|

市場調查報告書

商品編碼

1630251

德國包裝產業:市場佔有率分析、產業趨勢與統計、成長預測(2025-2030)Germany Packaging Industry - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

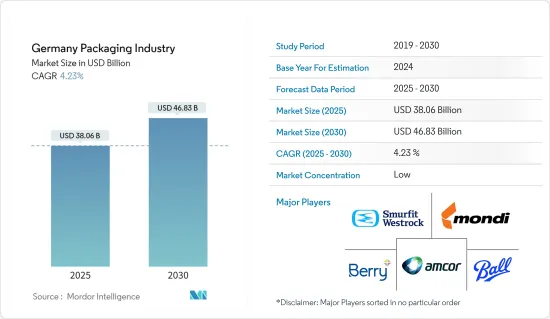

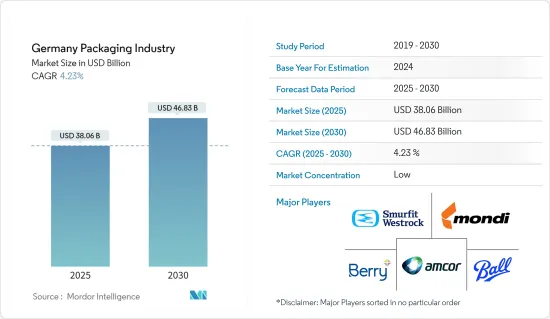

德國包裝產業預計將從2025年的380.6億美元成長到2030年的468.3億美元,預測期內(2025-2030年)複合年成長率為4.23%。

主要亮點

- 由於電子商務的快速成長,德國對包裝材料的需求不斷增加。為此,當地包裝公司正在轉向提供專為線上零售設計的經濟高效、安全且輕巧的解決方案。

- 這些產品採用創新設計,可在運輸過程中保護產品,同時最佳化材料使用。為了跟上線上訂單的成長,這些公司正在投資尖端的自動化包裝技術,包括機器人系統和人工智慧驅動的分類工具。這種自動化不僅簡化了操作,還確保了統一的包裝品質。

- 德國的包裝食品和個人保健部門對較小包裝尺寸的需求不斷成長,這一趨勢可能在未來幾年獲得成長勢頭。這種轉變是由於單人家庭的增加、對可重新密封和攜帶式包裝的偏好以及對保存期限的關注等因素造成的。

- 這些趨勢增加了從醬汁和調味料到糖果零食和加工水果等各種包裝材料的需求。為此,製造商正在設計創新的包裝解決方案,優先考慮產品新鮮度、最大限度地減少浪費並加強份量控制。

- 由於其重量輕且適應性強,對軟質塑膠包裝的需求正在增加。這種趨勢是由對緊湊、易於使用的包裝和先進設計的偏好所推動的。軟質塑膠不僅可以延長保存期限、降低運輸成本,還可以增加產品保護。出於環境考慮,製造商正在優先開發可回收和生物分解的軟質塑膠。

- 消費者轉向環保包裝材料的趨勢意義重大。鋁和玻璃因其環境效益和可回收性而在該地區越來越受歡迎。這一趨勢支持了更廣泛的遠離傳統塑膠的運動。

- 此外,歐洲理事會還針對一次性塑膠推出了新的歐盟範圍內的法規,並制定了雄心勃勃的回收目標。這些法規可能會對市場狀況產生影響。

德國包裝市場趨勢

德國塑膠包裝產業在監管收緊的情況下持續成長

- 在德國,由於解決方案供應商和最終用戶的積極努力,塑膠包裝解決方案的採用正在取得進展。 「德國製造」的聲譽為該地區的塑膠包裝公司創造了有利的環境。然而,德國政府對塑膠包裝產業實行嚴格的監管。德國包裝方法要求包裝設計應可回收、可回收,並使用可回收和可再生的材料。

- 由於各領域的需求不斷增加,製造商發現塑膠瓶的使用量不斷增加。例如,2023 年 6 月,可口可樂歐洲太平洋合作夥伴德國公司在其巴特諾伊納爾工廠運作了一條未使用的可回收 PET 生產線。這條生產線將裝瓶流行的碳酸飲料,包括可口可樂、芬達和雪碧,並重新推出不加糖的飲料。

- 軟性飲料,尤其是碳酸飲料,主要採用塑膠瓶包裝,尤其是聚對苯二甲酸乙二醇酯(PET)瓶。隨著消費量的增加,對這些寶特瓶的需求也在增加,推動了塑膠包裝產業的成長。根據非酒精飲料經濟協會 (WAFG) 的資料,到 2023 年,德國人均軟性飲料消費量約 124.5 公升,高於 2020 年的 114.7 公升。

