|

市場調查報告書

商品編碼

1628824

北美工廠自動化和工業控制:市場佔有率分析、行業趨勢和成長預測(2025-2030)North America Factory Automation and Industrial Controls - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

價格

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

簡介目錄

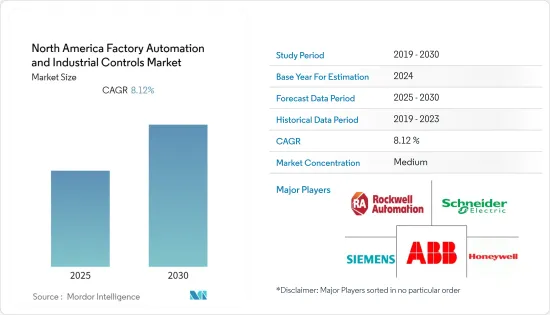

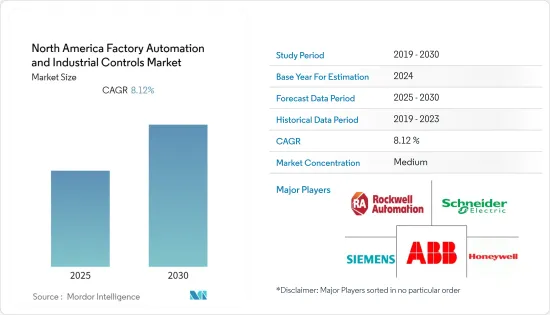

北美工廠自動化和工業控制市場預計在預測期內複合年成長率為 8.12%

主要亮點

- >為了節省能源和提高成本效益,該地區的工廠自動化和工業控制系統呈現日益成長的趨勢。根據牛津經濟研究院 2019 年的報告,預計未來 10 年美國將有超過 150 萬個工作因自動化而流失。該地區的汽車工業始終處於將機器人融入製造流程的前沿。約翰迪爾等行業領先製造商正在進行大量投資,將自動化技術整合到其產品和流程中。

- 有

- 。

- 例如,2020年3月,美國知名SCARA機器人製造商愛普生機器人宣布與Air 解決方案供應商 Engineering(AAE)合作

- 。近日,加拿大皇家銀行(RBC)與微軟合作推出Go Digital計劃,主要協助加拿大企業投資智慧自動化技術和雲端解決方案。

- 諸如先進製造夥伴關係(AMP) 之類的舉措擴大被採取,以促使當地工業、各大學和聯邦政府投資於新興的自動化技術。加拿大政府創建了一個名為「Automate Canada」的計劃,這是一個專門從事製造自動化解決方案的全球公司叢集。

- 然而,建立新的自動化製造工廠需要引進新的自動化技術,包括SCADA、DCS、RTU、PLC和HMI。建立這樣的製造工廠需要在設備、軟體和培訓方面進行大量資本投資。如此大的投資對於新參與企業來說很難建立他們的第一家工廠。

北美工廠自動化和工業控制市場趨勢

感測器和發射器現場設備推動市場成長

- 隨著工業操作中速度處理和物料輸送的進步和改進,在整個處理和處理階段提供相同程度的效率改進對於工業來說變得非常重要。這已成為產業避免和減少生產線及其他瓶頸、推動需求的關鍵方面。例如,汽車產業提供了快速回應市場需求、減少製造停機時間、提高供應鏈效率和擴大生產力的機會。

- 接近感測器用於智慧工廠的各種應用。隨著高速輸送機系統和自動化機器人的使用越來越多,這些感測器變得越來越重要。電容式感測器還具有高靈敏度,適用於涉及相對定位的任務。

- 光學接近感測器由於其尺寸小且能夠在惡劣條件下工作而得到了廣泛的應用。然而,其一般用途需要暗房應用,並且與其他類型的感測器相比其價格分佈較高。

- 智慧工廠涉及的流程高度依賴機器能否保持所需的輸入和輸出速度。這使您能夠確保最短的理想時間和最大的產量,並避免過度擁擠。由於這些特點,位置和速度感測器市場預計在研究期間將顯著成長。隨著工廠管理擴大採用電腦,預計該行業也將向數位系統轉變。

