|

市場調查報告書

商品編碼

1443437

鋰離子電池矽負極技術現況及展望(至2035年)<2024> LIB Si-Anode Technology Status and Outlook (~2035) |

||||||

迄今為止,碳基材料已成為鋰離子電池負極材料的主流。最初廣泛使用的是無定形碳材料,但現在天然石墨和人造石墨是主要選擇。近年來,為了克服石墨材料的理論容量限制,開發具有優異電化學反應活性和長壽命的材料,新型負極材料,特別是矽(Si)正在積極研究。對高容量負極材料的需求不斷增加,特別是在電動車和儲能係統中使用的大型電池市場。傳統上,碳基負極材料和石墨基負極材料一直是主流,但作為金屬複合材料的矽基負極材料越來越受到業界的關注。隨著對高容量負極的需求增加,獲取這些材料的競爭正在加劇。在這種情況下,研發和製造矽基負極材料的新公司數量正在穩步增加。

截至2020年初,只有10至20家公司在開發矽基高容量材料。不過,從目前的情況來看,已有60多家企業正積極致力於矽基材料的研發並準備量產。矽基材料對於開發高容量電池至關重要,這些電池可解決電動車續航里程限制並滿足快速充電能力的需求。電動車原始設備製造商和電池公司預計,到 2035 年,矽陽極材料的年增長率將達到 30%。矽負極材料在整個負極材料市場中的市佔率預計將從2019年的1%擴大到2030年的7%,到2035年進一步擴大到10%。

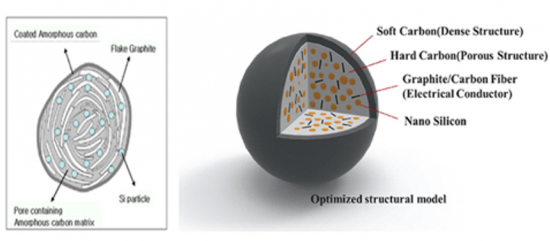

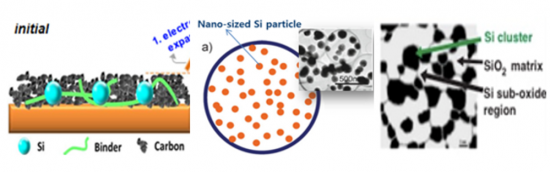

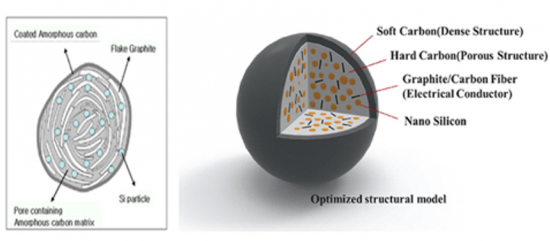

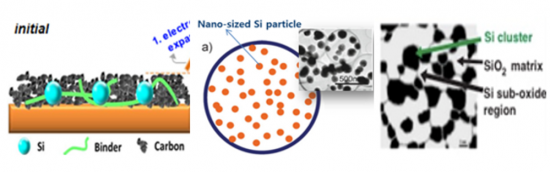

除碳基和石墨基材料外,Si-C複合材料、Si合金和SiOx是典型的鋰離子電池高容量負極材料。其中,SiOx和Si合金是最接近實用化的材料,一些電池製造商正在積極開發含有SiOx和Si合金的高容量電池。然而,壽命和體積膨脹(膨脹)等問題仍然存在,人們正在努力解決這些問題。在矽(Si)基負極領域,業界和學術界均就相關技術的最新趨勢進行了演講。

本報告對xEV(電動車)、ESS(儲能係統)和IT應用中使用的鋰離子電池負極材料市場進行了調查和分析,提供了高容量負極材料的最新發展狀況。 Si-C複合材料)在工業界和學術界都有應用。

