|

市場調查報告書

商品編碼

1636452

義大利電動汽車電池製造:市場佔有率分析、產業趨勢、成長預測(2025-2030)Italy Electric Vehicle Battery Manufacturing - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

價格

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

簡介目錄

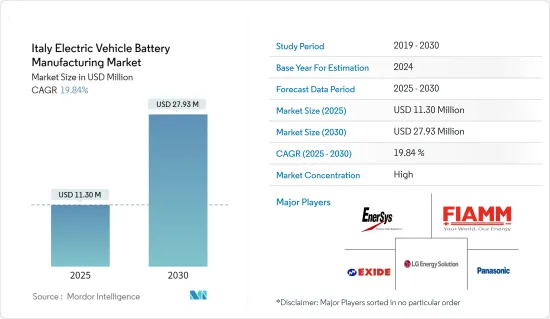

義大利電動車電池製造市場規模預計到2025年為1,130萬美元,預計2030年將達到2,793萬美元,預測期內(2025-2030年)複合年成長率為19.84%。

主要亮點

- 從中期來看,增加投資以提高電池產能和降低電池原料成本預計將在預測期內推動電動車電池製造需求。

- 另一方面,原料蘊藏量短缺可能會顯著抑制電動車電池製造市場的成長。

- 然而,擴大產能、加強技術進步和降低成本等電動車的長期雄心勃勃的目標預計將在不久的將來為電動車電池製造市場創造重大機會。

義大利電動汽車電池製造市場趨勢

鋰離子電池類型主導市場

- 鋰離子 (Li-ion) 電池徹底改變了電動車 (EV) 市場,並刺激了電池製造的創新。鋰離子電池的關鍵特性,如高能量密度、長循環壽命和快速充電,使其成為當今電動車的選擇。

- 此外,鋰離子二次電池具有優異的容量重量比,這使得它們優於其他技術。儘管鋰離子二次電池往往比其他替代品更昂貴,但市場領導者正在加大研發投入、擴大生產、加劇競爭,從而壓低價格。

- 電動車電池組和電池能源儲存系統(BESS)的平均價格一直在上漲,但到2023年將大幅下降,下降13%至139美元/kWh。據預測,這種下降趨勢預計將持續下去,到2025年將達到113美元/千瓦時,並在2030年進一步降至80美元/千瓦時。

- 在全球範圍內,各國政府正在推出政策和獎勵,以加速電動車(EV)的普及並擴大鋰離子電池的生產。作為一項策略性舉措,主要國際公司正在對當地企業進行大量投資,以擴大鋰離子電池的生產,特別是電動車(EV)的鋰離子電池生產。

- 例如,2024年2月,Automotive Cells公司獲得47億美元資金,在法國、德國和義大利建立三個鋰離子電池超級工廠。該合資企業得到了 Stellantis、梅賽德斯-奔馳和 Saft(TotalEnergies 子公司)等行業巨頭的支持,預計將在不久的將來推動先進鋰離子電池的需求,從而加強該地區的電動汽車電池製造。的。

- 此外,各國政府正在製定政策和獎勵,以促進電動車(EV)的採用和發展鋰離子電池產業。這些政府重點關注研究和開發,旨在尋找具有成本效益的材料替代品,以取代鈷等材料,而鈷等材料因高成本且供應有限而聞名。這項策略支點不僅降低了生產成本,也加強了永續的供應鏈。

- 例如,2024年7月,POSCO N.EX.T Hub推出了一款突破性的負極保護層,具有專為固態固態電池客製化的功能性黏合劑(PVA-g-PAA)。這項創新功能可確保均勻的鋰沉積,顯著減少鋰的使用量並提高電池壽命和能量密度。這些突破性技術可能在未來幾年加速國內電池生產。

- 因此,這些舉措和計劃預計將在預測期內提高鋰離子電池產量並顯著提高電動車電池產能。

乘用車板塊實現大幅成長

- 義大利汽車產業正在向電動車 (EV) 進行決定性轉型,以促進全球永續性並減少碳排放。這項轉變的關鍵因素是更加關注電動車電池的生產和改進。這項變化不僅正在改變義大利乘用車市場的動態,也影響著該產業的多個方面。

