|

市場調查報告書

商品編碼

1630307

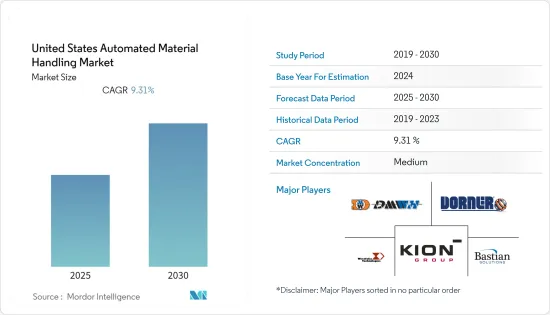

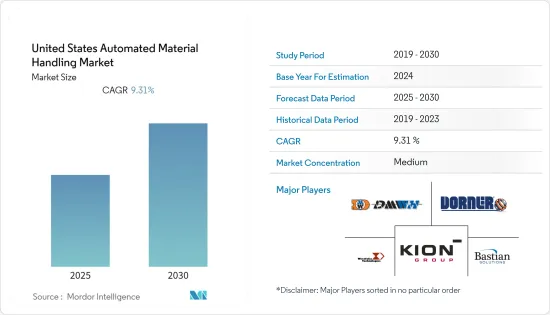

美國自動化物料輸送:市場佔有率分析、產業趨勢、統計與成長預測(2025-2030)United States Automated Material Handling - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

價格

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

簡介目錄

美國自動化物料輸送(AMH) 市場預計在預測期內複合年成長率為 9.31%

主要亮點

- 美國是世界上最發達的經濟體。該國的製造業是AMH市場的龐大需求來源,依賴主導的美國經濟,美國經濟佔該地區經濟產出的82%。

- 此外,由於該地區 AMH 製造商的技術進步率很高,例如自動化、人工智慧和機器學習,美國是全球 AMH 市場的主要投資者和創新者之一,這些技術正在迅速推動該行業的發展。 。在北美,對先進自動化物料輸送系統的需求不斷成長,加上人事費用持續上升以及僱用體力勞動的不便,進一步推動了美國AMH市場的發展。

- 該國的現代化製造設施依靠新技術和創新,以更快的速度和更低的成本生產更高品質的產品。事實證明,引入創新的軟體和硬體是當今競爭激烈的市場中生存的唯一可行方法。

- 例如,FDA 食品安全現代化法案 (FSMA) 將把重點從應對食源性疾病和摻假轉向預防,從而改變食品公司。因此,清洗和衛生已成為美國皮帶製造商的首要任務。不銹鋼也已成為該國流行的食品加工帶類型。美國郵局在採用滾筒輸送機後,在小包裹處理應用中實現了 60% 的節能。

- 此外,該國的物料輸送行業因大流行的爆發而受到嚴重干擾。製造工廠和配送中心的部分營運推遲了新 AMH 系統的訂單。在疫情最嚴重的時候,依賴人工揀貨的倉庫不得不關閉,嚴重影響了全球供應鏈。 DHL 報告稱,美國祇有 5-10% 的履約中心使用自動化系統。

- 然而,供應商在疫情期間努力增強其 AMH 產品。例如,2020年10月,創新供應鏈解決方案供應商StoecklinLogistics推出了動態MASterStacker Cranes(單元貨載ASRS)產品線。該起重機具有高加速度和行進速度、更高的能源效率和模組化結構,從而顯著提高了性能和高水準的可用性。新型起重機還具有更合規、更快的車輪和起吊裝置、不同起重機和負載容量的更高標準化、更快的組裝和製造時間、更輕的結構以及更容易獲取零件以進行維護。

美國自動化物料輸送市場趨勢

自主移動機器人(AMR)預計將佔據主要市場佔有率

- 在物流應用中,AMR 正在取代 AGV。這是因為,與 AGV 不同,AMR 配備了與慣性測量單元 (IMU)、雷射掃描測距儀、2D 和 3D 彩色相機以及馬達控制器相結合的更複雜的機載電腦。此類 AMR 不需要在工廠或倉庫安裝追蹤帶。

- 此外,AMR預計將逐漸取代堆高機。此外,Mobile Industrial Robots Inc.舉措設計了 MiR1,000 AMR。它可承受1000公斤的承重能力,並配備六個雷射掃描器、一個3D相機和一個人工智慧相機。