- 這些消費趨勢可能會將焦點轉向永續塑膠包裝解決方案,例如回收材料和生物分解性塑膠。公司可能會投資這些創新,以滿足消費者和監管機構對環境責任的要求。

- 塑膠瓶和容器是洗髮精、護髮素和乳液等個人保健產品的首選,因為它們具有成本效益、易於處理且不易破損。此外,環保塑膠材料的進步,例如回收和生物分解性的選擇,正在減輕永續性問題,並使它們對具有環保意識的消費者更具吸引力。例如,2024年8月,Alpla Werke Alwin Lehner GmbH &Co KG和zerooo發起者SEA ME GmbH推出了可重複使用且完全可回收的化妝品和個人保健產品寶特瓶。

德國包裝產業受到食品趨勢和環境問題的推動

- 在在家工作的持續趨勢的推動下,食品領域主要推動了德國包裝產業的發展。輕質、經濟高效且設計靈活的塑膠在食品包裝中佔據主導地位,使其成為方便產品儲存和使用的理想選擇。

- 儘管硬質塑膠包裝在大規模生產方面具有成本優勢,但紙質和紙板包裝因其便攜性和便利性也越來越受歡迎。這些成分不僅無需冷藏即可延長保存期限,而且被證明是環保的。

- 隨著經濟的繁榮,從超級市場到便利商店的現代零售商正在擴大他們的視野,特別是在冷凍食品產品方面。這種零售業的發展正在加速新興市場採用各種包裝技術,包括收縮膜、軟袋、封蓋膜、高阻隔材料、熱成型膜和貼體膜。

- 為了應對日益成長的環境問題,德國領先的快速消費品公司正在雄心勃勃地減少食品包裝中塑膠的使用,並轉向環保材料,其中紙質包裝的數量顯著增加。

- 食品包裝在確保安全交付給消費者方面發揮著至關重要的作用。隨著對功能性和美觀包裝的需求不斷增加,食品包裝領域的公司正在努力滿足這些期望。

- 已調理食品具有從托盤到袋子再到盒子的多樣化包裝需求,正在推動包裝市場的創新。製造商正在積極開發各種解決方案來滿足這項需求。

- 德國聯邦統計局的資料顯示,德國調理食品銷售額大幅成長,從2021年的439萬美元躍升至2023年的635萬美元。銷量的激增代表著銷量的增加,直接轉化為對包裝材料的需求增加,因為每道家常小菜都需要自己的包裝。

德國包裝產業概況

德國包裝市場分散,包括多家在市場上佔有重要地位的跨國公司。主要參與企業包括 Amcor plc、Berry Global Inc.、Mondi plc、OI germany GmbH &Co.KG(Owens-Illinois Inc. 的子公司)、Smurfit WestRock plc 和 Ball Corporation。德國包裝產業始終認為公司及其部門之間的產品發布、收購和聯盟旨在實現策略成長。

- 2024 年 11 月,Mondi plc 將在德國開設創新中心,旨在共同創造軟包裝解決方案的未來。這些體驗式工作室旨在讓 Mondi 客戶直接參與創新過程。這種親身參與將使客戶能夠利用 Mondi 深厚的專業知識、最尖端科技以及推動軟包裝領域永續轉型的承諾。透過整合試驗線、測試能力和協作空間,Mondi 準備加速新包裝和紙張解決方案的市場推出。

- 2024 年 10 月,Ardagh Group SA 旗下子公司 Ardagh Glass Packaging-Europe (AGP-Europe) 推出了全新的輕量標準酒瓶系列。這些瓶子在德國製造,專門迎合歐洲市場。值得注意的是,瓶子的重量從410克減輕到了360克。透過使用高達 80% 的回收玻璃屑玻璃,可以減輕重量,從而使每瓶二氧化碳排放減少 12%。

其他好處

- Excel 格式的市場預測 (ME) 表

- 3 個月分析師支持

目錄

第1章簡介

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章市場概況

- 市場概況

- 產業吸引力-波特五力分析

- 新進入者的威脅

- 買方議價能力

- 供應商的議價能力

- 替代品的威脅

- 競爭公司之間的敵對關係

- 技術簡介

- 產業價值鏈分析

第5章市場動態

- 市場促進因素

- 各國先進技術驅動的創新和客製化包裝解決方案的需求

- 對環保、便利的包裝解決方案的需求不斷成長

- 市場限制因素

- 政府法規和環境問題

第6章 市場細分

- 按材質

- 紙和紙板

- 玻璃

- 塑膠

- 金屬

- 其他

- 按包裝類型

- 難的

- 柔軟的

- 按行業分類

- 食物

- 飲料

- 藥品

- 家居用品/個人護理

- 其他最終用戶產業

第7章 競爭格局

- 公司簡介

- Amcor plc

- Berry Global Inc.

