|

市場調查報告書

商品編碼

1683108

亞太地區塑膠瓶和容器:市場佔有率分析、行業趨勢和統計、成長預測(2025-2030 年)Asia-Pacific Plastic Bottles And Containers - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

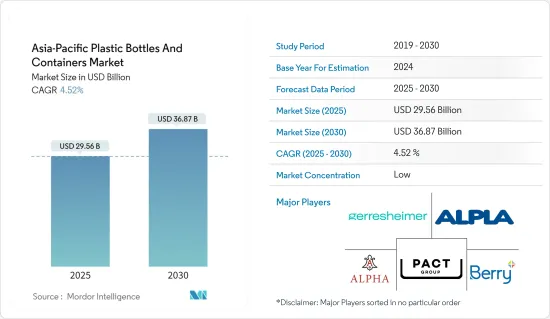

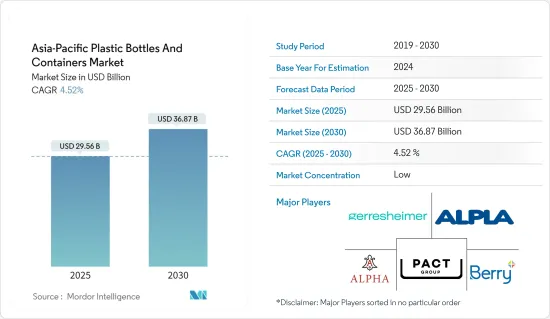

亞太地區塑膠瓶和容器市場規模預計在 2025 年為 295.6 億美元,預計到 2030 年將達到 368.7 億美元,預測期內(2025-2030 年)的複合年成長率為 4.52%。

在產量方面,市場預計將從 2025 年的 2,050 萬噸成長到 2030 年的 2,563 萬噸,預測期內(2025-2030 年)的複合年成長率為 4.57%。

主要亮點

- 塑膠包裝比其他產品更受消費者歡迎,因為塑膠材料重量輕、不易破碎、更易於物料輸送。甚至大型製造商也傾向於使用塑膠包裝,因為其生產成本低。此外,聚對苯二甲酸乙二酯(PET)和高密度聚苯乙烯(HDPE)等聚合物的引入擴大了寶特瓶的應用範圍。市場對寶特瓶的需求日益增加。

- 由聚對苯二甲酸乙二醇酯、聚丙烯和聚乙烯製成的塑膠瓶和容器由於重量輕且易於回收,被廣泛使用並受到最終用戶的青睞。塑膠材料的成本效益以及對包裝加工食品和各種食品和飲料產品的依賴可能會在預測期內對研究市場產生影響。

- 塑膠因其輕質特性而擴大被採用,因為輕質塑膠包裝可以在運輸包裝貨物時節省能源並減少排放。塑膠的輕量化特性是其市場拓展的一大優勢。與玻璃等其他材料相比,玻璃比塑膠重得多,因此在運輸過程中需要移動更多。

- 市場成長的另一個推動力是其在該地區各個行業的應用範圍不斷擴大。例如,在製藥業,塑膠瓶是錠劑、糖漿和膠囊的可靠包裝選擇,因為它們具有防潮性能,可以保持產品的穩定性。在個人護理和化妝品行業,塑膠瓶因其耐用性和美觀而成為包裝洗髮精、護髮素、乳液和乳霜的理想選擇。

- 然而,隨著對塑膠污染的擔憂日益加劇,製造商和消費者開始轉向其他具有環保特性的包裝材料。由於鋁和玻璃具有較高的可回收性,其消費採用率可能會增加。預計這將阻礙該市場的成長。

- 同時,亞太地區經濟成長持續向好、人口結構變化不斷活躍,對地區發展產生重大影響。超級市場和大賣場等有組織的零售業的成長正在增加對包裝商品的需求。這些商店需要大規模包裝來滿足消費者的多樣化需求,從而推動整個市場的發展。