目錄

報告概述

第一章 LIB概述

- LIB 的業績記錄

- LIB類型及特點

- 鋰離子電池原理

- 鋰離子電池組件

- 鋰離子電池的應用領域

- 負極材料技術現況及發展趨勢

第二章 鋰離子電池負極材料的種類及特點

- LIB負極材料所需的性能和類型

- 碳基負極材料的特性

- 金屬負極材料的特性

- 複合負極材料特性

第三章鋰離子電池高容量矽基負極材料技術發展現狀

- 高容量鋰離子電池的發展歷史與方向

- 高容量矽基負極材料的基本特性

- 合金基負極材料存在的問題及解決方案

- 高容量矽負極材料技術發展趨勢

第四章 高功率矽基負極材料技術發展現狀

- 高功率負極材料概述

- 高功率快充負極材料

- 從負極角度快速充電

第5章 鋰離子電池負極材料市場趨勢與展望

- LIB負極材料市場現狀

- 負極材料需求:依國家劃分

- 負極材料需求:依材料分類

- 市場狀況:依供應商分類

- 負極材料需求:LIB公司

- 鋰離子電池負極材料供應展望

- 負極材料產能展望

- 負極材料出貨現況及展望

- 負極材料供應展望

- 鋰離子電池負極材料價格展望

- 負極材料價格結構

- NG/AG/Si型

- 負極材料價格走勢

- NG/AG/Si型

- 各種石墨價格現狀

- 針狀焦及瀝青價格狀況

- 價格展望:以負極材料供應商劃分

- 負極材料價格結構

第六章 鋰離子電池負極材料廠商現狀

- LIB負極材料公司概況

- LIB負極材料廠商現狀

石墨/碳負極材料生產商

- 1. BTR

- 2. Shanshan

- 3. Zichen

- 4. Shinzoom (Changsha Xingcheng)

- 5. Kaijin

- 6. XFH (XiangFengHua)

- 7. Hitachi Chemical (Resonac)

- 8. Mitsubishi Chemical

- 9. JFE Chemical

- 10. POSCO FutureM

- 11. Aekyung Chemical

矽基負極材料製造商(韓國/亞洲)

- 12. Daejoo Electronic Materials

- 13. Shin-Etsu

- 14. MK Electronics

- 15. Il-jin Electric

- 16. EG

- 17. Hansol Chemical

- 18. Innox Eco Chemical

- 19. FIC Advanced Materials

- 20. LPN

- 21. Osaka Titan

- 22. POSCO Silicon Solution

- 23. TCK ((TOKAI CARBON KOREA)

- 24. NM Tech (Acquired by Truewin)

- 25. KBG

- 26. Neo Battery Materials

- 27. Korea Metal Silicon

- 28. EN PLUS

- 29. Lotte Energy Materials

- 30. Dong-jin Semichem

- 31. SJ Advanced Materials

- 32. IEL Science

- 33. S Materials

- 34. HNS

- 35. Y-Fine Tech

- 36. Hana Materials

矽基負極材料製造商(中國)

- 37. Haoxin Tech

- 38. Longtime Tech

- 39. Gotion

- 40. Shinghwa

- 41. Tianmulake

- 42. Chengdu Guibao

- 43. Jereh

- 44. Huawei

- 45. Xinan

- 46. Kingi

矽基負極材料製造商(北美、歐洲)

- 47. Group14 (With SK Materials)

- 48. NEXEON (With SKC)

- 49. Sila Nano Technologies

- 50. Enovix

- 51. Enervate

- 52. EO Cell

- 53. Amprius Technologies

- 54. Nanotek' Instrument

- 55. One D

- 56. Nanograf

- 57. LeydenJar

- 58. ADVANO

- 59. Targray

- 60. StoreDot

- 61. Trion Battery

- 62. Black Diamond Structures

- 63. Nanospan

第7章 參考資料

The anode material for lithium-ion batteries has predominantly been carbon-based to date. In the early stages, amorphous carbon materials were widely used, but presently, natural and synthetic graphite are the primary choices. Recently, there has been active consideration of new anode materials, particularly those centered around silicon (Si), to overcome the theoretical capacity limits of graphite materials and develop materials with excellent electrochemical reaction potential and extended lifespan. The demand for high-capacity anode materials has been increasing, particularly in the market for large-scale batteries used in electric vehicles and energy storage systems. While carbon and graphite-based anode materials were traditionally prevalent, there is a growing focus, especially within the industry, on silicon-based anode materials, which are metal composites. The competition to secure these materials has intensified as the need for high-capacity anode rises. In this context, there is a continual increase in new entrants developing and manufacturing silicon-based anode materials.

As of early 2020, silicon-based high-capacity materials were primarily developed by only 10-20 companies. However, the current landscape shows that over 60 companies are actively engaged in the development and preparation for mass production of silicon-based materials. Silicon-based materials are essential for the development of high-capacity batteries to address the range limitations of electric vehicles and meet the demand for fast-charging capabilities. Electric vehicle OEMs and battery companies anticipate a projected annual growth rate of 30% for silicon anode materials until 2035. The market share of silicon anode materials in the overall anode material market is expected to expand from 1% in 2019 to 7% in 2030 and further to 10% by 2035.