美國佔較大市場佔有率

- 美國一直以來都是採用重大技術創新的先驅。這些趨勢一直持續到今天。最近,福特在位於科隆的塗裝車間引入了協作機器人。六台協作機器人在 35 秒內打磨了嘉年華的車身,進一步改進了製造流程。此外,該國越來越多的公司正在採用自動化來最佳化業務。

- 美國石油和天然氣產業是自動化工作 PLC 系統的主要需求驅動力。自動化不僅使該國能夠生產大量石油和天然氣,而且還促進了石油產品在國內的順利分配。此外,豐田物料搬運北美公司 (TMHNA) 還選擇了兩項大學研究提案,透過 TMHNA 大學研究計畫獲得資助。

- 此外,該國是最大的原油生產國之一,也是石油和天然氣產業的重要參與企業。例如,根據EIA的數據,該國2019年原油產量為24.94兆英熱單位,至2030年,產量預計將達到30.01兆英熱單位。此外,德克薩斯州(美國)生產全國大部分原油,對生產設備的需求也很大。

- 其中許多外國公司正在採取聯盟和收購策略,預計將在全球範圍內取得長足進步。例如,2021年5月,帝國石油宣布收購埃克森美孚美國石油和天然氣資產,以加強在美國的影響力。該資產由約 700 口油氣井和注入井組成,佔地約 40,000 英畝二疊紀租賃土地。

北美工廠自動化和工業控制產業概況

由於參與企業眾多,北美工廠自動化和工業控制市場競爭非常激烈。參與企業從事產品開發、夥伴關係、併購和收購等策略活動。市場的主要發展包括:

- 2021 年 2 月 - ABB 宣布推出新的 GoFa 和 SWIFTI 協作機器人系列,擴大其協作機器人產品組合。這些機器人提供更高的承重能力和速度,補充了 ABB 的 YuMi 和單臂 YuMi 協作機器人系列。它們專為電子、醫療、消費品、物流以及食品和飲料等行業而設計。

- 2020年3月-歐姆龍公司在美國設立新的機器人安全自動化業務總部。該公司已在新工廠投資 1000 萬美元,用於設計、開發、測試和製造機器人和安全自動化解決方案。

其他好處

- Excel 格式的市場預測 (ME) 表

- 3 個月分析師支持

目錄

第1章簡介

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章市場動態

- 市場概況

- 產業價值鏈分析

- 產業吸引力-波特五力分析

- 新進入者的威脅

- 買家/消費者的議價能力

- 供應商的議價能力

- 替代品的威脅

- 競爭公司之間敵對關係的強度

- 評估 COVID-19 對產業的影響

- 市場促進因素

- 啟動嚴格的節能標準並促進本地生產

- 市場問題

- 貿易緊張局勢和金融措施收緊

第5章市場區隔

- 按類型

- 工業控制系統

- 集散控制系統(DCS)

- PLC(可程式邏輯控制器)

- 監控/資料採集(SCADA)

- 產品生命週期管理 (PLM)

- 人機介面 (HMI)

- 製造執行系統(MES)

- 現場設備

- 機器視覺系統

- 機器人(工業)

- 感測器和發射器

- 馬達和驅動器

- 其他現場設備

- 工業控制系統

- 按最終用戶產業

- 石油和天然氣

- 化學/石化

- 電力/公共產業

- 飲食

- 車

- 其他

- 按國家/地區

- 美國

- 加拿大

第6章 競爭狀況

- 公司簡介

- Schneider Electric SE

- Rockwell Automation Inc.

- Honeywell International Inc.

- Emerson Electric Company

- ABB Ltd.

- Mitsubishi Electric Corporation

- Siemens AG

- Omron Corporation

- Yokogawa Electric Corporation

- Yasakawa Electric Corporation

- KUKA AG(Midea Group)

- Fanuc Corporation

- Regal Beloit Corporation

- Nidec Motor Corporation

- Basler AG

第7章 投資分析

第8章市場的未來

簡介目錄

Product Code: 55074

The North America Factory Automation and Industrial Controls Market is expected to register a CAGR of 8.12% during the forecast period.