亞太地區塑膠瓶和容器市場趨勢

聚對苯二甲酸乙二醇酯(PET)佔據主要市場佔有率

- PET 塑膠瓶已成為笨重且易碎的玻璃瓶的廣泛替代品,因為它們可以為礦泉水和其他飲料提供可重複使用的包裝,並允許更經濟的運輸過程。

- PET 的高透明度和天然的二氧化碳阻隔性能使其用途廣泛,易於吹製成瓶並形成其他形狀。可透過著色劑、紫外線防護劑、氧氣阻隔劑/清除劑和其他添加劑來增強 PET 的性能,以開發出滿足品牌特定需求的瓶子。

- PET 已成為該地區瓶子製造商的主要包裝材料之一。 PET 具有適應各種形狀和尺寸的多功能性,是傳統玻璃和金屬容器無與倫比的替代品,使其成為包裝行業非常理想的選擇。

- 聚對苯二甲酸乙二醇酯(PET)瓶在各種產品領域越來越受歡迎。由於成本低、重量輕以及印刷技術的發展, 寶特瓶越來越受到高階消費者的歡迎。

- 根據永續化學品公司 Indorama Ventures 的報告,亞洲對再生聚對苯二甲酸乙二醇酯 (RPET) 的需求預計將從 2018 年的 60 萬噸穩步成長至 2023 年的 100 萬噸左右。

- 此外,2023 年 9 月,Indorama Ventures Public Company Limited 宣布已回收了 1,000 億個消費後寶特瓶。此舉轉移了 210 萬噸廢棄物,減少了 290 萬噸二氧化碳排放,並為建立 PET 循環經濟做出了貢獻。 Indorama Ventures 承諾投入超過 10 億美元用於廢舊寶特瓶廢棄物收集。

- PET 回收的未來與技術進步密切相關,這些技術進步會使回收過程更有效率、經濟高效且環保。收集、加工並將消費後 PET 產品轉化為新包裝材料的能力為減少對原始材料的依賴和減輕環境廢棄物提供了巨大的機會。

預計中國將佔較大市場佔有率

- 中國是世界主要塑膠生產國和消費國之一。據經合組織稱,預計未來40年中國塑膠使用量將大幅增加,到2060年將達到2.0312億噸以上。由於食品飲料、製藥和個人護理行業越來越依賴由PET(聚對苯二甲酸乙二醇酯)、HDPE(高密度聚苯乙烯)和其他聚合物製成的寶特瓶和容器,中國的塑膠生產和出口備受關注。

- 根據國際貿易中心(ITC)的資料,美國是中國塑膠製品最大的出口目的地。 2023年中國將向美國出口塑膠製品2.926億噸,與前一年同期比較增加8.00%。由於塑膠貿易具有較高的潛在成長機會,預計未來幾年該國對塑膠的需求將會增加。

- 中國正在經歷向永續和環保實踐的轉變,以推廣塑膠再生。因此,可口可樂等飲料公司已將再生塑膠作為減少環境影響策略的一部分。

- 2024年4月,美國飲料公司可口可樂在香港推出了由回收聚對苯二甲酸乙二醇酯 (rPET) 製成的可口可樂原味瓶、無糖可口可樂和可口可樂 Plus 瓶。

- 中國敦促商店和快遞公司減少「不合理」的塑膠包裝,到2025年將都市區垃圾焚燒率從目前的每天58萬噸提高到每天80萬噸左右。預計這些發展將增加該國對可回收塑膠包裝的需求。

亞太地區塑膠瓶及容器產業概況

亞太地區塑膠瓶和容器市場分散,主要參與者包括 Gerresheimer AG、Pact Group Holdings Limited、Alpla Group、Berry Global Inc. 和 Alpha Packaging Pvt。有限公司。市場參與者正在採取聯盟和收購等策略來加強其產品供應並獲得永續的競爭優勢。