In addition to carbon-based and graphite-based materials, Si-C composite, Si-alloy, and SiOx are representative high-capacity anode materials for lithium-ion batteries. Among these, SiOx and Si-alloy are the closest to commercialization, with some battery manufacturers actively developing high-capacity batteries by incorporating them. However, challenges such as lifespan and volume expansion (swelling) persist, prompting ongoing efforts to address these issues. In the realm of silicon (Si)-based anodes, recent announcements of related technological developments have been made by both industry and academia. Anode material companies are also concentrating on new technology development, fostering expectations for imminent commercialization.

This report serves as a technical document focusing on recent developments in the anode material market for lithium-ion batteries used in xEV (electric vehicles), ESS (energy storage systems), and IT applications. Specifically, it delves into the technological advancements and performance enhancements in Si-based anode development for high-capacity batteries. The report provides an overview of the latest developments in Si-based high-capacity anode materials (Si-alloy, SiOx, Si-C composite) by both industry and academia. It also examines the current status and challenges associated with batteries incorporating these materials, aiming to offer insights and potential solutions for future developments in high-capacity/high-output battery technologies.

Strong Point of this report:

- 1. Overall market share and technological status of anode materials for lithium-ion batteries. (including graphite-based and silicon-based materials.)

- 2. Technical issues and key technological factors related to high-capacity silicon-based anode materials.

- 3. Recent technological developments in silicon-based anode materials by battery manufacturers.

- 4. Applications and commercialization prospects for future silicon-based anode materials.

- 5. Technological trends and product introductions from over 70 global silicon-based anode material companies.

Table of Contents

Report Overview

Chapter I. Overview of LIBs

- 1.1. History of LIBs

- 1.2. Types and Characteristics of LIBs

- 1.3. Principle of LIBs

- 1.3.1. Charging / Discharging Reactions

- 1.3.2. Voltage

- 1.3.3. Movement of Charge and Ions

- 1.3.4. Theoretical Capacity

- 1.4. Components of LIBs

- 1.4.1. Cathode active materials

- 1.4.2. Anode active materials

- 1.4.3. Seperator

- 1.4.4. Electrolyte

- 1.5. Application areas of LIBs

- 1.6. Technology Status and Development Trend of Anode Materials

Chapter II. Types and Characteristics of LIB Anode Materials

- 2.1. Required Characteristics and Types of LIB Anode Materials

- 2.2. Characteristics of Carbon-based Anode Materials

- 2.2.1. Graphite-based Anode Materials

- 2.2.2. Amorphous Carbon-based Anode Materials

- 2.2.3. Carbon-based Anode Materials / Electrolyte Interfacial Reaction

- 2.3. Characteristics of Metal-based Anode Materials

- 2.3.1. Lithium Metal Anode Materials

- 2.3.2. Alloy-based Anode Materials

- 2.4. Characteristics of Compound-Based Anode Materials

- 2.4.1. Oxide-Based Anode Materials

- 2.4.2. Nitride-Based Anode Materials

Chapter III. Current Status of Technological Development for High-Capacity Si-Based Anode Materials for Lithium-ion Batteries

- 3.1. Development History and Direction of High-Capacity Lithium-ion Batteries

- 3.2. Basic Characteristics of High-Capacity Si-based Anode Materials

- 3.2.1. Lithium Insertion/Extraction Reactions of Si-based Anode Materials

- 3.2.2. Issues of Si-based Anode Materials and Degradation Mechanisms

- 3.2.3. Volume Expansion Control of Si-based Anode Materials

- 3.3. Problems and Solutions for Alloy-based Anode Materials

- 3.3.1. Representative Problems

- 3.3.2. Metal Composite-based Anode Materials

- 3.3.3. Metal-Carbon Composite-based Anode Materials

- 3.3. Trends in the Technological Development of High-Capacity Si Anode Materials

- 3.3.1. SiOx Anode Materials

- Structural Characteristics

- Electrochemical Properties

- Manufacturing Methods

- Application of Prelithiation Process

- 3.3.2. Si-C Composite Anode Materials

- 3.3.3. Si-M Alloy Anode Materials

- 3.3.4. Practical Application Research of Si Anode Materials

- Differences of Electrochemical Behavior

- Si Single Electrode and Si/Graphite Hybrid Electrode

- 3.3.5. Various Nanostructures of Si-based Anode Materials

- Si nanostructure

- Porous Si structure

- Nano-Si/C structure

- Nano-Si/metal or polymer structure

- 3.3.6. Binders for Si-based Anode Materials

- 3.3.7. Current Collectors for Si-based Anode Materials

- 3.3.8. Comprehensive Review of Research Trends in Si-based Anodes and Future Research Directions

