|

市場調查報告書

商品編碼

1628850

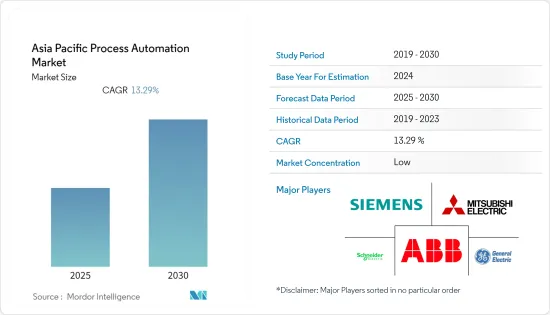

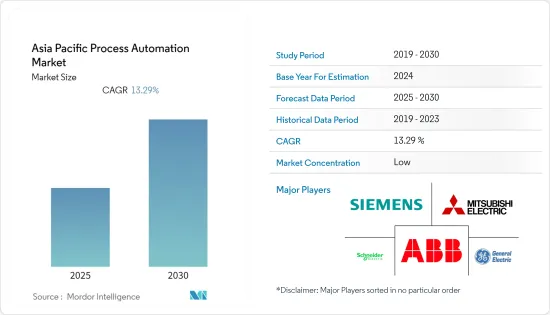

亞太地區流程自動化:市場佔有率分析、產業趨勢與成長預測(2025-2030)Asia Pacific Process Automation - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

價格

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

簡介目錄

亞太地區過程自動化市場預計在預測期內複合年成長率為13.29%

主要亮點

- 自動化產業正在透過結合製造的方面來實現最佳性能而發生革命性的變化。此外,對實現精益生產和縮短時間的關注正在加速市場成長。

- 自動化製造流程提供了許多好處,包括更輕鬆的監控、減少廢棄物和提高生產速度。該技術透過標準化來提高質量,並以低成本按時向客戶提供可靠的產品。

- 連接工業機械和設備並捕獲即時資料在 SCADA、HMI、PLC 系統和提供可視化的軟體的採用中發揮了關鍵作用。因此,您可以減少產品缺陷、減少停機時間、安排維護,並從反應性狀態切換到預測性和規範性狀態以進行決策。

- 此外,自動化控制系統的虛擬,也稱為虛擬機器和主機伺服器之間的薄層,是市場上觀察到的主要趨勢。虛擬機器包含作業系統和軟體。不同的作業系統使用虛擬機器在主作業系統之上運作。虛擬可以應用於工業場所的各層,例如伺服器、儲存、桌面、檔案和網路。好處包括最佳化資源利用和營運以及降低電力成本。

- 產品創新、策略合併和收購等供應商措施預計將推動該領域的需求。新產品被視為一項主要活動。 2020年5月,無線工業自動化和物聯網解決方案供應商OleumTech宣布推出新型智慧壓力變送器(HGPT智慧表壓力變送器)。

- 此外,可以使用虛擬機器在工廠車間的不同位置輕鬆存取單一實體伺服器上的不同工業自動化系統(例如 SCADA、PLC 和 MES)。它的採用是為了降低伺服器總成本並提高流程和離散製造業中採用工業自動化系統和軟體的靈活性。

亞太地區流程自動化市場趨勢

醫藥產業可望佔據較大市場佔有率

- 製藥業由於關注公共衛生安全而受到嚴格監管。準確性、可重複性和控制是自動化系統的主要優勢,有助於提高製藥生產設施的生產率、安全性和清潔度。對流程最佳化、法規遵循和供應鏈增強的需求正在推動整個製藥行業對自動化技術的投資。

- 此外,製造、測試、藥物開發、包裝和分銷等各種流程對流程自動化解決方案的需求不斷成長,是推動製藥業在流程自動化和儀器市場成長的因素之一。

- 此外,由於研磨、製粒、包衣和壓錠劑等複雜的製造程序,許多製藥公司正在進入製程自動化市場。

- 製藥業的系統和流程利用批量自動化和配方管理概念。配方中的輕微變化或甚至一種成分的省略或添加都可能改變藥物的配方或成分。這可能對消費者的健康和生計產生嚴重影響。流程最佳化和自動化確保每批產品的一致性。

- 此外,自動化還提供了更好的製程控制以及遠端監控流程的能力。它可以幫助您自動建立報告、輸入所需資料並即時共用資訊。自動化正在改變製藥業的產品開發、商業製造和即時監控。採用感測器和系統可以推動卓越製造,並幫助公司以最低的成本實現合規性。

