|

市場調查報告書

商品編碼

1628748

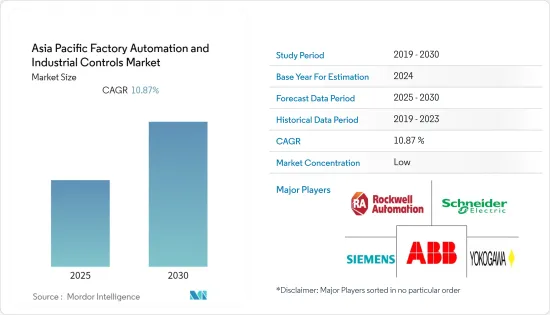

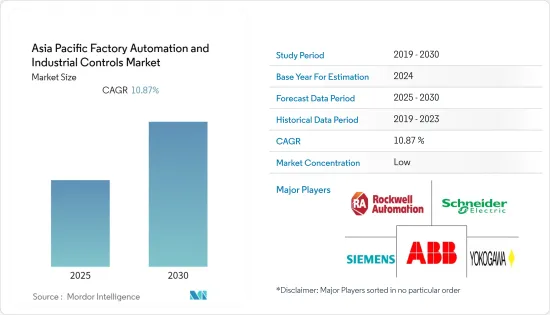

亞太地區工廠自動化和工業控制:市場佔有率分析、產業趨勢和成長預測(2025-2030)Asia Pacific Factory Automation and Industrial Controls - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

價格

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

簡介目錄

亞太工廠自動化和工業控制市場預計在預測期內複合年成長率為10.87%

主要亮點

- 此外,中國是受COVID-19大流行影響最嚴重的國家之一,大流行迫使其擴大勞動力,以解決技術純熟勞工短缺的問題,並避免因前所未有的情況而導致工作流程中斷,需要工廠自動化來取代。 ABB表示,在中國、美國和歐洲接受調查的1,900家建設公司中,81%有可能引進工業機器人。

- 此外,各行業對流程效率和降低生產成本的關注推動了亞太地區工廠自動化和工業控制系統市場的發展。製造業是亞太地區的重要產業,而在該產業中扮演重要角色的中國經濟,由於人事費用飆升以及傳統農民工缺乏永續性,正進入快速變革時期時期。這些趨勢正在推動經濟體採用自動化作為其製造流程的一部分。

- 此外,自動化流程的通訊支援使製造商更容易採用。感測器組件、更快的網路、高品質的診斷軟體、具有高可靠性和安全分層存取的靈活介面以及糾錯選項可提高生產率、持續高品質交貨,並最大限度地降低該地區的製造成本。

- 例如,三菱電機和英特爾合作為英特爾在馬來西亞的製造工廠開發下一代工廠自動化系統。這使我們能夠分析半導體生產線產生的現場資料,提高營運績效,並為節約能源做出貢獻,從而降低社會永續發展的成本。

- 該地區工業自動化的採用正在進一步進展,物聯網是跨越開發、生產和物流鏈的新技術方法的核心,現在被稱為智慧工廠自動化。例如,日本政府核准了日本振興計劃,為進一步強化製造業提供了一條路徑,發展目標為1.3兆美元。到 2023 年,在工業 4.0 的推動下,工業領域的企業收益預計將成長 4,900 億美元。

亞太地區工廠自動化與工業控制市場趨勢

汽車產業推動市場成長

- 汽車產業是佔據自動化製造設施很大佔有率的重要產業之一。已經證實,各汽車製造商的生產設施都實現了自動化,以保持準確性和效率。此外,電動車取代傳統汽車的趨勢日益明顯,預計將進一步擴大汽車產業的需求。

- 自動化對於該地區的汽車製造並不陌生。事實上,機器視覺正在透過執行基於影像的自動檢查和分析來實現自動檢查和製程控制,從而進入汽車製造領域。另一方面,自動化軟體和控制系統支援從零件供應到新車交付的一切。

- 2020年11月,現代汽車宣布與印尼政府合作,在該國建造第一家製造工廠。 2020 年 5 月 1 日作為新公司成立的現代機器人公司提到,為新工廠訂單了 370 台工業機械臂。現代汽車在東南亞的第一家製造工廠位於印尼首都雅加達附近,計劃於 2022 年建成。工廠用地面積77.6萬平方公尺,最大產能25萬台。