- 2023 年 10 月—Manjushree Technopack 與 Ganesha Ecosphere Group 的瓶到瓶級回收部門簽署了合作協議,共同開發和供應利用再生塑膠的食品和非食品級包裝產品。此次夥伴關係旨在幫助品牌遵守新的(塑膠廢棄物管理)PWM 規則,同時支持印度政府到 29 會計年度用再生塑膠取代高達 60% 的原生塑膠的雄心勃勃的目標。此次夥伴關係也旨在幫助建立循環經濟並加速採用 100%回收寶特瓶瓶。

- 2023 年 12 月 - 澳洲 Pact Group 與 Cleanway 廢棄物 Management、朝日飲料公司和可口可樂歐洲太平洋合作夥伴合作,在墨爾本開設了一家寶特瓶回收工廠。 Circular Plastics Australia(PET)工廠將消費後寶特瓶轉化為高品質食品級樹脂,用於製造新的再生 PET 飲料瓶和其他包裝產品。該廠每小時生產 2.5 噸 rPET 樹脂的能力,即每年生產 20,000 噸。

其他福利

- Excel 格式的市場預測 (ME) 表

- 3 個月的分析師支持

目錄

第 1 章 簡介

- 研究假設和市場定義

- 研究範圍

第2章調查方法

第3章執行摘要

第4章 市場洞察

- 市場概況

- 產業價值鏈分析

- 產業吸引力-波特五力分析

- 供應商的議價能力

- 買家的議價能力

- 新進入者的威脅

- 競爭對手之間的競爭

- 替代品的威脅

第5章 市場動態

- 市場促進因素

- 擴大採用輕量化包裝方法

- 人口和生活方式的變化

- 市場限制

- 人們對塑膠使用的環境問題的擔憂日益加劇

第6章 市場細分

- 按原料

- 聚對苯二甲酸乙二醇酯(PET)

- 聚丙烯(PP)

- 低密度聚乙烯(LDPE)

- 高密度聚苯乙烯(HDPE)

- 其他成分

- 按最終用戶產業

- 飲料

- 瓶裝水

- 碳酸飲料

- 乳類飲料

- 其他飲料

- 食物

- 化妝品

- 藥品

- 家居用品

- 其他行業

- 飲料

- 按國家

- 中國

- 印度

- 日本

- 澳洲和紐西蘭

- 東南亞

第7章 競爭格局

- 公司簡介

- Gerresheimer AG

- Pact Group Holdings Limited

- Alpla Group

- Berry Global Inc.

- Alpha Packaging Pvt. Ltd

- Mauser Packaging Solutions(Bway Holding Corporation)

- Greiner Packaging International GmbH

- Retal Industries Limited

- Zhejiang Xinlei Packaging Co. Ltd

- Shenzhen Zhenghao Plastic & Mold Co. Ltd

- Manjushree Technopack Limited

第8章投資分析

第9章:市場的未來

The Asia-Pacific Plastic Bottles And Containers Market size is estimated at USD 29.56 billion in 2025, and is expected to reach USD 36.87 billion by 2030, at a CAGR of 4.52% during the forecast period (2025-2030). In terms of production volume, the market is expected to grow from 20.50 million metric tons in 2025 to 25.63 million metric tons by 2030, at a CAGR of 4.57% during the forecast period (2025-2030).

Key Highlights

- Plastic packaging has become popular among consumers over other products, as plastic material is lightweight and unbreakable, making it easier to handle. Even major manufacturers prefer to use plastic packaging, owing to the lower cost of production. Moreover, the introduction of polymers, such as polyethylene terephthalate (PET) and high-density polyethylene (HDPE), is expanding the applications of plastic bottles. The market has been witnessing an increasing demand for PET bottles.

- Plastic bottles and containers made of polyethylene terephthalate, polypropylene, and polyethylene are widely used as the material is lightweight and easily recyclable, making it the preferred choice among the end-users. The cost-effective nature of plastic material and dependence on packaged, processed food and various beverages will influence the studied market over the forecast period.

- Plastics have been increasingly adopted due to their lightweight properties because lightweight plastic packaging can preserve energy in transporting packed goods and lower emissions. The lightweight properties of plastic are the primary advantage of expanding the market. Compared to other materials, such as glass, which is much heavier than plastic, more trips are required while transporting.