印度可望佔較大市場佔有率

- 在工業4.0的推動下,印度不斷創新並鞏固其在工廠自動化和工業控制系統產業全球市場的地位。研究市場中智慧科技的採用也對國民經濟產生正面影響。

- 隨著全球製造業變得更加整合,投資自動化的壓力越來越大。

- 印度智慧工廠的網路攻擊呈上升趨勢,引發了人們對工業控制系統使用的擔憂。政府已計劃遏制此類犯罪的增加。這符合智慧工廠使用國產工業控制系統以避免網路安全漏洞風險的成長趨勢。Honeywell等公司提供 ERP 和許多其他智慧製造解決方案。

- 此外,政府為重振印度遭受疫情打擊的經濟而推出的投資凸顯了基礎設施和電子產業以及中小企業的成長成為主要受益者。基礎設施和電子產業是工業控制系統硬體產品和軟體解決方案的大量用戶,預計將產生直接的正面影響。

- 此外,流程發現、流程最佳化、流程智慧和流程協作等技術和術語正在成為機器人流程自動化 (RPA) 的重要組成部分。未來,業務流程管理(BPM)和RPA之間的關係將繼續變得更加緊密。

亞太地區流程自動化產業概況

亞太地區過程自動化市場較為分散,新參與企業和主導企業都很少。公司不斷創新並結成策略夥伴關係以維持市場佔有率。近期市場發展趨勢如下:

- 2021 年 7 月 - 艾默生電氣公司宣布推出企業級資料管理軟體解決方案 Planet Web Optics Data Lake。

- 2020 年 5 月 - RoviSys 宣布與高階應用程式開發商 VANTIQ 合作,開發可在食品和飲料行業(除關鍵生命科學行業外)檢測和遏制 COVID-19 的應用程式。

其他好處

- Excel 格式的市場預測 (ME) 表

- 3 個月的分析師支持

目錄

第1章簡介

- 研究假設和市場定義

- 調查範圍

第2章 研究方法

第3章執行摘要

第4章市場動態

- 市場概況

- 產業吸引力-波特五力分析

- 供應商的議價能力

- 買方議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭公司之間的敵對關係

- 產業價值鏈分析

- 市場促進因素(日益關注能源效率和降低成本|安全自動化系統的需求|工業物聯網的出現)

- 市場挑戰(成本和實施挑戰)

- 行業標準和法規

- 對日本、中國和印度主要工業自動化中心的分析 - 根據過去三年的投資者活動和擴張活動確定。

第 5 章:評估 COVID-19 對亞太地區流程自動化產業的影響

- 根據疫情中短期影響所確定的關鍵主題分析-V型復甦、中期復甦、低迷復甦

- 中國過程自動化市場:基於最終用戶績效的基礎變數分析

- 日本製程自動化市場:基於最終用戶效能的基礎變數分析

- 印度製程自動化市場:基於最終用戶效能的基礎變數分析

- 供應相關挑戰的影響以及監管在市場振興中的作用

第6章 市場細分

- 按通訊協定

- 有線

- 無線的

- 依系統類型

- 按系統硬體

- 監控和資料採集系統(SCADA)

- 集散控制系統(DCS)

- 可程式邏輯控制器(PLC)

- 製造執行系統(MES)

- 閥門和致動器

- 馬達

- 人機介面 (HMI)

- 製程安全系統

- 感測器和發射器

- 依軟體類型

- APC(獨立和客製化解決方案)

- 先進的監理控制

- 多變量模型

- 推理與連續式

- 基於資料分析和彙報的軟體

- 其他軟體和服務

- 按系統硬體

- 按最終用戶產業

- 石油和天然氣

- 化工/石化

- 電力/公共產業

- 用水和污水

- 飲食

- 紙/紙漿

- 製藥

- 其他最終用戶產業

- 按國家/地區

- 中國

- 印度

- 日本

- 其他亞太地區

第7章 競爭格局

- 公司簡介

- ABB Ltd

- Siemens AG

- Schneider Electric

- General Electric Co.

- Mitsubishi Electric

- Rockwell Automation

- Emerson Electric Co.

- Honeywell International Inc.

- Fuji Electric

- Eaton Corporation

- Delta Electronics Limited

- Yokogawa Electric

第8章過程自動化產業關鍵創新者與挑戰分析

第9章投資分析及市場展望

簡介目錄

Product Code: 55754

The Asia Pacific Process Automation Market is expected to register a CAGR of 13.29% during the forecast period.