- 此外,隨著義大利擁抱清潔能源,轉型為電動車款已成為許多公司的中心主題。義大利的電動車銷量大幅成長。例如,根據國際能源總署(IEA)的報告,2023年電動車銷量將為13.6萬輛,比2022年成長19.3%,比2019年成長驚人的6.8倍。在這一勢頭和加拿大政府最近舉措的推動下,電動車銷量預計將進一步增加,這表明對電動車電池生產的需求激增。

- 為了對抗空氣污染並減少對石化燃料的依賴,義大利正在積極推廣電動車(EV)的採用,並將其擴展到更廣泛的乘用車領域。政府的多管齊下策略包括財政誘因、基礎設施增強和公眾意識提升宣傳活動,所有這些都是為了促進這一轉變。

- 作為其承諾的標誌,義大利於 2024 年 2 月撥款 9.5 億歐元(約 10 億美元)。該資金旨在透過加速向清潔汽車,特別是電動車(EV)的轉變,重振汽車產業。具體來說,羅馬的策略包括高達 13,750 歐元(15,042 美元)的慷慨補貼,主要使低收入者受益。這筆補助金用於購買一輛價值高達 35,000 歐元(38,290 美元)的新型全電動汽車。這些措施預計將增加該地區對乘用車的需求,並在預測期內增加對電池製造的需求。

- 此外,在義大利,主要汽車製造商正在推出尖端的插電式混合動力電動車(PHEV)。此舉反映了全行業向插電式混合動力車發展的趨勢,製造商尋求將電動車和傳統引擎的優勢結合起來,以滿足消費者需求和當地法規。

- 例如,2024年5月,Stellantis宣布計劃推出其500e小型電動車的混合動力版本,該車將在其位於義大利的Mirafiori工廠生產。 500e 已在義大利都靈生產。此類策略營運預計將促進混合動力乘用車在該地區的普及,並在短期內推動電池製造的需求。

- 因此,這些舉措和計劃預計將增強電動車需求,並在未來幾年顯著增加對電動車電池製造的需求。

義大利電動汽車電池製造業概況

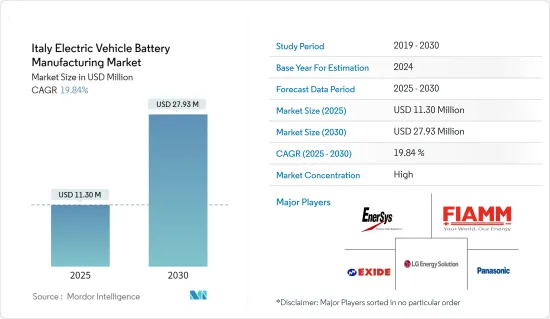

義大利電動車電池製造市場正在變得半固體。主要企業(排名不分先後)包括Panasonic Holdings、Exide Industries Ltd、EnerSys、FIAMM Energy Technology SpA 和 LG Chem Ltd。

其他好處:

- Excel 格式的市場預測 (ME) 表

- 3 個月的分析師支持

目錄

第1章簡介

- 調查範圍

- 市場定義

- 研究場所

第 2 章執行摘要

第3章調查方法

第4章市場概況

- 介紹

- 2029年之前的市場規模與需求預測(單位:美元)

- 最新趨勢和發展

- 政府法規政策

- 市場動態

- 促進因素

- 投資增加電池產能

- 電池原物料成本下降

- 抑制因素

- 原料蘊藏量不足

- 促進因素

- 供應鏈分析

- PESTLE分析

- 投資分析

第5章市場區隔

- 透過電池

- 鋰離子

- 鉛酸電池

- 鎳氫電池

- 其他

- 依電池形狀分類

- 方形

- 袋型

- 圓柱形

- 搭車

- 客車

- 商用車

- 其他

- 透過促銷

- 電池電動車

- 油電混合車

- 插電式混合動力電動車

第6章 競爭狀況

- 併購、合資、聯盟、協議

- 主要企業策略

- 公司簡介

- FIAMM Energy Technology SpA

- Panasonic Corporation

- LG Chem Ltd

- EnerSys

- Saft Groupe SA

- FAAM(Fabbrica Accumulatori Motocarri Montenero)

- Exide Industries Ltd

- STMicroelectronics NV

- MIDAC SpA

- Gotion High tech Co Ltd

- List of Other Prominent Companies

- 市場排名分析

第7章 市場機會及未來趨勢

- 電動車的長期目標

簡介目錄

Product Code: 50003719

The Italy Electric Vehicle Battery Manufacturing Market size is estimated at USD 11.30 million in 2025, and is expected to reach USD 27.93 million by 2030, at a CAGR of 19.84% during the forecast period (2025-2030).