- The market's growth can also be attributed to the expanding range of applications across diverse industries in the region. For instance, within the pharmaceutical industry, plastic bottles offer a reliable packaging option for tablets, syrups, and capsules due to their moisture-resistant properties that maintain product stability. In personal care and cosmetics, plastic bottles are an ideal option for packaging shampoos, conditioners, lotions, and creams, owing to their durability and visual appeal.

- However, with growing concerns about plastic pollution, manufacturers and consumers are also inclining themselves toward other packaging materials that offer environment-friendly properties. The consumption of aluminum and glass might witness rising adoption rates owing to their high recyclability. This is expected to hinder the growth of the market studied.

- Nevertheless, the Asia-Pacific region has experienced improved and better economic growth and dynamic demographic changes that have significantly influenced the region's development. The growth of organized retail, including supermarkets and hypermarkets, has heightened the demand for packaged goods. These outlets require extensive packaging to cater to the diverse needs of consumers, driving the overall market.

Asia-Pacific Plastic Bottles And Containers Market Trends

Polyethylene Terephthalate (PET) Segment Holds Major Market Share

- Plastic bottles made from PET are widely replacing heavy and fragile glass bottles since they offer reusable packaging for mineral water and other beverages, allowing a more economical transportation process.

- With its clarity and natural CO2 barrier properties, PET has wide applications and is easily blown into a bottle or molded into any other shape. PET properties can be improved with colorants, UV blockers, oxygen barriers/scavengers, and other additives to develop a bottle to match a brand's specific needs.

- PET has become one of the vital packaging materials among bottle manufacturers across the region. PET's versatility in accommodating different shapes and sizes has provided unparalleled alternatives to conventional glass and metal containers, making it a highly desirable choice in the packaging industry.

- Polyethylene terephthalate (PET) bottles are gaining a presence in various product areas. Low cost, low weight, and ongoing developments in printing technology have led to PET bottles gaining popularity among premium consumers.

- As per the report of Indorama Ventures, a sustainable chemical company, the demand for recycled polyethylene terephthalate (RPET) in Asia is expected to increase constantly from 0.6 million metric tons in 2018 to approximately 1 million metric tons in 2023.

- Further, in September 2023, Indorama Ventures Public Company Limited notified that it had recycled 100 billion post-consumer PET bottles. This has diverted 2.1 million tons of waste, preserved 2.9 million tons of carbon footprint, and helped in establishing a circular economy for PET. Indorama Ventures spent more than USD 1 billion on the waste collection of used PET bottles.

- The future of PET recycling closely revolves around technological advancements that make the process more efficient, cost-effective, as well as environmentally friendly. The ability to collect, process, and transform used PET products into new packaging materials provides an immense opportunity to reduce dependency on virgin resources, therefore mitigating environmental waste.

China Expected to Hold Significant Market Share

- China is one of the major producers and consumers of plastic globally. According to the OECD, China's plastics use is projected to grow considerably over the next four decades, reaching more than 203.12 million metric tons by 2060. The growing dependence on plastic bottles and containers made using PET (Polyethylene Terephthalate), HDPE (High-Density Polyethylene), and other polymers for food & beverage, pharmaceutical, and personal care industries has increased the focus on the production and export of plastics from China.

- According to data from the International Trade Center (ITC), China's largest export of plastic products is to the United States of America. China exported 292.6 million tons of plastic products to the USA in 2023, which was 8.00% higher than the previous year. The high potential growth opportunity in plastic trade is expected to increase the country's demand for plastic in the coming years.

- China is witnessing a shift in its focus on sustainable and eco-friendly practices to promote recycled plastic. This has resulted in beverage manufacturers such as Coca-Cola using recycled plastic as part of their strategy to reduce their environmental footprint.

- In April 2024, Coca-Cola Company, a United States-based beverage company, launched Coca-Cola Original, Coca-Cola No Sugar, and Coca-Cola Plus bottles made from recycled polyethylene terephthalate (rPET) in Hong Kong.