Key Highlights

- >

- Therefore, to save energy and to gain cost-benefit, the trend of factory automation and industrial control systems is gaining traction in the region. According to a 2019 report from Oxford Economics, the United States is projected to lose more than 1.5 million jobs to automation over the next decade.The regional automotive sector has always led the way in implementing robotics in their manufacturing processes. Key industry manufacturers, like John Deere, are making significant investments to integrate automated technology both into their products and processes.

- The region is witnessing increasing robotic technologies adoption. For instance, in March 2020, globally renowned SCARA robot manufacturer, Epson Robots, collaborated with the US-based automation solutions provider, Air Automation Engineering (AAE), as part of an initiative to increase its technical support in the Midwest United States.

- The adoption of factory automation solutions can help these manufacturers in cost savings, enhance productivity, and improve quality. Recently, Royal Bank of Canada (RBC) collaborated with Microsoft and launched the Go Digital program, mainly to help the Canadian businesses in investing in smart automation technologies and cloud solutions. Presently, the program is available to Canadian food manufacturers and will continue to expand to other industries over time.

- Initiatives, like 'Advanced Manufacturing Partnership (AMP)', are increasingly undertaken to make the regional industry, various universities, and the federal government to invest in the emerging automation technologies. The government in Canada created a program, Automate Canada, a global cluster of companies, specializing in manufacturing automation solutions. In the past, it also invested USD 230 million to help automate Ontario's manufacturing sector.

- However, establishment of new automated manufacturing plant mandates the deployment of emerging automation technologies Including SCADA, DCS, RTU, PLC, and HMI. The setting up of these manufacturing plants requires large capital investments for equipment, software, and training. Investing such a large amount is difficult for new entrants who are setting up their first plant.

North America Factory Automation and Industrial Controls Market Trends

Sensors and Transmitters Field Devices to Drive the Market Growth

- With the advancement and improvement in the processing of speed and material handling in the industrial operations, it has become important for the industries to bring similar level of efficiency improvement across the processing and handling stages. It has been an important aspect in the industry to avoid and reduce bottlenecks across the production line and beyond and has driven the demand. For instance, these offer opportunities to the automotive industry to react faster to market requirements, reduce manufacturing downtimes, enhance the efficiency of supply chains, and expand productivity.

- Proximity sensors are used in smart factory for varied applications. These sensors are becoming more important with the growing use of fast conveyer systems and automated robots. Capacitive sensors also have high sensitivity, making them a favorable choice for tasks related to relative positioning.

- Optical proximity sensors are finding an extensive use, owing to their small-size and ability to work in extreme conditions. However, their general use requires a dark room application, and they also come at a higher price point compared to other type of sensors.

- The processes involved in a smart factory are heavily dependent on the ability of machines to maintain desired rate of input and output. This ensures minimum ideal time and maximum output and avoids overcrowding. Due to these functions, the market for position and velocity sensors is expected to witness a significant growth during the study period. This industry is also projected to witness a shift toward digital systems, owing to increasing incorporation of computers for factory management.

United States Holds Significant Market Share

- The United States has traditionally been a forerunner in terms of adoption of key technological innovations. A continuation of these trends have been observed. Recently, Ford deployed cobots in its Cologne paint shop. The six cobots sand Fiesta bodies in 35 seconds, further improving the manufacturing process. Additionally, the country is home to various enterprises that are increasingly adopting automation to optimize operations.

- The US oil and gas industry has been a primary demand driver for PLC systems for automation tasks. Automation has not only enabled the high production of oil and gas in the country but also been responsible for the smooth distribution of oil products within the country. Further, Toyota Material Handling North America (TMHNA) selected two universities' research proposals to receive funding through the TMHNA University Research Program.

- Moreover, the country is one of the largest producers of crude oil and a prominent player in the oil and gas industry. For instance, according to EIA, the country produced 24.94 quadrillion Btu of Crude Oil in 2019, and by 2030, the production number is expected to reach 30.01 quadrillions Btu. Additionally, Texas (United States) produces the major share of crude oil in the country, and it is expected to hold a significant demand for production equipment.