Key Highlights

- Over the medium term, rising investments to enhance the battery production capacity and the decline in the cost of raw battery materials are expected to drive the demand for electric vehicle battery manufacturing during the forecast period.

- On the other hand, the lack of raw material reserves can significantly restrain the growth of the electric vehicle battery manufacturing market.

- Nevertheless, the long-term ambitious targets for electric vehicles like scaling up production capacity, enhancing technological advancements, and reducing costs are expected to create significant opportunities for the electric vehicle battery manufacturing market in the near future.

Italy Electric Vehicle Battery Manufacturing Market Trends

Lithium-Ion Battery Type Dominate the Market

- Lithium-ion (Li-ion) batteries have revolutionized the electric vehicle (EV) market, driving innovations in battery production. Their key attributes-high energy density, long cycle life, and swift charging-make them the preferred choice for today's EVs.

- Moreover, lithium-ion rechargeable batteries surpass other technologies due to their excellent capacity-to-weight ratio. Although they tend to be more expensive than alternatives, leading players in the market are boosting R&D investments and ramping up production, heightening competition, and pushing prices down.

- Despite rising average battery pack prices for EVs and battery energy storage systems (BESS), 2023 witnessed a significant dip, with prices falling to USD 139/kWh-a 13% decrease. Projections suggest this downward trajectory will persist, with prices anticipated to reach USD 113/kWh by 2025 and further decline to USD 80/kWh by 2030, driven by relentless technological and manufacturing progress.

- Globally, governments are rolling out policies and incentives to accelerate the adoption of electric vehicles (EVs) and expand Lithium-ion battery production. In a strategic move, major international firms are channeling significant investments into local companies to boost lithium-ion battery production, particularly for electric vehicles (EVs).

- For example, in February 2024, the Automotive Cells Company clinched a USD 4.7 billion funding to set up three lithium-ion battery gigafactories in France, Germany, and Italy. This venture, backed by industry giants like Stellantis, Mercedes-Benz, and Saft (a TotalEnergies subsidiary), is poised to elevate the demand for advanced lithium-ion batteries in the near future, subsequently bolstering EV battery manufacturing in the region.

- Additionally, governments nationwide are pushing policies and incentives to accelerate electric vehicle (EV) adoption and advance the Lithium-ion battery industry. With a focus on R&D, these governments aim to discover cost-effective substitutes for materials like cobalt, known for their high cost and limited availability. This strategic pivot not only reduces production expenses but also strengthens a sustainable supply chain.

- As an illustration, in July 2024, the POSCO N.EX.T Hub introduced a groundbreaking anode protection layer, equipped with a functional binder (PVA-g-PAA), tailored for all-solid-state batteries. This innovative feature guarantees even lithium deposition, significantly curtailing lithium usage, while enhancing battery lifespan and energy density. Such breakthroughs are set to expedite battery production in the country in the forthcoming years.

- Consequently, these initiatives and projects are poised to boost lithium-ion battery production and markedly elevate EV battery manufacturing capacity during the forecast period.

Passengers Cars Segment to Witness Significant Growth

- Italy's automotive sector is making a decisive shift towards electric vehicles (EVs), driven by a global push for sustainability and a commitment to reducing carbon emissions. A key element of this transformation is the intensified focus on the production and refinement of electric vehicle batteries. This shift is not only altering the dynamics of Italy's passenger car market but also influencing various facets of the industry.

- Moreover, as Italy embraces clean energy, the transition to electric vehicles has become a central theme for numerous companies. EV sales in Italy have surged dramatically. For instance, in 2023, the International Energy Agency (IEA) reported 136,000 electric vehicles sold, marking a 19.3% increase from 2022 and a staggering 6.8-fold rise since 2019. With this momentum and buoyed by recent Canadian government initiatives, EV sales are poised to climb further, signaling a booming demand for EV battery production.