Key Highlights

- The automation industry has been revolutionized by combining the digital and physical aspects of manufacturing, aiming to deliver optimum performance. Further, the focus on achieving zero waste production and shorter time to market has augmented the market's growth.

- Automation of manufacturing processes has offered various benefits, such as effortless monitoring, reduction of waste, and production speed. This technology offers customers an improved quality with standardization and dependable products within time and at a much lower cost.

- Connecting the industrial machinery and equipment and obtaining real-time data have played a vital role in the adoption of SCADA, HMI, PLC systems, and software that offer visualization; thus enables reducing the faults in the product, reducing downtime, scheduling maintenance, and switching from being in the reactive state to predictive and prescriptive stages for decision-making.

- Moreover, the virtualization of automation control systems is a key trend observed in the market, also known as the thin layer between the virtual machine and host server. The virtual machine contains the operating system and software. Different operating systems are operated on top of a primary operating system using virtual machines. Virtualization can be applied on layers in an industrial premise, such as server, storage, desktop, file, and network. It provides benefits, such as optimum resource utilization and operation, as well as power cost savings.

- Vendor activity, such as product innovations, strategic mergers, and acquisitions, etc., taking place in the space is expected to drive the demand. New products are considered as the primary activity. In May 2020, OleumTech, wireless industrial automation, and IoT solution provider announced the launch of new smart pressure transmitters (HGPT smart gauge pressure transmitters).

- Further, different industrial automation systems, such as SCADA, PLCs, and MES on a single physical server, can be easily accessed at a different location on the plant floor using virtual machines. It has been adopted to reduce the overall cost for servers and increase the flexibility in adopting industrial automation systems and software in the process and discrete industries.

APAC Process Automation Market Trends

Pharmaceutical Industry is Expected to Hold Significant Market Share

- The pharmaceutical industry is highly regulated due to the importance placed on public health safety. Accuracy, repeatability, and control are the key benefits of an automated system, helping to enhance productivity, safety, and cleanliness in pharmaceutical manufacturing facilities. The need for process optimization, regulatory compliance, and enhancements in the supply chain are driving investment in automation technologies across the pharmaceutical industry.

- Moreover, an increase in the need for process automation solutions to various processes such as manufacturing, testing, drug development, packaging, and distribution are among the factors that are likely to propel the growth in the pharmaceutical industry in the process automation and instrumentation market.

- Additionally, many pharmaceutical companies have entered the market for process automation due to complex manufacturing processes such as milling, granulation, coating, and tablet pressing.

- Systems and processes in pharmaceutical units utilize concepts of batch automation and recipe management. If there is any slight change in the recipe or even a single ingredient is missing/added, the formula and composition of the drug change. This can seriously affect the health and lives of consumers. Process optimization and automation ensure that consistency is maintained in each batch.

- Further, automation offers better control of processes and the ability to monitor processes from remote locations. It assists in automatically creating reports, entering essential data, and sharing real-time information. Automation is transforming pharma concerning product development, commercial production, and real-time monitoring. It can foster manufacturing excellence by adopting sensors and systems to help companies achieve compliance at the lowest costs.

India is Expected to Account For Significant Market Share

- Fuelled by Industry 4.0, India continues to innovate and consolidate its position in the global market in the factory automation and industrial control systems industry. The embracing of smart technologies in the studied market has also positively impacted the national economy.

- Increased global manufacturing integration is raising the pressure for automation investment, as cost minimization with quality maximization looms ever more significantly as an operating paradigm for Indian manufacturers.

- With cyber-attacks increasing in smart factories in India, there is growing concern about using Industrial Control Systems. The government has plans to curb the rise of such crimes. This aligns with the growing trend of the usage of industrial control systems manufactured in the country for smart factories to avoid the risk of cybersecurity breaches. A company like Honeywell completes smart manufacturing solutions, including ERP and numerous others.

- Moreover, with investment roll-outs by the government to revive the pandemic hit India economy, infrastructure, and the electronics industry are marked as the primary beneficiaries alongside the growth of small and medium-sized enterprises. The infrastructure and electronics industry are heavy users of the industrial control systems' hardware products and software solutions and are expected to have a direct positive effect.

- Further, technologies and terminologies such as process discovery, process optimization, process intelligence, and process orchestration are becoming a more significant part of Robotic Process Automation (RPA). There is an ongoing trend of increasing a closer relationship between business process management (BPM) and RPA in the future.