- 雖然許多物流業務仍然依賴手動或紙質揀選系統,但自主移動機器人現在可以消除大量不必要的步行。根據美國人口普查局的資料分析,倉庫工人平均每年浪費近 7 週時間在不必要的移動上,造成超過 43 億美元的勞動成本。

- 此外,北美機場業是世界上最大的機場業之一。它每年為大約 10.115 億國內和國際乘客提供服務。它也是世界上最大的機場之一的所在地,預計將加強自動化的採用力度,以防止經營模式崩壞。例如,全球自動化行李處理系統供應商 Crisplant 設計、製造並安裝了與加拿大航空運輸安全局 (CATSA) 在加拿大哈利法克斯國際機場部署的安全檢查設備整合的全自動行李處理系統。

- 此外,所研究市場的供應商正在透過併購策略擴大其在該地區的足跡。例如,2020年5月,Geek+與Conveyco達成策略夥伴關係關係,加速AMR(自主移動機器人)解決方案在北美尤其是美國。 Geek+解決方案經過驗證的效率、可擴展性和成本節約將透過這種夥伴關係為該地區所有行業的客戶帶來巨大的價值,實現靈活的物流。

零售業預計將佔據主要市場佔有率

- 美國零售和電子商務領域的顯著成長以及倉儲擴張正在成為市場成長的關鍵驅動力。該地區的大多數零售商計劃實現倉庫自動化,而不是在昂貴的租賃環境中擴大倉庫。根據Robo Business倉庫自動化報告,美國近80%的倉庫仍由人工操作。只有 15% 的倉庫實現了機械化,自動化程度不到 5%。這為 AMH 市場在預測期內在美國各地持續成長提供了一條漫長的道路。

- 此外,美國是該地區的主要零售市場之一。據估計,每年全國三分之二以上的GDP來自零售消費。該國的電子商務部門的銷售額持續超過實體店。隨著自動化成為關鍵的差異化因素,線上零售商和全通路零售商之間的競爭日益加劇。

- 零售業是對輸送機等自動物料輸送系統有至關重要要求的主要產業之一。輸送機極大地幫助線上零售商移動貨物並提高配送效率。此外,越來越多的零售商正在投資擴大倉庫空間。例如,黑石集團投資 187 億美元建造 1.79 億平方英尺的倉庫空間,以滿足美國不斷成長的零售需求。亞馬遜公司是另一個例子,利用自動化技術來解決倉庫激增的問題。近年來,該公司引進了自動物料輸送機,並為其倉庫增添了許多先進的輸送機技術。

- 為了滿足電子商務通路不斷成長的需求,多家公司正在該地區推出履約物流中心。例如,2020年12月,PFS宣佈在達拉斯地區開設一個新的履約物流中心,以經營四個品牌的履約計畫。履約中心通常配備多個輸送機系統以有效地輸送產品,這些擴張活動預計將對美國輸送機市場產生積極影響。

- 然而,由於 COVID-19 疫情的爆發,2020 年 3 月、4 月和 5 月的零售銷售疲軟。這些因素對這幾個月美國零售業中自動化物料輸送的使用產生了負面影響。然而,零售業在 2020 年下半年出現了大幅成長,恢復了 AMH 等自動化系統的使用。

美國自動化物料輸送產業概況

美國自動化物料輸送市場細分且競爭激烈。產品推出、高額研發投入、夥伴關係與收購是國內企業維持激烈競爭所採取的主要成長策略。

- 2021 年 1 月 - TGW Logistics Group 計劃將美國輸送機資產出售給 Material Handling Systems, Inc. (MHS)。兩家公司已簽署協議,收購預計將於 2021年終生效。林肯國際公司在整個併購過程中為 TGW 提供指導。透過此次出售,TGW 將調整其策略性投資組合,專注於其在北美不斷成長的綜合業務。

- 2020 年 7 月 - 范德蘭德開發了 HOME PICK,這是一種獨特的 3D、基於穿梭機的自動存儲和搜尋系統(AS/RS),該系統基於由ADAPTO 提供支援的貨到人(GtP) 揀選解決方案。非常適合食品零售商透過集中履約中心 (CFC) 實現規模經濟。使用 ADAPTO 和模組化工作站,HOMEPICK 的可擴充性是面向未來的。有序訂單可確保每個配送路線的正確訂單和最大的配送效能,從而節省大量時間和成本。

