|

市場調查報告書

商品編碼

1636175

亞太地區電動車鋰離子電池:市場佔有率分析、產業趨勢與成長預測(2025-2030)Asia-Pacific Lithium-ion Battery For Electric Vehicle - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

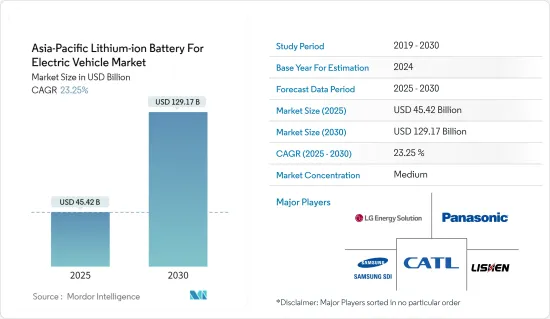

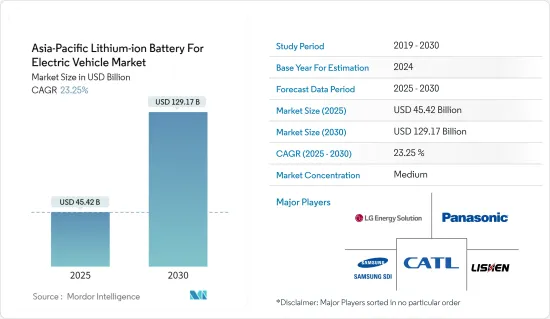

預計2025年亞太地區電動車鋰離子電池市場規模為454.2億美元,預測期內(2025-2030年)複合年成長率為23.25%,到2030年預計將達到1291.7億美元。

主要亮點

- 鋰離子電池價格的下降、電動車滲透率的提高以及政府的支持措施和舉措預計將在預測期內推動亞太電動汽車鋰離子電池市場的成長。

- 另一方面,替代電池技術的興起可能會阻礙預測期內的市場成長。

- 新興國家混合動力電動車(HEV)應用對鋰離子電池的需求預計將為亞太地區電動車鋰離子電池市場創造巨大機會。

亞太地區電動車鋰離子電池市場趨勢

純電動車 (BEV) 領域出現顯著成長

- 純電動車(BEV)通常也稱為帶有馬達的電動車。純電動車是全電動汽車,這意味著它們沒有內燃機 (ICE)、燃料箱或排氣管,而是依靠電力來推進。車輛的能量來自電池組並透過電網充電。純電動車是零排放車,這意味著它們不會產生傳統汽油動力汽車造成的有害廢氣和空氣污染。

- 多年來,隨著電動車,尤其是純電動車 (BEV) 的發展和普及,亞太地區的汽車產業正在經歷轉型。隨著技術的進步、政府的支持以及人們對環境問題認知的提高,純電動車已成為應對氣候變遷挑戰和減少對石化燃料依賴的有前景的解決方案。

- 近年來,純電動車的採用在全球範圍內顯著成長。電池技術的改進增加了續航里程,充電基礎設施的普及也開始克服最初的進入障礙。此外,特斯拉、比亞迪、塔塔、豐田和本田等汽車製造商在推動純電動車採用方面發揮關鍵作用,提供價格實惠的車款來吸引廣大消費者。

- 根據國際能源總署(IEA)預測,2023年中國純電動車(BEV)保有量約1,600萬輛。同樣,同年印度、日本和韓國的純電動車保有量分別約為15萬輛、29萬輛和46萬輛。同樣,2023年中國純電動車銷量將超過540萬輛。印度的純電動車銷量約為8.2萬輛,而日本和韓國的純電動車銷量分別為8.8萬輛和12萬輛。隨著純電動車銷量的持續成長,對鋰離子電池等電動車電池的需求變得越來越重要。

- 此外,亞太地區是純電動車最大的市場之一,也是全球最大的電動車電池製造地區。 2023年中國電動車電池需求量約為每年417GWh,約佔全球需求量的54%,較2022年大幅成長32%以上。這凸顯了該地區在電動車電池技術方面的主導地位的重要性。同樣,根據國際能源總署(IEA)的數據,在中國的帶動下,亞太地區的鋰離子電池製造能力預計在未來幾年將大幅成長。該機構預計,中國鋰離子電池製造能力將從2022年的約1.20太瓦時增加到2030年的4.65太瓦時。