APAC Process Automation Industry Overview

The Asia Pacific Process Automation Market is moderately fragmented, with few new entrants and few dominant players. The companies keep on innovating and entering into strategic partnerships to retain their market share. Some of the recent developments in the market are:

- July 2021 - Emerson Electric Corporation announced the launch of its Planet Web Optics Data Lake, an enterprise-level data management software solution that helps manufacturers reduce data complexity to fully leverage operations data across a production site or from multiple locations to improve profitability enterprise-wide.

- May 2020 - RoviSys announced its collaboration with VANTIQ, a developer of high-end applications to develop applications that can detect and contain COVID-19 in the food and beverage industry, apart from the critical life science sector.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHADOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Buyers

- 4.2.3 Threat of New Entrants

- 4.2.4 Threat of Substitutes

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Industry Value Chain Analysis

- 4.4 Market Drivers (Growing emphasis on energy efficiency & cost reduction| Demand for Safety Automation Systems| Emergence of IIoT)

- 4.5 Market Challenges (Cost & Implementation Challenges)

- 4.6 Industry Standards & Regulations

- 4.7 Analysis of the major Industrial Automation hubs in the Japan, China, and India - To be identified based on the investor activity & expansion activities undertaken over the last 3 years

5 ASSESSMENT OF THE IMPACT OF COVID-19 ON THE PROCESS AUTOMATION INDUSTRY IN ASIA PACIFIC

- 5.1 Analysis of the key themes identified based on the near & medium-term effects of the pandemic - V-shaped recovery, Mid-range recovery & Slump recovery

- 5.2 China Process Automation Market - Base variable analysis based on end-user performance

- 5.3 Japan Process Automation Market - Base variable analysis based on end-user performance

- 5.4 India Process Automation Market - Base variable analysis based on end-user performance

- 5.5 Impact of Supply-related challenges & the role of market regulations in spurring activity

6 MARKET SEGMENTATION

- 6.1 By Communication Protocol

- 6.1.1 Wired

- 6.1.2 Wireless

- 6.2 By System Type

- 6.2.1 By System Hardware

- 6.2.1.1 Supervisory Control and Data Acquisition System (SCADA)

- 6.2.1.2 Distributed Control System (DCS)

- 6.2.1.3 Programmable Logic Controller (PLC)

- 6.2.1.4 Manufacturing Execution System (MES)

- 6.2.1.5 Valves & Actuators

- 6.2.1.6 Electric Motors

- 6.2.1.7 Human Machine Interface (HMI)

- 6.2.1.8 Process Safety Systems

- 6.2.1.9 Sensors & Transmitters

- 6.2.2 By Software Type

- 6.2.2.1 APC (Standalone & Customized Solutions)

- 6.2.2.1.1 Advanced Regulatory Control

- 6.2.2.1.2 Multivariable Model

- 6.2.2.1.3 Inferential & Sequential

- 6.2.2.2 Data Analytics & Reporting-based Software

- 6.2.2.3 Other Software & Services

- 6.2.1 By System Hardware

- 6.3 By End-user Industry

- 6.3.1 Oil and Gas

- 6.3.2 Chemical and Petrochemical

- 6.3.3 Power and Utilities

- 6.3.4 Water & Wastewater

- 6.3.5 Food and Beverage

- 6.3.6 Paper & Pulp

- 6.3.7 Pharmaceutical

- 6.3.8 Other End-user Industries

- 6.4 By Country

- 6.4.1 China

- 6.4.2 India

- 6.4.3 Japan

- 6.4.4 Rest of Asia Pacific

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 ABB Ltd

- 7.1.2 Siemens AG

- 7.1.3 Schneider Electric

- 7.1.4 General Electric Co.

- 7.1.5 Mitsubishi Electric

- 7.1.6 Rockwell Automation

- 7.1.7 Emerson Electric Co.

- 7.1.8 Honeywell International Inc.

- 7.1.9 Fuji Electric

- 7.1.10 Eaton Corporation

- 7.1.11 Delta Electronics Limited

- 7.1.12 Yokogawa Electric

8 ANALYSIS OF MAJOR INNOVATORS & CHALLENGERS IN THE PROCESS AUTOMATION INDUSTRY

9 INVESTMENT ANALYSIS & MARKET OUTLOOK

02-2729-4219

+886-2-2729-4219