|

市場調查報告書

商品編碼

1626292

法國工廠自動化和工業控制設備:市場佔有率分析、行業趨勢、統計和成長預測(2025-2030)France Factory Automation and Industrial Controls - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

價格

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

簡介目錄

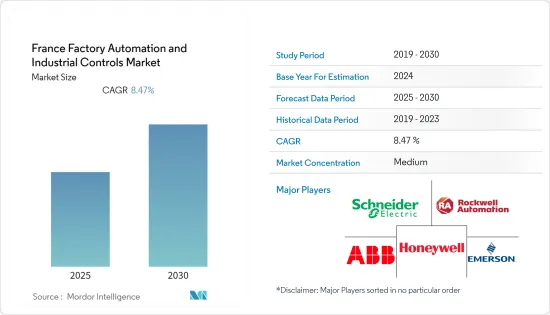

法國工廠自動化和工業控制設備市場預計在預測期內年複合成長率為8.47%

主要亮點

- 法國工業部門佔GDP的近17%,其中製造業是最重要的部分之一。法國正在透過物聯網和 M2M 向高度工業化的經濟邁進,以適應工業 4.0。它透過分析見解和減少浪費來幫助製造部門提高效率、減少系統故障並最佳化成本。

- 法國目前製造業產值居世界第八位,主要製造業領域包括食品飲料、機械設備、飛機、汽車、金屬及金屬加工製品、船舶及鐵路等。

- 由於用於控制工業設備的軟體應用程式的使用增加,這些製造商的市場佔有率預計將顯著成長。

- 此外,化學、化妝品、製藥和汽車行業基礎設施對工業機器人的投資也在穩步增加。物料輸送在拾放機器人的興起中發揮關鍵作用。

- 然而,自動化生產線總是需要較高的初始投資,而法國經濟成長疲軟是引入自動化的障礙。

法國工廠自動化和工業控制設備市場趨勢

可程式邏輯控制器的採用預計將顯著成長

- 可程式邏輯控制器是一種工業數位電腦,設計用於在惡劣的工業環境中運作以實現工業自動化。這些電腦主要用於控制工業製造過程,機器人設備、機器和組裝可以透過 PLC 輕鬆、自主地控制。

- PLC 使用必要的參數進行預先編程,處理和分析接收到的資料,並在必要時觸發輸出。 PLC 可輕鬆記錄和監控運行時資料,例如機器生產率、溫度、自動啟動/停止過程以及機器故障時產生的警報。

- 它還具有檢查設備和程式狀態的能力,因此如果出現問題或錯誤,它可以比其他控制設備更快修復。輸入和輸出指示器在系統內很容易辨識。

- 法國的汽車工業正在不斷發展,隨之而來的是對機器人自主製造和組裝的需求。 PLC 因其堅固性、靈活性和易於可程式設計而在控制製造過程中發揮重要作用。

- PLC 的高級功能可讓您透過網路瀏覽器進行資料通訊並將資料與雲端連接,讓您的工廠輕鬆採用工業物聯網和工業 4.0。

工業機器人可望主導市場

- 工業機器人領域包括關節型機器人、直角座標機器人、 SCARA機器人、協同機器人(cobots)、並聯機器人、取件機器人等。工業機器人因其更高的精度、靈活性、減少的產品損壞、速度和最終的營運效率而擴大被大多數最終用戶和應用所採用。

- 協作機器人和協作機器人的使用正在迅速增加,因為它們利用先進的感測器、軟體和臂端工具來快速、安全地響應環境變化並幫助提高效率。

- 在工業機器人中配備人工智慧後,汽車產業的組裝變得更有效率、更有效率且具有成本效益。該領域的工業機器人,特別是圓柱形機器人,透過製造過程的自動化徹底改變了汽車生產。

- 法國擁有許多著名的製造公司,包括空中巴士、Daher、雷諾集團和海軍集團。此外,創新叢集和創新平台包括ID 4 Car、EMC2、Others、Clarte、Proxinnov等。

- 因此,該國工業部門具有巨大的成長潛力。因此,對工廠自動化和現場設備的需求不斷成長,以實現此類製造工廠的自動化。工業機器人在製造自動化中扮演重要角色。

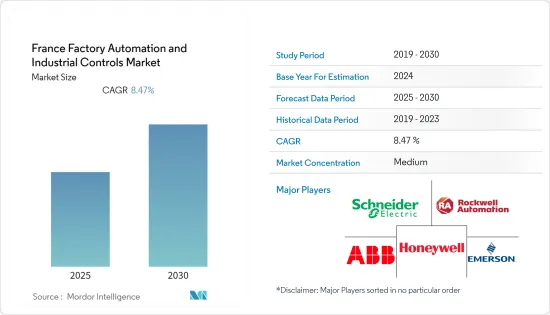

法國工廠自動化及工控設備產業概況

法國工廠自動化和工業控制設備市場適度分散,參與者規模各異。市場適度整合,從事工業自動化和工控設備先進技術的企業眾多。隨著自動化程度的提高,公司正在透過與其他自動化公司合作來投資市場。