- 為了加速純電動車的普及,各國正實施各種措施和獎勵。例如,為了減少電動車對先進化學電池(ACC)的進口依賴,印度政府於2021年初核准了針對ACC國內製造的生產連結獎勵(PLI)計畫。該計劃五年內總成本為 21.2 億美元。該計劃設想在日本建立具有競爭力的ACC電池製造系統(50GWh)。此外,5GWh利基ACC技術也被納入該計劃。這些措施支持了電動車應用對鋰離子電池的需求。

- 此外,由於電動車普及率的提高以及政府加速電動車使用的舉措,預計泰國、印尼、新加坡、馬來西亞和菲律賓等東南亞國家鋰離子電池的採用將迅速增加。例如,印尼有一個雄心勃勃的目標,即到2025年電動車佔所有汽車銷量的20%,印尼政府的目標是到2030年在國內生產60萬輛電動車。這些目標轉化為電動車供應鏈(包括鋰離子電池市場)內的各種里程碑。

- 2024年初,泰國電動車委員會將推出第二階段電動車封裝EV3,以促進電動車產業的持續發展,並鼓勵新參與企業在泰國投資電動車製造5年核准,為期四年(2024-2027年)。該包裝旨在鼓勵涵蓋整個電動車產業生態系統的投資。作為一攬子計劃的一部分,泰國政府根據車型和電池容量列出了購買電動車、電動皮卡和電動摩托車的補貼。自2017年以來,由於持續的電動車推廣包裝,泰國已在電動車產業投資18億美元用於純電動車、純電動二輪車、電動車零件和充電站的製造。

- 因此,由於上述因素,BEV細分市場很可能在預測期內主導電動車(EV)鋰離子電池市場。

印度正在經歷快速成長

- 印度已成為鋰離子電池成長最快的市場之一,大力推動電動車 (EV) 的採用。例如,根據國際能源總署(IEA)的數據,2023年印度純電動車(BEV)銷量將達到約82,000輛,較2022年成長70%以上。此外,印度政府的目標是到2030年,新登記的私家車30%、巴士40%、商用車70%、二輪車和三輪車80%為電動車。由於這些因素,未來對鋰離子電池等電動車電池的需求可能會大幅增加。

- 此外,政府還採取了各種措施和獎勵,鼓勵從傳統內燃機汽車轉向電動車,大大增加了對鋰離子電池的需求。 FAME(混合動力汽車和電動車的更快採用和製造)等舉措使印度在充電基礎設施、電池製造和電動車購買者補貼方面進行了大量投資,我們正在創造一個有利於市場成長的環境。

- 最近,2024 年 3 月,印度政府核准了一項價值 5 億美元的新電動車計劃,旨在吸引全球電動車公司的投資並將印度定位為領先的電動車製造中心提供了獎勵。其他目標包括為印度消費者提供先進的電動車車型、擴大印度製造生態系統、降低生產成本以及培育具有競爭力的國內汽車製造業等。

- 許多國內外公司正在投資印度的鋰離子電池市場,旨在利用對能源儲存不斷成長的需求以及向永續解決方案的轉變。例如,2022年4月,電池巨頭Exide Industries宣布計畫投資約7.18億美元在卡納塔克邦建立鋰離子電池製造工廠。第一階段將在 2024 年運作6GWh 鋰離子電池製造工廠,並在未來幾年內逐步擴建至 12GWh 綜合鋰離子電池工廠。

- 此外,2023 年 4 月,電池技術新興企業Log9 Materials 在班加羅爾賈庫爾開設了該國第一家鋰離子電池製造工廠。該工廠初始產能為50MWh。該公司還計劃在2025年第一季將鋰離子電池產能擴大至1GWh,電池組產能擴大至2GWh。

- 總體而言,由於龐大的消費群、支援措施以及電池製造的不斷進步,印度電動車(EV)鋰離子電池市場預計將在未來幾年進一步成長。

亞太地區電動汽車鋰離子電池產業概況

亞太地區電動車鋰離子電池市場已腰斬。該市場的主要企業包括(排名不分先後)松下公司、寧德時代新能源科技有限公司、天津力神電池股份有限公司、三星SDI和LG能源解決方案有限公司。