- In a bid to tackle air pollution and reduce reliance on fossil fuels, Italy is vigorously promoting the adoption of electric vehicles (EVs), extending this push to encompass a broader range of passenger cars. The government's multifaceted strategy includes financial incentives, infrastructure enhancements, and public awareness campaigns, all designed to facilitate this transition.

- As a testament to its commitment, in February 2024, Italy allocated a significant 950 million euros (about USD 1 billion) in subsidies. This funding aims to accelerate the shift to cleaner vehicles, especially electric cars (EVs), and rejuvenate the automotive sector. Specifically, Rome's strategy includes generous subsidies of up to 13,750 euros (USD 15,042), predominantly benefiting low-income individuals. This financial boost is intended for purchasing new, fully electric vehicles, capped at a price of 35,000 euros (USD 38,290). Such measures are poised to amplify the demand for passenger cars in the region and subsequently heighten the need for battery manufacturing during the forecast period.

- In addition, leading automotive manufacturers are introducing state-of-the-art plug-in hybrid electric vehicles (PHEVs) in Italy. This trend reflects a wider industry movement towards PHEVs, as manufacturers seek to merge the benefits of electric and conventional engines, catering to both consumer desires and regional regulations.

- For example, in May 2024, Stellantis announced its plan to launch a hybrid version of its 500e compact electric car, with production slated at its Mirafiori facility in Italy. The 500e is already in production in Turin, Italy. Such strategic maneuvers are set to boost the uptake of hybrid passenger vehicles in the region and drive the demand for battery manufacturing in the foreseeable future.

- Consequently, these initiatives and projects are anticipated to bolster EV demand and substantially elevate the need for EV battery manufacturing in the coming years.

Italy Electric Vehicle Battery Manufacturing Industry Overview

Italy's electric vehicle battery manufacturing market is semi-consolidated. Some of the key players (not in particular order) are Panasonic Holdings Corporation, Exide Industries Ltd, EnerSys, FIAMM Energy Technology SpA, and LG Chem Ltd, among others.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Scope of the Study

- 1.2 Market Definition

- 1.3 Study Assumptions

2 EXECUTIVE SUMMARY

3 RESEARCH METHODOLOGY

4 MARKET OVERVIEW

- 4.1 Introduction

- 4.2 Market Size and Demand Forecast in USD, till 2029

- 4.3 Recent Trends and Developments

- 4.4 Government Policies and Regulations

- 4.5 Market Dynamics

- 4.5.1 Drivers

- 4.5.1.1 Investments to Enhance the battery production capacity

- 4.5.1.2 Decline in cost of battery raw materials

- 4.5.2 Restraints

- 4.5.2.1 Lack of Raw Material Reserves

- 4.5.1 Drivers

- 4.6 Supply Chain Analysis

- 4.7 PESTLE ANALYSIS

- 4.8 Investment Analysis

5 MARKET SEGMENTATION

- 5.1 Battery

- 5.1.1 Lithium-ion

- 5.1.2 Lead-Acid

- 5.1.3 Nickel Metal Hydride Battery

- 5.1.4 Others

- 5.2 Battery Form

- 5.2.1 Prismatic

- 5.2.2 Pouch

- 5.2.3 Cylindrical

- 5.3 Vehicle

- 5.3.1 Passenger Cars

- 5.3.2 Commercial Vehicles

- 5.3.3 Others

- 5.4 Propulsion

- 5.4.1 Battery Electric Vehicle

- 5.4.2 Hybrid Electric Vehicle

- 5.4.3 Plug-in Hybrid Electric Vehicle

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers and Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Strategies Adopted by Leading Players

- 6.3 Company Profiles

- 6.3.1 FIAMM Energy Technology SpA

- 6.3.2 Panasonic Corporation

- 6.3.3 LG Chem Ltd

- 6.3.4 EnerSys

- 6.3.5 Saft Groupe SA

- 6.3.6 FAAM (Fabbrica Accumulatori Motocarri Montenero)

- 6.3.7 Exide Industries Ltd

- 6.3.8 STMicroelectronics N.V

- 6.3.9 MIDAC SpA

- 6.3.10 Gotion High tech Co Ltd

- 6.4 List of Other Prominent Companies

- 6.5 Market Ranking Analysis

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 Long-term ambitious targets for electric vehicles

02-2729-4219

+886-2-2729-4219