其他好處

- Excel 格式的市場預測 (ME) 表

- 3 個月分析師支持

目錄

第1章簡介

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章市場洞察

- 市場概況

- 產業吸引力-波特五力分析

- 供應商的議價能力

- 買方議價能力

- 新進入者的威脅

- 競爭公司之間的敵對關係

- 替代品的威脅

- 產業價值鏈分析

- COVID-19 市場影響評估

第5章市場動態

- 市場促進因素

- 增加製造複雜性和技術可用性

- 對提高訂單準確性和增加 SKU 的需求不斷成長

- 智慧城市物流的出現以及機器人技術在倉儲應用上的普及

- 市場限制因素

- 供應鏈技能差距與勞動力短缺

- 初始成本高

第6章 市場細分

- 依產品類型

- 硬體

- 軟體

- 服務

- 依設備類型

- 自動導引運輸車(AGV)

- 自動堆高機

- 自動拖車/曳引機/標籤

- 單元貨載

- 組裝

- 特殊用途

- 自主移動機器人(AMR)

- 雷射導引車

- 自動儲存和搜尋系統(ASRS)

- 固定通道(堆垛機高機+穿梭系統)

- 輪播(水平輪播+垂直輪播)

- 垂直升降模組

- 自動輸送機

- 腰帶

- 滾筒

- 調色盤

- 開賣

- 堆垛機

- 常規型(高電位+低電位)

- 機器人

- 分類系統

- 自動導引運輸車(AGV)

- 按最終用戶產業

- 飛機場

- 車

- 飲食

- 零售/倉庫/配送中心/物流中心

- 一般製造業

- 藥品

- 小包裹

- 其他

第7章 競爭格局

- 公司簡介

- Kion Group AG

- Bastian Solutions Inc.

- DMW&H

- Westfalia Technologies Inc.

- Dorner Manufacturing Corporation

- Cornerstone Automation Systems LLC

- Oceaneering International Inc.

- Aethon Inc.

- Daifuku Co. Ltd

- Remtec Automation

- Siggins Company

- Honeywell Intelligrated

- Vanderlande Industries BV

第8章投資分析

第9章 市場機會及未來趨勢

簡介目錄

Product Code: 67237

The United States Automated Material Handling Market is expected to register a CAGR of 9.31% during the forecast period.

Key Highlights

- The United States is the most advanced economies in the world. The country's manufacturing sector, which is a huge source of demand for the AMH market, hinges on the dominant US economy, accounting for 82% of the region's economic output.

- Moreover, United States is one of the major investors and innovators in the global AMH market owing to the high rate of technological advancements among regional AMH manufacturers, such as automation, AI, and machine learning, and are rapidly driving the industry forward. Increasing demand for advanced automated material handling systems and ever-increasing labor costs with the inconvenience of employing a manual workforce in North America is further driving the United States AMH market.

- Modern manufacturing facilities in the country rely on new technologies and innovations to produce higher quality products at faster speeds, with lower costs. Implementing innovative software and hardware proves the only feasible way to survive in the current competitive market.

- For instance, the FDA Food Safety Modernization Act (FSMA) transforms food companies by shifting the focus from responding to foodborne illness and foreign material contamination to preventing it. As a result, cleanability and sanity have become the biggest priorities of belt manufacturers in the US. Stainless steel also emerged as a popular belt type for food processing in the country. The US post offices also witnessed a 60% energy savings in parcel-handling applications after employing roller conveyors.

- Furthermore, the material handling industry in the country has been significantly disrupted due to the pandemic outbreak. Partial operations within manufacturing facilities and distribution centers have resulted in delayed orders for new AMH systems. During the peak pandemic, warehouses that used manual picking had to halt their operations, thus severely impacting the global supply chain. DHL reported that only 5-10% of the fulfillment centers in the United States are using automated systems already.