- Mondi plc

- Ball Corporation

- Ardagh Group SA

- Crown Holdings, Inc.

- OI Germany GmbH & Co. KG(Owens-Illinois Inc.)

- Smurfit WestRock plc

- Stora Enso Oyj

- Constantia Flexibles GmbH

第8章投資分析

第9章 市場機會及未來趨勢

The Germany Packaging Industry is expected to grow from USD 38.06 billion in 2025 to USD 46.83 billion by 2030, at a CAGR of 4.23% during the forecast period (2025-2030).

Key Highlights

- In Germany, the surge of e-commerce has led to a heightened demand for packaging materials. In response, regional packaging companies are pivoting, providing cost-effective, secure, and lightweight solutions specifically designed for online retail.

- These offerings feature innovative designs that safeguard products during transit while optimizing material usage. To handle the uptick in online orders, these firms are channeling investments into cutting-edge automated packing technologies, including robotic systems and AI-driven sorting tools. Such automation not only streamlines operations but also guarantees uniformity in packaging quality.

- Germany's packaged food and personal care sectors are witnessing an escalating demand for smaller pack sizes, a trend poised to gain momentum in the coming years. This shift is attributed to factors like the rise of single-person households, a preference for resealable, on-the-go packaging, and best-before-date considerations.

- These dynamics amplify the need for packaging materials in items ranging from sauces and dressings to confectionery and processed fruits. In response, manufacturers are crafting innovative packaging solutions that prioritize product freshness, minimize waste, and enhance portion control.

- The need for flexible plastic packaging is on the rise, driven by its lightweight nature and adaptability. This trend is bolstered by the preference for compact, user-friendly packaging and design advancements. Flexible plastics not only extend shelf life and cut transportation costs but also bolster product protection. In light of environmental concerns, manufacturers are prioritizing the development of recyclable and biodegradable flexible plastic variants.

- There's a noticeable consumer shift towards eco-friendly packaging materials. Aluminum and glass are gaining traction in the region, celebrated for their environmental benefits and recyclability. This trend underscores a broader movement away from traditional plastics.

- Additionally, the European Council has rolled out new EU-wide regulations targeting single-use plastics and setting ambitious recycling goals. These regulations are poised to influence the market landscape.

German Packaging Market Trends

Germany's Plastic Packaging Sector Navigates Growth Amidst Stricter Regulations

- Germany is increasingly adopting plastic packaging solutions, driven by advancements from solution suppliers and end users. The "Made in Germany" reputation has fostered a conducive environment for the region's plastic packaging companies. However, the German government has imposed stringent regulations on the plastic packaging industry. The German Packaging Law mandates that packaging be designed for recycling, emphasizing recyclability and using recyclable and renewable materials.

- Manufacturers are witnessing an expansion in the use of plastic bottles, with rising demand across various sectors. For instance, in June 2023, Coca-Cola Europacific Partners Germany activated an unused returnable PET line at its Bad Neuenahr facility. This line will bottle popular carbonated soft drinks, including Coca-Cola, Fanta, and Sprite, and reintroduce sugar-free variants.

- Soft drinks, especially carbonated ones, are primarily packaged in plastic bottles, especially polyethylene terephthalate (PET) bottles. As consumption rises, so does the demand for these plastic bottles, fueling growth in the plastic packaging sector. Data from the Economic Association of Non-Alcoholic Beverages (wafg) indicates that in 2023, the average German consumed approximately 124.5 litres of soft drinks, up from 114.7 litres in 2020.

- This growing consumption trend may lead to a pivot towards sustainable plastic packaging solutions, such as recycled materials or biodegradable plastics. Companies will likely invest in these innovations to align with consumer and regulatory demands for environmental responsibility.

- Plastic bottles and containers are favoured for personal care products like shampoos, conditioners, and lotions due to their cost-effectiveness, ease of handling, and resistance to breakage. Moreover, advancements in eco-friendly plastic materials, including recycled and biodegradable options, have alleviated sustainability concerns, making them more appealing to environmentally conscious consumers. For instance, in August 2024, Alpla Werke Alwin Lehner GmbH & Co KG and zerooo initiator SEA ME GmbH unveiled a reusable and fully recyclable PET bottle tailored for cosmetics and personal care products.