- 2020 年 10 月,日本汽車零件供應商 DENSO 開發了獨特的雲端原生工廠物聯網平台,透過雲端連接其全球所有工廠。這使得工廠能夠即時響應當地需求驅動的生產變化,並允許生產團隊即時分析不同設施的工人移動和運作條件,從而增強了Denso的全球生產系統。

- 智慧先進製造和快速轉型中心 (SAMARTH) Udyog Bharat 4.0舉措旨在提高印度製造業對工業 4.0 的認知,並使相關人員能夠應對智慧製造挑戰。

中國佔較大市場佔有率

- 引領工業機器人市場的中國在該地區的工廠自動化方面處於領先地位,不僅是亞太地區而且是全球領先的製造國。中國正在增加工業機器人的出貨量,並採用各種工業控制系統軟體,促進大規模工廠自動化。

- 製造業是中國經濟的支柱之一,正經歷快速轉型。隨著人口老化和人事費用上升,基於廉價移工的傳統模式已不再永續。此外,全球70%的電腦、通訊設備和家用電子電器產品是中國製造的。

- 中國人口老化需要自動化。根據中國國家統計局的數據,中國勞動年齡人口(15歲至64歲人口)為9.98億。人口下降始於 2014 年,預計到 2050 年將下降至 8 億。

- 該國的工業控制系統在能源、交通、水利和市政等各個領域不斷湧現。隨著資訊科技與工業的深度融合以及物聯網的快速發展,網路化控制系統正成為我國工業自動化的發展趨勢。

- 與中國龐大的製造地規模及其僱用的工人數量相比,實施工廠自動化、製程自動化技術和機器人技術的公司數量很少。這一趨勢為中國工業自動化領域的公司帶來了巨大的機會。

亞太工廠自動化與工業控制產業概況

由於眾多參與企業,亞太工廠自動化和工業控制市場競爭非常激烈。參與企業從事產品開發、夥伴關係、併購和收購等策略活動。市場的主要發展包括:

- 2021 年 4 月-工業機器人製造新興企業Youibot 完成由軟銀亞洲資金籌措主導的 1,547 萬美元融資。該公司80%的年收益來自中國,計劃將籌集的資金用於研發。

- 2021 年 3 月 - 新加坡電信和現代汽車公司簽署合作備忘錄,共同為現代汽車集團新加坡創新中心的製造平台開發支援 5G 的智慧工廠用例。

- 2021 年 2 月 - 三菱電機宣布將在名古屋工廠內建立工業機電一體化系統製造廠。

其他好處

- Excel 格式的市場預測 (ME) 表

- 3 個月分析師支持

目錄

第1章簡介

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章市場洞察

- 市場概況

- 產業價值鏈分析

- 產業吸引力-波特五力分析

- 供應商的議價能力

- 消費者議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭公司之間敵對關係的強度

- 評估 COVID-19 對產業的影響

第5章市場動態

- 市場促進因素

- 啟動嚴格的節能標準並促進本地生產

- 市場問題

- 貿易摩擦和金融措施收緊

第6章 市場細分

- 按類型

- 工業控制系統

- 集散控制系統(DCS)

- PLC(可程式邏輯控制器)

- SCADA(監控/資料採集)

- 產品生命週期管理 (PLM)

- 人機介面 (HMI)

- 製造執行系統(MES)

- 企業資源規劃系統(ERP)

- 其他工業控制系統

- 現場設備

- 機器視覺系統

- 機器人(工業)

- 感測器和發射器

- 馬達與驅動器

- 其他現場設備

- 工業控制系統

- 按最終用戶產業

- 石油和天然氣

- 化學/石化

- 電力/公共產業

- 飲食

- 車

- 製藥

- 其他

- 按國家/地區

- 中國

- 印度

- 日本

- 韓國

- 其他亞太地區

第7章 競爭格局

- 公司簡介

- Schneider Electric SE

- Rockwell Automation Inc.

- Emerson Electric Company

- Yokogawa Electric Corporation

- ABB Ltd.

- Siemens AG

- Mitsubishi Electric Corporation

- Honeywell International Inc.