- Most of these foreign players are adopting partnership and acquisition strategy, which is also bringing advancement at a global level. For instance, in May 2021, Empire Petroleum announced the acquisition of ExxonMobil's oil and gas assets in US to strengthen its presence in the United States. The assets comprise of about 700 oil, gas, and injector wells and accounts for 40,000 net acres of Permian leasehold, approximately.

North America Factory Automation and Industrial Controls Industry Overview

The North America factory automation and industrial controls market is competitive due to several players in the market. Players are involved in product development and strategic activities such as partnerships, mergers, and acquisitions. Some of the key developments in the market are:

- February 2021- ABB announced the expansion of its collaborative robot portfolio with the launch of its new GoFa and SWIFTI cobot families. These robots offer higher payloads and speeds, to complement YuMi and Single Arm YuMi in ABB's cobot line-up. These are designed to serve industries such as electronics, healthcare, consumer goods, logistics, food and beverage and others.

- March 2020 - Omron Corporation opened a new robotics and safety automation business headquarters in the United States. The company invested USD 10 million in the new facility, where it would design, develop, test, and manufacture robotic and safety automation solutions.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Market Overview

- 4.2 Industry Value Chain Analysis

- 4.3 Industry Attractiveness - Porter's Five Forces Analysis

- 4.3.1 Threat of New Entrants

- 4.3.2 Bargaining Power of Buyers/Consumers

- 4.3.3 Bargaining Power of Suppliers

- 4.3.4 Threat of Substitute Products

- 4.3.5 Intensity of Competitive Rivalry

- 4.4 Assessment of Impact of COVID-19 on the Industry

- 4.5 Market Drivers

- 4.5.1 Launch of Stringent Energy Conservation Standards and Drive for Local Manufacturing

- 4.6 Market Challenges

- 4.6.1 Trade Tensions and Monetary Policy Tightening

5 MARKET SEGMENTATION

- 5.1 By Type

- 5.1.1 Industrial Control Systems

- 5.1.1.1 Distributed Control System (DCS)

- 5.1.1.2 PLC (Programmable Logic Controller)

- 5.1.1.3 Supervisory Control and Data Acquisition (SCADA)

- 5.1.1.4 Product Lifecycle Management (PLM)

- 5.1.1.5 Human Machine Interface (HMI)

- 5.1.1.6 Manufacturing Execution System (MES)

- 5.1.2 Field Devices

- 5.1.2.1 Machine Vision Systems

- 5.1.2.2 Robotics (Industrial)

- 5.1.2.3 Sensors and Transmitters

- 5.1.2.4 Motors and Drives

- 5.1.2.5 Other Field Devices

- 5.1.1 Industrial Control Systems

- 5.2 By End-user Industry

- 5.2.1 Oil and Gas

- 5.2.2 Chemical and Petrochemical

- 5.2.3 Power and Utilities

- 5.2.4 Food and Beverages

- 5.2.5 Automotive

- 5.2.6 Other End-user Industries

- 5.3 By Country

- 5.3.1 United States

- 5.3.2 Canada

6 COMPETITIVE LANDSCAPE

- 6.1 Company Profiles

- 6.1.1 Schneider Electric SE

- 6.1.2 Rockwell Automation Inc.

- 6.1.3 Honeywell International Inc.

- 6.1.4 Emerson Electric Company

- 6.1.5 ABB Ltd.

- 6.1.6 Mitsubishi Electric Corporation

- 6.1.7 Siemens AG

- 6.1.8 Omron Corporation

- 6.1.9 Yokogawa Electric Corporation

- 6.1.10 Yasakawa Electric Corporation

- 6.1.11 KUKA AG (Midea Group)

- 6.1.12 Fanuc Corporation

- 6.1.13 Regal Beloit Corporation

- 6.1.14 Nidec Motor Corporation

- 6.1.15 Basler AG

7 Investment Analysis

8 Future of the Market

02-2729-4219

+886-2-2729-4219