- China has been prompting merchants and delivery companies to reduce "unreasonable" plastic wrapping and increase garbage incineration rates in cities to about 800,000 tons per day by 2025, up from 580,000 tons currently. Such developments are expected to increase the country's recyclable plastic packaging demand.

Asia-Pacific Plastic Bottles And Containers Industry Overview

The Asia Pacific Plastic Bottles and Containers market is fragmented with the presence of major players like Gerresheimer AG, Pact Group Holdings Limited, Alpla Group, Berry Global Inc., and Alpha Packaging Pvt. Ltd. Players in the market are adopting strategies such as partnerships and acquisitions to enhance their product offerings and gain sustainable competitive advantage.

- October 2023 - Manjushree Technopack entered into a collaboration agreement with the bottle-to-bottle grade recycling division of Ganesha Ecosphere Group to co-develop and supply food and non-food grade packaging products made of recycled plastics. The partnership sets to serve the brands in complying with the new (Plastic Waste Management) PWM rules while supporting the Indian government's ambitious target of replacing up to 60% of virgin plastic with recycled plastic by FY29. The partnership also aims to help create a circular economy and accelerate the adoption of 100% recycled plastic bottles.

- December 2023 - Pact Group, an Australia-based company, in partnership with Cleanway Waste Management, Asahi Beverages, and Coco-Cola Europacific Partners, opened a PET bottle recycling plant in Melbourne. The Circular Plastics Australia (PET) plant will convert used plastic bottles into high-quality food-grade resin, which will be used to make new recycled PET beverage bottles and other packaging products. The facility is equipped to produce 2.5 tons of rPET resin per hour and 20,000 tons of rPET resin each year.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Value Chain Analysis

- 4.3 Industry Attractiveness - Porter's Five Forces Analysis

- 4.3.1 Bargaining Power of Suppliers

- 4.3.2 Bargaining Power of Buyers

- 4.3.3 Threat of New Entrants

- 4.3.4 Intensity of Competitive Rivalry

- 4.3.5 Threat of Substitute Products

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Increasing Adoption of Lightweight Packaging Methods

- 5.1.2 Changing Demographic and Lifestyle Factors

- 5.2 Market Restraints

- 5.2.1 Growing Environmental Concerns Over the Use of Plastics

6 MARKET SEGMENTATION

- 6.1 By Raw Materials

- 6.1.1 Polyethylene Terephthalate (PET)

- 6.1.2 Polypropylene (PP)

- 6.1.3 Low-Density Polyethylene (LDPE)

- 6.1.4 High-Density Polyethylene (HDPE)

- 6.1.5 Other Raw Materials

- 6.2 By End-user Vertical

- 6.2.1 Beverages

- 6.2.1.1 Bottled Water

- 6.2.1.2 Carbonated Soft Drinks

- 6.2.1.3 Dairy-based

- 6.2.1.4 Other Beverages

- 6.2.2 Food

- 6.2.3 Cosmetics

- 6.2.4 Pharmaceuticals

- 6.2.5 Household Care

- 6.2.6 Other End-user Verticals

- 6.2.1 Beverages

- 6.3 By Country

- 6.3.1 China

- 6.3.2 India

- 6.3.3 Japan

- 6.3.4 Australia and New Zealand

- 6.3.5 South East Asia

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Gerresheimer AG

- 7.1.2 Pact Group Holdings Limited

- 7.1.3 Alpla Group

- 7.1.4 Berry Global Inc.

- 7.1.5 Alpha Packaging Pvt. Ltd

- 7.1.6 Mauser Packaging Solutions (Bway Holding Corporation)

- 7.1.7 Greiner Packaging International GmbH

- 7.1.8 Retal Industries Limited

- 7.1.9 Zhejiang Xinlei Packaging Co. Ltd

- 7.1.10 Shenzhen Zhenghao Plastic & Mold Co. Ltd

- 7.1.11 Manjushree Technopack Limited