- 3.3.9. Examples of Si-based Anode Material Developments in Academic/Industries

- 3.3.10. Key Technology Roadmap for Si-Based Anode Materials

- 3.3.1. SiOx Anode Materials

Chapter IV. Current Status of High-Output Si-Based Anode Material Technology Development

- 4.1. Overview of High-Output Anode Materials

- 4.2. Anode Materials for High-Output Fast Charging

- 4.2.1. Intercalation Materials

- 4.2.2. Alloy-based Materials / Transition Materials

- 4.2.3. Nano-Structured Micro-Sized Particles (Nano-structured micro-sized particles)

- 4.2.4. Si-Graphite Hybrid Materials (SEAG)

- 4.2.5. Graphene-SiO2 Materials (Graphene Ball)

- 4.3. Fast Charging from Anode Perspective

- 4.3.1. Factors Influencing Anode Materials (Active Materials)

- 4.3.2. Factors Influencing Electrodes

- 4.3.3. Design of Fast Charging Technology by Major Battery Companies

- 4.4.4. Summary and Future Outlook

Chapter V. Trends and Outlook in the LIB Anode Material Market

- 5.1. Current Status of LIB Anode Material Market

- 5.1.1. Demand for Anode Materials by Country

- 5.1.2. Demand for Anode Materials by Material Type

- 5.1.3. Market Status by Supplier

- 5.1.4. Demand for Anode Materials by LIB Companies

- SDI/LGES/SKon/Panasonic/CATL/ATL/BYD/Lishen/Guoxuan/AESC/CALB

- 5.2. Supply Outlook for LIB Anode Materials

- 5.2.1. Outlook of Anode Material Production Capacity

- 5.2.2. Status and Outlook of Anode Material Shipments

- 5.2.3. Supply Outlook for Anode Materials

- 5.3. Price Outlook for LIB Anode Materials

- 5.3.1. Anode Material Price Structure

- NG/AG/Si-based

- 5.3.2. Anode Material Price Trends

- NG/AG/Si-based

- 5.3.3. Price Status of Different Types of Graphite

- 5.3.4. Price Status of Needle Coke and Pitch

- 5.3.5. Price Outlook by Anode Material Suppliers

- 5.3.1. Anode Material Price Structure

Chapter VI. Current Status of LIB Anode Material Manufacturers

- 6.1. Summary of LIB Anode Material Companies

- 6.2. Current Status of LIB Anode Material Manufacturers

Graphite/Carbon-Based Anode Material Manufacturers

- 1. BTR

- 2. Shanshan

- 3. Zichen

- 4. Shinzoom(Changsha Xingcheng)

- 5. Kaijin

- 6. XFH(XiangFengHua)

- 7. Hitachi Chemical(Resonac)

- 8. Mitsubishi Chemical

- 9. JFE Chemical

- 10. POSCO FutureM

- 11. Aekyung Chemical

Si-based Anode Material Manufacturers (Korean/Asian)

- 12. Daejoo Electronic Materials

- 13. Shin-Etsu

- 14. MK Electronics

- 15. Il-jin Electric

- 16. EG

- 17. Hansol Chemical

- 18. Innox Eco Chemical

- 19. FIC Advanced Materials

- 20. LPN

- 21. Osaka Titan

- 22. POSCO Silicon Solution

- 23. TCK((TOKAI CARBON KOREA)

- 24. NM Tech(Acquired by Truewin)

- 25. KBG

- 26. Neo Battery Materials

- 27. Korea Metal Silicon

- 28. EN PLUS

- 29. Lotte Energy Materials

- 30. Dong-jin Semichem

- 31. SJ Advanced Materials

- 32. IEL Science

- 33. S Materials

- 34. HNS

- 35. Y-Fine Tech

- 36. Hana Materials

Si-Based Anode Material Manufacturers (Chinese)

- 37. Haoxin Tech

- 38. Longtime Tech

- 39. Gotion

- 40. Shinghwa

- 41. Tianmulake

- 42. Chengdu Guibao

- 43. Jereh

- 44. Huawei

- 45. Xinan

- 46. Kingi

Si-based Anode Material Manufacturers (North America, Europe)

- 47. Group14 (With SK Materials)

- 48. NEXEON (With SKC)

- 49. Sila Nano Technologies

- 50. Enovix

- 51. Enervate

- 52. EO Cell

- 53. Amprius Technologies

- 54. Nanotek' Instrument

- 55. One D

- 56. Nanograf

- 57. LeydenJar

- 58. ADVANO

- 59. Targray

- 60. StoreDot

- 61. Trion Battery

- 62. Black Diamond Structures

- 63. Nanospan