- However, vendors strived to enhance their AMH product offerings during the pandemic. For instance, in October 2020, StoecklinLogistics, a supplier of innovative supply chain solutions, introduced a line of dynamic MASTerStacker Cranes (unit load ASRS) that feature high acceleration and moving speeds, improved energy efficiency, and modular construction that delivers vastly improved performance and high levels of availability. The new cranes also have more straightforward and faster wheels and hoists, greater standardization across different cranes and load-carrying capacities, shorter assembly and manufacturing times, lighter construction, and improved accessibility to components for maintenance.

US Automated Material Handling Market Trends

Autonomous Mobile Robots (AMR) is Expected to Hold Significant Market Share

- AMRs are replacing AGVs in logistical applications. This is because, unlike AGVs, AMRs incorporate more sophisticated onboard computers that are coupled to inertial measurement units (IMU), laser scanning range finders, 2D and 3D color cameras, and motor controllers. Such AMRs do not require tracking strips to be placed in a factory or warehouse.

- Moreover, it is expected that AMRs would gradually replace forklifts in particular too. Further, Mobile Industrial Robots Inc. has taken the first initiative to design the MiR1000 AMR. It can tolerate a payload of 1000kg and equip with six laser scanners, 3D cameras, and an artificially intelligent camera.

- While many logistics operations still rely on manual and paper-based picking systems, autonomous mobile robots can now eliminate a lot of unnecessary walking. According to US Census Bureau data analysis, the average warehouse worker wastes nearly seven weeks per year in unnecessary motion, accounting for more than USD 4.3 billion in labor.

- Moreover, the North American airport industry is one of the largest airport industries in the world. It provides services to about 1,011.5 million domestic and international passengers every year. It is also home to some of the world's biggest airports and is expected to bolster the adoption of automation to ensure no disruptions in the business model. For instance, Crisplant, a foremost global supplier of automated baggage handling systems, designed, manufactured, and installed fully automated baggage handling systems, integrated with the security screening equipment deployed by the Canadian Air Transport Security Authority (CATSA), in Canada's Halifax International Airport.

- Further, vendors in the studied market are expanding their foothold in the region by the merger and acquisition strategy. For instance, in May 2020, Geek+ and Conveyco entered into a strategic partnership to accelerate access to AMR (Autonomous Mobile Robot) solutions in North America, especially in the United States. The demonstrated efficiency, scalability, and cost-saving of Geek+ solutions will bring significant value and enable flexible logistics for customers across industries in the region through this partnership.

Retail Industry is Expected to Hold Significant Market Share

- The significant growth of the United States retail and e-commerce sector and warehouse expansion is becoming a primary driver of market growth. Most of the region's retailers plan to automate their warehouse establishments rather than expand in a high-priced rental environment. According to the Robo Business Warehouse Automation Report, almost 80% of the United States' warehouses are still manually operated. Only 15% of all the warehouse establishments were mechanized, and not more than 5% were automated. This provides a long runway for the AMH market to grow consistently across the country over the forecast period.

- Moreover, the United States stands to be one of the major retail markets in the region. It is estimated that more than two-thirds of the country's GDP is generated from retail consumption every year. In the country's e-commerce sector, the sales growth continues to increase more than the physical stores. With automation being the key differentiating factor, there is increasing competition between online and omnichannel retailers.

- Retail is one of the major industries, wherein the requirement for automated material handling systems such as conveyors is essential. It immensely helps online retailers with the movement of goods and increases good delivery efficiency. Furthermore, retailers are increasingly investing in expanding warehouse space. For example, Blackstone Group invested USD 18.7 billion on 179 million square feet of US warehouse space to cater to the country's growing retail demand. Amazon.com Inc is another such example, adopting automation techniques to solve its warehouse growing problems. In recent years, the company has been rolling out automated material handling machines and has added many advanced conveyor technologies to its warehouses.

- Multiple companies in the region are starting fulfillment distribution centers with the growing demand from e-commerce channels. For instance, in December 2020, PFS announced its new fulfillment distribution center in the Dallas area and operated e-commerce fulfillment programs for four brands. The fulfillment centers are generally equipped with several conveyor systems to efficiently transport products, and such expansion activities are expected to impact the conveyor market in the United States positively.

- However, the outbreak of COVID-19 dented the retail sales in March, April, and May in 2020. Such factors negatively impacted the usage of automated material handling in the United States' retail landscape in those months. However, the retail sector witnessed a significant surge in late 2020, which bounced back the usage of automated systems such as AMH.