- 2021 年 9 月 - Orange Business Services 和西門子透過在資料分析、專用 5G 網路、工業IoT、網路安全、雲端和邊緣運算領域合作,擴大法國製造業的工業 4.0 範圍。

- 2021 年 5 月-Schneider Electric與樂家集團合作加速脫碳。樂家集團是產品設計、生產和商業化領域的全球領導者,定義了脫碳新藍圖,該集團已在整個集團範圍內製定了單一的全球策略。

- 2021 年 4 月 - 西門子和 Google Cloud 宣布將合作簡化生產營運,以提高生產現場的效率。西門子計畫將Google雲端的頂級資料雲和人工智慧/機器學習(AI/ML)能力整合到其工廠自動化解決方案中,以支援製造業的製造流程。

其他好處:

- Excel 格式的市場預測 (ME) 表

- 3 個月分析師支持

目錄

第1章簡介

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章市場概況

- 市場概況

- 產業價值鏈分析

- 產業吸引力-波特五力分析

- 供應商的議價能力

- 消費者議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭公司之間敵對關係的強度

- 評估 COVID-19 對產業的影響

第5章市場動態

- 市場促進因素

- 自動化技術的興起

- 擴大機器對機器 (M2M) 技術的引進

- 市場挑戰

- 安裝成本高

- 行業法規政策

- 技術簡介

第6章 市場細分

- 按類型

- 工業控制系統

- 集散控制系統(DCS)

- 可程式邏輯控制器(PLC)

- 監控/資料採集 (SCADA)

- 產品生命週期管理 (PLM)

- 製造執行系統(MES)

- 人機介面 (HMI)

- 其他工業控制系統

- 現場設備

- 機器視覺

- 工業機器人

- 馬達和驅動器

- 安全系統

- 感測器和發射器

- 其他現場設備

- 工業控制系統

- 按最終用戶產業

- 石油和天然氣

- 化學/石化

- 電力/公共產業

- 飲食

- 汽車/交通

- 製藥

- 其他最終用戶產業

第7章 競爭格局

- 公司簡介

- Schneider Electric SE

- Rockwell Automation Inc.

- Honeywell International Inc.

- Emerson Electric Company

- ABB Ltd

- Mitsubishi Electric Corporation

- Siemens AG

- Omron Corporation

- Yokogawa Electric Corporation

- Fanuc Corporation

第8章投資分析

第9章 未來展望

簡介目錄

Product Code: 46907

The France Factory Automation and Industrial Controls Market is expected to register a CAGR of 8.47% during the forecast period.

Key Highlights

- The country's industrial sector contributes nearly 17% to the GDP, in which manufacturing is one of the most important parts. France is adapting to industry 4.0 by moving a highly industrialized economy through IoT and M2M. This is helping the manufacturing sector to increase its efficiency, reduce system failures and optimize the cost through analytical insight and cutting down on wastage.

- France is currently ranked eighth in the world for manufacturing output, the biggest segments in manufacturing sector includes food products and beverages, machinery and equipment goods, aircrafts, automobiles, metals and fabricated metal products, ships and trains.

- The market share of these manufacturing industries is expected to grow to a significant extent due to increase in use of software applications that are used to control industrial devices.

- Alslo, there has been increase in industrial robot investment at steady rate in chemical, cosmetic, pharmaceutical industries and in the infrastructure of automotive industry. Material handling has played the important role to increase pick and place robots.

- However, there is always a high initial investment requirement for automated production line which hinders the automation adoption in France due to the stagnated growth in the economy of the country.

France Factory Automation & Industrial Controls Market Trends

Programable Logic Controller Expected to Witness Signifcant Growth in the Adoption

- Programable Logic Controller is an industrial digital computer which is designed to operate in tough industrial environment for industrial automation. These computers are mainly used to control manufacturing process in industry, robotic devices, machines, assembly lines can be easily and autonomously controlled with PLC.

- PLCs are pre-programmed with required parameters; they process and analyse the received data and trigger outputs as per need. PLC easily records and monitors runtime data like machine productivity, temperature, automatic start and stop processes, generation of alarms when a machine fails and many more.

- It also provides a function that can check the state of facilities and programs so that if there are problems or errors, it is possible to make repairs quickly compared to other control units. Input and output indicators are easily identifiable in a system.

- The automobile industry in France in growing and with it the need of autonomous manufacturing assembly controlled by robots is also increasing. PLC plays an important role in controlling manufacturing processes due to their rugged, flexible and easily programmable features.

- The advanced features of PLC can communicate data through web browser and connect data with clouds, this enables easy adoption of Industrial Internet of Things and Industry 4.0 in a factory.