其他好處

- Excel 格式的市場預測 (ME) 表

- 3 個月分析師支持

目錄

第1章簡介

- 調查範圍

- 市場定義

- 研究場所

第 2 章執行摘要

第3章調查方法

第4章市場概況

- 介紹

- 2029年之前的市場規模與需求預測(單位:美元)

- 最新趨勢和發展

- 政府法規和措施

- 市場動態

- 促進因素

- 鋰離子電池價格下降

- 電動車的擴張

- 政府支持措施和舉措

- 抑制因素

- 新的替代電池技術

- 促進因素

- 供應鏈分析

- 產業吸引力-波特五力分析

- 供應商的議價能力

- 消費者議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭公司之間敵對關係的強度

第5章市場區隔

- 按車型

- 客車

- 商用車

- 其他(摩托車、Scooter等)

- 依推進類型

- 純電動車(BEV)

- 插電式混合動力汽車(PHEV)

- 混合動力電動車(HEV)

- 按地區

- 印度

- 中國

- 日本

- 韓國

- 泰國

- 印尼

- 越南

- 其他亞太地區

第6章 競爭狀況

- 併購、合資、聯盟、協議

- 主要企業策略及SWOT分析

- 公司簡介

- Panasonic Corporation

- Samsung SDI Co. Ltd

- Contemporary Amperex Technology Co. Ltd(CATL)

- BYD Company Limited

- Tianjin Lishen Battery Joint-Stock Co. Ltd

- Trontek Electronics Pvt. Ltd

- Greenfuel Energy Solutions Pvt. Ltd

- LG Energy Solution Ltd

- SK Innovation Co Ltd

- AESC Group Ltd

- Tesla Inc.

- 其他知名公司名單(公司名稱、總部地點、相關產品及服務、聯絡等)

- 市場排名分析

第7章 市場機會及未來趨勢

- 電動車採用固體鋰離子電池

The Asia-Pacific Lithium-ion Battery For Electric Vehicle Market size is estimated at USD 45.42 billion in 2025, and is expected to reach USD 129.17 billion by 2030, at a CAGR of 23.25% during the forecast period (2025-2030).

Key Highlights

- Declining lithium-ion battery prices, the increasing adoption of electric vehicles, and supportive government policies and initiatives are expected to drive the growth of the Asia-Pacific lithium-ion battery for electric vehicle market over the medium term of the forecast period.

- On the other hand, emerging alternative battery technologies are likely to hinder market growth during the forecast period.

- Nevertheless, the need for lithium-ion batteries for hybrid electric vehicle (HEV) applications in emerging economies is expected to create vast opportunities for lithium-ion batteries for the electric vehicle market in Asia-Pacific.

Asia-Pacific Lithium-ion Battery for Electric Vehicle Market Trends

The Battery Electric Vehicle (BEV) Segment to Witness Significant Growth

- Battery electric vehicles (BEVs) are also commonly referred to as electric vehicles with an electric motor. BEVs are fully electric vehicles that typically do not include an internal combustion engine (ICE), fuel tank, or exhaust pipe and rely on electricity for propulsion. The vehicle's energy comes from a battery pack, which is recharged from the grid. BEVs are zero-emission vehicles, as they do not generate harmful tailpipe emissions or air pollution hazards caused by traditional gasoline-powered vehicles.

- The automotive industry in Asia-Pacific has been transforming over the years, with electric vehicles, particularly battery electric vehicles (BEVs), gaining momentum and popularity. With growing technological advancements, government support, and increasing environmental concerns, BEVs have emerged as a promising solution to address the challenges of climate change and reduce reliance on fossil fuels.

- In recent years, the adoption of battery-electric vehicles has grown significantly worldwide. The improvement of battery technology has led to extended driving ranges and a surge in charging infrastructure that is helping overcome the initial entry barriers. Further, automakers such as Tesla, BYD, Tata, Toyota, and Honda have been playing a vital role in popularizing BEVs, offering affordable models that appeal to a broader range of consumers.

- According to the International Energy Agency (IEA), the battery electric vehicle (BEV) car stocks in China stood at around 16 million units in 2023. Similarly, in the same year, countries such as India, Japan, and South Korea had approximately 0.15 million, 0.29 million, and 0.46 million units of BEV car stock, respectively. Similarly, in 2023, BEV sales in China stood at over 5.4 million. India sold around 82,000 units of BEV cars, while Japan and South Korea sold 88,000 and 120,000 units of BEV cars, respectively. As the sales of BEVs continue to rise, the demand for EV batteries, such as lithium-ion batteries, has become increasingly vital.