- Omron Corporation

- Yaskawa Electric Corporation

第8章投資分析

第9章市場的未來

簡介目錄

Product Code: 53011

The Asia Pacific Factory Automation and Industrial Controls Market is expected to register a CAGR of 10.87% during the forecast period.

Key Highlights

- Moreover, with China being one of the worst-hit countries in the COVID 19 outbreak, the pandemic has also highlighted the need for factory automation to replace labor to deal with a skilled labor shortage and avoid disruption in the workflow due to the unprecedented nature of the situation. According to ABB, 81% of companies amongst 1,900 construction firms based in China, the United States, and Europe surveyed are likely to adopt industrial robots.

- Furthermore, the Asia-Pacific factory automation and industrial control systems market is primarily driven by the increased focus on enhancing process efficiencies and reducing the cost of production across various industry verticals. Manufacturing serves as a significant industry in Asia-Pacific and China's economy being a significant contributor is undergoing a rapid transformation as labor costs have risen and the conventional model of migrant workers has lost the sustainability. Such trends have pushed the economy to adopt automation as a part of their manufacturing processes.

- Moreover, the communications support for automated processes have facilitated easier adoption among the manufacturers. Sensor components, faster networks, quality diagnostic software, and flexible interfaces with high levels of reliability and secured hierarchical access, along with error-correction options have added productivity, continued quality deliveries, and minimized the cost of manufacturing in the region.

- For instance, the collaboration between Mitsubishi Electric and Intel on the next-generation factory automation system for Intel's manufacturing facility in Malaysia; This has enabled field data generation from semiconductor manufacturing lines to be analyzed for improving operational performance and contribute to energy savings, thereby, cost savings toward a sustainable society.

- With IoT at the center of new technological approaches for development, production, and the entire logistics chain, otherwise known as smart factory automation, has further driven the adoption of industrial automation in the region. For instance, the Japanese government approved a plan known as the 'Rebirth of Japan,' which outlines the route towards strengthening the manufacturing sector further by targeting the development of USD 1.3 trillion. It is expected that, by 2023, companies in the industrial sector could grow revenues by as much as USD 490 billion as a result of Industry 4.0.

APAC Factory Automation and Industrial Controls Market Trends

Automotive Industry to Drive the Market Growth

- The automotive industry is one of the prominent sectors that hold a significant share in automated manufacturing facilities. It is observed that the production facilities of various automakers are automated to maintain accuracy and efficiency. Further, the growing trend of replacing conventional vehicles with EVs is expected to further augment the automotive industry's demand.

- Automation, in the region, is currently no stranger to automotive shop floors. In fact, Machine Vision has found a way in the automotive making by carrying out imaging-based automatic inspection and analysis for automatic inspection and process control. Whereas automation software and control systems have been supporting everything from component supply to the delivery of new vehicles.

- In November 2020, Hyundai Motors announced a partnership with the Indonesian government to build its first manufacturing plant in the country. Hyundai Robotics launched as a new company on May 1st, 2020, mentioned that the order is for 370 industrial robotic arms for the new facility. Located near Jakarta, Indonesia's capital city, Hyundai Motors' first manufacturing plant in Southeast Asia is anticipated to be built by 2022. The plant is being constructed in an area of 776,000 sq m, with a manufacturing capacity of up to 250,000 cars.

- In October 2020, DENSO, a Japan based automotive supplier developed its own cloud-native Factory-IoT platform, to connect all its factories around the world via cloud, this has strengthened DENSO's global production system, by enabling factories to respond immediately to production changes based on local demand, and allow production teams to conduct real-time analysis of the movement of workers and operation statuses of different facilities.

- The Smart Advanced Manufacturing and Rapid Transformation Hub (SAMARTH) Udyog Bharat 4.0 initiative aims at enhancing awareness about Industry 4.0 within the Indian manufacturing industry and help stakeholders address challenges related to smart manufacturing.

China to Hold Significant Market Share

- China has led the industrial robot market, which has driven its way to factory automation in the region and is one of the leading manufacturing countries in the Asia-Pacific region and globally. The increase in shipment of industrial robots in the country and the adoption of various Industrial Control System software across the country facilitates factory automation at scale.

- Manufacturing is one of the pillars of China's economy and is undergoing a rapid transformation. As the population ages, along with rising labor costs, the legacy model based on inexpensive migrant workers is no longer sustainable. Moreover, 70% of the world's computers, communication equipment, and consumer electronics are made in China.