US Automated Material Handling Industry Overview

The United States automated material handling market is fragmented and highly competitive. Product launches, high expense on research and development, partnerships and acquisitions, etc., are the prime growth strategies adopted by the companies in the country to sustain the intense competition.

- January 2021 - TGW Logistics Group planned to sell certain US conveyor assets in Norton Shores (Michigan) to Material Handling Systems, Inc. (MHS). The contract between the two companies has been signed, and the acquisition is expected to take effect by the end of 2021. Lincoln International guided TGW through the whole M&A process. With the sale, TGW adjusts its strategic portfolio and focuses on the growing integration business in North America.

- July 2020 - Vanderlande created the HOME PICK, based on a goods-to-person (GtP) picking solution that makes use of ADAPTO and is a unique 3D, shuttle-based automated storage and retrieval system (AS/RS). It is ideal for food retailers to realize economies of scale through centralized fulfillment centers (CFCs). By using ADAPTO and modular workstations, HOMEPICK's scalability also makes it future-proof. The sequenced orders ensure the proper order per delivery route and maximum delivery performance, which results in significant time and cost savings.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Buyers

- 4.2.3 Threat of New Entrants

- 4.2.4 Intensity of Competitive Rivalry

- 4.2.5 Threat of Substitutes

- 4.3 Industry Value Chain Analysis

- 4.4 Assessment of the Impact of COVID-19 on the Market

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Increasing Manufacturing Complexity and Technology Availability

- 5.1.2 Increasing Demand for Improving Order Accuracy and SKU Proliferation

- 5.1.3 Emergence of Smart City Logistics and Wide Adoption of Robotics in Warehouse Applications

- 5.2 Market Restraints

- 5.2.1 Gap in Supply Chain Skills and Workforce Shortage

- 5.2.2 High initial costs

6 MARKET SEGMENTATION

- 6.1 By Product Type

- 6.1.1 Hardware

- 6.1.2 Software

- 6.1.3 Services

- 6.2 By Equipment Type

- 6.2.1 Automated Guided Vehicle (AGV)

- 6.2.1.1 Automated Forklift

- 6.2.1.2 Automated Tow/Tractor/Tug

- 6.2.1.3 Unit Load

- 6.2.1.4 Assembly Line

- 6.2.1.5 Special Purpose

- 6.2.2 Autonomous Mobile Robots (AMR)

- 6.2.3 Laser Guided Vehicle

- 6.2.4 Automated Storage and Retrieval System (ASRS)

- 6.2.4.1 Fixed Aisle (Stacker Crane + Shuttle System)

- 6.2.4.2 Carousel (Horizontal Carousel + Vertical Carousel)

- 6.2.4.3 Vertical Lift Module

- 6.2.5 Automated Conveyor

- 6.2.5.1 Belt

- 6.2.5.2 Roller

- 6.2.5.3 Pallet

- 6.2.5.4 Overhead

- 6.2.6 Palletizer

- 6.2.6.1 Conventional (High Level + Low Level)

- 6.2.6.2 Robotic

- 6.2.7 Sortation System

- 6.2.1 Automated Guided Vehicle (AGV)

- 6.3 By End-user Vertical

- 6.3.1 Airport

- 6.3.2 Automotive

- 6.3.3 Food and Beverage

- 6.3.4 Retail/Warehousing/ Distribution Centers/Logistic Centers

- 6.3.5 General Manufacturing

- 6.3.6 Pharmaceuticals

- 6.3.7 Post and Parcel

- 6.3.8 Other End-Users

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Kion Group AG

- 7.1.2 Bastian Solutions Inc.

- 7.1.3 DMW&H

- 7.1.4 Westfalia Technologies Inc.

- 7.1.5 Dorner Manufacturing Corporation

- 7.1.6 Cornerstone Automation Systems LLC

- 7.1.7 Oceaneering International Inc.

- 7.1.8 Aethon Inc.

- 7.1.9 Daifuku Co. Ltd

- 7.1.10 Remtec Automation

- 7.1.11 Siggins Company

- 7.1.12 Honeywell Intelligrated

- 7.1.13 Vanderlande Industries B.V.

8 INVESTMENT ANALYSIS

9 MARKET OPPORTUNITIES AND FUTURE TRENDS

02-2729-4219

+886-2-2729-4219