- Moreover, being one of the largest markets for BEV vehicles, Asia-Pacific is also the largest EV battery manufacturing region in the world. China led from the front with an EV battery demand of about 417 GWh per year, or about 54% of the world demand in 2023, recording a surge of over 32% from 2022. This highlights the importance of the region's dominance in EV battery technologies. Similarly, as per the International Energy Agency (IEA), the lithium-ion battery manufacturing capacity in the Asia-Pacific region is expected to grow significantly in the coming years, with China leading the way. The agency estimated that the Chinese lithium-ion battery manufacturing capacity will rise to 4.65 TWh in 2030 from around 1.20 TWh in 2022.

- To accelerate the adoption of BEVs, countries have been implementing various initiatives and incentives. For example, to reduce dependency on imported advanced chemistry cell (ACC) batteries for electric vehicles, the Indian government approved a Production Linked Incentive (PLI) Scheme in early 2021 for the manufacturing of ACCs in the country. The total outlay of the Scheme is USD 2.12 billion for five years. The scheme envisages establishing a competitive ACC battery manufacturing setup in the country (50 GWh). In addition, 5 GWh of niche ACC technologies is also covered under the scheme. Such initiatives are supporting the demand for lithium-ion batteries for EV applications.

- Further, Southeast Asian countries such as Thailand, Indonesia, Singapore, Malaysia, and the Philippines are expected to see rapid growth in the adoption of lithium-ion batteries due to the increasing prevalence of EVs and government initiatives to accelerate EV use. For example, Indonesia has an ambitious target of having EVs make up 20% of all car sales by 2025, and the Indonesian government aims for 600,000 EVs to be domestically produced by 2030. Such targets are translated into different milestones within the EV supply chain, including the lithium-ion batteries market.

- In early 2024, the EV Board in Thailand approved the second phase of the EV Package, known as EV 3.5, for four years (2024-2027) to promote the EV industry's continuous progress and facilitate investment opportunities in EV manufacturing in Thailand for new players. The package aims to boost investments covering the entire EV industry ecosystem. As part of the package, the Thai government will offer subsidies for the purchase of electric cars, electric pickup trucks, and electric motorcycles based on the vehicle types and battery capacities. Thailand's continuous EV promotion package since 2017 has resulted in investments in the EV industry worth USD 1.8 billion in manufacturing BEVs, battery electric motorcycles, EV parts and components, and charging stations.

- Therefore, due to the factors mentioned above, the BEV segment is likely to dominate the lithium-ion battery for electric vehicle (EV) market during the forecast period.

India to Witness Fastest Growth

- India is emerging as one of the fastest-growing markets for lithium-ion batteries, driven by a strong push toward the adoption of electric vehicles (EVs). For example, according to the International Energy Agency (IEA), battery electric vehicle (BEV) sales in India reached around 82,000 units in 2023, an increase of over 70% from 2022. Additionally, the Indian government aims for an EV target of 30% of newly registered private cars, 40% of buses, 70% of commercial cars, and 80% of 2-wheelers and 3-wheelers by 2030. These are likely to create a substantial demand for EV batteries, such as lithium-ion batteries, in the coming years.

- Besides, the government has also implemented a range of policies and incentives to encourage the shift from traditional internal combustion engine vehicles to EVs, significantly boosting the demand for lithium-ion batteries. With initiatives such as the Faster Adoption and Manufacturing of Hybrid and Electric Vehicles (FAME) scheme, India is making substantial investments in charging infrastructure, battery manufacturing, and subsidies for EV buyers, creating a conducive environment for market growth.

- More recently, in March 2024, the Indian government approved a new USD 500-million-worth EV Policy, offering a range of incentives to draw investments from global EV companies and position India as a prime manufacturing hub for state-of-the-art EVs. Other objectives include providing Indian consumers with access to cutting-edge EV models, expanding the Make in India ecosystem, lowering costs of production, and fostering a competitive domestic auto manufacturing industry.