Industrial Robotics are expected to dominate the market

- The industrial robotics segment consists of articulated robots, cartesian robots, SCARA robots, collaborative industry robots (cobots), parallel robots, piece picking robots, etc. The adoption of industrial robots has been increasing in most end-users and applications as these robots enhance accuracy, flexibility, reduced product damage, speed, and ultimately the efficiency of operations.

- The use of collaborative robots or cobots is increasing rapidly as they are utilizing advanced sensors, software, and end-of-arm tooling that quickly and safely respond to the changes in the environment and assist in improving efficiency.

- With the help of artificial intelligence in industrial robots, the automotive sector's assembly lines have become more productive, efficient, and cost-effective. Industrial robotics on the shop floor, especially cylindrical robots, transformed automobile production by automating the manufacturing process.

- France is home to many reputable manufacturing companies that include Airbus, Daher, Groupe Renault, naval Group, and many others. Furthermore, the presence of innovation cluster and innovation platforms include ID 4 Car, EMC2, and other, Clarte, Proxinnov, and others.

- Thus, there is a huge potential for the growth of the country's industrial sector. This increases the need for factory automation and field devices to automate such manufacturing factories. Industrial Robots play important role in automation in manufacturing industry.

France Factory Automation & Industrial Controls Industry Overview

The France Factory Automation and Industrial Controls Market is a moderately fragmented market, with presence of many small and large players. Many companies are engaged in industrial automation and advanced technologies in industrial control devices, the market is moderately consolidated. Considering the increasing automation, companies are investing in the same, by partnering with other automation companies.

- September 2021 - Orange Business Services and Siemens struck a deal to combine in data analytics, private 5G networks, industrial IoT, cybersecurity, cloud and edge computing to expand the industry 4.0 space in French manufacturing sector.

- May 2021 - Schneider Electric partnered with Roca Group to accelerate decarbonization. Roca Group, a world leader in the design, production, and commercialization of products to define a new roadmap toward decarbonization, has been establishing a single, global strategy across the group.

- April 2021 - Siemens and Google Cloud announced their collaboration to streamline production operations for boosting shop floor efficiency. Siemens plans to integrate Google Cloud's top data cloud and artificial intelligence/machine learning (AI/ML) capabilities with its factory automation solutions to assist manufacturers in the manufacturing process.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGTHS

- 4.1 Market Overview

- 4.2 Industry Value Chain Analysis

- 4.3 Industry Attractiveness - Porter's Five Force Analysis

- 4.3.1 Bargaining Power of Suppliers

- 4.3.2 Bargaining Power of Consumers

- 4.3.3 Threat of New Entrants

- 4.3.4 Threat of Substitutes

- 4.3.5 Intensity of Competitive Rivalry

- 4.4 Assessment of COVID -19 impact on the Industry

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Gaining Prominence for Automation Technologies

- 5.1.2 Increasing Deployment of Machine-to-Machine (M2M) Technologies

- 5.2 Market Challenges

- 5.2.1 High Installation Costs

- 5.3 Industry Policies and Regulations

- 5.4 Technology Snapshot

6 MARKET SEGMENTATION

- 6.1 By Type

- 6.1.1 Industrial Control Systems

- 6.1.1.1 Distributed Control System (DCS)

- 6.1.1.2 Programable Logic Controller (PLC)

- 6.1.1.3 Supervisory Control and Data Acquisition (SCADA)

- 6.1.1.4 Product Lifecycle Management (PLM)

- 6.1.1.5 Manufacturing Execution System (MES)

- 6.1.1.6 Human Machine Interface (HMI)

- 6.1.1.7 Other Industrial Control Systems

- 6.1.2 Field Devices

- 6.1.2.1 Machine Vision

- 6.1.2.2 Industrial Robotics

- 6.1.2.3 Motors and Drives

- 6.1.2.4 Safety Systems

- 6.1.2.5 Sensors & Transmitters

- 6.1.2.6 Other Field Devices

- 6.1.1 Industrial Control Systems

- 6.2 By End-user Industry

- 6.2.1 Oil and Gas

- 6.2.2 Chemical and Petrochemical

- 6.2.3 Power and Utilities

- 6.2.4 Food and Beverage

- 6.2.5 Automotive and Transportation

- 6.2.6 Pharmaceutical

- 6.2.7 Other End-user Industries

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Schneider Electric SE

- 7.1.2 Rockwell Automation Inc.

- 7.1.3 Honeywell International Inc.

- 7.1.4 Emerson Electric Company

- 7.1.5 ABB Ltd

- 7.1.6 Mitsubishi Electric Corporation

- 7.1.7 Siemens AG

- 7.1.8 Omron Corporation

- 7.1.9 Yokogawa Electric Corporation

- 7.1.10 Fanuc Corporation

8 INVESTMENT ANALYSIS

9 FUTURE OUTLOOK

02-2729-4219

+886-2-2729-4219