- 6.2.2 Mining and Metal

- 6.2.3 Power

- 6.2.4 Food and Beverage

- 6.2.5 Life Sciences

- 6.2.6 Aerospace and Military

- 6.2.7 Water and Wastewater

- 6.2.8 Other End-user Verticals

- 6.3 By Geography

- 6.3.1 North America

- 6.3.1.1 United States

- 6.3.1.2 Canada

- 6.3.2 Europe

- 6.3.2.1 Germany

- 6.3.2.2 United Kingdom

- 6.3.2.3 France

- 6.3.3 Asia

- 6.3.3.1 China

- 6.3.3.2 Japan

- 6.3.3.3 South Korea

- 6.3.4 Australia and New Zealand

- 6.3.5 Latin America

- 6.3.6 Middle East and Africa

- 6.3.1 North America

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Texas Instruments Incorporated

- 7.1.2 TE Connectivity Inc.

- 7.1.3 Omega Engineering Inc.

- 7.1.4 Honeywell International Inc.

- 7.1.5 Rockwell Automation Inc.

- 7.1.6 Siemens AG

- 7.1.7 STMicroelectronics Inc.

- 7.1.8 ams AG

- 7.1.9 NXP Semiconductors NV

- 7.1.10 Infineon Technologies AG

- 7.1.11 Bosch Sensortec GmbH

- 7.1.12 Sick AG

- 7.1.13 ABB Limited

- 7.1.14 Omron Corporation

8 ANALYSIS OF LIMIT SWITCHES

- 8.1 Current Market Scenario

- 8.2 Market Dynamics