- Various local and international players are investing in the Indian lithium-ion battery market, aiming to capitalize on the country's burgeoning energy storage needs and its transition toward sustainable solutions. For example, in April 2022, battery behemoth Exide Industries announced plans to invest about USD 718 million to set up a lithium-ion cell manufacturing plant in Karnataka. In its first phase, a 6 GWh lithium-ion cell manufacturing facility is likely to become operational by 2024, gradually expanding to a 12 GWh capacity integrated lithium-ion battery facility over the next few years.

- Furthermore, in April 2023, the battery technology startup Log9 Materials inaugurated the country's first lithium-ion cell manufacturing facility in Jakkur, Bengaluru. The plant has an initial capacity of 50 MWh. The company is also working on expanding its lithium-ion cell manufacturing capacity to 1 GWh and its battery pack manufacturing capacity to 2 GWh by the first quarter of 2025.

- Overall, with a large consumer base, supportive policies, and increasing progress in the batteries manufacturing, the lithium-ion battery for electric vehicle (EV) market in India is poised for further growth in the coming years.

Asia-Pacific Lithium-ion Battery for Electric Vehicle Industry Overview

The Asia-Pacific lithium-ion battery market for electric vehicles is semi-fragmented. Some of the key players in the market (not in any particular order) include Panasonic Corporation, Contemporary Amperex Technology Co. Limited, Tianjin Lishen Battery Joint-Stock Co. Ltd, Samsung SDI Co. Ltd, and LG Energy Solution Ltd.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Scope of the Study

- 1.2 Market Definition

- 1.3 Study Assumptions

2 EXECUTIVE SUMMARY

3 RESEARCH METHODOLOGY

4 MARKET OVERVIEW

- 4.1 Introduction

- 4.2 Market Size and Demand Forecast in USD until 2029

- 4.3 Recent Trends and Developments

- 4.4 Government Policies and Regulations

- 4.5 Market Dynamics

- 4.5.1 Drivers

- 4.5.1.1 Declining Lithium-ion Battery Prices

- 4.5.1.2 Increasing Adoption of Electric Vehicles

- 4.5.1.3 Supportive Government Policies and Initiatives

- 4.5.2 Restraints

- 4.5.2.1 Emerging Alternative Battery Technologies

- 4.5.1 Drivers

- 4.6 Supply Chain Analysis

- 4.7 Industry Attractiveness - Porter's Five Forces Analysis

- 4.7.1 Bargaining Power of Suppliers

- 4.7.2 Bargaining Power of Consumers

- 4.7.3 Threat of New Entrants

- 4.7.4 Threat of Substitute Products and Services

- 4.7.5 Intensity of Competitive Rivalry

5 MARKET SEGMENTATION

- 5.1 By Vehicle Type

- 5.1.1 Passenger Vehicles

- 5.1.2 Commercial Vehicles

- 5.1.3 Other Vehicle Types (Bikes, Scooters, etc.)

- 5.2 By Propulsion Type

- 5.2.1 Battery Electric Vehicle (BEV)

- 5.2.2 Plug-in Hybrid Electric Vehicle (PHEV)

- 5.2.3 Hybrid Electric Vehicle (HEV)

- 5.3 By Geography

- 5.3.1 India

- 5.3.2 China

- 5.3.3 Japan

- 5.3.4 South Korea

- 5.3.5 Thailand

- 5.3.6 Indonesia

- 5.3.7 Vietnam

- 5.3.8 Rest of Asia-Pacific

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers and Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Strategies Adopted & SWOT Analysis for Leading Players

- 6.3 Company Profiles

- 6.3.1 Panasonic Corporation

- 6.3.2 Samsung SDI Co. Ltd

- 6.3.3 Contemporary Amperex Technology Co. Ltd (CATL)

- 6.3.4 BYD Company Limited

- 6.3.5 Tianjin Lishen Battery Joint-Stock Co. Ltd

- 6.3.6 Trontek Electronics Pvt. Ltd

- 6.3.7 Greenfuel Energy Solutions Pvt. Ltd

- 6.3.8 LG Energy Solution Ltd

- 6.3.9 SK Innovation Co Ltd

- 6.3.10 AESC Group Ltd

- 6.3.11 Tesla Inc.

- 6.4 List of Other Prominent Companies (Company Name, Headquarter, Relevant Products & Services, Contact Details, etc.)

- 6.5 Market Ranking Analysis

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 Adoption of Solid-state Lithium-ion Batteries for Electric Vehicles