- The country's aging population necessitates automation. According to China's National Bureau of Statistics, the country's working-age population, people aged between 15 and 64 years, is 998 million. The decline in this population started in 2014, and is expected to drop as low as 800 million by 2050.

- The industrial control system in the country has emerged across various fields, like the energy, transportation, water, and municipal sectors. Due to the deep integration of information technology and industry and the rapid development of the Internet of Things, the networked control system is becoming the development trend of industrial automation in China.

- The number of companies deploying factory and process automation technologies and robotics in the country is less when compared to the enormous size of China's manufacturing base and the number of workers it employs. This trend presents a great opportunity for companies in the industrial automation sector in China.

APAC Factory Automation and Industrial Controls Industry Overview

The Asia Pacific factory automation and industrial controls market is competitive due to several players in the market. Players are involved in product development and strategic activities such as partnerships, mergers, and acquisitions. Some of the key developments in the market are:

- April 2021 - Youibot, a start-up company that makes industrial robots, closed an investment of USD 15.47 million in the funding round led by SoftBank Ventures Asia alongside others. The company generates 80% of its annual revenue in China and has plans to spend the raised funds on research and development.

- March 2021 - Singapore Telecommunications and Hyundai Motor Company entered into an MoU to collaborate and develop a 5G-enabled smart factory use case for the manufacturing platform of Hyundai Motor Group Innovation Centre Singapore.

- February 2021 - Mitsubishi Electric announced the establishment of Industrial Mechatronics Systems Works within the premises of the company's Nagoya Works in Nagoya, Japan.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Value Chain Analysis

- 4.3 Industry Attractiveness - Porter's Five Forces Analysis

- 4.3.1 Bargaining Power of Suppliers

- 4.3.2 Bargaining Power of Consumers

- 4.3.3 Threat of New Entrants

- 4.3.4 Threat of Substitutes

- 4.3.5 Intensity of Competitive Rivalry

- 4.4 Assessment of Impact of COVID-19 on the Industry

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Launch of Stringent Energy Conservation Standards and Drive for Local Manufacturing

- 5.2 Market Challenges

- 5.2.1 Trade Tensions and Monetary Policy Tightening

6 MARKET SEGMENTATION

- 6.1 By Type

- 6.1.1 Industrial Control Systems

- 6.1.1.1 Distributed Control System (DCS)

- 6.1.1.2 PLC (Programmable Logic Controller)

- 6.1.1.3 Supervisory Control and Data Acquisition (SCADA)

- 6.1.1.4 Product Lifecycle Management (PLM)

- 6.1.1.5 Human Machine Interface (HMI)

- 6.1.1.6 Manufacturing Execution System (MES)

- 6.1.1.7 Enterprise Resource Planning (ERP)

- 6.1.1.8 Other Industrial Control Systems

- 6.1.2 Field Devices

- 6.1.2.1 Machine Vision Systems

- 6.1.2.2 Robotics (Industrial)

- 6.1.2.3 Sensors and Transmitters

- 6.1.2.4 Motors and Drives

- 6.1.2.5 Other Field Devices

- 6.1.1 Industrial Control Systems

- 6.2 By End-user Industry

- 6.2.1 Oil and Gas

- 6.2.2 Chemical and Petrochemical

- 6.2.3 Power and Utilities

- 6.2.4 Food and Beverages

- 6.2.5 Automotive

- 6.2.6 Pharmaceutical

- 6.2.7 Other End-user Industries

- 6.3 By Country

- 6.3.1 China

- 6.3.2 India

- 6.3.3 Japan

- 6.3.4 South Korea

- 6.3.5 Rest of Asia pacific

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Schneider Electric SE

- 7.1.2 Rockwell Automation Inc.

- 7.1.3 Emerson Electric Company

- 7.1.4 Yokogawa Electric Corporation

- 7.1.5 ABB Ltd.

- 7.1.6 Siemens AG

- 7.1.7 Mitsubishi Electric Corporation

- 7.1.8 Honeywell International Inc.

- 7.1.9 Omron Corporation

- 7.1.10 Yaskawa Electric Corporation

8 INVESTMENT ANALYSIS

9 FUTURE OF THE MARKET

02-2729-4219

+886-2-2729-4219