Germany's Packaging Industry is Driven by Food Trends and Environmental Concerns

- The food sector, bolstered by the persistent work-from-home trend, primarily drives Germany's packaging industry. Lightweight, cost-effective, and design-flexible, plastics dominate food packaging, making them ideal for easy product storage and use.

- While rigid plastic packaging boasts cost advantages for large-scale production, paper and cardboard packaging are rising in popularity, mentioned for their portability and convenience. These materials not only extend shelf life without refrigeration but also back environmental friendliness.

- As economies flourish, modern retail outlets, from supermarkets to convenience stores, are broadening their horizons, especially in frozen food offerings. This retail evolution accelerates the adoption of diverse packaging technologies in emerging markets, including shrink films, flexible bags, lidding films, high-barrier materials, thermoforming films, and skin films.

- In response to growing environmental concerns, major FMCG companies in Germany are ambitiously cutting down on plastic use in food packaging, pivoting towards eco-friendly materials, with paper-based packaging witnessing a notable surge.

- Ensuring safe delivery to consumers, food packaging plays a pivotal role. As demand rises for both functional and visually appealing packaging, companies in the food packaging sector are gearing up to meet these expectations.

- Ready meals, with their diverse packaging needs ranging from trays to pouches and boxes, are driving innovation in the packaging market. Manufacturers are actively developing varied solutions to cater to these demands.

- Data from Statistisches Bundesamt reveals a notable uptick in Germany's ready meals revenue, soaring from USD 4.39 million in 2021 to USD 6.35 million in 2023. This revenue surge, indicative of heightened sales volumes, directly correlates to an increased demand for packaging materials, as each ready meal necessitates its own packaging.

German Packaging Industry Overview

The fragmented German packaging market includes various global players with significant market presence. Key players encompass Amcor plc, Berry Global Inc., Mondi plc, O-I Germany GmbH & Co. KG (a subsidiary of Owens-Illinois Inc.), Smurfit WestRock plc, and Ball Corporation, among others. The German packaging industry has consistently witnessed trends such as product launches, acquisitions, and collaborations among businesses and their units, all aimed at strategic growth.

- November 2024: Mondi plc has inaugurated an innovative hub in Germany, aimed at co-creating the future of flexible packaging solutions. These experiential studios are designed for Mondi's customers to engage directly in the innovation process. This hands-on involvement allows them to leverage the company's vast expertise, cutting-edge technology, and commitment to driving sustainable change in the flexible packaging sector. By consolidating pilot lines, testing capabilities, and collaborative spaces, Mondi is poised to accelerate the market introduction of its new packaging and paper solutions.

- October 2024: Ardagh Glass Packaging-Europe (AGP-Europe), a division of Ardagh Group S.A., has unveiled a new lightweight range of standard wine bottles. Manufactured in Germany, these bottles cater specifically to the European market. Notably, the bottles have undergone a weight reduction from 410g to 360g. This achievement was made possible by incorporating a high recycled glass cullet level of up to 80%, resulting in a commendable 12% decrease in carbon emissions for each bottle produced.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumption and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGTHS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Threat of New Entrants

- 4.2.2 Bargaining Power of Buyers

- 4.2.3 Bargaining Power of Suppliers

- 4.2.4 Threat of Substitute Products

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Technology Snapshot

- 4.4 Industry Value Chain Analysis

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Demand for Innovative and Customized Packaging Solution Aided with Country-s Adoption of Advanced Technology

- 5.1.2 Increasing Demand for Eco-friendly and Convenient Packaging Solution

- 5.2 Market Restraints

- 5.2.1 Government Regulations and Environmental Concerns

6 MARKET SEGMENTATION

- 6.1 By Material

- 6.1.1 Paper and Paperboard

- 6.1.2 Glass

- 6.1.3 Plastic

- 6.1.4 Metal

- 6.1.5 Other Materials

- 6.2 By Packaging Type

- 6.2.1 Rigid

- 6.2.2 Flexible

- 6.3 By End-user Vertical

- 6.3.1 Food

- 6.3.2 Beverage

- 6.3.3 Pharmaceutical

- 6.3.4 Household and Personal Care

- 6.3.5 Other End-user Verticals

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Amcor plc

- 7.1.2 Berry Global Inc.

- 7.1.3 Mondi plc

- 7.1.4 Ball Corporation

- 7.1.5 Ardagh Group S.A.

- 7.1.6 Crown Holdings, Inc.

- 7.1.7 O-I Germany GmbH & Co. KG (Owens-Illinois Inc.)

- 7.1.8 Smurfit WestRock plc

- 7.1.9 Stora Enso Oyj

- 7.1.10 Constantia Flexibles GmbH